Tuning and auto gadgets / From Autoclub

- What should a podium look like?

Internal podiumTable: advantages and disadvantages of internal podiums

- Table: advantages and disadvantages of external podiums

- Manufacturing and installation of an internal podium in the door

Gallery: covering the podium with artificial leather

Installing car audio requires a creative approach. Sound quality largely depends on where and how the speakers are placed. For them, podiums are elements of acoustic design. The elements are useful and in some cases necessary. What’s important is that you can make such podiums with your own hands.

DIY speaker rings

Today, most modern vehicles come with standard speakers. However, lovers of loud music in cars are often not satisfied with their sound, so they buy larger speakers. In this case, a different kind of problem arises - how to install large-sized equipment in the cabin so that, on the one hand, it does not disturb passengers, and on the other hand, to create truly clear sound?

One of the common ways to solve the problem is to make podiums for speakers. They can not only improve sound quality, but also take the performance of the speaker system to a whole new level.

A DIY acoustic shelf allows you to mount speakers of different sizes and shapes

Installation and fastening of the podium in the car

The traditional method to securely secure a homemade podium is to screw it with self-tapping screws from the inside of the casing. This, on the one hand, will ensure the quality of fastening, and on the other hand, will not spoil the appearance of the entire structure.

To carry out this procedure, you will need only two tools: a screwdriver and soundproofing materials.

Main stages of the procedure

The process of installing and fixing any podium in any part of the car is as follows:

- Take a ready-made podium with a speaker built into it.

- The podium is screwed on the inside of the casing with self-tapping screws.

- However, to achieve truly clear sound, you will need to experiment with the installation - some screws will be tightened all the way, and some will not. That is, you need to give the podium such a position so that the speaker can reveal its sound to the maximum.

- It is recommended to soundproof the doors and ceiling (in this case you can achieve even clearer sound).

- After completing all the work, reassemble the ceiling, racks or doors (depending on where exactly the podium was mounted).

How to make spacer rings for speakers

You will need : plywood, drill, jigsaw, sealant, varnish.

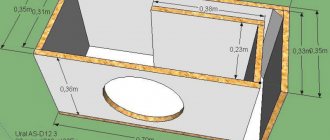

The thickness, width and other dimensions of spacers for columns are calculated individually in each case, so there are no universal sizes of spacers. The diagrams presented above can act as a template, which will be modified locally.

The total thickness of the spacer is determined individually. Approximately, for a speaker mounting depth of 52 cm, spacer rings 16 mm thick should be suitable.

Procedure:

- Determine the outer and inner diameter of the rings (using a sample or speaker).

- Cut out the spacer slides with a jigsaw, having previously drilled holes for installing the jigsaw blade.

- Fasten all parts of the spacer (if they are composite) using glue or self-tapping screws.

- Try on the door spacers and modify them if necessary. Make sure that the spacers fit tightly to the surface, nothing interferes with the correct positioning of the speaker, and the door trim is installed without problems (modify locally).

- Coat the rings with several layers of varnish.

When installing spacers, make sure that it and the speaker are secured as tightly as possible (stick vibration isolator strips under the ring), this will eliminate the occurrence of vibrations and rattling. Seal all cracks using caulk. It is recommended to combine the installation of spacers with sound insulation of doors.

Installing speakers in Granta rear doors

The procedure for working with the rear doors is identical to the front ones. Important difference : homemade spacers are not required here. The plant produces a set of special mounts for installing 13 cm speakers in the rear doors.

Articles for ordering online:

| Speaker Mount - Rear Left | 21907901033 |

| Speaker Mount - Rear Right | 21907901032 |

| Rear left column trim | 21906202095 |

| Rear right column trim | 21906202094 |

| Trim for front left door | 21906102097 |

| Trim for front right door | 21906102096 |

Installation sequence:

- Disassemble the door;

- Cut a hole in the door card for the lining;

- Install the speaker mount on the door;

- Replace the standard audio terminals with normal ones;

- Connect the wires to the column, secure it;

- Install the trim and assemble the door.

You can replace the fastening with improvised materials, but factory production takes into account all bends.

Tags: spacer rings, router

Comments 98

Please tell me which in your opinion is better, kicx or ural? In terms of speakers. Thank you very much)

Read more: Parking near the bus stop

I understand which is better.))) But comparing my two options, which is better?

