The heated rear window function increases the safety of the car not only in bad weather when the window fogs up, but also in winter when the surface is covered with frost. Violations in the operation of the system lead to a significant deterioration in visibility, making it more difficult for the driver to assess the situation on the road behind the car. And trying to maneuver becomes a problem.

If the rear window heating does not work, you can try to fix the defect yourself.

What affects traffic safety?

Almost all heating systems are electrical appliances and they are not particularly reliable. But if the heated seats or steering wheel does not work, then such malfunctions only affect comfort, and you can completely do without them.

But the lack of heated rear window and side mirrors can become a serious problem, since in this case there is already a negative impact on traffic safety.

With the rear window and side mirrors frozen, the driver is completely deprived of visibility of what is happening behind the car, and in such conditions it is not far from an accident.

Also, any reversing without a normal view from behind is an unpleasant and, in winter, a dangerous procedure, since to assess the situation the driver needs to lean out of the window and control the movement in this not very comfortable position.

How to find broken glass heating filaments

Access to the conductive strips on the rear window is easy, so to troubleshoot, you can use a conventional multimeter, including an ohmmeter and a voltmeter. Both methods are suitable.

Visual inspection

In case of gross violations of the integrity, instrument monitoring may not be necessary; the break or disappearance of an entire section of the strip is noticeable to the eye. It is better to check what is found using a magnifying glass; under it, the defect is visible in all details.

Purpose and design

The purpose of the rear window heater can be judged by the very name of the system - by heating it fights condensation that settles on the surface, the cause of which is the difference in temperature in the cabin and outside.

In the autumn-spring period, this condensation causes “fogging” (a water film is formed, which greatly limits visibility), and in winter it turns into ice and frost, through which it is generally impossible to see what is happening behind.

As for the side mirrors, they are located outside and should not “fog up” or freeze, since there is no temperature difference as such. But there are other reasons why a water film and frost form on the surface of the mirror, reducing visibility.

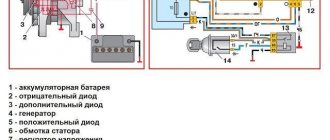

The design of any heater is very simple, and on all cars they are built according to the same principle. If we consider only the rear window, its heating system includes:

- Conductive threads and busbars applied to a transparent surface (from the inside);

- Heater power cables (powered from the on-board network);

- Protective elements (relay, fuse);

- Controls (power key with signal diode installed on the front panel).

The main working element in this chain is the threads running along the surface. They have a fairly high resistance, which ensures their heating when electric current passes through them.

The threads are connected to tires laid along the edges of the glass, together with them they form a grid corresponding to the size of the heated area. One of the buses is connected to the power circuit, and the second is connected to ground.

In what cases is it useless to repair heating elements?

If there is a significant area of damage, when almost all the threads are broken and over a large area, it is unlikely that it will be possible to restore the mesh to nominal efficiency. There is no hope for the reliability of the result. This glass must be replaced together with the heating element.

As a last resort, you can use an external heater installed under the glass, but this is a temporary measure, it works slowly, unevenly, consumes a lot of energy, and if the glass is very frozen, it can cause cracks and even spillage of tempered glass.

Power supply diagram and operating principle

The heated rear window is powered not directly from the energy source, but through the ignition switch, and there is a logical explanation for this.

Like any heating element, it consumes a large amount of electricity during operation, so to prevent the battery from discharging (if the driver forgot to turn off the heating), it was powered through the ignition switch.

In general, the power supply circuit is as follows: the electric current after the lock passes through the fuse and is supplied simultaneously to the output of the heating switch and one power contact of the relay (the second contact is connected by wiring to the “positive” bus of the grille).

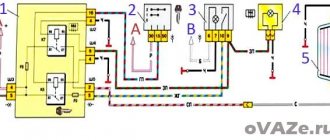

Using the Hyundai Accent as an example, it looks like this.

When turned on, the key closes the circuit and the voltage from it is supplied to the relay winding, as a result of which the relay closes its power contacts and the current is supplied to the “positive” bus and moves along the conductive threads (which causes them to heat up) to the “minus” bus.

The circuit diagram is shown below.

What are the fuses in the Lada Priora mounting block responsible for?

