The VAZ-2114 was produced by the AvtoVAZ plant as a modernized version of the Lada Samara - VAZ 2109. The changes in appearance immediately attract attention. The car has become more modern, getting rid of the rough outlines of the hood of the “nine”. But the main thing that interested car enthusiasts was what’s under the hood of the VAZ 2114? After all, it is the technical characteristics that determine how successful the use of the car will be.

VAZ 2114

What is under the hood of the VAZ 2114

Under the hood of the VAZ 2114 its key mechanisms are located. First of all, this is an engine - four-cylinder, single-row, with 8 or 16 valves. From the receiver, compressed air enters it and passes through the air filter (to the right of the engine).

In addition, under the hood of the 2114 there are:

- The windshield washer reservoir is to the left of the engine.

- The hydraulic tank for the brake system is just above the air filter.

- The battery is in the lower right corner.

- The cooling system expansion tank is on the right, above the battery.

- Fuel system adsorber - between the hydraulic drive reservoir and the expansion tank of the cooling system.

- The gearbox is under the engine, on the right side.

The adsorber on the VAZ 2114 appeared in order to comply with Euro-2 and Euro-3 environmental standards. It is designed to capture spent fuel vapors that have not liquefied. With the help of an adsorbent (usually activated carbon), the vapors are absorbed. A malfunction of the device is indicated by a characteristic hissing sound when opening the fuel tank, and a drop in engine speed at idle.

How does the VAZ 2114 engine work?

The base design of the VAZ fourteenth series engine is an injection system. It is based on distributed fuel injection into the cylinders through electromagnetic injectors - injectors equipped with sprayers. The composition of the fuel-air mixture is regulated by an electronic controller that receives information from the vehicle's sensors.

The first injection engines at VAZ were put into mass production back in 1996. However, they did not gain popularity at first, since the serviceability of the injectors, spark plugs and fuel pump was highly dependent on the quality of the fuel. The difficulty of diagnosing the injection device also had an impact. After modernizing the injection system, the production of VAZs with carburetor engines was completely discontinued by 2006.

The engine operating cycle consists of the following stages:

- When the ignition is turned on, the injection system controller starts the fuel pump using a relay.

- From the pump, the fuel passes through a fine filter, fuel lines, and is supplied to the fuel rail, which is mounted on the intake manifold.

- The fuel pressure regulator, which is located on the ramp, bleeds “excess” fuel back into the tank. This is necessary for accurate dosing of fuel injection.

- From the ramp, through the sprayer on the injectors, fuel is supplied to the intake manifold of the engine cylinders.

- Next, the spent fuel vapors are captured by a separator, from where the vapors condensed into liquid are drained back into the tank. The air passes through the air filter and enters the throttle body intake hose. If the car is equipped with an adsorber, then part of the vapor is absorbed by activated carbon.

Thus, the necessary elements for the operation of the VAZ 2114 injection engine are:

- fuel pump – electric, submersible type, with a working pressure of at least 3.2 bar;

- electronic fuel injection system controller;

- pressure control fitting and fuel pressure regulator, which are attached to the fuel rail;

- electromagnetic valves – injectors;

- cleaning filter system and throttle assembly.

All control of the distributed fuel injection system is carried out through the ECU - an electronic control unit. It reads the vehicle's sensors and controls the operation of the fuel system. Since the operation of the entire vehicle depends on the health of the ECU, it is not recommended to try to reflash it yourself.

Camshaft position sensor

This mechanism is located near the cylinder block. The main task is to transmit data to the ECU regarding the current operating cycle. Among specialists, the mechanism is called a Hall sensor. The operation of the device is based on the following principle: in accordance with the location of the crankshaft, the position of the gas distribution mechanism is determined. The data received by the sensor is reported to the electronic unit. Fuel is injected and the mixture is subsequently ignited.

How to change the engine on a VAZ 2114

The VAZ 2114 engine changed throughout the entire production period of this car. The first models of the VAZ 2114 or “Samara-2” (as it began to be called by analogy with its predecessor) rolled off the production line with an engine from the VAZ 2109. It was an eight-valve injection engine with a relatively small volume - only one and a half liters. This engine did not differ in terms of developed power, which was 78 horsepower.

Since 2007, VAZ 21114 engines began to be installed on cars, with an increased volume of 1.596 liters and a maximum power of 80-84 hp. With. This engine complied with the Euro-3 environmental standard.

