The upper support bearing is an important element in the design of the Granta front strut. The “supports” are involved in the rotation of the front strut during a turn, and also absorb axial loads and provide rigidity to the mechanism.

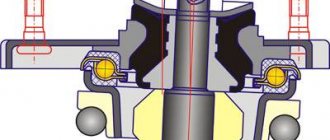

The “support” itself is a housing of two cups, inside of which the bearing itself is located, consisting of a rubber separator with balls inside. It also contains gaskets (vibration and noise insulators). The listed elements, as well as the design of the front support, are presented in the photo.

Video review of the SS20 suspension (front struts, springs, bearings).

Video: “SS20 suspension: briefly about the main thing”

How to replace the support bearings of the front struts of a Lada Granta (VAZ 2190)

The upper support bearing is an important element in the design of the Granta front strut. The “supports” are involved in the rotation of the front strut during a turn, and also absorb axial loads and provide rigidity to the mechanism.

The “support” itself is a housing of two cups, inside of which the bearing itself is located, consisting of a rubber separator with balls inside. It also contains gaskets (vibration and noise insulators). The listed elements, as well as the design of the front support, are presented in the photo.

Video review of the SS20 suspension (front struts, springs, bearings).

Video: “SS20 suspension: briefly about the main thing”

Ways to increase the clearance of Largus

The domestic station wagon is very popular due to its unpretentiousness and reliability. One of the important indicators is solid ground clearance. Transporting goods with these vehicles is a common occurrence. And this inevitably leads to an increase in the load on the suspension, namely on the shock-absorbing struts, which sag due to weight, resulting in a decrease in ground clearance.

We must not forget the quality of Russian roads. It is sometimes impossible to move through potholes and potholes without damaging the suspension. In any case, the amount of ground clearance in this regard is crucial. Because of these factors, many Largus owners try to increase the ground clearance with their own hands. Today there are several ways to do this inexpensively and quickly.

Increasing ground clearance with your own hands

In order to increase ground clearance (suspension lift), car owners use several basic techniques:

- installation of wheels or tires with a larger radius;

- installation of special spacers for shock-absorbing struts;

- replacing the springs with stiffer ones, as well as installing extended shock absorbers.

Some people use air suspension for these purposes. From the point of view of rationalism (and Largus is mainly used by people who prefer the practicality of a station wagon), this is unjustified. Firstly, the equipment is expensive, and secondly, not every car owner can install air suspension with his own hands. Plus, the compressor and receiver will take up useful space in the trunk, which is again impractical.

Causes and signs of failure, diagnostics

The node takes a dynamic (variable) load, and failure, as well as replacement, is usually required for several reasons:

- Part wear, time to failure (service life);

- Accidents, frequent driving in potholes, aggressive driving style;

- Contamination of the support bearing from the inside, ingress of moisture and dust;

- Malfunction of suspension (shock absorbers, springs).

The main sign that a support bearing will need to be replaced is that the Granta rattles and creaks under the hood or near the struts. This appears after 80-100 thousand kilometers, under appropriate operating conditions of the car.

The design of the “support” and the front pillar is complex; the following elements can fail:

- The entire support, including the body (rarely) - position 4;

- Support bearing (more often) – position 8;

- Rubber gaskets wear out (more often) - position 9.

Diagnostics of support bearings

To diagnose a breakdown, do the following:

- Raise the hood, find the front supports;

- Place your hand over the knot;

- Start to strongly rock the car from bottom to top (or ask an assistant);

- If you feel a knock or hear, as well as other incomprehensible sounds, it means that there are problems. It is worth disassembling or replacing the front support mechanism.

- Watch the diagnostic video:

How to check support bearings

What is this?

It is not uncommon for owners of the domestic “fourteenth” VAZ model to notice that a knock occurs in the A-pillars. The reason for its appearance is failed support bearings.

Support rod brand SS20

But you don’t need to start replacing right away. The first priority is to check the condition of the support. And only then take appropriate actions.

In analysis

There are several types of supports:

- A bearing with an integrated inner or outer ring. No clamping flanges are required for its installation. There are corresponding holes for installation;

- With detachable outer ring;

- With detachable inner ring;

- Finishing and cutting structure, the characteristic feature of which is its strong rigidity.

Preparatory measures for replacing the support bearing Do-it-yourself grants

Replacing the support bearing of the Lada Granda strut can be done in two ways.

- Removing the front strut and unscrewing the wheel alignment bolts.

- Removing the strut module along with the rotating mechanism and brake disc assembly without unscrewing the adjusting fasteners.

