A car owner who independently maintains equipment needs to know how to determine early or late ignition on an engine. If adjusted incorrectly, the power unit loses power and consumes more fuel. Please note that adjustment is only possible on some types of motors equipped with a mechanical pulse distributor.

The car driver needs to be able to determine late and early ignition.

Early or late ignition: what is it?

When a gasoline engine is running, the spark must jump between the electrodes before reaching top dead center. The advance is set manually or programmed in the control unit.

... about the value of the ignition timing

A broken angle causes premature or late ignition of the mixture, which negatively affects the operation of the power plant.

An identical problem is possible on a diesel engine due to incorrect fuel injection timing.

What are the dangers of an incorrectly set OZ?

So, we have already found out that if the ignition of the fuel assembly in the form of a spark generated by the spark plug occurs earlier than usual, the expansion of the compressed mixture as a result of its combustion will begin to occur even before the piston has passed TDC, that is, at the stage of its ascent. This means that it will be more difficult for the piston to travel the rest of the way up before it begins to move downwards, during which the optimal release of energy from the exhaust gases occurs.

With late ignition, the amount of useful work performed by the piston also decreases, since part of the path it will travel by inertia, and part of the energy will be wasted and sent to the exhaust system, warming it up instead of increasing the efficiency of the power unit.

The consequences of an incorrectly set ignition can be very serious. If you allow the engine to operate for a long time at a late ignition, all the conditions for the optimal combustion process will be violated. In particular, at the moment at which the exhaust gas pressure peaks, the piston is already moving downwards, so the entire fuel assembly does not have time to burn, which leads to the deposition of unburned particles on the cylinder walls. Accumulating, such deposits can lead to coking of the engine, which can lead to its breakdown and the need for major repairs.

But one should not assume that earlier ignition is less dangerous. In this case, the energy released during the combustion process is directed against the movement of the piston, braking it on the way to TDC, and this causes serious shock loads, and not only on the cylinder head - the crankshaft may also suffer. It is these impacts that manifest themselves in the form of clearly visible metallic knocks. If you do not respond to such symptoms, further operation of the power unit risks deformation of the connecting rods, burnout of the pistons, as well as accelerated wear of the crankshaft liners. And these problems are more serious than the consequences of late ignition.

So the correct OZ is a guarantee of long-term and trouble-free operation of the engine. However, on modern injection engines, the on-board computer is responsible for the correct installation, so you will not be able to adjust the ignition timing yourself. The only option in case of problems is to reflash the ECU, or enter corrective information into the control unit.

You may ask why electronics allow ignition failures? There are objective reasons for this. The fact is that the ignition timing is controlled based on data coming from numerous sensors. Based on this information, the ECU determines in what volume and at what moment to supply fuel and air into the combustion chamber, as well as when to supply a spark to ignite the mixture. In this case, malfunctions in the operation of the sensors are the main reason for changes in the SOP, and the on-board computer does not always react correctly to such situations. A secondary, less common reason for changes in SOP is a violation of the geometry of the components of the power unit.

In such situations, all that remains is to check the proper operation of the sensors. And, of course, the marks on the crankshaft/camshaft match. However, on early versions of injection engines, the ECU is only responsible for the functioning of the fuel supply system, so adjustment work on setting the ignition is carried out in approximately the same way as on carburetor engines.

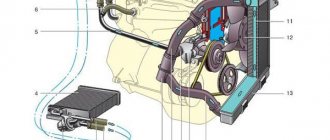

Operating principle of the ignition system

Regardless of the type of power system, candles are used to ignite the mixture; a high-voltage discharge pierces the air gap. In autodiesel engines, the air is pre-compressed, which allows the temperature to reach +600°C. The fuel injected by the nozzle ignites and the expansion stroke begins, accompanied by the downward movement of the piston.

On the injector

On engines with an early type injector, a contactless system with a distributor and a Hall sensor is found. Later, they began to use a control unit that determines the position of the shafts and automatically adjusts the advance angle. It is impossible to say unequivocally which ignition is better, since each of the systems has its own advantages and disadvantages.

On the carburetor

On engines with a carburetor, a mechanical distributor is used that distributes current pulses among the cylinders. Instead of a contact group, a switch can be used that works with a Hall sensor and controls the operation of the coil. But the distribution of high-voltage pulses is carried out by a mechanical device. Spark discharges appear after the starter starts turning the engine shaft. After successive flashes of the mixture, the power unit will start working.