So let's now go over the fuses:

- Fuse F1 is responsible for the electric radiator fan of the engine cooling system

- Fuse F2 is responsible for the heated rear window

- Fuse F3 is responsible for the high beam (starboard side)

- Fuse F4 is responsible for the high beam (left side)

- Fuse F5 is responsible for the sound signal

- Fuse F6 is responsible for the low beam (left side)

- Fuse F7 is responsible for the low beam (starboard side)

- Fuse F8 is responsible for the alarm signal

- Fuse F9 is responsible for the heater fan

- Fuse F10 is responsible for the instrument cluster, interior lighting, brake light

- Fuse F11 is responsible for the windshield wiper, heated rear window (control)

- Fuse F12 is responsible for output “15” devices

- Fuse F13 is responsible for the cigarette lighter

- Fuse F14 is responsible for the side light (left side)

- Fuse F15 is responsible for the side light (right side)

- Fuse F16 is responsible for terminal “15” of the ABS

- Fuse F17 is responsible for the left fog lamp

- Fuse F18 is responsible for the right fog lamp

- Fuse F19 is responsible for seat heating

- Fuse F20 is responsible for the immobilizer control unit

- Fuse F21 is responsible for the rear fog light

- Fuse F22 – F30 – reserve location for fuse

- Fuse F31 is responsible for the electrical package control unit

- Fuse F32 – reserve location for fuse

Malfunctions

Despite the design simplicity of the rear window heating circuit, it breaks quite often. The most common system malfunction is a blown fuse.

But there are a number of other breakdowns that can occur with the device:

- Damage to conductive threads;

- Oxidation of contacts;

- Broken power supply;

- Relay burnout.

Some of these faults lead to a complete failure of the system, others lead to a decrease in its efficiency or uneven heating of the surface (unthawed areas remain on it).

Circuit elements

A blown fuse is a common failure because the system consumes a large amount of energy during operation. The operation of glass heating under heavy load leads to the fact that the protective element fails.

Also, the relay through which the threads are powered often fails.

Conductive threads

The second common problem is damage to the threads. The thickness of the conductive path is insignificant and it is very easy to break it. Most often, the threads are damaged by the drivers themselves.

Ice forms on the interior side and many, trying to get rid of it quickly, without waiting for the heater to do it, remove it manually - using scrapers. But even the softest scraper can easily damage conductive tracks.

In this case, the system as a whole remains operational, but the broken thread will not heat up, and unheated areas will appear on the glass, reducing visibility.

One broken thread will not particularly affect the view, but several damaged paths can seriously complicate the driver's ability to assess what is happening behind the car.

The car owner has the opportunity to restore damaged threads, but this procedure is complicated by the fact that it is not always possible to visually detect the location of the break, and this is necessary to carry out repair work.

But electrical measuring instruments - voltmeters, ohmmeters or multimeters - help with this.

For example, if you have a voltmeter, the diagnostic technology is as follows:

- We connect the “negative” probe of the device to “ground”, and wrap the “positive” probe with foil (so that during the test the sharp end of the probe does not cause additional damage to the threads);

- We start the engine and turn on the window heater;

- We run a “positive” probe along a thread that does not heat up and look at the readings of the device.

The standard voltage in threads is 5 V, this is the value that a voltmeter should show when the “positive” probe touches the track. At the location of the break, a power surge will certainly occur, after which all that remains is to mark the area with the damage.

Approximately the same technology is used to check threads using an ohmmeter, with the only difference being that a break is determined by a jump in resistance.

Other problems

Other malfunctions of the rear window heating - broken wiring, oxidation of wires and broken relays - are determined and eliminated in the same ways as other electrical appliances - by testing the wires, replacing parts with known-good elements, cleaning contacts, etc.

Heated rear window: diagnostics

As practice shows, malfunctions of the rear window heater are often associated with mechanical damage or failure of individual elements. For example, a relay or switch may “stick,” or heating fuses may blow.

It also happens that the heating filaments themselves are damaged when transporting goods (this is especially true for a hatchback or station wagon type body). Often the heated rear window fails after unprofessional tinting of the rear window or attempts to tint the rear window.

In any case, if the heater malfunctions, the heating may not work completely or partially (a separate area of the glass does not warm up). Please note that the heating only works when the key is inserted into the ignition.

Moreover, on some cars, the rear window heater will only work when the internal combustion engine is started, in order to prevent the battery from being discharged. The fact is that heating is a powerful consumer (current from 10 to 25 A) and car manufacturers take this into account.

- Now about the malfunctions. As a rule, if after pressing the power button the indicator light in the button does not light up, this usually indicates that the rear window heating fuse has blown or the switch itself has failed. If the indicator is on, but the filaments do not heat, then you need to check the relay or connectors for connecting the heater to the network. In such a situation, you need to study the diagram according to the manual for a specific car, then identify the problematic element and replace it.