Well, as if Kicks and Urals are different... At least you wrote the models))) But I’ll tell you - listen and find out what’s best for you!

Kicx pd-5.2 and Ural ak47s comp.

You have to listen and then choose!))

Well, as if Kicks and Urals are different... At least you wrote the models))) But I’ll tell you - listen and find out what’s best for you!

There is an option to take either one or the other, I can’t choose (I already had Kicks like that. Not bad. They say that crossovers are an extra overpayment of money. You can get by with Conders, right?

I'm not your advisor here. I had neither one nor the other.

I tried everything and settled on the same device!

I tried to do it using something like a real radius bar (I drilled holes). I didn't really like it. It's more convenient with this thing.

Yes, any radius can be adjusted. I also made a sleeve and a pin on which I put this device. Otherwise the self-tapping screw will quickly gouge everything! I cut about 50 rings - the flight was normal. Instead of laminate, I used 1 plywood and fixed the knitting needles into the original plank of the router.

You need to make the base out of something solid, then it won’t gouge with a self-tapping screw. But even with a bushing the option is not bad!

If you have a cutter and don’t make a ruler, you can’t find a piece of plexiglass...

As you may have noticed, I made myself a ruler.

My friend, we made spacers in the Nissan Sunny in exactly the same way)) A convenient topic for a cutter!))

I wanted to share an idea on how to cut straight rings without a radius bar, but in the end I took it and made a radius bar)))))

Threat Respect for the idea!

Thank you! But this is not quite a radius bar. This one has an attachment to the base of the router and many, many holes for different diameters.

What you are talking about is just a type of radius bars. Moreover, it’s not the most convenient;)

But it is the cheapest and easiest to manufacture.

Nene, I’m talking about the inconvenience of branded strips that are screwed on and have holes

Understood. I've never worked with one like this.

But it is the cheapest and easiest to manufacture.

Read more: Fines based on VIN code traffic police website

I myself use one similar to yours, only welded (a friend cooked it). Very comfortably!

You will need : plywood, drill, jigsaw, sealant, varnish.

The thickness, width and other dimensions of spacers for columns are calculated individually in each case, so there are no universal sizes of spacers. The diagrams presented above can act as a template, which will be modified locally.

The total thickness of the spacer is determined individually. Approximately, for a speaker mounting depth of 52 cm, spacer rings 16 mm thick should be suitable.

Procedure:

- Determine the outer and inner diameter of the rings (using a sample or speaker).

- Cut out the spacer slides with a jigsaw, having previously drilled holes for installing the jigsaw blade.

- Fasten all parts of the spacer (if they are composite) using glue or self-tapping screws.

- Try on the door spacers and modify them if necessary. Make sure that the spacers fit tightly to the surface, nothing interferes with the correct positioning of the speaker, and the door trim is installed without problems (modify locally).

- Coat the rings with several layers of varnish.

When installing spacers, make sure that it and the speaker are secured as tightly as possible (stick vibration isolator strips under the ring), this will eliminate the occurrence of vibrations and rattling. Seal all cracks using caulk. It is recommended to combine the installation of spacers with sound insulation of doors.

Let us remind you that new speakers are not the only popular accessory for Lada Priora.

Machining a cylindrical hole

As a result of these actions, a cylindrical hole is formed suitable for installing speakers. Before installation is carried out, it is worth noting the need to paste the resulting cylindrical hole with Vizomat 10, as was the case at the stage of pasting the outer side of the wooden ring.

An aspect of gluing a cylindrical hole is the pursuit of two goals, among which are:

• protection of the column and its contacts from water (it can get on the column when the glass is completely lowered);

• creating a trumpet effect.

To achieve these results, Vizomat 10 is cut into thick strips, resulting in the Vizomat being several mm shorter than the cylindrical hole and not touching the completely lowered glass.

The density of the entire structure plays an important role. To achieve the optimal density, you can cover the circumference of a wooden ring with Bitoplast, as a result of which the mounted column will be pressed as much as possible against the homemade ring.

We install 16 cm speakers in the Lada Granta, and also cover their circumference with Bitoplast. This pasting is carried out in order to maintain the intensity of the sound, since air will not escape under the door trim.