And since 2010, a model with a 16-valve engine has been produced. It's also a four-cylinder engine, but instead of two valves per cylinder there are four. The 16-valve engine has more power - 98 horsepower, faster acceleration, but is more susceptible to breakdowns than the eight-valve engine.

Thus, under the hood of the VAZ 2114 there are key mechanisms, the main one of which is the engine. Its operation is based on a distributed fuel injection system, which is regulated by an electronic control unit.

Source

What to do if the radiator leaks

Old VAZ models still had copper radiators installed, but now not every elite model can have such a miracle, but on domestic cars the aluminum radiator has firmly secured its position. Everything is clear here, it’s a matter of the price of metal, but now how can those who don’t have a propane torch repair a car radiator with their own hands? Everything is quite simple, and many chemical plants producing various polymers have made sure that repairing a car radiator with their own hands is accessible to everyone.

You will learn how to work with vinyl stickers on cars in the article.

You will learn what tuning is in Dagestan in our material at https://avtopolza.ru/tyuning-russkix-avto/dagestanskij-avtotyuning/ link.

Naturally, breakdowns of car radiators can be very different, and if it is a small leak, then the old folk method will cope with it - pour mustard into the coolant, which will penetrate and clog the small crack. After a head-on car collision, you will most likely have to buy a new radiator, since restoring the old one will cost a much larger amount. But this type of repair should be treated very carefully; it is preferable to eliminate the cause from the outside, so as not to clog the cooling and heating system with mustard or any other additives.

The history of the creation of the VAZ-2114 car

The first VAZ-2114 appeared in 2001, and mass production began in 2003 and continued until 2013. The main manufacturer of the car is the Volzhsky Automobile Plant.

VAZ-2114 belongs to the family of small class passenger cars. Its restyled model VAZ-2109, produced since 1984, was a continuation of the family of front-wheel drive cars. The car, successful in its layout, transmission and engine, became the first AvtoVAZ line not related to technical borrowing from the FIAT-124.

The interior of the VAZ-2114 was equipped with a new instrument panel (the so-called “European panel”), a height-adjustable steering column, a steering wheel from the VAZ-2110, central door locking, an upgraded heater, and front electric windows.

Engine tuning

For naturally aspirated engines, the following type of tuning is usually used:

- receiver complete with 54 mm throttle body at the inlet;

- straight-through spider 4/2/1 at the outlet;

- camshaft Nuzhdin 10.93 or Dynamics 118 instead of the factory equipment.

The dynamics of the internal combustion engine will improve, the power will increase to 85 - 90 hp. With. Next is just lightening the crankshaft, modifying the intake manifold and milling the cylinder head.

For 16 valve engines, tuning has the same principles, since chipping it does not make sense. To achieve 120 l. With. You can increase the damper to 56 mm, use a direct-flow type exhaust, Nuzhdin 8.85 or Stolnikov 8.9 280 camshaft.

Thus, only one engine, modification 21126, bends the valves on the VAZ 2114. All other engines are considered safe and provide a real service life of about 270,000 km.

Features of the eight-valve VAZ-2114 engine

The eight-valve engine installed on the VAZ-2114 is easy to operate and maintain, and, taking into account the speed limit on highways of no higher than 90 km/h, it is practically not inferior to sixteen valve engines.

Unlike sixteen valve engines, the valves on 2111, 21114 and 11183, when the belt breaks, do not meet the piston and do not create problems for the owner associated with repairs. Moreover, if such a malfunction occurs on the road, it can be easily eliminated. To do this, it is enough to have a spare belt and the necessary tools: a head for “19”, open-end wrenches for “8”, “10”, “13”, “17”, as well as a special key for adjusting the belt tension by the position of the roller.

Thermal valve clearances must be adjusted every 30 thousand km, observing the temperature regime during adjustment, which should be within 20-30 degrees.

Regulation is made by replacing calibrated spots, the size of which alternates every 0, 02 and 0.03 mm. The exhaust valve clearance should be at least 0.35 mm, and the intake valves should be 0.20 mm. The accuracy of the set gaps affects the injection phase. When setting the clearances above the permissible ones, the camshaft cams open and close the valves with some delay in time, and if they are too small, they advance their response time. Too small gaps or their absence disrupt the tight fit of the valve disc to the seat and most of the time it operates in a half-open state, as a result of which the high-temperature flame bends around the edges of the disc, causing them to burn out. Valve guides are also subject to temperature effects, causing their maximum permissible runout (0.03 mm).

