Schematic electrical diagrams, connecting devices and pinouts of connectors

The speed sensor is an element of the vehicle's electronic control system. It depends on its readings how much fuel will be supplied, how much air will bypass the throttle valve when idling, and what the speedometer readings will be.

The speed sensor of a VAZ car is based on the use of the Hall effect, that is, a stream of pulses is transmitted from the device to the car's ECU, the frequency of which is proportional to the speed of the car. Auto electronics, analyzing incoming data, selects the required idle speed and sends a signal to a device that regulates the engine idle speed, which optimizes the composition of the air-droplet mixture entering the combustion chamber, bypassing the throttle valve.

During a distance of one kilometer, the speed sensor transmits over 6000 pulses to the ECU. Based on the parameters of the time analysis of inter-pulse signals, the on-board computer transmits data to the dashboard, thereby determining the speedometer readings.

As in many other cars, the VAZ speed sensor is located in the upper part of the gearbox housing, not far from the engine oil level dipstick. You can get to it from two sides: from above, by opening the hood and disconnecting the adsorber, and from below, using the inspection hole for convenience.

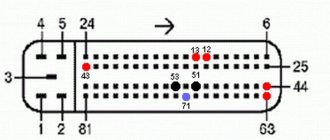

Pinout DS 2109, 2110, 2112, 2114, 2115

If you understand how to connect the speed sensor, then there is the following pinout that you should follow. At the same time, it is important to understand the essence of the operation of the DS to study the circuit diagram of the sensor, which is attached to this article.

The factory speed sensor of VAZ cars is manufactured with some differences in connections to the block connector. The square-shaped connector is used in Bosh electronics systems. The circle-shaped connector is used in electronic systems such as January 4 and GM.

When connecting a sensor, you should choose devices with contact group digitization such as “-”, “A”, “+” (internal designation on the block contacts) instead of digital designations such as “1”, “2”, “3”. In addition, preference should be given to devices with a metal-type rod, since plastic rods are very short-lived.

What is it for?

The speed sensor has a lot of work to do. It informs the electronic control unit about the correct fuel supply, determines and sets the ignition timing, and is responsible for the quality of the air-fuel mixture.

Scheme

The sensor collects all kinds of data and transmits them in the form of signals to the electronic control unit. There, the information is checked and appropriate adjustments are made to the operation of the injection engine.

How to check the VAZ speed sensor

A failed speedometer sensor in a VAZ car is easily determined - in this case, the speedometer stops working, and it may also show some signs of life, but display incorrect information.

Using a tube, pliers or other available tools, rotate the sensor axis. In this case, you should see the voltmeter readings changing: the higher the speed, the higher the voltage (from 0.5 to 10 V). If this does not happen, the sensor requires replacement.

Vehicle traffic control

This function is performed by the speed sensor, which takes part in the formation of the fuel mixture by the controller. It replaced the mechanical cable drive previously installed on carburetor VAZ 2112 models. The operating diagram of the element is as follows:

A malfunction of the speed meter is indicated by such signs as failure of the speedometer, unstable operation of the power unit and loss of idle speed when coasting. An indirect sign can also be the short-term display of the “Check Engine” sign on the instrument panel. If you pay closer attention, increased gasoline consumption will become noticeable. If the sensor fails, you can continue driving, but you should replace it as soon as possible. The product cannot be repaired.

Replacing a car speed sensor

As for its location, look for the DS in the engine compartment in close proximity to the exhaust manifold. To be honest, the place where it is installed cannot be called ideal. While the car is running, the manifold heats up. The sensor wires rub against it, which over time leads to malfunctions and short circuits. Therefore, experts recommend that the first step is to properly insulate the wiring, and also use some kind of clamps so that the wires do not come into contact with the collector. This significantly extends its service life.

If the check shows that the DS is faulty, it needs to be replaced. Repairing sensors and similar small electronic devices is a thankless task. In a garage environment, this is unlikely to be possible, and the only thing that can be done is to clean the contacts from oxidation (this can be a problem).

It doesn’t matter whether you have an injection car or a carburetor with a Europanel - the connection of the speed sensor to the instrument cluster is identical.