Both methods cannot be performed without removing the strut, but using the second method, which is described below, you can avoid another wheel alignment.

Preparation for repair

It is advisable to carry out the replacement in an inspection hole, so you will save time on the convenience of performing operations to remove/install the unit. The car is in first gear; to comply with safety regulations, use wheel chocks.

Tools for work

- Any jack.

- Large wrench to remove chassis bolts.

- A long 30mm wrench for unscrewing the hub nut.

- Clamps for tightening shock absorbers.

- Tool for removing tie rod ends.

- Hammer, chisel, core.

- Set of keys (22, 17, 13).

- "Ratchets" on 13, 17, 19.

- Hex key for unscrewing the rod nut.

- Special heads. "Eshki" E8 and E12.

- Large negative screwdriver.

- Pliers.

- Penetrating lubricant such as WD-40.

- Torque wrench for tightening the rod nut.

Required set of new parts

- Supports or individual support bearings, depending on the breakdown;

- Rubber gaskets (if you are only changing the bearing);

- Boot with tie rod cotter pin (if replacement is required).

Removing the shock absorber strut and disassembling it

We remove and disassemble the shock absorber strut when it is necessary to replace the upper support, bearing, spring, and telescopic strut. The telescopic stand is non-removable and cannot be repaired. We carry out the work on an inspection ditch or overpass, but you can get by on a flat platform. There are two options for removing the shock absorber strut. The first allows you to avoid subsequent adjustment of the steering wheel alignment angles, the second method requires less work, but after it requires adjustment of the steering wheel alignment angles. We replace the telescopic stand according to the second option. In the first option, remove the strut together with the steering knuckle, without loosening the nuts of the upper (adjusting) and lower bolts securing the strut to the steering knuckle. At the same time, disconnect the tie rod end from the swing arm of the shock absorber strut (see below). We disconnect the ball joint from the steering knuckle (see “Removing the ball joint”). We remove the outer CV joint from the wheel hub (see “Removing the front wheel drives”), and also remove the pad guide with the caliper and cylinder (see “Replacing the front wheel brake disc”).

We tie the bracket to the brake hose bracket, making sure that the hose is not stretched. If the rack is supposed to be disassembled...

...using a 22mm spanner wrench, loosen the tightening of the rod nut, holding the rod from turning with a 6mm hexagon.

Using a socket or a 13mm wrench, unscrew the three nuts securing the upper strut support to the body...

...and remove the shock absorber strut along with the fist. To remove the shock absorber strut, use the second method to disconnect the tie rod end from the shock absorber strut swing arm. To do this, unscrew the nut securing the ball pin of the tie rod end.

We install an adjustable stop under the finger, press it and, striking the rotary lever with a hammer, press the finger out of the lever. Using a “22” spanner, loosen the tension of the rod nut, holding the rod from turning with a “6” hexagon, and with a “13” socket, unscrew the three nuts securing the upper support of the strut to the body (see above).

We remove the brake hose coupling from the shock absorber strut holder.

Use a chisel or paint to mark the location of the adjusting bolt relative to the rack. With this method, after assembly, the deviation of the wheel camber angle from the original value will be insignificant.

Using a 19mm socket, unscrew the nut of the upper bolt securing the strut to the steering knuckle, holding the bolt from turning with a 17mm wrench.

Remove the top bolt and eccentric washer from the steering knuckle.

Using a 19mm socket, unscrew the nut of the lower bolt securing the strut to the steering knuckle, holding the bolt from turning with a 17mm wrench.

Removing the shock absorber...

...and the upper support plate.

During subsequent assembly, the support plate must be strictly oriented with the arrow towards the front of the car, as well as the arrow on the upper strut support.

Arrow placement on base plate and top support.

We clamp the rack in a vice and install two spring ties diametrically opposite each other, so that they engage the four coils of the spring.

Front support bearings for Lada Granta. When to change

The service life of the front support bearings for the Lada Grant is even approximately difficult to calculate. A trained ear will immediately detect tapping sounds when driving over uneven surfaces. The original Grant support bearings of the front struts are not particularly reliable, since there are complaints about both the materials and the design of the standard bearing.

Factory standard support bearing for Granta and Kalina 2 assembled

On average, the front strut supports on a Grant have to be changed after 50-60 thousand mileage. Sometimes it is possible to reach 75-80 thousand if used on smooth roads.

A worn front strut bearing knocks ungodly, and if worn severely, it can cause a broken support cup if the driver has poor hearing or strong nerves. Also, the wear of the support cannot but affect the car’s handling and the behavior of the front end when cornering and when changing lanes. Therefore, there is no point in delaying replacement.