It also happens that the heating works, but very weakly, the glass warms up slowly. This indicates that there is poor contact somewhere on the connectors, the contact resistance becomes greater and the power on the heating threads decreases.

To check this, you need a multimeter, which is switched to voltmeter mode to measure direct current. The device measures the voltage at the heating and battery input terminals. The voltage difference should not be more than 1 Volt.

The next malfunction is a break in the rear window heating threads (one thread may be broken or I will splice several). You can see problematic threads by inspecting the glass from the outside after turning on the heating. If fogged streaks are visible after turning on the heater, this definitely indicates a problem with the threads.

It is important to understand that the conductive paths on the rear window are easily damaged; you can only wipe the glass from the inside with a soft cloth. However, if the threads are already damaged, there are three ways to solve the problem:

- rear window replacement;

- installation of a separate heater;

- rear window heating repair;

Naturally, the first method is expensive and least preferable. The second solution can be considered more of a “crutch” than a full-fledged solution. In fact, we are talking about installing a small portable fan heater in the rear window area. By the way, in severe frosts such heating can cause cracks to appear.

As for repairs, if the rear window is not tinted, then you can try to solve the problem relatively inexpensively. The main task is to find the damaged area and restore conductivity. Let's figure it out.

How to find a damaged rear window heating area

Repairing the rear window (more precisely, its heating if the filaments are damaged) usually begins with the question of how to find the location of the broken glass heating filament.

In fact, it is not difficult to determine the damaged area if you know the layout and design of the heating itself. You also need to know how to check. First, just turn on the heating, after which you can see which thread is not working. Having remembered which glass heating thread is broken, you also need to find the break point itself. Often the gap cannot be determined visually. For this reason, a DC voltmeter or ohmmeter is required. A voltage indicator will also work.

- So, if one glass heating thread or several threads do not work, but the rest work, you should take into account the design features of the heating as part of troubleshooting.

Let's start with the fact that the rear window heater of a car is designed as follows:

- two conductive bars are glued to the sides of the glass;

- heating filaments are connected to the busbars (resistance about 10 Ohms).

It turns out that each thread is a separate heating element, that is, it does not depend on the others. Due to this parallel connection scheme, the break of one or more threads will not completely disable the heating.

As already mentioned, to determine the damaged area, you should prepare a voltmeter with a measurement limit of 15 V, then turn on the heater. By the way, there are other methods of determination (for example, using a multimeter, ohmmeter or LED tester), but using a voltmeter makes the process most convenient.

Taking into account the fact that one heater bus is connected to the body, the negative terminal of the voltmeter is connected to the body (it is best to use a clamp-type fastening). To connect, you can use any bolts or screws screwed into the car body, brackets on the trunk lid, etc.

To check whether the rear window heater is heating, just use the “positive” probe to touch the “positive” heating bar, then the “negative” one. On the first bus the voltage is normal +12 V, on the second – 0 V.

On many cars, the tire on the left is ground, while the tire on the right is power. By the way, if the tires are difficult to reach, you can use a feeler gauge to touch any threads at the points where they are connected to the tires and exit the seal. A voltmeter will allow you to determine where the fault is hidden.

When the heating is turned on, the indicator on the button is on, and there is 12 V on the heating power bus, but the heating does not heat, then the wiring to the power bus is normal. If there is no power on the bus, this indicates that there is poor contact at the bus power supply terminal or there are problems with the relay. If there is 12 V on the ground bus, there may be poor contact in the terminal connecting the wire to the minus bus or in the circuit connecting the wire to the ground of the car.

- After the first stage of testing, which allows you to determine the quality of the power supply to the heating, you can proceed to searching for the location of the thread break. In fact, the filament is a ribbon resistance of about 10 ohms. This means that in different parts of the thread the resistance is also different (for example, 12 V, 3 - 6 V and then 5 - 0 V).

It turns out that even if it is not known which thread is not working, it is enough to measure the voltage on all threads in the middle of each. Threads with a break will have a voltage of either 12 or 0 V. If the indicator is 12 V, the break is on the left, if it is 0 V, then the break is on the right. Then the probe is slowly moved towards the cliff. Where the tension has changed dramatically, this is the problem area.

Methods for recovering conductive strips

Of all the malfunctions, the most unpleasant is the breakage of current-carrying threads. In this case, the system seems to remain working, but it does not function fully.