Exhaust system repair

The performance of the exhaust system is often overlooked, considering that it is at the very end of the fuel combustion process and does not in any way affect the operation of the system as a whole. But this opinion is erroneous, since any obstacles at the exit of exhaust gases can catastrophically reduce engine power until it stops. In addition, in modern systems, fuel is burned, which improves environmental performance and, accordingly, removes the unpleasant smell of exhaust.

Lambda probe

Of the entire exhaust system, there are several elements that fail most often. Let's start with the electronic filling of the exhaust system, and the first we will have is the lambda probe. This exhaust gas analysis sensor in modern engines regulates the composition of the air-fuel mixture to ensure ideal fuel combustion.

Lambda probe VAZ 2114

There is nothing to break here, but it has a warranty period of usually 100,000 km, after which the metals that are responsible for the sensor’s ability to analyze gases simply lose their abilities. This repair is simple: the contacts are removed from the sensor, after which it is unscrewed with a spark plug wrench, and a new sensor is put in its place, the contact terminals are connected back.

Corrugation and pants

A corrugation is a flexible hose that connects the elements of the exhaust system. Thanks to its elasticity, vibrations from the engine are not transmitted further, but, taking all the vibrations upon itself, it most often fails, and if it breaks, it is replaced.

The so-called “pants”, that is, the muffler and resonator, can burn out, but this only happens with exhaust systems made of low-quality and thin stainless steel. If desired, burnt metal can be welded with special electrodes, but such repairs are short-lived, so it is better to replace them.

Connecting parts

In addition to the main elements, there are many gaskets between them, which also lose their properties and need to be replaced. Clear signs of a faulty exhaust system are loud exhaust noise and vibration when the engine is running. In addition, if the lambda probe on the car's display panel fails, the engine will light up yellow, however, only an on-board computer or a multifunctional station in a specialized service station will be able to determine the exact breakdown.

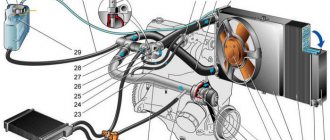

Engine diagram and structure

Before we begin to consider the issue of the engine design and description of the characteristics, it is necessary to consider the design of the components and parts that are located directly in the main power unit and outside.

Diagram and design of the Samara-2 engine

Also, it’s worth looking at a cross-section of the VAZ-2114 engine:

Cross section of the Samara engine

Show hidden content

1 – oil pan drain plug; 2 – oil pan; 3 – oil filter; 4 – coolant pump; 5 – exhaust manifold; 6 – intake manifold; 7 – carburetor; 8 – fuel pump; 9 – cylinder head cover; 10 – camshaft bearing cover; 11 – camshaft; 12 – crankcase ventilation hose; 13 – valve adjusting washer; 14 – pusher; 15 – valve cotters; 16 – valve springs; 17 – oil scraper cap; 18 – valve guide; 19 – valve; 20 – cylinder head; 21 – spark plug; 22 – piston; 23 – compression piston rings; 24 – oil scraper ring; 25 – piston pin; 26 – cylinder block; 27 – connecting rod; 28 – crankshaft; 29 – connecting rod cover; 30 – oil level indicator; 31 – oil pump receiver

Characteristics of an 8-valve engine

Many motorists remember how at the end of the 90s of the 20th century and the beginning of the 2000s, the VAZ 2108-09, which was also called “Samara,” was popular on the roads of the CIS. These cars became legendary in that era. Due to the high popularity, the AvtoVAZ plant decided to resume production of these models with some modifications.

VAZ-2114 engine under the hood

Firstly, the VAZ-2114 received a modified engine . In essence, this is an injection version of the Samara. Although it received some features from modern engines. If we consider in more detail, the Samara-2 engine (this is the type installed on the VAZ-2114) is a mixture of two engine options into one: from the VAZ 2108 and VAZ 2110.

Many motorists liked the Samara-2 power unit and fell in love with it. The main indicator was ease of repair and inexpensive spare parts. Thus, the 8-valve engine has become the standard for “price-quality” indicator.

When the basic information has been reviewed, you can proceed directly to considering the characteristics of the motor.

