Subscribe to topic

Notification by e-mail about replies to a topic during your absence from the forum.

Subscribe to this forum

Notification by e-mail about new topics on the forum during your absence from the forum.

Download/Print theme

Download the theme in various formats or view a printable version of the theme.

Author: Alex October 05, 2016 Category: Maintenance and repair

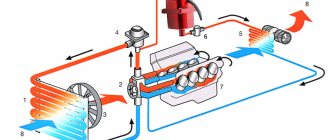

The engines of modern cars have great power, generating a huge amount of heat during operation. For the cooling system to work efficiently, you need a properly functioning water pump. The pump must pump the liquid well in the cooling system.

The mechanism of the water pump (pump) is very simple, and therefore there are several ways in which you can easily check the pump without removing it from the engine. Much, of course, depends on the quality of the mechanism parts and the coolants used. However, all deviations from normal operation are malfunctions of the water pump. These defects can be identified by certain signs in its work.

The easiest way to check the performance of the pump with the engine running is to feel the pulsations of the coolant on the hose coming from the radiator. Be careful not to touch the air fan blades with your hands.

Remove the timing belt cover and inspect the pump control vent hole. If there are traces of coolant leakage or brown deposits, the oil seal must be replaced. If you hear whistling sounds when the engine is running, then the reason lies in the failure of the bearings.

Increased noise during its operation can also occur when the bearing located near the pulley is destroyed. This defect is associated with rapid wear of the inner ring of the bearing, which leads to an increase in the radial and axial runout of the pump shaft. The first sign of bearing failure is the entire pump seizing. The reason for this defect is excessive tension on the timing belt, resulting in an increase in the radial load on the bearing. The wear on the drive belt also increases.

Having loosened the belt tension, remove it from the pulley, and then determine the shaft play. If axial and radial play is felt by hand, and its limits are two tenths of a millimeter or more, then the bearing must be changed. Bearing destruction and impeller jamming can occur due to misalignment of the factory boring of the bearing seats.

The main cause of leaks in the pump housing and connections is engine vibration. However, pouring cold antifreeze or antifreeze while the engine is running and hot can also lead to cracking of the sealing gaskets. Internal wear of the seals causes coolant to leak into the bearing cavity, washing out their lubricant. Which leads to corrosion and rapid destruction.

Pump design

The pump body is made of steel or aluminum, and inside it there is a shaft with a pulley on which the impeller is located. Also inside the pump you can see channels for supplying and discharging coolant. The rotation of the impeller ensures optimal fluid circulation in the system.

Have you already read our article about how different colors of antifreeze differ and whether they can be mixed? The information is quite interesting - https://avtopub.com/antifrizyi-raznyih-tsvetov/

Many cars have pumps whose impellers and casings are made of alloys of various metals, but there are also impellers made of plastic. You can find the pump at the front of the engine.

see also

Comments 25

if the stream in the barrel goes at xx and it is smooth and if there is no hum or rattle in its operation, and as the engine speed increases, the stream increases, then the pump is working.

Give it a whirl and watch how a stream of antifreeze flows into the barrel. it should increase many times over

If there is a trickle, then the pump is alive. The culprit is the thermostat, check it with boiling water and everything will become clear. Remove it for a couple of minutes.

I'm starting to overheat and steam out of the silencer, I need to change the gasket...

What's the air like there? Does the heater run antifreeze in circles in a circle? Does it heat up normally? If the stream is stronger then yes the pump works. It may be that the impeller has turned, but it doesn’t always turn, only when you give it more gas. This happened to me.

The pump either pumps or it doesn’t, there are no intermediate states, so if there is a trickle, then everything is fine with it. The thermostat wedge can be detected by the heating dynamics of the radiator pipes - up to 75 degrees they should be cold, with a further increase in temperature they begin to warm up gradually, if they immediately warm up, then change the thermostat. If the radiator pipes are both equally hot when two fans are running, then you need to wash the radiator, from the outside, in the sense of washing the honeycombs, and it is better to wash it from the engine compartment outwards, towards the bumper, so that debris does not clog further into the radiator honeycombs. You should check the quality of the radiator flushing “against the light”, otherwise on the outside it can be absolutely clean and shiny, but inside everything is clogged with debris - seeds from plants, poplar fluff, flies/bugs, jammed honeycombs with pebbles, etc., etc....