Replacing the VAZ speed sensor: step-by-step instructions:

- Drive into the pit - it will be more convenient to work from below - and wait until the engine cools down.

- Turn off the vehicle's power by removing the cable from the negative terminal of the battery. Do not close the hood after this, this will provide you with lighting.

- Locate the speed sensor on the transmission. Clean it and everything near it with a rag to remove any dirt.

- By pressing the spring clip, disconnect the wire block from the sensor.

- Dismantle the sensor itself by unscrewing it counterclockwise - with your fingers or an open-end wrench to “22”.

- Carefully, so as not to break anything, install a new part in place of the removed part. Connect the wire block to it and the procedure for replacing the speed sensor can be considered complete.

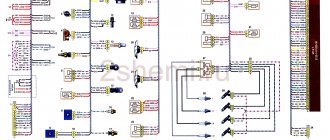

Diagram of the VAZ engine management system with BOSCH controller - ECM 21104 1.6 16V

1 – block of the ignition coil wiring harness to the ignition system harness; 2 – block of the ignition system harness to the ignition coil wiring harness; 3 – ignition coils; 4 – immobilizer warning sensor; 5 – immobilizer control unit; 6 – spark plugs; 7 – nozzles; 8 – diagnostic block; 9 – block of the ignition system harness to the ABS cabin group harness; 10 – controller; 11 – electric fuel pump; 12 – block of the ignition system harness to the fuel level sensor harness; 13 – fuel level sensor harness connector to the ignition system harness; 14 – block of the ignition system harness to the injector harness; 15 – injector harness block to the ignition system harness; 16 – block of the ignition system harness to the side door harness; 17 – speed sensor; 18 – idle speed regulator; 19 – throttle position sensor; 20 – coolant temperature sensor; 21 – mass air flow sensor; 22 – oil pressure warning lamp sensor; 23 – phase sensor; 24 – oxygen sensor; 25 – crankshaft position sensor; 26 — knock sensor; 27 – solenoid valve for purge of the adsorber; 28 – oil level sensor; 29 – coolant temperature indicator sensor; 30 – block of the ignition system harness to the instrument panel harness; 31 – instrument panel harness connector to the ignition system harness; 32 – ignition relay; 33 – ignition relay fuse; 34 – fuse for the electric fuel pump power supply circuit; 35 – electric fuel pump relay; 36 – electric fan relay; 37 – controller power supply fuse; 38 – ignition system harness block to the air conditioner connector; 39 – instrument cluster; 40 – ignition switch; 41 – electric fan of the cooling system; 42 – on-board control system unit; 43 – starter relay; 44 – contacts of the 8-terminal blocks of the instrument panel harness and the front harness; 45 – contacts of the 21-terminal blocks of the instrument panel harness and the rear harness; 46 – trip computer; 47 – diagnostic connector.

Why the speedometer does not work on the VAZ 2110 injector

All instruments on the VAZ 10 that indicate the speed of the vehicle are pointers, and signs of a malfunction are determined by deviations from the norm of the speedometer needle. If the speedometer is faulty, the arrow when the car is moving:

- does not deviate from zero, that is, does not show speed at all;

- stuck in one position, does not move in any direction;

- jumps, sharply changing readings, while the displayed speed does not correspond to reality.

There are other signs of a faulty speedometer, for example, the device works on a cold engine, and its readings correspond to the norm. As the engine warms up completely, the needle freezes and stops moving.

The main reason why the speedometer on a VAZ-2110 injector does not work is contamination (oiling) of the speed sensor (DS), failure especially often occurs if oil from the gearbox or engine gets onto the DS (for example, there is a leak from the valve cover of the internal combustion engine ). There are also other reasons:

- the speedometer itself has failed;

- the speed sensor is broken (this part on AvtoVAZ cars is not highly reliable);

- there is no normal contact in the DS plug or a break (short circuit) of the wires has occurred;

- The speedometer drive gears installed in the gearbox broke.

Checking the performance of the speedometer 2110

Before you start changing anything, you need to find out why the device does not show speed. First of all, they start checking with the speed sensor, since most often all malfunctions are associated with it. We inspect the DC for contamination, see if there is a break in the wires.