At this point, the installation of speakers in the front doors of Granta is completed, and all that remains is to assemble the door. After such installation, the weight of the doors increases slightly and, accordingly, the protrusion from the installed column increases slightly.

What should a podium look like?

As follows from the above, the podium for the midrange or midbass is not a simple decorative element, but a necessary component of the audio system that affects the sound quality. To effectively perform its task—damping unnecessary vibrations—the podium must be heavy. The heavier the better.

In order for a part to be heavy, it must be made of the appropriate material. But in practice, plywood is most often used, since it is easy to process at home.

Did you know that archaeologists discovered the first archaeological artifact made from a material reminiscent of modern plywood in the territory of Ancient Egypt. The plywood casket dates back to the 15th-16th centuries BC. e.

Plywood is a relatively light material. To increase weight, podiums are made as large as possible. Of course, taking into account the features of the car interior.

Installation of 16 cm speakers using spacers

A spacer is, in this case, a wooden product that follows the shape of the column. It is made in the form of a ring; the material used is usually fiberboard, MDF board or plywood. But even in this case, you may need to cut the metal of the door, which in my opinion is a little blasphemous in relation to the car.

Spacer made of two rings, MDF material

- The inner diameter of the ring is measured so that the speaker is freely attached to it, and for the best sound, they try to ensure that the speaker fits as tightly as possible to the ring.

- The outer diameter should be such that the column is attached tightly to the ring, and, if possible, fits behind the upholstery so that the metal of the door does not have to be cut.

The video below shows the installation of a 16 cm speaker system in the front doors of a Lada Priora. The principle is the same.

Video

Cost of services for manufacturing & installation of rings

Making simple rings 1 hour 600–1600 rub. Production of complex rings 2-3 hours 1600–2600 rub. Making rings for tweeters 1 hour 800–1200 rub. Manufacturing of supporting elements for midrange and tweeter speakers 2–4 h 1000–1500 rub. Making rings for a subwoofer (wood) 1 hour 400–800 rub. Making rings for a subwoofer (metal) 1 hour 800–1200 rub.

Installation of rings on self-tapping screws / bolts 0 / 50–100 rub.

Installation of rings on speakers is free if you order installation of acoustics from us.

Manufacturing of other elements

What advantages do podiums provide?

Before you start assembling a podium for speakers with your own hands for a car, it will not be superfluous to find out why they are made in the first place and what they provide.

Acoustic podiums objectively have a number of advantages. Someone simply mounts a speaker, which is quite powerful and of high quality, but decides not to use the podium. Although the sound quality will be much weaker than with an additional design.

It is also worth adding that there are no particular problems with installation. Here you definitely won’t have to cut out the metal elements of the door. But the noise will probably disappear, low-frequency sounds will increase, and the sound will become more transparent. Of course, if the driver is not a music lover and the main thing for him is that there is simply music, all these modifications will turn out to be superfluous and unnecessary. But those who understand car audio and love to enjoy music understand perfectly well that there is no place without a podium.

The podium also becomes a constructive solution that allows you to install speakers or loudspeakers of substantial size, for which the car does not have standard seats.

Regarding what else podiums can provide, it is worth emphasizing several points:

- creates a voluminous and most pleasant, high-quality sound;

- the design improves the appearance of the car if you choose the right materials and colors;

- with the help of a podium you can emphasize the beauty of branded and expensive speakers;

- the same podium easily hides external defects in acoustics;

- Various materials are suitable for manufacturing, among which the favorites are wood, carbon fiber and fiberglass;

- When finishing, you can use various coatings, including genuine leather, Alcantara, or regular carpet.

Why install speakers on podiums

The first and obvious justification for the need to use podiums is that with their help you can move the dynamic head out of the standard seat if it does not fit there in depth. However, this is not the only reason.

For any speaker to sound, it needs a properly calculated acoustic design and a rigid base designed to dampen parasitic vibrations.

In home and stage systems, heavy, rigid enclosures are used that perform both functions at once. Subwoofers are made in a similar way for automotive systems.

The acoustic design of the mid-frequency speakers and “midbass” is formed by the design elements of the car. In this case, the cavities behind the casing act as the internal space of the sound column.

