If the design of the car allows you to adjust the ignition yourself, then drivers often try to find the golden mean between early and late ignition. If the ignition is later, then the formation of sparks on the spark plugs occurs later, and accordingly, the fuel-air mixture is ignited later. In order for the engine to produce maximum power, stability and frequency, the ignition must be adjusted and set to the optimal setting.

Early or late ignition

Ignition of the mixture in the working chambers of the cylinders too early or too late causes poor performance of the internal combustion engine. The engine may not pull uphill, accelerate slowly, vibrate strongly, etc.

Signs of an incorrectly set ignition:

- the engine starts with difficulty;

- increased fuel consumption;

- the motor cannot develop power;

- in idle mode (idle speed), the internal combustion engine either stalls or over-gasses;

- the engine responds poorly to pressing the gas pedal;

- The internal combustion engine overheats;

- the engine detonates.

You can easily determine that the ignition needs to be adjusted if you hear popping sounds from the muffler and the car “sneezes.” It is recommended not to operate the machine in this mode, but to adjust it immediately. Moreover, one of the signs is detonation, which can destroy valves, pistons and cylinders.

Messages [1 to 20 of 25]

1↑ Topic by OlegatoR 05-08-2011 16:44:17

- OlegatoR

- Participant

- Inactive

- Name: Oleg Zhurba

- From: urban-type settlement Magdagachi, Amur region.

- Registered: 17-06-2011

- Messages: 34

Topic: Where to turn the ignition?

Where earlier, where later, who can tell?

2↑ Reply from Konstantin 05-08-2011 18:44:31

- Konstantin

- Experienced

- Inactive

- From: Tyumen

- Registered: 11-05-2011

- Messages: 303

- Reputation: 24

- Motorcycle: IMZ 8.103.10

Re: Where to turn the ignition?

Clockwise, early against later, this is simple on any technique, if you turn according to the movement of the machine or slider, then later, and if towards a meeting, counter-early.

3↑ Reply from OlegatoR 06-08-2011 17:22:20

- OlegatoR

- Participant

- Inactive

- Name: Oleg Zhurba

- From: urban-type settlement Magdagachi, Amur region.

- Registered: 17-06-2011

- Messages: 34

Re: Where to turn the ignition?

Thanks I'll know

4↑ Reply from M67-36 07-08-2011 11:10:19

- M67-36

- Assistant

- Inactive

- Name: Denis

- From: Angarsk

- Registered: 30-07-2011

- Messages: 246

- Reputation: 7

- Motorcycle: Ural M67-36; Dnepr 11

Re: Where to turn the ignition?

5↑ Reply from jipss 07-08-2011 11:22:13

- jipss

- Moderator

- Inactive

- Name: Dima

- From: Gornozavodsk, Perm region.

- Registered: 18-07-2010

- Messages: 2 495

- Reputation: 175

- Motorcycle: Ural 'grom', Ural M72m, cross M-104, forest IMZ with sidecar.

If the ignition is set incorrectly

If the ignition is early, it is because the spark appears early. At the moment when the piston just began to rise, the fuel-air mixture ignited and this explosion goes against the rising piston, resulting in a waste of energy.

Because the gasoline mixture ignites early, the piston experiences a greater force against its movement. This reduces the life of the crankshaft, pistons, connecting rod and pins.

The signs of early ignition can be determined by the following points:

- During operation of the internal combustion engine, a metallic noise appears, as if something is hitting the cylinder.

- The idle speed fluctuates and there is instability.

- If you press the gas sharply, the engine seems to choke and does not immediately respond to the supply of more fuel.

As for the installed late ignition, it also negatively affects the performance of the engine and the service life of its component parts.

In this case, the mixture is ignited late, that is, when the piston is already going down. The fuel burns out, if it has time, when the piston moves back (up).

Signs of late ignition:

- The internal combustion engine cannot reach speed. Reacts poorly to pressing the accelerator pedal.

- Fuel consumption is higher than normal.

- Carbon deposits and coke form on the piston and cylinder walls, which then, even with the ignition set correctly, interferes with operation.

- Due to uneven combustion of the fuel-air mixture, the internal combustion engine quickly overheats.

Untimely combustion of the mixture

A little theory. Ideally, on 4-stroke power plants, the air-enriched fuel composition should ignite at the top point of the piston stroke. In other words, this must happen at the moment when the piston part (piston) reaches TDC. It turns out that a little earlier than the piston reaches its apogee. This is explained by the fact that the composition needs a certain time for ignition and combustion. After this chemical process, gases are formed that move the KVShM part down. Then a new work cycle begins.