If the electrical part of the sensor is faulty, the Check Engine light on the instrument panel lights up. During computer diagnostics, if the sensor is faulty, the scanner displays error code P-0501, P-0501 or P-0503. Another error is detected by the on-board computer installed on the car.

There are also other signs of a faulty DS:

- at idle, the internal combustion engine is unstable, and the engine may stall at low speeds;

- fuel consumption has increased.

It is quite difficult to check the electrical circuit from the DS to the speedometer on a VAZ-2110 injector car, so here it is better to seek the help of specialists.

The DS drive gears located in the gearbox may also break. The drive itself is easy to check - you need to unscrew the two bolts that secure it with a 10th key and perform a visual inspection of this mechanism.

Other deviations

We have discussed the possibility of replacing a device if it is not functioning, but it often happens that the data is displayed on the dashboard incorrectly. For example, a driver drives at the maximum permissible speed limit, but at the same time he constantly receives fines for violations. Of course, you can drive with such a device, roughly focusing on the deviation indicators, but it is best to adjust it.

To do this, let's look at the types of speedometers. Mechanical speedometers are installed on 8-valve engines. They are equipped with a carburetor system. Sometimes options for installing additional electronic devices are possible. In these variants, pointer instruments are used; their malfunction can be identified due to deviations. There are three types of deviations:

- The arrow is in position 0;

- The arrow is in one position;

- The arrow constantly changes readings.

If the arrow is at zero, then the previous options can be used for repairs. If the needle readings are unstable, or if it hangs in a chaotic position, there is a possibility that the speed sensor is faulty. In such cases, in addition, the odometer does not work and because of this the driver cannot determine the number of kilometers traveled. In order to understand that the engine is in a faulty state, it is worth monitoring the operation of the engine. If the motor may stall on its own at some points, or its operation is unstable and the engine begins to trip, then this may be the result of a breakdown. Also one of the reasons may be increased gasoline consumption. For more accurate readings, you can run car diagnostics when errors p0501-p0503 are displayed - the reason will lie precisely in the failure of the DS. If the failure of the DS is electrical-related, then a check light will light up on the dashboard.

In this case, you can dismantle the device and use a screwdriver to recreate the rotation of the core. It is necessary to rotate counterclockwise. At the same time, we constantly monitor the readings of the multimeter. The lower voltage should be 1 V, and the upper voltage more than 5. Rotate the wheel, with each rotation the device should display 6 pulses. If the signal appears, but the speedometer of the VAZ-2110 does not work, then the problem may be in the sensor drive. In this case, it would be best to replace it.

On carburetor engines with 8 valves, everything is much simpler. A cable is connected to the gearbox, which controls the position of the arrow. Therefore, to diagnose it, it is enough to disconnect it from the gearbox and look at its integrity. We inspect the end of the cable, and more specifically the tetrahedron. If there is no mechanical damage on it, then everything is intact. After this, we turn the tip and monitor the readings on the dashboard. If this starts to pick up speed, then everything is in order, but if it rotates freely, incorrect readings may occur.

Speedometer malfunctions VAZ 2110 carburetor

On early 2110 cars with a carburetor, the speedometer needle is driven from the gearbox by a mechanical cable, and it is much easier to determine the cause of the malfunction here than in an electronic circuit. Checking the serviceability of the speedometer cable is simple: it must be disconnected from the gearbox - if the tetrahedron at its end is intact, then everything is in order in this connection.

Next, we take the tip of the cable with our fingers and try to twist it; if there are no breaks in the cable, the speedometer needle should begin to move (rise). If the vehicle rotates too freely with its fingers, the cable is most likely broken. To check the tens mechanical speedometer itself, you need to remove the instrument cluster.

Replacing the VAZ 2110 speedometer

On a VAZ-2110 with an injector, a separate device indicating the speed of the car is not sold, and the instrument cluster on 2110-11-12 is replaced as an assembly. If it turns out that the cause of the malfunction lies in the instrument panel, it must be replaced. We remove the instrument cluster (old model) as follows:

- on opposite sides of the steering wheel from below, unscrew the two screws of the plastic frame;

- unscrew the two top screws of the plastic frame, the frame is secured with 4 screws in total,

- pushing the cover forward, disconnect all the plugs from it;

- unscrew the screws securing the instrument panel, they are located on the sides of the combination;

- we pull off the instrument panel from the upper latches and move it towards the steering wheel;

- at the back of the instrument cluster, disconnect the two plugs;

- We take out the dashboard, now all that remains is to install a new part and reassemble it in the reverse order.