Checking the condition of the water pump

Checking the pump on a car is not that difficult. First, you need to warm up the engine so that it reaches operating temperature. After this, follow these steps:

- Pinch the upper pipe at the radiator outlet with your hand. When the pump is working, you will feel the pressure it creates. Be careful during this task as coolant temperatures are typically 90°C or more. If the antifreeze in the system does not pulsate or the pulsation is barely felt, perform a more detailed check.

- It is necessary to remove the timing mechanism protection and inspect the pump visually. Sometimes coolant leaks, which can be caused by a damaged seal, are immediately visible. In addition, signs of pump malfunction may include grayish or red-colored deposits in the area where it is located. In this case, the part will have to be removed.

- If you hear the characteristic sound of a faulty bearing while the motor is running, you need to check the pump for play in the shaft area. Just rock the pump drive gear. Sometimes everything is “cured” by simply replacing the bearing.

How to check?

An important point is to check the pump. Many car enthusiasts believe that in order to diagnose it, it is necessary to dismantle the part, but in most cases you can do without this. There are a number of signs by which you can understand that the problem is in the pump. To begin with, it is worth noting that most manufacturers recommend replacing the water pump after 60-80 thousand kilometers. In some cases, regulations indicate the need to replace simultaneously with the timing belt. Therefore, if the pump on your car has gone through such a mileage, then it makes sense to replace it at the first opportunity. Please note that using low-quality antifreeze or mixing incompatible types of coolant can lead to increased wear on the pump. Therefore, always pay attention to the composition of the liquid you use for cooling.

Diagnostics is carried out in the following order:

- Start the engine and warm it up to operating temperature;

- Next, pinch the pipe that goes from the radiator to the pump with your hand. When the pump is fully operational, you will feel the pressure it creates. Usually, this is felt in the form of fairly strong tremors. If they are, then there are no problems with the water pump;

- If the shocks are weak or completely absent, then you need to move on to a more thorough inspection of the pump. Turn off the engine; on some models you will need to remove the timing case. Pay attention to the presence of leaks near the pump mounting location; antifreeze may also leak through the pulley seal. If there are such signs, then it is definitely necessary to remove the pump and troubleshoot it.

It is also worth remembering that pump malfunctions have a number of additional signs that cannot be missed. In particular, in case of some malfunctions, the pump begins to howl or knock, and, in almost all cases, the motor overheats. There are known cases when owners brought the car to a car service center to replace the camshaft, but in fact it turned out that the pump was knocking.

Life time

The cooling system pump is a consumable item. Some automakers recommend changing it every 4 years or 60,000 km (whichever comes first). But reviews and practice indicate that pumps from well-known manufacturers operate properly for approximately 100,000 km. That is why many drivers are accustomed to changing the pump simultaneously with every second timing belt replacement. That is, every 100-120 thousand km (a high-quality pump can be used as much as two timing belts).

The service life of the pump directly depends on what kind of liquid is poured into the cooling system. If you are used to driving on water or cheap antifreeze/antifreeze, this can speed up the wear process of the pump.

How to fix the problem?

If a malfunction is identified, it should be eliminated as soon as possible. Here it is worth understanding that the pump is still a consumable, and in most cases it is easier to completely replace it. If there is a leak through the gasket, simply remove the pump and replace the gasket. Please note that normal tightness is required here. Therefore, be sure to carefully tighten the fastening nuts. Many drivers lubricate the gasket with sealant; such a precaution will not be superfluous. This will significantly reduce the risk of leakage. After some time, you should check the tightness of the nuts; they may loosen due to engine vibration. If the cause is the bearing or impeller, then the best solution is to replace the water pump. Repair in this case is complicated, but its effectiveness is low, so it is better to buy a new part and install it. Don’t forget to bleed the cooling system after replacing the pump; this will remove all air pockets, which will increase its efficiency. Conclusions. The cooling system must operate at maximum efficiency, otherwise engine problems will occur. Therefore, it is simply necessary to know how to check the pump without removing it from the engine. This will avoid costly repairs to the power unit and save you a lot of money.