Worn strut bearings may stick

Cracks in the rubber bushing of the strut support

Overview of the main shock absorber manufacturers

By default, hydraulic ones from SAAZ (Skopovsky Automobile Plant) are installed from the factory. They are not particularly distinguished by their quality, but with moderate use they can last up to 60,000 km.

- Kayaba: Japanese, characterized by high quality, reliability, and long service life. When purchasing, be careful, as some of the products are made in China.

- ASOMI: domestic manufacturer for GAZ, VAZ, LADA models. One year warranty from the date of installation. Judge the quality for yourself.

- SS (SS): also a domestic manufacturer of racks for VAZs. Quality guarantee for two years, according to the owners' reviews, they are not bad, a little harsh.

In general, all shock absorbers are divided into three categories:

- Highway;

- Standard;

- Sport.

The differences in the categories are insignificant and unnoticeable for the average driver. The kit comes with a warranty card and operating instructions.

What are the best rack supports for Granta?

The main requirements for Granta and Kalina 2 support bearings are endurance and reliability. The support bearing takes the entire load from the car body, as well as from the shock absorber strut, allowing the latter to rotate freely around the longitudinal axis.

The dynamic loads of the shock absorber rod are absorbed by a rubber damper. The more reliable it is, the longer the support will last. The spring rests against a support cup with a rubber-coated ball support bearing. However, different manufacturers offer different solutions for support.

Prop with modified caster

Thus, some supports are produced with reinforced bearings (balls of larger diameter), there are supports with a changed caster angle. To do this, the axis of the shock absorber strut is shifted by 6 or 12 mm, which ensures a change in the caster angle to 1°40′ or 2°45′, respectively.

In addition, supports are produced both for Lada Granta and Kalina 2 with electric power steering (article 21900-2902821-10), and for cars without electric power steering (article 21900-2902821-00).

Standard supports cost about $12 apiece, owner reviews about them are not the most encouraging, so most often you have to buy replacements for the original:

- Support bearing SS20 series Master, Gold, Drive, differ in caster angle and damper design. They last quite a long time and are easy to install. The price is about 26 dollars per piece.

ANVIS 2190

Rack Mounts , $27/pair, 6mm offset. Available for both Granta and Kalina 2 with and without EUR. Compatible with all types of springs (11190 or 11196), as well as the most popular KAYABA or SACHS struts. Sevi thrust bearings starting at $20 per pair. A budget option with the strut tilted by 1 degree and the shock absorber axis shifted back by 6 mm. Demfi , article number dff21901 (2190-2902822-12), are sold without a support bearing, which has catalog number 1118-2902840 . The price is about 15 dollars. Reviews are contradictory.

Technologies of the future , article number 2192-2902821 , price about 26 dollars per pair. There are few reviews, mostly positive. Budget Slovak supports LSA , sold without bearings, price about $10 per pair. supports (SA 0156) , complete with bearing, price 10 dollars apiece, run well, good assembly, bearing of standard sizes.

Is it possible to save money when purchasing

Trying to save money on shock absorbers is not a wrong concept, especially if the driver is neat and takes good care of his car. Why not purchase non-original spare parts, especially since the price difference is significant with Chinese products. Of course, manufacturers from China have recently greatly improved the quality of automotive components, but you shouldn’t rely on estimates, it’s better to calculate and check everything.

How often should shock absorbers be changed?

So, let’s take the Japanese brand KYB as the original; one Excel-G shock absorber from this company costs 2.5 thousand rubles, together with the installation of steam it will cost 7 thousand. In defiance, we take the Chinese equivalent for a thousand rubles, a pair will cost 4 thousand. In total, we saved 4 thousand. The service life of Chinese shock absorbers is 25 thousand maximum, that is, in a year and a half they will have to be changed again, and that’s 4 thousand again, plus adjustment and balancing. Japanese is enough for 4.5 years. During this time, 12 thousand will be spent on cheap shock absorbers, plus the cost of adjusting the suspension and balancing.

It is necessary to regularly check your shock absorbers for calm and safe movement on our roads.

Your car has traveled more than 80,000 km and you have never checked the shock absorbers?

Do your car tires have worn out areas and the slopes wear out very quickly?

Does your car “sag” when passing sharp turns?

Did you begin to feel every bump and hole while driving and the car began to behave uncertainly?

Are the shock absorber body and rod coated with oil?

If you answered “yes” once to any of the questions, immediately check yours and find out when you need to change the shock absorber.