Replacing the VAZ 2110 speed sensor

The main cause of speedometer problems is the failure of the speed sensor, and if the DS is faulty, it must be replaced. It is not difficult to replace the sensor on a VAZ “ten”; almost any driver can do this work independently. The operation is especially simple on a car with an 8-valve engine. Let's start replacing:

- we place the car on a flat horizontal plane; you can do without a pit or a car lift;

- we find the sensor - it is located on top of the gearbox housing, not far from the oil dipstick;

- to disconnect the plug from the sensor, press on the locking bracket;

- Using a 22mm key, we unscrew the sensor itself counterclockwise, often the DS is unscrewed by hand;

- When installing a new part, we use manual force; it is not recommended to tighten the DS with a wrench, as you can break the part or strip the thread.

When installing, we put the connector in place, it should click into place, and the work can be considered complete. With sufficient skill, this operation is completed in 5-10 minutes.

Car owners often encounter a problem when, after replacing the sensor, the speedometer needle begins to “lie” - show the wrong speed. It should be noted that several types of DS have been developed for the VAZ Tens, and they have different catalog numbers. When purchasing, you should pay attention to the number of the failed sensor, and you must purchase a new part only with the same marking.

What else is the reason for the speedometer not working?

However, often the reason for the speedometer malfunction lies elsewhere:

- Oil and dust get into the speed sensor, which is located in the engine compartment under the hood of the car.

The malfunction is eliminated after removing dirt and oil by washing the sensor. If the DS fails and needs to be replaced, any car owner can perform this simple operation independently.

The replacement sequence is as follows:

- place the machine on a flat horizontal surface;

- open the hood and find the speed sensor on the gearbox;

- by pressing the latch bracket, the plug is disconnected from the DS:

- to remove the sensor, use a 22 mm wrench, turning it counterclockwise;

- The new part is installed by screwing it in by hand. The use of a wrench is not recommended, as you may miscalculate the rotation and break the thread;

- install the connector, as evidenced by the click of the fixed part.

The driver should buy a new DS with similar markings. Otherwise, the speedometer needle will display incorrect readings.

- For some unknown reason, the VAZ 2110 speedometer stopped working. First of all, you need to check the most accessible elements associated with the speedometer. Since the car compartments are not ideally clean, dirt and moisture can damage any part, including wires and contacts.

Under the influence of moisture and dirt, wires and contacts can oxidize. Eliminating this cause is simple: the contacts must be removed, cleaned of oxidized deposits, wiped dry and reinstalled.

It is also necessary to check the integrity of the wires. Externally good wires may have broken sections of cores inside. Checking the serviceability of the wires involves ringing their surface with a tester.

During operation, the splines and elements that rotate the speedometer cable may be damaged. Such a defect may impair the operation of the instrument panel. You can verify its serviceability by testing it.

- The third, very important defect is the malfunction of the speed sensor. This device is located on the gearbox, adjacent to the exhaust manifold. This factor leads to heating and chafing of the DC wires.

The reasons for the sensor being out of working condition, the fault can be determined at the service center. The technician will perform this procedure in the presence of the car owner.

To troubleshoot the problem yourself, you should do the following:

- The speed sensor must be removed by unscrewing it from the gearbox;

- connect the DC wire to a screwdriver or drill, set the rotation counterclockwise;

- turn on the ignition.

The movement of the arrow indicates that the sensor is working properly. The weak link is most likely located in the vehicle's transmission. It is difficult for a driver without experience to cope with this task. In this case, the problem must be solved by car service specialists.

If the speedometer needle on a VAZ 2110 does not work, the speed sensor must be replaced.

The speedometer on a VAZ 2110 with an injector is an important element of any car, not excluding the “top ten”. VAZ 2110 drivers even with little experience can check and find the source of the malfunction of this device.

