P0336 - Crankshaft Position Sensor "A" Performance/Range Problem.

Code P0336 indicates a problem with the crankshaft position sensor (CPS). The DPCV monitors engine speed and controls the engine valves to make sure the pistons are working properly.

The crankshaft sensor transmits important information to the engine control unit (ECU), which allows the controller to adjust fuel injection as well as ignition timing. DPCV, working properly together with the ECU, ensures excellent engine performance.

When the crankshaft sensor fails to provide the correct information to the control unit, a P0336 code is generated.

What does P0336 mean?

Trouble code P0336 indicates that the engine control module (ECM) has detected a malfunction in the crankshaft position sensor A circuit.

The crankshaft position sensor records the crankshaft speed, controls the operation of the engine valves (in particular, the operation of the pistons), as well as the engine itself. The ECM uses information received from the crankshaft position sensor to control fuel injection and ignition timing. The crankshaft position sensor and ECM are required to operate properly to operate your vehicle safely.

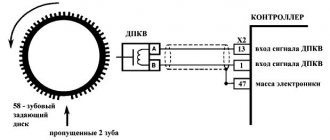

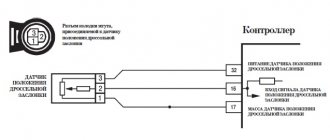

The crankshaft position sensor consists of a rotating disc and a stationary sensor. Most crankshaft position sensors have a voltage wire, a ground wire, and a signal wire that allows the ECM to receive a revolutions per minute (RPM) signal.

Using the above information, as well as data received from the camshaft position sensor, the ECM controls the fuel injection process and also regulates ignition timing. If the ECM does not receive or receives an erroneous signal from the crankshaft position sensor, P0336 will be stored in its memory.

The following error codes may also appear with P0336:

- Trouble P0335 - Crankshaft Position Sensor “A” - Circuit Malfunction

- Trouble P0337 - Crankshaft Position Sensor “A” - Low Signal

- Trouble P0338 – Crankshaft Position Sensor “A” – Signal High

- Error P0339 - Crankshaft position sensor “A” - poor electrical contact

Symptoms of malfunction

The main driver symptom of P0336 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up.

- The motor can operate, but with reduced performance (drop in power).

- The engine may crank but will not start.

- The car stalls or has trouble starting.

- Jerking/misfire at idle or under load.

- Increased fuel consumption.

Depending on the make and model, the engine control unit may use the CKP sensor to estimate engine speed and position. Therefore, the engine will operate, but not at maximum efficiency. With P0336, you may experience difficulty starting, rough idling, or poor acceleration.

Causes of error P0336

- Worn or damaged gear

- Foreign object in contact with gear

- Short circuit or open circuit of the crankshaft position sensor

- Short circuit, break or damage to the crankshaft position sensor wires

- Corroded or damaged crankshaft position sensor connector

- Misfires in engine cylinders

- Malfunction of the crankshaft position sensor

- Camshaft position sensor malfunction

- ECM malfunction

523.EXE

Check the processes running on your PC using the online security database. You can use any type of scan to check your PC for viruses, Trojans

,

spyware

and other

malware

.

processes:

The most effective methods are those using sophisticated computer technology.

What does this method provide? First of all, it allows you to control the entire internal combustion engine. The diagnostic accuracy is exceptional. Errors that may arise as a result are automatically eliminated using special programs.

Types of work:

Computer data processing is carried out by introducing “software” (programs) into the processor of the device, focused on:

How to do it? Drivers usually use the services of a car service center. This is not the only option. With some preparation, it is possible to diagnose a car yourself.

The state of the required systems is determined by gradually scanning each node. Defects that cannot be eliminated by the intervention of electronic correctors are eliminated during minor, medium or major repairs.

How does a mechanic diagnose a P0336 code?

When diagnosing this error code, a mechanic will do the following:

- Reads all error codes stored in the ECM memory using an OBD-II scanner

- Check the crankshaft position sensor for damage

- Check electrical wires for wear, short circuits and damage. It is also important to make sure that the sensor wires are not too close to the spark plug wires.

- Check the crankshaft position sensor connector for corrosion or any damage.

- Check the crankshaft position sensor wiring harness insulation for damage.