The difficulty is caused by the fact that the strips attached to the rear glass cannot be replaced, and it is not possible to install new ones, but it is quite possible to restore them. Repairing conductive threads is a simple operation and can be done by any car enthusiast.

A number of methods are used to restore stripes.

Conductive pastes, varnishes, paints

In auto accessory stores you can purchase repair kits for restoring conductive glass heating strips, the main components of which are the specified varnishes and pastes.

The essence of the repair with their help is very simple: tape is glued to the sides of the damaged strip (so that only the thread remains uncovered), the break area is cleaned and degreased.

After this, all that remains is to apply the paste or varnish, allow time to dry (usually 24 hours), remove the tape and check the functionality of the heater.

Metal powder, varnish, glue

The use of steel metal powder and a binder - varnish or glue. This method is good because all the components are at hand and you don’t need to buy anything.

The repair technology is as follows: we attach a magnet to the outside of the glass at the break site, and cover the break site with tape on the sides.

Using a file from any metal part, rub the powder, which we apply to the tear site (the magnet will hold it), then coat it with varnish or glue, and after drying, remove the tape.

The essence of the method is that metal powder, held by a magnet, will connect the strips of the heating system to each other, eliminating the gap, and simply fix the resulting bridge with varnish or glue.

Application of non-ferrous metal chips

Application of shavings from non-ferrous metals (copper, brass) and binders. This method is characterized by high repair speed and ease of implementation.

The technology is as follows: we cover the break area with tape. Mix the components - shavings and glue (varnish) in even proportions. Heat must be turned on before application.

And then we simply apply the mixture with a brush, while the current passing through the strip will ensure that the applied layer dries quickly.

All of these methods make it possible to restore the rear window heating equally well.

Block under the hood

In most VAZ 2105 models (with the exception of the earliest models), the fuse box is located from the passenger compartment under the hood: you can see it under the windshield, opposite the passenger seat.

Table: which fuse is responsible for what

In addition to the fuses indicated in the table, there are 4 spare fuses on the mounting block - F18-F21. All fuses are painted in a specific color:

- 7.5 A - brown;

- 10 A - red;

- 16 A - blue;

- 20 A - yellow.

How to remove the mounting block

To remove the fuse box, you will need a 10 mm socket wrench. To dismantle the fuse box you must:

- Disconnect the negative terminal of the battery.

- Disconnect the plug connectors in the passenger compartment.

The plug connectors both on the interior side and in the hood have a specific color. The connector sockets on the fuse block are marked with the same color (in the form of colored circles). This is done so that when assembling the block you do not confuse which connector is connected where. If there is no color marking on the block, you should make it yourself (for example, with a marker). A new or repaired unit is installed in place in the reverse order of dismantling.

The old and new fuse blocks are interchangeable. If you want to install a new type of block instead of the old one, you will not need to make any changes to the design of the car. The difference between the blocks is only in the type of fuses used: on the old ones - cylindrical, on the new ones - plug-in.

Repair of mounting block

If there are interruptions in the operation of the vehicle's electrical equipment, the first thing you need to do is check the fuse box. If one of the fuses fails, it is strictly not recommended to replace it with a fuse capable of withstanding a current higher than the rated one . Such a fuse may cause burnout of wiring, lamps, motor windings or other electrical equipment.

When repairing a fuse box, certain rules must be followed. For example:

- if any fuse is blown, you need to try to find the reason for this, that is, check the entire section of the circuit for which this fuse is responsible;

- If you have installed additional electrical equipment in the car, you need to recalculate the rated current that the fuse responsible for this section of the circuit must withstand. To do this, it is necessary to divide the total load (power) of the consumers of this section of the circuit by the value of the on-board voltage (12 V). The resulting figure needs to be increased by 20–25% - this will be the required value of the fuse operation current;

- When replacing the block, you should pay attention to whether there are jumpers between the contacts of the old block. If there is, then you need to make the same ones on the new one.

If you have the opportunity to choose between old and new type blocks, you should definitely install a new type of mounting block: tighter fuse contacts on such a block will immediately save you from many problems associated with loose fuses in old type blocks.

Repairing the mounting block most often involves replacing fuses or restoring a burnt track. You can check the fuse with a multimeter: replace the failed fuse with a new one.

Replacing a burnt track

In some cases, when the load in the circuit increases, it is not the fuse that burns out, but one of the tracks of the block. In this situation, you need to evaluate the degree of burnout: if the damage is minor and the remaining components of the block are not damaged, such a track can be restored. For this you will need:

- soldering iron;

- tin and rosin;

- wire 2.5 sq. mm.