During operation, car acoustics experience significant vibration loads. If they are not extinguished, they are transferred to the sheathing panels and other structural elements, usually made of rather thin materials. These vibrations distort the sound.

The purpose of podiums is to absorb vibrations and dampen them. Prevent the spread of parasitic vibrations.

What is the best way to strengthen the walls of plastic spacers?

- Log in to reply to this topic

#1 OFFLINE ltd500

- From: Moscow

I understand that it sounds crazy, but there are reasons for this and this is a temporary solution, and I ask you not to throw poop. And I know it's better to replace it with something else

There are plastic spacers for the speakers in the front doors and they are of complex shape. For making them from wood or aluminum, they want some inhumane money, which I would rather spend on the speakers themselves

In principle, they are quite rigid, two-layer. But I understand that it is not enough and most likely they will rattle, so it occurred to me to strengthen their structure with a bay between the layers, something.

Preparatory work before installing speakers in the front doors Grants

Before the installation of 16 speakers in Grantu begins, it is worth noting the need to enhance the wave dispersion effect. Thus, it is necessary to glue an additional layer of Bitoplast 10 on top of Vizomat MP-2. This kind of action is not mandatory, but will reduce the reflection of sound directly from the door itself.

It is also worth noting the use of Bitoplast 10, and not foam rubber. The fundamental difference between these materials is the different degrees of water absorption. Foam rubber absorbs water like a sponge, resulting in corrosion inside the door.

As for the additional materials that were mentioned at the very beginning, it is at this stage that it is necessary to install the spacer on the door. You can buy it at any car audio store. As for the possibility of making spacers (rings) yourself?

Modern fashion for car audio

Today, most modern vehicles come with standard speakers. However, lovers of loud music in cars are often not satisfied with their sound, so they buy larger speakers. In this case, a different kind of problem arises - how to install large-sized equipment in the cabin so that, on the one hand, it does not disturb passengers, and on the other hand, to create truly clear sound?

One of the common ways to solve the problem is to make podiums for speakers. They can not only improve sound quality, but also take the performance of the speaker system to a whole new level.

A DIY acoustic shelf allows you to mount speakers of different sizes and shapes

Manufacturing and installation process

When starting to make podiums for cars, you need to think through an action plan and divide all the work into several key stages.

Each of the steps can affect the result, so you should approach the work as responsibly as possible, strictly following the instructions and calculating all the details in advance.

Making your own podiums for placing acoustics in the cabin or trunk of a car does not seem so difficult if everything is broken down into clear and consistent steps. The car owner is required to:

- think over the form;

- make a platform;

- assemble a podium;

- fill the structure;

- cover with decorative materials.

Now each step should be considered separately.

Before drawing drawings and cutting out parts, you need to choose the place where the structure will be located in the future.

What you definitely shouldn’t do is assemble a speaker system and only then look for where to mount it. There is a risk of simply not finding a place and not fitting into the dimensions of the interior elements or even the spacious luggage compartment.

Form

To install HF tweeters, that is, high-frequency speakers, powerful speakers, you must first decide on the shape of the future design.

The shape of the podium is selected based on the configuration of the speaker or tweeter itself. It can be a circle, oval, square, etc.

Making a platform for a column

- Measure the size of the speaker for the radio. And also take measurements of the protective mesh.

- Draw a ring on the cardboard, taking into account the fact that the internal diameter corresponds to the diameter of the place where the column will be planted. And the outer diameter of the ring is equal to the diameter of the protective mesh. To get it right, you need to add 6 mm to the annular diameter. For a decorative ring.

- Transfer the cardboard model onto a sheet of plywood and trace it. It is better to take plywood of at least 8 mm.

- Cut out all the details - shapes. It is better to glue the decorative ring to the base and attach it with small nails.

Details for the podium

Tightness is the key to high-quality sound

In order to achieve the maximum effect from the installation, almost every stage of the installation of 16-centimeter speakers requires additional sealing. After the installation of the ring is completed, and the use of plastic spacers has led to the formation of gaps between the door and the ring, it is necessary to glue the ring with Visomat 10 on the outside.

The outer side no longer has holes and cracks, and a void has formed between the ring and the door, which can be filled with polyurethane foam. Without waiting for the foam to dry completely, we remove its protrusions, which will certainly interfere with the installation of the column itself.