- Check the gear for looseness or damage

- Check the gap between the gear and the top of the crankshaft position sensor

- Clear error codes from the ECM and test drive the vehicle to see if P0336 appears again

- Counts crankshaft speed readings using a scanner (when starting the car engine)

- If there is no speed reading, check the signal from the crankshaft position sensor using a scanner

- Check the resistance of the crankshaft position sensor using a volt-ohmmeter and compare the value obtained with the value specified in the manufacturer's specifications

- Check the camshaft position sensor and its wires. Because the crankshaft and camshaft work together, improper operation of the camshaft position sensor and/or damage to the camshaft position sensor wiring may affect the operation of the camshaft position sensor.

- Eliminates misfires in engine cylinders (if equipped)

If the problem persists, the mechanic will check the engine control module (ECM).

Recommended Tools to Fix P0336

There are several important tools that you should keep on hand. They will help you fix the P0336 trouble code. These tools include:

- Car charger.

- Multimeter.

- OBD-II scanner.

- Oscilloscope.

- Electrical contact cleaner.

Previous post Error P0137 - what it means, symptoms, causes, diagnosis, solution

Next entry Error P0170 - what it means, symptoms, causes, diagnosis, solution

Common errors when diagnosing code P0336

The most common mistake when diagnosing a P0336 code is to replace the crankshaft position sensor without considering other possible causes of the error.

The problem may be a malfunction of the camshaft position sensor, misfire in the engine cylinders, or worn or damaged electrical wires.

Before replacing the crankshaft position sensor, it is necessary to perform a thorough diagnosis and consider all possible causes of the error.

On which cars is this problem most common?

The problem with code P0336 can occur on different machines, but there are always statistics on which brands this error is more common. Here is a list of some of them:

- Audi

- BMW

- Buick (Buick Park Avenue)

- Cadillac

- Chery (Chery Amulet)

- Chevrolet (Chevrolet Aveo, Camaro, Captiva, Cruz, Lacetti, Tahoe, Traverse)

- Citroen (Citroen C3, C4, C5)

- Daewoo (Daewoo Matiz)

- Dodge (Dodge Nitro)

- Ford (Ford Mondeo, Transit, Focus, Fusion)

- Honda (Honda Accord, Stream, Fit, Civic)

- Hummer H2

- Hyundai (Hyundai Getz, Grand Starex, H1, Santa Fe, Elantra, ix35)

- Isuzu

- Kia (Kia Optima, Picanto, Sid, Sorento, Sportage)

- Land Rover (Land Rover Freelander)

- Mazda (Mazda RX-8)

- Mercedes (Mercedes w211)

- Mitsubishi (Mitsubishi Pajero, L200)

- Nissan (Nissan Pathfinder, X-Trail)

- Opel (Opel Antara, Astra, Insignia)

- Peugeot (Peugeot 206, 207, 307, 308, 407, Partner)

- Pontiac (Pontiac Bonneville, Grand AM)

- Porsche (Porsche Cayenne)

- Rover

- Ssangyong (Sanyeng Aktion, Kyron)

- Toyota

- Volvo (Volvo xc90)

- VAZ 2107, 2110, 2112, 2114, 2115

- Gazelle Business, Cummins, Next, Sobol, ZMZ 405, UMZ 4216

- Lada Granta, Kalina, Niva, Priora

- UAZ

With fault code P0336, you can sometimes encounter other errors. The most common ones are: P0017, P0131, P0137, P0302, P0303, P0335, P0337, P0338, P0339, P0441, P2105.

What repairs can fix the P0336 code?

- Replacing a worn or damaged gear

- Repairing or replacing damaged crankshaft position sensor wires

- Repairing or replacing a damaged or corroded crankshaft position sensor connector

- Repairing or replacing a damaged or faulty crankshaft position sensor electrical circuit

- If necessary, eliminate misfires in engine cylinders

- Replacing a faulty crankshaft position sensor

- Replacing a faulty camshaft position sensor

- ECM replacement and reprogramming

Diagnosis and problem solving

Begin your diagnosis by visually inspecting all system-related wiring harnesses and connectors. Inspect electrical circuits, sensors, and connectors that are contaminated with engine oil, coolant, or power steering fluid.

Petroleum-based liquids are known to corrode the protective insulation of wires and cause short circuits or open circuits. This may cause the P0336 code to appear.