Is there any point in renovation?

Of course, almost any spare part can be repaired, but the question is the feasibility of this idea. We do not recommend repairing the pump, since its cost is not exorbitant. In addition, it is extremely undesirable to restore the pump on cars in which the pump is connected to the timing belt. Otherwise, you risk a very serious risk, since a jammed pump can lead to a broken belt. And this is already fraught with dire consequences for the engine, requiring significant investments.

Technical features

First, let's look at the main technical characteristics and features of the water pump; this will allow us not only to make a correct diagnosis, but also to understand why the breakdown occurred.

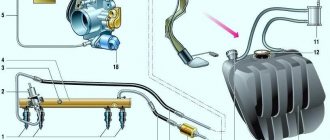

Antifreeze is pumped using an impeller, which is mounted on a shaft. The drive is carried out from the crankshaft of the motor; a belt drive is used for this. Here it is worth clarifying that in practice there are 2 drive methods used for the pump:

- Directly from the crankshaft

. This method is used on engines with a timing chain. Usually one belt drives the generator and pump, sometimes the power steering and air conditioning pump are also connected here;

- Another option is timing belt drive.

There is one serious drawback here. When the bearing jams in the pump, the belt breaks, which leads to breakdown of the gas distribution system, and under certain conditions, to a complete overhaul of the engine. In this case, you should carefully monitor the condition of the pump.

The pump housing is usually located at the front of the motor. This allows for the most optimal pumping of coolant through the system. It is also precisely this approach that makes it possible to use the crankshaft pulley as a moving element. In addition, placing the part at the front makes it easier to access for repairs.

The main malfunctions of the pump are directly related to its technical features; accordingly, this must be taken into account when carrying out diagnostic actions. As a rule, all signs of a malfunction are completely related to the characteristics of the various elements that ensure the operation of your car's cooling system.

Which pump to choose? Famous manufacturers

The best choice is original products. This is a guarantee that the part will fit the car exactly and will withstand the declared service life. The high cost of such spare parts is usually quite justified.

If you choose from substitutes, buyers often prefer water pumps from European brands:

- SKF;

- Hepu;

- Saleri Sil;

- Valeo.

These parts are made of high-quality metals, they are equipped with impellers and bearings with a long service life. The cost is high, but you don’t have to worry about quality.

You can also take a closer look at the German manufacturer Ruville and the Italian companies Graf and Dolz. Water pumps from the manufacturers Profit, JP Group and Thermotec are also considered normal, but these options are best chosen if you have a limited budget.

If the water pump fails before the time stated by the manufacturer, the reason is a manufacturing defect or the purchase of a fake. We recommend choosing Ruville, Valeo and SKF products.

Causes of malfunction

The following reasons are identified that affect the deterioration of the mechanism:

- Damage to the rotating components of the impeller : during intensive operation, small wings of the rotating part break off. This is especially true for plastic impellers. When the wings break off, the pump can no longer pump antifreeze at the required intensity - the engine constantly overheats.

- Drain hole clogged . This problem leads to the fact that antifreeze cannot fully circulate through the circuit. Clogged drainage can be easily tracked without removing the pump. If you suspect that the drain holes are clogged, simply turn on the cabin heater.

- De-synchronization of element and timing pulleys . In this case, the seals and bearings work in extreme conditions and wear out extremely quickly. The reason for such a breakdown is a manufacturing defect: either low-quality materials were used during assembly, or an unreliable assembler was used.

We need to speak in more detail about the third reason. No car owner is insured against manufacturing defects. But in this case, everything is serious with the prefix “hyper”. If you install a pump with potential out of sync, then the use of such a defective unit will lead to a sharp increase in timing wear. In the best case, the driver may encounter a broken belt, in the worst case, the valves “knock”.