How to quickly change the support bearings of struts on a Lada Granta

To replace the standard worn support bearings on the Lada Kalina 2 and Grant, according to theory, it is necessary to completely remove the front strut. This is due to a loss of time, a bunch of special tools, and not everyone has experience in this regard. The strut support can be replaced without removing the shock absorber from the car, quickly and with your own hands.

What is needed to replace supports. Tools and accessories

To work, we will need a standard set of heads and plumbing tools. However, here is the complete list:

- Tie for springs of any design.

- Two jacks or a jack and a stand.

- Hexagon to keep the shock absorber rod from turning.

- New strut mounts complete with bearings.

- Magic penetrating lubricant WD-40 or something similar.

- Litol-24 or other grease.

Changing the Grant strut supports with your own hands

The process of replacing support bearings without removing the struts from the Granta is as follows:

- We tear off the wheel bolts, hang the car on a jack, and remove the wheel.

- We unscrew the stabilizer link to untie the stabilizer link from the link.

- We tear off the shock absorber rod nut, holding the rod itself with a hexagon.

- We load the rack; to do this, we place a second jack or stand under it. We load until the entire load is transferred to the second jack (stand).

- We compress the spring using ties, but not completely.

- We remove the stand (second jack), the stand should go down.

- We completely unscrew the support bearing. Now you can remove it from inside the wheel arch.

- We carefully clean the support cup from dirt; if installing the SS20 support, remove the lower support cup, marked in the photo.

- We install a new support and carry out assembly in the reverse order.

Since it is possible, we check the condition of the tie rod ends and ball joints, paying special attention to the condition of the boots. If they are damaged (cracks, tears), it is advisable to replace them with new ones.

Source

Device

Let's first analyze its device.

Here is a picture of a thrust bearing. In its upper part there are three studs for its fastening and one central fastening through the inside of the support.

This video was created to explain the essence of installing a support bearing, the purpose of which for some reason most car enthusiasts forget. They only know the purpose of shock absorbers and springs, although the support is an equally important element in the car’s suspension.

Video

https://youtube.com/watch?v=5Yveq%2520%E2%80%B3%26gt%3B

Scheme for assembling struts for Granta vehicles

The video above (see pictures) shows:

• Attaching the upper part of the rack to the body mudguard;

• The stand itself is disassembled with a spring and upper support;

• Support bearing (there are several types).

The upper support serves to smooth out the loads coming from the wheels through the shock absorber onto the car body and distribute them evenly.

Support bearing wear

With use, the support bearing wears out and grinds, creaks, knocks, and the most dangerous thing is when play appears. All this is reflected in the condition of the rack itself and the entire wheel assembly.

So, if you lift the car on a lift and move the wheel sideways, right/left, you will notice a large free play of the entire assembly, which will tell us that the support bearing requires replacement.

If you look from above, where the shock absorber rod is attached, you will notice its movement from side to side. You can also place your hand on the top of the shock absorber where the rod nut is located. In this place the play is clearly felt.

When the bearing balls wear out, the load on the front suspension elements increases and the vehicle's handling deteriorates. Consequently, all this negatively affects overall traffic safety.

Replacing the rack support

https://youtube.com/watch?v=VLNGuUsv4DM

To replace the support bearing, the strut must be removed from the car, disassembled, after compressing the spring with special ties. The faulty support is removed, a new one is installed, the rod fastening nut is tightened, the ties are removed and the stand is installed on the car.

After replacing the supports, it is recommended to check the wheel alignment on a stand to check the wheel alignment angles.

That's all, write comments. Goodbye!

In this article we will get acquainted with a small but very important component of a car's suspension - this is the front strut support bearing (in common parlance, a support bearing).

Let's try to find out why it is needed, what threatens it, and how to determine that a part requires replacement.

There is not a single unnecessary part in the machine, so if at least one of them fails, this can pose a threat to its overall performance. As a rule, a harbinger of malfunctions can be:

- changes in vehicle behavior;

- the appearance of extraneous sounds and knocks;

- unusual vibrations.

There is a common point of view - a good knock will always appear, although the fruits of such a result often turn into expensive repairs or more tragic consequences.

What to do about the knocking?

If you do not pay attention to the problem and do not change the silent blocks on the grant, the knocking will become increasingly stronger. Therefore, it’s time to drive the car into the pit, remove the engine protection, and look at all the details. You can swing the car from the desired side, whether you hear a knock or not, but it will happen if the silent block on the grant has become completely unusable. If the problem is in the stretcher, then you need to pull it too, the resulting knock will be proof that the cause of the breakdown has been found.

You can replace the silent blocks with grants, the price of which seems reasonable, right in the pit, without the need to remove the levers.