Multimeter test

Then connect the scanner to the vehicle's diagnostic port and get all the stored trouble codes. After this, continue testing the voltage and ground signals. Most models use five volt power. Also check the ground signal and the third wire, the control circuit, should be sending a signal to the PCM.

Disconnect the electrical connector from the CKP sensor and test it according to the manufacturer's recommendations using a multimeter. Replace the sensor if resistance values do not meet manufacturer specifications. If all CKP circuit resistance values are within specifications, proceed to the next step.

Checking with an oscilloscope

Connect the positive test lead of the oscilloscope to the signal lead of the CKP harness, and connect the negative lead to the CKP ground circuit. Select the appropriate voltage setting on the oscilloscope and turn it on.

With the transmission in park or neutral and the engine idling, observe the waveform on an oscilloscope. Focus on unexpected spikes or glitches in the waveform pattern.

If you notice any spikes or glitches, gently move the wiring harness and connector while looking at the waveform diagram. You are trying to determine whether the problem is a weak connection or a faulty CKP.

Notice the voltage blocks in the waveform pattern. If some of them are missing, this indicates a broken or worn toothed ring. Also check the CKP magnetic tip for excessive metal debris and clean if necessary. If the waveform is normal, proceed to the next step.

Now reconnect the oscilloscope test leads to the same circuits near the PCM connector and observe the waveform pattern. If an abnormality is detected, there is most likely an open or short circuit between the CKP connector and the PCM connector.

If no open or shorted circuits are found, the problem with the P0336 code may be due to a faulty PCM or its programming.

Additional comments for troubleshooting P0336

The existing fault must be corrected as soon as possible. If the problem is left unaddressed for a long time, it can cause damage to other engine components. When replacing the crankshaft position sensor, it is recommended to use only original spare parts.

Also, when diagnosing the P0336 error, it is important to consider all possible causes of the malfunction, since sometimes the problem may be a damaged gear or misfire in the engine cylinders.

A little about the error

Error P0523, which is displayed by your on-board computer, indicates a malfunction of the engine oil pressure sensor (EOP). Its task is not to miss the moment of pressure drop, and there is hardly any need to explain how serious the consequences can be if your Lada Granta is not repaired in time.

The operation of the device is simple, but extremely useful. Inside it there is a membrane, which bends under the pressure of oil, while closing or opening the contacts. The contacts are connected to a warning light, which will immediately notify the driver if there is a lack of oil in the engine. So, your warning light may be on. The computer reminds you of error P0523. What could have led to this?

How to check the crankshaft sensor ZMZ 409

Checking the ZMZ 409 crankshaft sensor occurs as follows:

- We take a simple tester and place the measuring bar on the diode and start ringing the contacts.

- We take the first and second contacts and check the resistance. During normal operation, the resistance is between 650 and 750 ohms.

- Now we check the sensor for inductance. You can find out how to do this by reading this article .

Computer diagnostics

The most effective methods are those using sophisticated computer technology.

What does this method provide? First of all, it allows you to control the entire internal combustion engine. The diagnostic accuracy is exceptional. Errors that may arise as a result are automatically eliminated using special programs.

Types of work:

Computer data processing is carried out by introducing “software” (programs) into the processor of the device, focused on:

How to do it? Drivers usually use the services of a car service center. This is not the only option. With some preparation, it is possible to diagnose a car yourself.

The state of the required systems is determined by gradually scanning each node. Defects that cannot be eliminated by the intervention of electronic correctors are eliminated during minor, medium or major repairs.

Other problems

Carrying out vehicle diagnostics makes it possible to decipher fault codes in the control relays of various components, road terrain sensors, fuel mixture saturation and some other indicators. The designations are numbered as follows after “P”:

- 0500, 0501, 0506, 0511 – problems with the speed and idle speed sensor;

- 0560, 0562, 0563 – differences in on-board network voltage;

- 0615, 0616, 0617 – problems with the additional starter relay;

- 0627, 0628, 0629 – signal about a malfunction of the fuel pump relay;

- 0645, 0646, 0647 – displays problems with the compressor clutch;

- 0685, 0686, 0687 – short circuit to the main relay circuit;

- 0691, 0692 – fan element malfunction;

- 1123, 1124, 1127, 1128 – substandard mixture in idle mode;

- 1301, 1302, 1303, 1304 – critical misfire in the cylinders;

- 1410, 1425, 1426 – problems in the absorber purge valve circuit;

- 1513, 1514 – open circuit in the idle speed regulator circuit;

- 1602, 1606, 1616, 1617 – violation of the rough road sensor readings;

- 2301, 2303, 2305, 2307 – short circuit to the cylinder ignition coils.