Track repairs are carried out in the following sequence:

- We clean and degrease the damaged area.

- We remove burnt and irreparable fragments of the track.

- We prepare a piece of wire of the required length, remove the insulation along the edges and process it with a soldering iron and solder.

- Solder the prepared wire in place of the burnt track.

If the tracks have multiple damages, it is easier to replace the entire block.

Video: how to repair a blown fuse box track

Repair kits and thread restoration products

When carrying out repair work, it is recommended to use repair kits designed for this purpose, especially since they are not particularly expensive, and they include everything necessary.

For example, a popular kit for repairing conductive threads of the glass heating system PERMATEX PER-09117 consists of:

- Degreasing wipe;

- Sandpaper for stripping threads;

- Adhesive compound;

- Activator;

- Conductive glue;

- Self-adhesive template.

But in addition to repair kits, you can also purchase simply conductive adhesives or pastes.

In general, the choice of means for repairing rear window heating is very extensive and allows you to find a suitable option for any car owner.

Below is just a small list of adhesives and kits for such work:

- Set PERMATEX PER-21351;

- Glue for repairing threads “Kontaktol”;

- Conductive glue “Astrokhim”;

- Matrix glue;

- Conductive paint "Pro Glass";

- Glue "AVS Crystal".

And there are many such means. But at the same time, it is important to understand that very cheap glues and varnishes are not always of high quality and allow you to properly eliminate breaks.

Do-it-yourself rear window heating repair: glue and soldering

Let us immediately note that there are several ways to repair a heating filament with your own hands. We will not consider some of them due to the low probability of obtaining the desired result at home (for example, galvanization).

- As for available solutions, the simplest and most common method for repairing a heated rear window with thread breaks of no more than 1 or 2 mm is to use a special conductive glue for repairing heated glass or a special paste (for example, Done Deal DD6590).

In short, you need to study the instructions, after which a small amount of conductive paste or glue is applied to the site of the thread break. The loan should be waited until the paste dries.

Note that in the case of glue, it is better to apply the product with an “overlap” on entire parts of the thread, 10 mm on each side (before the break and after). The glue is applied in two layers; you can also put a thin (diameter no more than 0.5 mm) copper wire between the layers. To make the thread look neat after repair, you can use a stencil while applying glue.

- The next method is soldering the threads with soft solder to restore the integrity of the threads with breaks larger than 1 mm. This method is reliable and effective, but requires care and consideration of certain features.

Please note that you should not try to clean the thread with fine sandpaper, as this may further damage the tape. The reason is that the thread is only a few tens of microns thick and is simply erased by mechanical action. It is optimal to simply degrease the area that needs to be soldered. To do this, moisten a soft rag in alcohol and gently wipe the thread without pressing.

We also recommend reading the article on how to make a heated car windshield with your own hands. From this article you will learn about the available solutions for implementing heated front glass, as well as what you need to consider when performing this procedure.

Next, taking into account the fact that the gap is more than 1 mm, you should prepare a piece of copper wire. This segment will serve as a jumper. Since a current of 1 A passes through the thread, the jumper requires wires with a cross-section of 0.17 mm2 (diameter 0.45 mm). The length of the jumper should be 2 cm longer than the break itself.

First, the jumper should be tinned with a thick layer of POS-61 tin-lead solder, but the thread itself does not need to be tinned. In order for the solder to lay down and stick, before soldering, the thread in the soldering area with a brush should be coated with a small layer of zinc chloride flux.

Having completed the preparation, the jumper is pressed against the heating filament, after which it is heated with a 12W soldering iron for no more than 1 second. If the jumper holds, you should not check the reliability of the fixation, as there is a risk of tearing off the newly restored thread.

Having soldered one end of the jumper, the other is soldered in the same way, after which the glass should be washed with water to remove any remaining flux. You can also cover the top of the jumper with transparent superglue for additional protection. This glue is relatively heat-resistant, and the heating itself does not heat up more than 70 degrees.

Features of the mirror heater device

Heated side mirrors are another system that affects driving safety, although not to such a significant extent as the counterpart for the rear window. Therefore, it is still considered an optional equipment, which is not found on all cars.

Note that this is not a separate system, but an additional one. In fact, it consists only of conductive strips applied to a special substrate, which is fixed to the inside of the mirror.