On engines with a carburetor, a distributor is used to adjust early or late ignition

How to determine early and late ignition

The following are signs of incorrect setting of the ignition timing on engines:

- with forced ignition (liquid and gaseous fuel);

- with ignition of fuel from compression.

On gasoline

Signs of early combustion of the mixture:

- difficult starting with attempts of the crankshaft to start rotating in the opposite direction;

- unstable operation in idle mode;

- drop in dynamics and detonation combustion of fuel (with the correct octane number).

A sign of early ignition of the mixture is a drop in dynamics.

With late ignition, the car owner notices an increase in fuel consumption while maintaining the standard driving style. The engine warms up quickly, the cooling system fan operates more often. Many drivers note a decrease in power, which negatively affects the dynamics.

On diesel

Diesel engines differ from gasoline engines only in the way the mixture is ignited. If the timing of the start of fuel injection is incorrectly adjusted, malfunctions appear that are identical to problems caused by incorrect adjustment of the ignition system on gasoline engines.

... about adjustments on a diesel engine

It should be noted that on a diesel engine, the injection timing is adjusted according to the marks on the fuel pump drive.

On a car with HBO

When using gaseous fuel, it is necessary to set the ignition early to reduce emissions of the burning mixture into the exhaust manifold. Signs of mistuning are no different from those on gasoline engines.

What is a moment

The phrase “ignition timing” itself should be taken literally. This is the period of time at which the fuel mixture in the cylinder begins to ignite. Not the duration of combustion, but precisely the moment.

This is due to the fact that the fuel mixture does not ignite instantly. Yes, it flashes very quickly (in a split second). However, these moments can be decisive for high-quality and complete combustion of fuel. The movement of the ignition front of the combustible mixture is measured at 20-30 meters per second. This is a lot, but still not instantaneous.

Consequences of an incorrectly set ignition

With early or late ignition, symptoms are observed:

- drop in engine power and vehicle acceleration dynamics;

- difficulty starting the engine (the problem progresses as the air temperature drops);

- increased fuel consumption;

- unstable operation in idle mode;

- overheating and combustion of the working mixture in the collectors;

- the appearance of engine detonation during fuel combustion, destroying pistons and rings.

Late or early ignition increases fuel consumption.

Methods for setting the ignition timing on a car

To configure the following methods are used:

- using a special device;

- connecting an incandescent lamp;

- by the sound of work;

- by spark.

By strobe

A stroboscope is an optical device that allows you to control the moment a spark is fired.

...about diagnostics using a strobe light

To adjust, you need to set the marks on the crankshaft pulley to the required angle and check the position of the slider in the distributor.

Then you should connect the device to the battery (observing polarity) and install the sensor on the wire of cylinder 1. Before checking the correct angle, you must connect an additional cable to the ignition coil terminal connected to the breaker or switch.

Algorithm for adjusting early or late ignition when using a strobe light:

- Clean the surfaces of the pulley and engine crankcase from any dirt covering the ignition adjustment notches. The position of the marks depends on the car model.

- Start and warm up the engine to operating temperature.

- Remove the distributor cap and make sure the slider is in the correct position.

- Press the button on the side of the device and direct the light mark onto the pulley; the applied mark should not jump and be perceived as stationary. Assess the position of the light spot relative to the notch on the front cover.

- Adjust the angle (if necessary) and recheck the settings.

The stroboscope controls the moment of spark supply when determining early or late ignition

According to the control light

In the absence of special equipment, the owner can set the ignition using a light bulb. The technique is characterized by reduced accuracy and is used for repairs on the road. To perform the work you will need a 12 V incandescent lamp, a socket with wires 400-500 mm long and a set of wrenches.

To find out when the spark is fired, you need to:

- Set the piston in cylinder 1 to the upper position (for example, according to the marks on the gas distribution mechanism drive or along the notches on the crankshaft pulley or flywheel).

- Connect the light bulb to the terminal on the coil connected to the breaker or switch.

- Connect the opposite wire to the negative terminal of the battery or body.

- Loosen the distributor, turn on the ignition and rotate the assembly until the lamp turns on.