Chronic overheating of the internal combustion engine caused by other factors can also lead to wear and tear of the cooler.

Another marker of wear (which, however, can only be seen after disassembling the mechanism) is play in the rotating parts. Backlash indicates imminent failure of the pulleys, displacement of the central axis and damage to the seals.

The last life hack for motorists who do not want to remove the pump, but want reliable information about its functional condition. Carefully inspect the junction of the cooler and the internal combustion engine. If there are significant antifreeze leaks, then the water pump does not have long to live.

Replacing the pump

After checking the water pump, repairing it, or purchasing a new element, all that remains is to install it in place. We advise you to pay maximum attention to the moment of installing the gasket and tightening the fastening bolts. Some experts advise using sealants to provide reliable protection against leaks. Sometimes this is not possible because on some vehicles the sealant will prevent the pump from being loosened in the future to replace the timing belt.

In some cases, car owners decide to replace the coolant and flush the system at the same time as replacing the pump. Instructions for performing washing were published on our website earlier - https://avtopub.com/kak-promyit-sistemu-ohlazhdeniya-dvigatelya-samostoyatelno/

In addition, follow the manufacturer's recommendations regarding bolt tightening torque (this information is in the service manual). Otherwise, you may pinch the gasket or damage the threaded connection. Finally, you need to fill in the coolant.

Important! If you used a sealant, wait a few hours for it to dry.

In the process of adding antifreeze or antifreeze to the cooling system, it is necessary to get rid of air pockets. After installing a new or restored pump and warming up the power unit, be sure to inspect the installation site for coolant leaks.

Signs of trouble

I would like to immediately note that in order to determine faults in the water pump, you will need to remove the unit and disassemble it. Only this method provides a real opportunity to see the resulting traces of corrosion, signs of cavitation and contamination.

Practice clearly shows that this happens on a wide variety of machines:

The car won't start. What could happen?

Category: Instructions

- VAZ 2107;

- Volkswagen Passat;

- FF2, that is, Ford Focus 2nd generation;

- Lada Granta;

- Kia Spectra;

- Chevrolet Aveo;

- Audi A5;

- Nissan Qashqai;

- Mitsubishi Outlander;

- Toyota Camry;

- Skoda Octavia, etc.

Moreover, the situation is approximately the same everywhere. That is, it is impossible to determine whether there are problems without disassembling and looking inside the cooling system water pump.

Therefore, the main emphasis is on indirect signs. With their help, the driver gets the opportunity to diagnose the problem in advance and prevent serious consequences.

The following indirect signs are distinguished:

- A thin whistle appears without interruption during engine operation. Moreover, it comes from the area of the camshaft pulley of the internal combustion engine. A whistle indicates that a higher bearing is failing;

- Coolant leaks. Traces of antifreeze can be seen directly on the power unit, or under the bottom of the car, that is, on the asphalt;

- Pump play. To check for its presence, simply grab the pump pulley with your hand and try to swing the device up and down.

Do not forget about the possible airing of the system, due to which the antifreeze does not fully perform its functions, the engine overheats and a number of resulting breakdowns occur. Here it would be correct to remind you about removing the air lock from the cooling system. Also, be sure to read the material about checking the cap of the expansion tank, which is directly related to the engine cooling system.

I won't talk about how the pump changes. Usually replacement is carried out according to the owner's manual from the car manufacturer. The point is to drain the cooling liquid, disconnect the pipes, first turn off the power to the car, and dismantle the problem unit.

The design and location of all pumps are different, therefore there is no universal instruction. You can find a video online, or simply take the car to a car service center.

conclusions

In order to verify for yourself that the old pump is worn out and how it differs from the new one, simply take the old and new element and rotate the impeller on them in turn.

Comparison of the operation of the old and new pump. Check for play and ease of rotation.

You can clearly see from your example that on the old element its rotation will occur with interference, while on the new element it will not be necessary to exert excessive effort.