Table of main characteristics of the Samara-2 engine 8 valves:

| Name | Characteristic |

| engine's type | In-line, longitudinal type, 4-cylinder, 8-valves |

| Fuel type | Gasoline (installation of gas equipment is possible) |

| Cylinder arrangement | 1-4-3-2 |

| Injection system | Distribution, injection type |

| Control | Bosch, "January" or GM |

| Camshaft location | Upper |

| Drive unit | Front |

| Piston and ring diameter | 82 – nominal (tolerances by group: A – 82.00-82.01, B – 82.01-82.02, C – 82.02-82.03, D – 82.03-82.04, E – 82.04-82.05) |

| Crankshaft | Cast iron |

| Cylinder block | Cast iron |

| Timing system | Belt and roller |

Chassis design features

The VAZ-2114 car is front-wheel drive. The power unit and gearbox are located in the engine compartment. Clutch drive is cable, mechanical. The gears in the box are controlled by a handle located in the cabin through a rocker mechanism.

Front suspension type: independent, telescopic. The front suspension struts are the main supporting elements in which the rotating elements are assembled. The strut assembly includes a spring that rests on the upper and lower support cups. The upper part of the rack is attached to the body with three bolts, and the lower part is attached to a brace, attached to the body spar by two brackets.

At the bottom of the strut, the bracket connects to the hub steering knuckle.

The wheel is turned by a steering rod connected to the steering rack. The rod turns the strut assembly, while at the top it turns on a support bearing, and at the bottom - on a ball joint. The anti-roll bar links the suspension on both sides and ensures its synchronous operation.

Knock sensor, DTOZH, speed and others

In addition to the above mechanisms, other very important devices can be found in various corners of the engine compartment. The location of the VAZ-2114 injector sensors is quite chaotic, some are located directly on the power unit, others in other places - the gearbox, on electrical circuits.

Some equally important mechanisms include:

- The knock sensor is sensitive to various engine vibrations. Based on the received pulses, the ECU determines the qualitative composition of the mixture. Located on the cylinder block.

Engine temperature sensor - the only and simple, but extremely important task assigned to this device is to monitor the coolant temperature.

Speed sensor – from the name itself it is clear that this controller is necessary to measure the speed of a car. The DS transmits impulses to the ECU, which processes them and determines the speed of the car; the resulting result is displayed on the instrument panel by the speedometer.

Idling speed – not only reads information, but also corrects engine operation. DXH, using a special needle, controls the pipe - closes and opens. Due to this, the amount of oxygen supplied to the throttle assembly changes.

Mass air flow sensor - reads the data and transmits it to the control unit, which, based on the information received, determines the optimal ratio of the various components of the fuel-air mixture. A breakdown of the air flow sensor leads to the fact that the car significantly loses power, and the driver begins to feel a significant increase in the amount of gasoline consumed by the car.

Crankshaft position sensor

You can often hear drivers with many years of experience calling this mechanism nothing other than a synchronization sensor. This name comes from the principle of operation of the device. The tasks of the DPKV are to synchronize the operation of the electronic unit and the gas distribution mechanism.

The VAZ-2114 is equipped with an inductive type DPKV. The cost of such a sensor is relatively small. If a vital controller for a car fails, most drivers prefer to immediately replace the device with a new one.

If the DPKV breaks down, further operation of the vehicle will become impossible. Without this mechanism, the fuel supply system will stop working, because the ECU will not receive information about when it is necessary to give a command to inject fuel into the cylinders. The location of the DPKV is in close proximity to the camshaft.

Electronics are responsible for fuel delivery in the VAZ-2114 car system. Without TPS, the control unit will not be able to determine the optimal time to supply gasoline. Deviations from the correct operation of the TPS lead to an increase in the amount of fuel consumed. The operation of many other car systems depends on the angle at which the remote control is located: cooling, fuel supply.

see also

The TPS is located near the idle speed sensor. In the “fourteenth” system, the work of these two devices is closely linked.

When the TPS breaks down, the car begins to twitch in a certain position of the damper, and instability of engine operation is also noted. All VAZ-2114 8 valve sensors are interconnected in their operation, so two different devices sometimes exhibit the same symptoms of malfunction. If symptoms of a breakdown occur, it is necessary to take a comprehensive approach to checking all controllers.

Pros and cons of the VAZ-2114

The period of the early 2000s was marked by the appearance of the VAZ-2114 on the market and during this period, approximately until 2006, it was considered prestigious to buy this car not only in Russia, but also in foreign countries. After six years and a massive influx of imported cars into the trade, the car that had taken the first step in the development of the domestic automobile industry began to be casually called a “scraper,” or even more roughly, a “pelvis.” The good news is that the percentage of such people is very small and the “hard worker” car continues to work to this day and helps out all segments of the population.