The subsystem is connected to the power supply circuit of the glass heating and they are switched on together.

The presence of a mirror heater makes it somewhat easier to identify the cause of the malfunction. Everything is very simple - if both devices do not work at the same time, the breakdown should be looked for in the fuses, relays and control key.

But when only one of the heaters does not work, the wiring to them and its connection points and conductive strips are checked.

Heating system design, typical malfunctions

The glass heater in the car is quite simple. Typically, threads are applied to the glass surface, which can heat up when current passes. Other components that ensure startup, proper operation and power supply of the circuit are a button, wiring, relay, fuse, battery.

Frequent problems:

- The heating is ineffective and streaks of fog appear. The defect indicates damage to the threads. To identify the problem, you need to inspect the stripes; the place of damage is easy to detect - it will be foggy.

- Heating and sweating occur very slowly, which means poor contact and possible problems with voltage. It is necessary to check the indicators at the input and storage.

- If the heating does not work at all, but the light on the button lights up, the fuse may have failed or the problem lies in the power connectors.

- If the system does not work and the control light does not light up, you need to pay attention to the heating relay. The button, voltage and ground are checked.

- With a working system, defrosting does not occur. This happens when winter comes and the ambient temperature drops significantly, the glass freezes up. The heater power is not enough to thaw the ice. It is recommended to clean the glass by hand so that the threads can work normally.

Complete failure of the heating system is rare. The integrity of the threads is often compromised. If problems occur with the device, you can carry out repairs yourself.

Seat heaters

Heated seats are another system that is becoming more common on cars. Although it is completely separate, it is built on the same principle as the heated rear window.

Therefore, their reasons are similar:

- Damage to conductive strips (laid in the seat);

- Broken wiring;

- Fuse blown;

- Control key malfunction;

- Relay burnout.

And since the general principle of constructing heaters is the same, the repair methods are similar. It is only important to know where the circuit components are located and how the wiring is routed.

Why do heating elements break?

A break can occur for mechanical or electrical reasons:

- the metal of the thread gradually oxidizes, the cross-section decreases, and the released power increases; severe overheating causes the thread to evaporate and the contact to disappear;

- when cleaning glass, a thin strip of sprayed metal can easily be damaged with the same consequences;

- even minor thermal deformations lead to a weakening of the structure of the conductive strip, which ends in the appearance of microcracks and loss of electrical contact.

Most often, one or more threads break; the entire mesh rarely fails completely. This can usually occur due to a power system failure, a blown fuse, or a failed relay or switch.

Sometimes switching is complicated by the introduction of an automatic electronic relay with timer shutdown, which does not add reliability.

Fuses and relays, where to look for them?

Since most often the cause of non-working heating is a fuse and relay, before performing diagnostics and repairs, you should first find out where these elements are located, and each car has different locations.

VAZ-2107

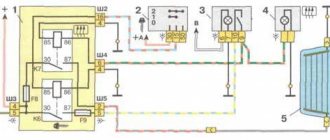

On the VAZ-2107, the relay and fuse responsible for the rear window heating are located in one mounting block, installed in the engine compartment on the right near the engine shield.

In the electrical diagram, the relay is marked “R1”, but it can be visually identified by its location - it is on the far left.

As for the fuse, its marking is “F5”, and in the block it is located third from the left in the second row of fuses.

VAZ-2114

On the VAZ-2114, these elements are also installed in a mounting block installed near the engine shield, but they are located slightly differently.

The relay responsible for the operation of the glass heating on this car in the diagram is designated “K7”, and it is located in the second row of relays in the center.

The fuse is marked with the index “F4” and it is installed in the left row of fuses, fourth from the top.

Lada Priora"

On the Lada Priora, the relay and fuse should also be found in the mounting block, but it is located in the cabin, under the dashboard on the left side (closed with a decorative cover).

In the diagram of this car, the rear window heating relay is designated as “K1” and it is installed in the top row, second from the left.

As for the fuse, its marking is “F2” and you need to look for it in the top row of fuses, where it is installed second from the left.

Lada "Kalina", "Granta"

In the Lada Kalina, the required components are placed in a mounting block, which, like the Priora, is installed on the left side of the dashboard and closed with a lid.

The required relay in this car is designated by the index “K10” and it is installed in the second row of relays in the middle (it is located a little separately from the others).

The fuse in the diagram is designated as “F8” and it is installed in the top row, eighth from the left (approximately in the middle).

In the Lada "Grant", the placement and designation of the components of the heating system circuit does not differ from the "Kalina".