How to set early late ignition

Obviously, the concept of early or late ignition means untimely operation of the system as a whole. The candle gives an impulse, the enriched composition is ignited, but not at the time required. When ignition is late, there is a delay, and when ignition is early, it is advanced. Both options are considered negative and require urgent adjustment. In automotive systems that have the ability to manually adjust the OZ, untimely ignition can be adjusted.

How to set the ignition timing with your own hands

Setting the ignition correctly means that you need to find the desired ignition timing (IAF). The tuning is done at idle, although this is understandable, but suddenly someone decided to put the car on a jack and tune it at speed.

To adjust the ignition, you need to know that the optimal good engine crankshaft speed at idle is from 850 to 900 rpm. The ignition timing angle should be between -1 and +1 degrees. This is a degree relative to top dead center (TDC).

A popular device used to set the ignition is a strobe light. With a strobe, the settings are more precise. But, if it is not there, then set it up using a control light.

If a light bulb is used for adjustment, it is connected to the positive terminal on the ignition distributor (distributor), and the light bulb base is connected to ground. Let's look at the configuration options separately.

Now we have begun to disassemble the power units of automobiles. Please write in the comments what kind of car you have and with what engine. Later, materials on such engines will be published with useful information, for example, if the timing belt breaks, whether the valves are bent, also technical characteristics, design, on which cars such engines are installed, etc. We have already reviewed the ZC engines from the Honda plant, 3UZ-FE, 3S-FE, 1AZ-FE.

Strobe setting

- Start the engine, heat it to operating temperature and turn it off.

- Connect the strobe light to the car's network.

- Unscrew the nut securing the distributor cap - ignition breaker.

- Place the alarm sensor on the high-voltage wire of the first cylinder.

- If there is a vacuum corrector hose on the distributor, then it must be disconnected and plugged.

- Direct the strobe light onto the engine crankshaft pulley.

- Now start the engine and leave it idling.

- Now you need to turn the distributor body and fix it so that the mark on the crankshaft pulley coincides with the mark on the timing mechanism.

- If the marks match, tighten the nut.

How to set the ignition with a control light

- Rotate the engine crankshaft until the mark on its pulley coincides with the timing mark.

- In this case, the ignition distributor slider should be directed to the first cylinder.

- Now you need to loosen the distributor nut.

- One wire is connected to the core of the warning lamp (control) and to the ignition coil wire (bobbin).

- The second wire connects the ground and the light bulb base. The light should light up.

- After this, you need to turn on the ignition by turning the ignition key and turning the distributor body clockwise. When the distributor rotates, the light will go out in some position. In this position, tighten the distributor clamping nut.

Why is the SOP not always the same?

- Initial phase. At the moment the spark is applied (1-1.5 milliseconds), a small part of the fuel in the spark breakdown zone is ignited (approximately 6-8% of the total volume).

- Main phase. Due to the sharp increase in temperature in the combustion zone of the first phase, the main part of the fuel in the central part of the combustion chamber is ignited.

- The final phase of combustion. The mixture is ignited in the peripheral areas of the combustion chamber. The third phase lasts until the exhaust valves open.

It has been practically established that the most effective conversion of thermal energy from fuel combustion into rotational movement of the crankshaft is achieved if the peak pressure in the combustion chamber occurs 10-12° after TDC. The nature of combustion of the mixture in the combustion chamber depends on many parameters: temperature, quality and octane number of gasoline, spark charge density, actual engine load and crankshaft speed. Therefore, the SOP cannot be constant in different engine operating modes.

Other methods of setting the ignition

Method by ear

Some people set the ignition by ear. Rotate the distributor and determine how the engine operates. This method is the simplest:

- Start the engine.

- Loosen the distributor nut.

- Rotate the distributor and determine for yourself how the internal combustion engine works. The engine should operate smoothly in the found position, without vibration. At the same time, the engine should develop the highest idle speed.

- After this position has been found, you now need to turn the distributor a couple of degrees clockwise and secure it with a nut.

Spark method

Another tuning method is using a spark. To do this, you need to align the marks on the crankshaft pulley with the timing mark. The slider mark points to the first cylinder. After this, you need to loosen the distributor nut and pull out the central high-voltage wire from the distributor cover.

Afterwards, bring this wire closer to ground so that there is 5 mm between them, and turn on the ignition. Rotate the distributor body 20 degrees clockwise. 20 degrees is 1-1.5 cm. Now you should slowly turn the distributor counterclockwise until a spark appears between the disconnected distributor wire and ground. In whatever position the spark appears, we leave the position of the distributor in that position and tighten it.