A huge plus about this car is that it can withstand all aggressive attacks both from its operation on poor-quality road surfaces and from natural conditions.

As with any machine, even a very expensive one, minor repairs are inevitable and maintenance is also necessary, but the price of these costs is offset by the honest return of all its energy. The VAZ-2114 car is reliable and there is nothing in its components that can break down critically; it can be repaired both in the city and in the wilderness, being far from super car services.

Body structure of Lada Samara 2114

The body of Samara is worth a closer look. It itself is all-metal, welded, load-bearing structure. Some body elements, for example, non-removable ones, are connected to each other by resistance welding, and in those places where access is partially limited - by semi-automatic electric welding in an inert gas environment. The manufacturer sealed body elements such as panel joints or welds with mastic. In general, the issue of protection (anti-corrosion) of the body of the Lada Samara 2114 should arise already when purchasing a car. Yes, the manufacturer provides underbody protection for a period of 5 years, but the car enthusiast should not forget that not all Lada parts are processed during assembly. In any case, there are places that are inaccessible for protection. Moisture, dust, dirt, snow and road treatment chemicals when they come into contact with metal have a detrimental effect on them.

Therefore, it is imperative to carry out anti-corrosion protection. It is worth noting that when selling a Samara 2114, the treated body is valued at much more expensive. Passive and active - these are two types of protection for the body of your car. Passive protects the metal surface from atmospheric influences, and active creates a thin anti-corrosion layer on the metal. Passive mastic is often used to preserve the bottom, wings, and sometimes shock absorber niches. It is worth noting that mastic should only be applied to a clean, dry surface in a thick layer before starting active driving.

Repair at the service center

Repairing a VAZ 2114 with your own hands is a difficult task that requires certain knowledge and skills. The car manufacturer, in the official document “VAZ 2114 Operating Manual,” urges car owners not to try to fix malfunctions on their own every time. Only at the service center will technicians be able to connect the diagnostic connector and read the VAZ 2114 error codes.

The error codes from the dashboard do not match the professional ones. The fault code for the coolant temperature sensor on the dashboard is 15, and on a professional computer it is 0115. Before going to the service, you should read the fault codes from the car’s on-board computer and compare them with professional ones. To read the codes on the dashboard, do the following:

- Without inserting the key into the ignition, press and hold the odometer reset button;

- insert the key into the lock, turn it to position 1, release the button, at this moment testing of the devices will begin;

- Press and release the button again - the software version will be displayed on the monitor;

- Press and release the odometer button again, then a fault code will appear. If two errors occur, the sum of their codes is reflected.

A more in-depth diagnosis will be carried out by professionals. The manufacturer leaves little for the car owner to do independently. Judging by the typical set of spare parts, these are only two points (the repair manual describes them): installing a spare wheel and replacing fuses.

For a VAZ 2114 car, repairs and maintenance are often best performed at a service facility.

Before you go

Those who nevertheless studied at a driving school and remember the teachings of the teachers know what to do before driving a car. This is especially true for our domestic models, which do not have an abundance of sensors and a computer that monitors all indicators.

Check the levels of working fluids, oil, coolant in the radiator, even in the washer - these minor checks will give you the opportunity to never find out how a car radiator is repaired, and you will not be repairing the car yourself, much less find out how much a major repair costs jammed engine.

Engine compartment of VAZ 2114

Also, look under the car more often, since most breakdowns begin with minor leaks, which an attentive owner will definitely notice in time.

Driving technique

Gear shifting and clutch operation are those nuances that are definitely worth paying attention to, since the ability to change gears in time and smoothly release the clutch greatly affects ride comfort.

VAZ 2114 clutch design

In order to notice in time that a car is behaving somehow wrong, it is not necessary to thoroughly know its design, but every driver simply must know how a car’s clutch works. VAZ cars mostly have a permanently closed clutch, which means that when you press the pedal, you release the pressure and driven discs from the frictional engagement.

Clutch pedal operation

Among the nuances of operation, it is worth noting that if the clutch is not fully released, trying to pull the car up a steep climb, it is easy to burn the friction linings on the driven disk. This will entail forced repair of the clutch unit. So if you want your clutch to work happily for a long time, try to keep it less fully depressed or released, of course, without sacrificing ride comfort.