However, if you cannot determine the source of the speedometer problems, you need to draw the attention of technical service specialists to this problem.

Some recommendations

- The search for the cause of the speedometer's inoperability should begin with an external inspection of the DS and the wires going to it. Wires often break in close proximity to the plug.

- If the speed sensor is covered with a layer of dirt or oily, you need to remove it, wipe it, reinstall it and check the speedometer readings again. Perhaps after this the instrument needle will again begin to show speed normally.

- If you cannot figure out the problem yourself, you should contact an electrician at a car service center.

Speed sensor

Carburetor models use a cable mechanical speedometer system, so there is no speed sensor. It's simply not needed.

Do I need to change

Not only the speedometer and odometer readings, but also the quality of the fuel mixture supplied to the cylinders, the idle speed of the vehicle, engine stability and fuel consumption depend on the information received by the ECU from the sensor.

A failed DS will “confuse” the electronic unit, which simply will not understand whether the car is moving or standing still. As a result, the speed will begin to fluctuate, the engine will stall at idle, and fuel consumption will increase.

Checking a mechanically driven speed sensor is not difficult. On the removed sensor, we find the pin and turn it with pliers, having attached the connector to it in advance. If the speed sensor is working, the arrow on the instrument cluster will jump, if there is no reaction, then there is a problem with the drive or electrical wiring.

Checking the wiring to the instrument cluster is also not difficult, take a paperclip (you can use any other metal object) and insert it into the middle pin on the connector, then touch it to the engine housing, the arrow on the combination should twitch, otherwise you need to look for the cause in a wiring fault or sensor connector (oxidation, breakage, etc.).

Symptoms of a problem

The problem may be that the connection diagram is broken, there are disturbances in the electrical circuit, or the connector does not work. In addition, the pinout of the speed sensor, which was mixed up during the assembly process, often becomes a problem.

An indirect sign of a malfunction is that the car stalls when idling.

You, as a driver, will easily notice the presence of incorrect indicators on the speedometer, and also pay attention to the warning light that requires you to check the engine (Check Engine). If such phenomena are detected, there is no doubt - the speed sensor needs to be replaced.

»

When is diagnostics needed?

Due to the limited number of pulses and for many other reasons (motor oil, dirt has gotten on the sensor, contacts or wires located near the speed sensor have oxidized, there is mechanical damage to the part, etc.) in the “tens” it is often possible to observe flaws in the operation speedometer or its complete inoperability. At the same time, most often, problems arise when coasting at idle and the “CHECK” system lamp turns on (error code “24”). Be that as it may, any of the mentioned signs requires the car owner to mandatory diagnose the speed sensor, because the causes of malfunctions may lie in it, or they may lie in a completely different place.

Troubleshooting

To begin troubleshooting the problem, you first need to find the device. From the photo you can determine how the speed sensor on the VAZ 2110 looks externally.

Ears for fastening

As for its location, look in the engine compartment in close proximity to the exhaust manifold. They say frankly that the place where it is installed cannot be called ideal. It's all about the collector. While the car is running, the manifold heats up. The sensor wires rub against it, which over time leads to malfunctions and short circuits.

Therefore, experts recommend that the first step is to properly insulate the wiring, and also use some kind of clamps so that the wires do not come into contact with the collector. This significantly extends its service life.

Having checked the device visually and not determining the presence of breakdowns, this tells us that the element itself is faulty. This problem can be solved by replacing it.

Preparatory activities

Proper replacement of the speed sensor on a VAZ 2110 implies the mandatory purchase of a new device that meets all the requirements of your car.

Connector

Basically, when purchasing a device, follow two basic rules.

- Choose a sensor whose connectors inside the block are marked -, A and +. Usually the designations 1, 2 and 3 are used there. There is no fundamental difference between them, it will simply be much easier to carry out the pinout with such markings. It is the incorrect connection that often becomes the reason that you have to seek help from a service station. And these are completely different financial costs.

- The rod on the element must be made of metal. If the stem is plastic, it will last you about 6 months. It is not in your best interest to replace regularly. But don’t forget to check the metal rod for play, correct rotation, and the presence of a washer in the package.