How to reset a fault code

You can reset the u0100 error on a Lada Granta with an automatic transmission using the built-in control system; for this you need to:

- Start the engine and let it warm up to operating temperature.

- Turn off the engine.

- Disconnect the battery terminals for 20 minutes.

- Reconnect the terminals.

- Turn the ignition key to position No. 2 and wait 2 minutes.

- Turn the key to its original position (position – “0”).

Error on Lada Granta panel

In this case, there is no need to flash the “brains” of the car. Firmware for the Lada Granta automatic will most likely not help in solving this problem, so you should look for another reason.

In addition to this error, owners of domestic cars may encounter code p0504. Error p0504 on the Granta automatic is a consequence of a faulty brake pedal sensor. As a rule, a spring fails, which could break, as a result of which the contact pad of the sensor does not return to its original position.

This breakdown can be eliminated in the following way - adjust the position of the sensor itself using a special nut that secures it.

If the sensor breaks, it should be replaced. Error p0504 on the Granta automatic machine should disappear.

Motor repair

A major overhaul of a VAZ 2110 engine means restoring the engine and its components to factory standards. This operation is carried out when the motor has passed its service life and there is exhaustion in the main components.

Due to the fact that the engines have been in use for a long time, some engines are 10-15 years old, a major overhaul is inevitable. So, the combustion chambers have already worn out, and the pistons have burned out from service life and mileage. In addition, engine oil for the VAZ 2110 no longer helps to maintain performance to such an extent.

So, it is worth repairing the power unit at a car service center, especially with regard to the 16-valve engine. The VAZ 2110 8-valve engine is used by most motorists in garage conditions, since it has a simple design that is similar to the Classic and Samara power units.

FakeHeader

Comments 41

Consent to the processing of personal data

I hereby confirm and give my voluntary consent to the site not Error. Ru (Internet address https://neoshibka.ru/) in accordance with Article 9 of the Federal Law of July 27, 2006 N 152-FZ “On Personal Data” for the processing and use of my personal data specified during the registration and commenting process , or when filling out any other contact form on this site, with or without the use of automation tools, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), retrieving, using, transferring (distributing, providing, access), depersonalization, blocking, deletion, destruction of personal data in order to collect statistics and improve the services provided by the site. The processing of personal data is also carried out for the purposes of my information notification (distribution of information, if desired, there is an unsubscribe function) and for conducting analytics and statistics.

Error p0363 VAZ 2107

Error p0363 VAZ 2107

Error codes for the VAZ 2112 dashboard P0030 code P0030 is a question for VAZ idle. Heater of the oxygen sensor to the converter, open circuit 0 found p0363, p1301. 2107 errors p0363 Section for newcomers to our forum and novice diagnosticians Deciphering errors VAZ 2110 21134 lights up 8.

0336 E-gas sensor signal error (electronic P0363-Accelerator pedal detected) causes fuel trim malfunction 91 49k 1 p2135. P0336 crank position 2104. 2107, lada injector, vaz, Lada forum, VAZ club.

Formation conditions

In order for error p0336 to be generated in the memory of the electronic control unit, the following conditions must be simultaneously recorded:

- The car engine is started.

- When the gear rotates, the crankshaft position sensor records additional pulses or their omissions when the control mark passes through it. The value of the pulses depends on the car model (for example, on the popular Chevrolet Lacetti car the number of teeth is 58).

- The number of recorded additional pulses or their omissions recorded by the sensor is two or more per rotation of the toothed disk.

- Depending on the car model, the number of cycles at which the conditions described above are recorded ranges from 10 to 100 revolutions of the toothed disk with a control mark.

Please note that the Check Engine warning light on most cars does not show a crankshaft sensor error immediately after the first such emergency start. For example, on the same Chevrolet Lacetti, the warning lamp is activated only after the third ignition start under the specified conditions. At the same time, error information is written to RAM.