Reno Logan

But in Reno Logan, the designers did something quite interesting, but inconvenient for car owners. Two fuses are responsible for heating the rear window (“F01” is the power circuit, which also powers the windshield wipers, and “F32” is the relay winding circuit) and they are both installed in the mounting block.

To get to the unit, open the driver's door and remove the cover installed at the end of the front panel.

Fuse “F01” is the top one on the left, and “F32” is at the bottom of the block in the middle row (there is only one there).

As for the relay, its designers moved it outside the mounting blocks and installed it separately. You should look for it under the front panel on the left side (driver's side).

Chevrolet Lacetti

The Chevrolet Lacetti also uses a split circuit with two fuses. The first of them, marked “F6,” is located in the interior mounting block (sixth in the left row). The block itself is located at the end of the front panel on the left.

This protective element is responsible for powering the relay windings of a number of equipment - heated glass, air conditioning compressor, headlights, power windows.

Scheme for switching on heated glass and mirrors.

Another fuse – “Ef7”, responsible for powering the circuit, is located in the mounting block installed in the engine compartment (behind the battery). The same block also contains a relay, designated “K10” in the diagram (the middle one in the lowest row of relays).

Ford Focus

In a Ford Focus, the power supply circuit for heating the vehicle elements includes two relays and one fuse. But one of the relays only partially relates to the heated glass - the so-called ignition relay, from which a number of control units and relay windings are also powered, including the one responsible for powering the heated rear window.

It is located in a mounting block installed in the engine compartment and is designated by the index “K8”.

As for the fuse and the relay itself, they are installed in the interior mounting block located under the storage compartment. The fuse in the circuit is marked with the index “F105”, and the relay – “K19”.

Daewoo Matiz

On Daewoo Matiz, the elements of the rear window heating power circuit are located in the mounting block installed in the engine compartment, on the right near the engine panel.

The fuse is designated “Ef7”, and you need to look for it in a horizontal row (standing on the side of the car near the fender), it is the seventh in a row.

The relay marking is “K3”, and it is on the far right in the top row of relays.

Since these circuit elements are considered irreparable and if they burn out they need to be replaced.

For replacement, you should select parts that have the same operating parameters as those that have failed. And knowing their location will greatly simplify the work. Also read how to diagnose a car using a laptop.

Priora fuse box diagram

| Fuse no. | Current strength, A | "Standard" and "Norm" | “Norma” with air conditioning and “luxury” |

| F1 | 25 | Engine cooling radiator fan | Reserve |

| F2 | 25 | Heated rear window | Mounting block, rear window heating relay (contacts). Electrical package controller, contact “10” of XP2 block. Rear window heating element. |

| F3 | 10 | Right headlight, high beam | Right headlight, high beam lamp. Instrument cluster, headlight high beam indicator. |

| F4 | 10 | Left headlight, high beam | |

| F5 | 10 | Sound signal | Mounting block, horn relay. Sound signal. |

| F6 | 7.5 | Left headlight, low beam | |

| F7 | 7.5 | Right headlight, low beam | |

| F8 | 10 | Alarm signal | Mounting block, alarm relay. Alarm sound. |

| F9 | 25 | Priora heater fuse | Reserve |

| F10 | 7.5/10* | Interior lighting, instrument panels, brake light | Instrument cluster, pin “20”. Brake light switch. Brake light bulbs. Interior lighting unit. Interior lighting. The door sill light on the right front door. Additional brake signal. |

| F11 | 10/20* | Wiper | Mounting block, high speed windshield wiper relay. Switch for cleaners and washers, contact “53a”. Wiper and washer switch, contact “53ah”. Heated rear window switch. Mounting block, rear window heating relay (winding). Windshield wiper motor. Rear window wiper motor (2171,2172). Windshield washer motor. Rear window washer motor (2171,2172). Airbag control unit, pin “25”. |

| F12 | 20/10* | Terminal 15 devices | Instrument cluster, pin “21”. Electrical package controller, contact “9” of block X2. Electromechanical power steering control unit, contact “1” of block X2. Reversing light switch. Reversing lamps. Parking system control unit, contacts “11” and “14”. |

| F13 | 15 | Cigarette lighter fuse Priora | |

| F14 | 5 | Left headlight, parking light, license plate light, trunk light | Side light lamps (left side) Instrument cluster, main light indicator License plate lights Trunk light Electrical package controller, pin “12” of block X2 |