- Tighten the fastener and check that the settings are correct.

Aurally

When adjusting, the technician detects signs of early or late ignition by rotating the distributor relative to the base with the engine running and warm. It is necessary to achieve maximum idle speed without dips, and then tighten the distributor mounting bolt.

... about hearing diagnostics

The technique is not highly accurate, requires experience and good hearing from the tuner, and is used in case of roadside repairs.

By spark

The technology is identical to adjustment using a lamp, but involves removing the spark plug from 1 cylinder (the piston is at the top point). Then you need to turn on the ignition and rotate the distributor, determining the moment the spark appears. Then you should tighten the fastening, install the spark plug in the well and check the correct operation.

Ignition adjustment VAZ 2101 - 2107

On domestic carburetor cars, from time to time there is a need to adjust the ignition. How can you find out that the ignition has gone wrong or is set incorrectly? Try, when driving in top gear, at minimum speed (40-50 km in fourth gear), to sharply press the gas pedal. If you hear a ringing, unpleasant sound similar to metal from under the hood, this indicates detonation (improper combustion of fuel). Detonation is caused either by ignition too early or by poor quality fuel. Late ignition manifests itself in shaking when the engine is turned off. You turn off the engine, but it can’t stop; there are times when the engine can shake ten times - there shouldn’t be any shaking at all! - this is a late ignition.

What to do if you detect earlier or late ignition? As the owner of a classic VAZ, you will need a key for 13, and even if this is your first time, don’t worry - it’s very simple. To adjust, take a wrench and loosen the bolt securing the distributor so that you can rotate it. If your car shakes when turned off, you need to advance the ignition. You have already loosened the distributor mounting bolt, try turning it slightly: right - left, note that standing at the left wing of the car and turning the distributor counterclockwise, you make the ignition earlier and at the same time the engine runs louder and more smoothly. When making adjustments, in the vast majority of cases, it is enough to turn the distributor a couple of millimeters, or even half a millimeter - there is no need to turn it by centimeters. So you advanced the ignition a little and tightened the distributor bolt back. Try to start it. When you ignite early, the car starts better, try turning it off - the car no longer shakes? If not, then this indicates that the ignition is no longer late; if it still shakes a little, advance it a little more. After the car has stopped shaking, you should drive onto the highway and check if you are too ahead of the ignition. To check, drive out onto the road, engage a higher gear at low revs and sharply press the pedal to the floor. If there are no loud detonation sounds, the ignition is set normally, but if you hear a detonation ringing, you should delay the ignition a little. In order to delay the ignition, loosen the distributor bolt again and turn the distributor itself in the opposite direction - clockwise. Don’t get carried away, make adjustments 1-2 millimeters at a time. After installing a later ignition, turn off the car at idle speed - it should not shake (I repeat, shaking is an excessively late ignition), if there is no shaking, drive out and check for detonation.

After setting the ignition angle, you should adjust the idle speed; you can read about this in the article about adjusting the idle speed on a classic VAZ.

Briefly about adjusting the idle speed: using the mixture quality adjustment bolt, you should achieve the loudest and most stable operation of the engine, and then use the quantity bolt to lower the speed until the engine operation remains stable.

Creator of AutoBelyavcev.ru, Denis

Checking for correct installation

After setting the angle is completed, it is necessary to check:

- Warm up the power unit to operating temperature and drive onto a flat, straight section of the highway.

- Accelerate with gear shifts up to a speed of 50 km/h.

- Stabilize the movement, and then sharply press the throttle pedal.

If the settings are correct, a brief knock will appear, indicating detonation combustion of the mixture. The absence of sound indicates a delay in the pulses, and prolonged detonation indicates an early spark. In this case, it is necessary to make additional adjustments and recheck the result.

Advice from professionals

- According to experts, the ignition on a VAZ 2106 car can be considered adjusted only if no more than 2 finger knocks are heard at a speed of 60 km/h;

- In the absence of a multimeter or voltmeter, the ignition can be adjusted using a conventional 12 Volt control;

- This method of ignition adjustment, in addition to the VAZ 2106, is suitable for all carburetor “classics”.

As we see, adjusting the ignition on a VAZ 2106 car can be done independently, without any help or contacting a car repair shop. This concludes our article.