Viewing diagnostic fault code cards for Lada Granta automatic transmission

| P062FController, error reading - writing EEPROM | |||

| Conditions for the DTC | Emergency mode | Conditions for turning on the malfunction indicator | Possible reasons |

| — |

| Automatic transmission controller |

| Diagnosis procedure for code P062F | |||

| Step | Examination | Test results | |

| YES | NO | ||

|

| Go to step 2 |

|

| Are the contacts in the connectors OK? | Replace KUAKP |

|

| P0705 Automatic transmission mode switch position sensor, circuit faulty | |||

| Conditions for the DTC | Emergency mode | Conditions for turning on the malfunction indicator | Possible reasons |

| For at least 5 s, signals for switching on two modes of the automatic transmission mode switch are present simultaneously. Supply voltage of the AMC > 10 V | Strong jerks when shifting gears Locking of the torque converter clutch is prohibited | The warning light comes on 3 drive cycles after the DTC occurs. | Harness (short circuit between transmission range switch and AMC) Transmission range switch |

| Diagnostic procedure for code P0705, sheet 1 | |||

| Step | Examination | Test results | |

| YES | NO | ||

|

| Check the reliability of the contacts in the KUAKP connector and in the block to the KUAKP |

|

Related DTC Discussions

- Need help Honda Civic P0336

I have a 2003 Civic LX 1.7L engine. It has code PO336. I switched to the crank sensor and pigtail but the engine light still comes on with the same code. I check the voltage at the pig's tail and it reads 12V and the ground resistance is fine. This starts most of the time. The speed sensor shows and drives normally, but the light... - Fault code p0336 on 2003 Bonneville

Bonneville runs fine but keeps setting crankshaft position code p0336. The sensor was replaced 2 times and all wiring was checked at a workshop at a cost of $500+. Now they offer to “flash” the ECU at a cost of $160. Does this seem like a reasonable solution?… - 2011 chevy traverse lt 3.6l v6 p0017, p2105, p0336, p0303

My friend called and said her car stalled at a light and wouldn't start, so we went out to try to charge the battery and finally got it to start, but the service light was flashing and it couldn't go over 1500 rpm or 15 mph we said home and ran the scan tool and p0017... - 1997 Camaro RS codes P0302, P0336, P0441

Hello, I have a 1997 camaro rs. Service English the light came on so I took it to AutoZone and came up with these codes: P0302, P0336, P0441. I know what the codes mean, but I don't know how to fix it. The people at AutoZone said it was most likely one of these codes that caused the other two. What code… - 2000 Buick Park Ave Ultra codes P0131, PP0336, P0137

HELP PLEASE ok so 00 park ave ultra…. Last week it started stalling intermittently, I played a guessing game for a few days, got all new spark plugs and wires, crank sensor, alternator, fuel pump and filter, upstream o2 sensor and idle air position sensor…. Now every morning... - 1996 cadillac fleetwood 5.7L Lt1 codes P0335 P0336

I replaced the leaking water pump and tuned the engine...cap, rotor, wires and plugs...now I got the check engine light and the codes read...PO 335 and PO 336 after it's been running for a while ...starts well, runs well...no firing. .ideas ok.. and I replaced the crank sensor.... cleared the codes and they come back sometimes... - p0336 1999 Grand Am - Wanting to Give Up

This car was my mom's. He began to die as she walked along the road. It will start again but stop immediately. The check engine light did not come on. She took it to the dealer and they couldn't see what it was. They said they thought it needed a head gasket, then maybe they'll see what the... - 1997 Volvo 850 R code P0336

I drive a 1997 Volvo 850 R with 82,000 miles. It starts to close and stall when driving for more than 30 minutes, especially when accelerating after stopping. I pulled my codes and among all the cylinder misfires I got P0336 and P0172. Can someone please tell me what this means and how I can fix... - 02 pontiac grand am 3.4 p0336

Need help, replaced both crankshaft sensors, egr valve fuel pump and still getting code p0336 and when it warms up it won't fire cranks but won't start, even checked coil packs and fuel pressure, any ideas ... - 2001 Chevy Tahoe code P0336 HELP!!!!

Hello, I have a 2001 Tahoe that will not start or if I get it it will not continue to run. If it starts and I press the gas, it shuts off. I auto scanned it and got the crankshaft position sensor code P0336. I have no idea if I need to find it or if the problem is actually why it won't start. ...