After using one of the methods for adjusting the ignition of domestic carburetor cars (VAZ, UAZ, Volga, NIVA, etc.), drive around and check how the adjustment affected the operation of the internal combustion engine.

For diagnostic accuracy, you need to:

- First warm up the engine.

- Then accelerate to a speed of 45 km/h.

- Turn on speed 4 and press the gas pedal all the way.

- At the same time, we evaluate how the engine behaves, whether it detonates or not.

- If the ignition timing is set well, after switching to 4th gear at a speed of 45 km/h, a short-term detonation will appear for 2-3 seconds and disappear after pressing the gas pedal.

- If detonation does not disappear quickly, then early ignition has occurred.

- If there was no detonation at all, then the ignition turned out to be late, you will have to set it “early”.

If it was not possible to set the ignition to the optimal mode the first time, then repeat again and again until the correct result appears. By repeated adjustments, you can achieve automaticity and learn how to adjust the ignition with your own hands, without instruments, by ear.

When and why do you need to configure?

Before moving on to answering the question, let's pay a little attention to the theoretical understanding of the subject. When a substance burns in the cylindrical flasks of an engine, it does not do so immediately, but gradually; with instantaneous decay, there would be no problems with pre-ignition. But the air-fuel mixture requires time, calculated in fractions of a second. If we add to this equation that the crankshaft rotates around its axis at an inconsistent speed, then we get a problem - the substance will burn either ahead of time, or a little later. The result will be unstable engine service; it will overheat, which will lead to detonation and completion of work before its service life.

- Ignition too early will result in pressure from the gases preventing the piston from moving and reaching the top point. This will result in less power and more fuel consumption due to unstable rocking at low rpm.

- And late ignition will lead to the fact that the air-fuel elements will burn for a long time, because of this the heart of the vehicle will overheat and more fuel will be consumed.

To avoid these unpleasant consequences, it does not hurt to ensure that the substance ignites and burns according to the amount of shaft rotation and corresponds to the optimal motor load. Old cars, invented by Ford, shifted responsibility for adjustments to the driver. The design includes a special lever-handle.

Modern models are equipped with a distributor with a part of the centrifugal mechanism.

This thing was a regulatory structure with several light weights and springs to balance the internal elements. When the rotational number increased, the loads were distributed to the sides and set the support part-breaker in motion. The more the shaft accelerated, the more the loads were distributed over the area and, as a result, the advance angle increased. But these safety functions do not function well if the octane rating of the fuel does not meet the engine manufacturer's requirements, even if the factors in question are satisfied, the wrong octane rating will lead to detonation.

In the last century, in such a situation, you could simply open the hood and manipulate the distributor in the required direction with your own hands. When using low octane fuel, it was necessary to ensure that the spark plug fired later. On current models, this is regulated by a special sensor that monitors and regulates temperature, speed and other engine compartment processes.

Which systems need adjustment?

The process of initial setup and correction while the engine is running largely depends on the design of the ignition system, among which there are 3 main types:

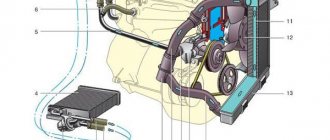

- Contact ignition system. A mechanical breaker opens the primary circuit of the ignition coil. The high-voltage pulse generated on the secondary winding of the coil flows to a mechanical distributor, which directs the spark charge to the spark plug through a high-voltage wire. To maintain optimal SOP in all engine operating modes, a vacuum and centrifugal regulator is used. A subtype of the contact system is considered to be a contact-transistor type of design;

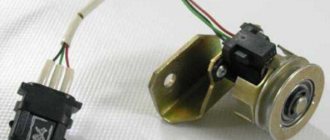

- Contactless ignition. The operation of the ignition system is no different from the contact type, with the exception of the method of selecting the moment of pulse formation on the primary winding of the ignition coil. Instead of a mechanical breaker, an electronic switch is used, which works in tandem with a pulse sensor. The drive of the distributor axis, as in the case of contact ignition, is implemented from the engine crankshaft. But instead of the contact method of transmitting voltage to the primary winding, pulses are formed on the Hall sensor. The signal is read by a commutator that controls the low voltage coil;

- Electronic ignition. The formation and distribution of high-voltage pulses is entrusted to electronic devices. Information about the actual load, crankshaft speed and camshaft position is analyzed by the engine control unit. The ignition is configured at the design and test stage by entering the appropriate data into the ignition map. Changing these parameters is possible only with the help of special equipment and is aimed at increasing engine power.

The initial installation of the SPD in contact and non-contact systems is achieved by correctly positioning the distributor runner relative to one of the cylinders at the end of the compression stroke.