| F15 | 5 | Right headlight, parking light | Side light lamps (right side) Glove compartment lamp |

| F16 | 10 | Terminal 15 ABS | Hydraulic unit, contact "18" |

| F17 | 10 | Left fog lamp | |

| F18 | 10 | Right fog lamp | |

| F19 | 15 | Seat heating | Seat heating switch, contact "1" Front seat heaters |

| F20 | 5/10* | Immobilizer control unit | Recirculation switch (switch on) Mounting block, relay for low beam headlights and parking lights (automatic lighting control system) Heater electric fan relay Automatic lighting control switch Windshield wiper and external lighting control unit, contacts “3”, “11” Automatic climate control system controller installation, pin “1” Automatic window cleaning system sensor (rain sensor), pin “1” |

| F21 | 7.5/5* | Rear fog lights | Light switch, contact "30" Diagnostic block, contact "16" Clock Automatic climate control system controller, contact "14" |

| F22 | -/20* | Reserve | Windshield wiper motor (automatic) Mounting block, windshield wiper relay and windshield wiper high speed relay, (contacts) |

| F23 | -/7.5* | Reserve | Windshield wipers and external lighting control unit, pin “20” |

| F24-F30 | Reserve | ||

| F31 | 30 | Electrical package control unit | Electrical package controller, terminal “2” of block X1 Electrical package controller, terminal “3” of block X1 Driver’s door module, pin “6” Threshold light of the left front door |

| F32 | Reserve | ||

* - for the “Norma” configuration with air conditioning and “luxury”

| Relay | "Norm" | "Norma" with air conditioning | "Lux" |

| K1 | relay for turning on the electric radiator fan of the engine cooling system | Reserve | Relay for turning on the low beam and side lights of the headlights (automatic lighting control system) |

| K2 | rear window heating relay | ||

| K3 | starter activation relay Priora | ||

| K4 | additional relay (ignition relay) | ||

| K5 | space for backup relay | ||

| K6 | windshield washer and wiper relay | ||

| K7 | headlight high beam relay | ||

| K8 | horn relay | ||

| K9 | alarm relay | ||

| K10 | Reserve | Fog light relay | |

| K11 | Reserve | Front seat heating relay | |

| K12 | Reserve | ||

Signs of breakdown

You can understand that there are problems with heating by the following signs:

- The glass begins to sweat when the warning light does not work. The first thing you need to do is check what voltage and serviceability of the fuses

- The glass does not heat up when the control lamp is on. The reason may be due to lack of voltage

- Condensation appears in some places; this may be due to a broken thread. Can be restored through repairs, special varnishes

- Defrosting does not occur even though the system is working properly. This can happen if the glass is heavily iced and there is not enough voltage; you need to clean the ice yourself.

There can be many reasons for the breakdown, ranging from the switch to the wiring itself, which can only be repaired by disassembling the entire dashboard.

If the reason is a broken thread, you can try to restore it. There are many different ways to solve this problem, which look like this:

- To eliminate a break, up to one millimeter, you need to prepare a special adhesive composition, for example (Kontaktol, Elekont), a syringe, or a glass cleaner. Special glue is applied to the area where there is a break, and insulating tape is tightly applied on both sides.

- You can use soft soldering or resort to the option of galvanic application of the material. But this procedure is labor-intensive and difficult to carry out in garage conditions.

- If the width of the gap exceeds two millimeters, you need to use a tinned copper core with a cross-section of 0.2 millimeters. It is better to perform soldering with POS-61 solder, but do not tinning the thread.

This is interesting: Reasons for the appearance of oil on spark plugs, solutions

Other causes of malfunction

Despite the simplicity of the design of the heating system, it includes a number of elements that can break over time. The power button, wiring, heating filaments, pres and relays - all these parts, if broken, do not allow you to use heating. If after checking the fuse and relay box you still cannot find the cause, check out the list of other possible faults:

- Oxidation of contacts in the installation compartment;

- Broken wiring;

- Breakage or partial damage of threads on the plane;

- Mechanical failure of the system.

The reason, invisible during a cursory diagnosis, is a broken wiring. Without a multimeter, it is difficult to determine the exact location of the break. The heating filaments are quite fragile, so you should be careful when interacting with the inside of the glass. Often when tinting a car, these threads are damaged. Resoldering and restoration takes a long time, so this function does not work in many “fours”. Minor faults are not critical and are repaired when the exact location of the breakdown is identified. The design does not require any maintenance, but you should be careful when interacting with the heating filaments.