Until 2004, the VAZ 2109 was equipped with 1.1, 1.3, 1.5 liter carburetor engines, similar to the VAZ 2108 engines. In subsequent mass production, the installation of injectors was used. The excellent performance of the engine largely ensured the popularity of the VAZ 2109.

The VAZ 2109 engine is represented by 4 generations:

- Basic VAZ 2109 with a volume of 1.3 liters. The model was developed on the basis of 2108. The service life of the motor reaches 200 thousand kilometers with careful operation. The disadvantages of the model include rapid wear of the cooling system and problems with ignition.

- The 1.1-liter VAZ 2109 was used for the “nine” in 1984-1996. In this four-cylinder modification, the displacement is reduced due to the reduction in piston stroke. The weak engine did not contribute to the popularity of the model.

- The VAZ 21093 carburetor is designed for a working volume of 1.5 liters and is capable of producing a power of 73 liters. With. and has proven itself well among car owners due to its high reliability and wear resistance. VAZ 21093 became the prototype of modern Lada engines.

- The VAZ 21093i injector is also designed for a volume of 1.5 liters, but produces a power of 79 liters. With. The engine was installed on a large number of VAZ car models. Its advantages are a significant increase in power while reducing fuel consumption, and improved environmental performance. The disadvantages include the usual disadvantage of injectors - the almost complete impossibility of repair.

VAZ-2109 injector

There are rumors on the Internet that the VAZ 2109 injector has long ceased to be popular among car owners.

Anyone who wants to exchange a domestic car for a foreign car is mistaken. For the same money they will buy a beautiful firebird, under whose plumage there will be a decrepit, senile body, like that of a courier during the Kaiser’s reign. Yes, the VAZ has its drawbacks, but it also has quite a few advantages: if you buy even a used car from one owner and with low mileage, then the engine will almost always please you, the electronics will not seem stupid, so you can close your eyes to the rest .

Just don’t wave your hands now and say that domestic g... doesn’t sink in water. The interior is not a gift, but its explosiveness is fully justified by the material from which the body is made. This is not a piece of plastic covered with foil. Perhaps tuning the interior will help you.

The car is not wasted on trifles: if the problem is in the pads, then it will remain there. It happens that the panel goes out right on the road, but the problem is quickly eliminated, the stove fails, but you can find an approach to it with skillful tuning. There is a desire to change it to a more advanced tenth model - the problem will quickly be solved. You can sell a 2109 injector quite quickly, whereas a foreign car takes months to wait for a buyer.

And no need to say that you ride on the toilet. Even a Volkswagen with 25 years of life would not allow itself to be called that. And you! Oh, I wish I could take our nine-wheeler for a ride to Moscow! After that, you can erect a monument to her and become a pedestrian, and hang a photo with your iron friend in a frame on the wall.

It’s not for nothing that they say that the VAZ is a cheap car. For citizens of Russia and post-Soviet countries there will be no problems with spare parts for a long time. Do you want to do the renovation yourself? There is a lot of information in stores and on the Internet. Try to dig up so much material for a Korean car. You would rather love the domestic auto industry than a prince from far away, rusting right under your windows.

He doesn’t want to, my dear, it starts, there are no spare parts in the workshops, you have to wait for months until they bring it. But for our cars there is always a green light. Chairs in the evening – money in the morning! The VAZ is not as bad as it might seem at first, although it requires some fine-tuning. Do you still want to try a foreign car in action? Then buy at least an unfucked version, at least ride for pleasure until breakdowns lead to a nervous breakdown.

Converting a carburetor to an injector

VAZ 21093 injection engines

It is possible to do this. As promised, we provide instructions. The alteration can be carried out in your own garage, preferably with an assistant.

An object

The object of modification can be not only the VAZ 2109, but also the G8, as well as the VAZ 21099 (cars with carburetor engines). The goal and objective of the operation: to convert the unit into a 16-valve injector by installing a cylinder head from a VAZ 2112. Already at the stage of completing the conversion, without even adjusting the ECU, a big difference is felt. The dynamics of the car increases, the car behaves differently on the highway, and gas consumption decreases. On the other hand, the car's performance deteriorates at low speeds, but they are compensated by improved traction at high speeds (after 2000 rpm).

Note. Any owner of a “nine” will be glad that now his car will show the same acceleration in 4th speed as in the past in 3rd. If only the road is straight, then the “injector” will show itself and easily reach the level of 5000 rpm.

Preparation

The operation, of course, requires proper preparation. The following components should be, as they say, at hand:

- A cylinder head from a “two-piece”, equipped with a receiver and manifolds;

cylinder head VAZ 2112

- Special knock regulator (sensor);

- Throttle pipe with throttle position regulator;

- Mass air flow sensor and much more (a detailed list can be read or downloaded from other articles on our website).

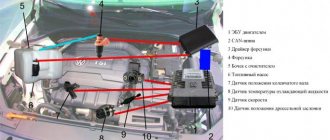

VAZ 2109 engine injector: control system diagnostics

Before touching upon general issues of diagnosing the control system, it is worth getting acquainted with the controller lamp

If a malfunction occurs while driving the car, the controller will detect it and notify the driver using “CHECK ENGINE”, while storing in its memory the necessary codes about the nature of the malfunction. With their help, the process of diagnosis and subsequent repair of the fuel injection system will be facilitated. It is the controller that is able to coordinate the operation of VAZ sensors and systems that are part of the general composition of all fuel injection units.

A few words about the DST-2M digital tester.

It is used to diagnose the engine injection control system. It is worth remembering that only a competent specialist can make the correct diagnosis. No matter how much an inexperienced mechanic strives to automate the process of diagnosing a car, having the necessary tools, he will not succeed without certain skills, which can in some cases aggravate an already difficult situation.

Diagnostics includes the following steps:

- checking the fuel supply system, the operability of all sensors, actuators and the ignition system;

- reading fault codes;

- compression measurement;

- data monitoring of the entire control system.

Once the injector has been diagnosed, the entire range of necessary services becomes clear if it is associated with a failed electronic system responsible for the performance of the engine.

Injection of youth: history of the development of VAZ injection

Already in the mid-eighties, when front-wheel drive Sputniks were rolling off the Tolyatti assembly line with might and main, it became clear to VAZ engineers that the future lay clearly in the so-called fuel injection: a power system devoid of an archaic carburetor. They started developing it - technological lag was definitely not part of the plant’s plans.

Not for the sake of boasting, but for the benefit

And the point here was not at all a matter of ambition or the desire to show off the consumer: the classical power system did not meet the two most important criteria - stability of settings and toxicity standards. Even Solex, which was quite modern at that time, could not be compared with the so-called “injector”, because it did not “know how” to prepare an equally balanced fuel-air mixture under different engine operating conditions, and it was not particularly reliable, requiring regular cleaning and adjustment . While in the West, the unspoken norm was considered to be at least five years and 80,000 km without intervention in the power system, not counting the routine replacement of filters.

Even a cursory analysis showed that it is the power system with an electronic engine control unit, and not a mechanical or electromechanical injector, that has the highest stability of characteristics and “exhaust purity”. At that time, there were many types of injection in the world, and without the proper experience, it was not easy for engineers to make a decision - which option to choose? However, they were inclined towards electronic control, as the most progressive and effective.

The promising power system was planned not only (and not so much) for the modernization of the still old cars of the eighth family, but for the future “ten” . Its production was planned to begin at the turn of the eighties and nineties, and it was simply impossible to remain with an outdated carburetor - especially considering the plans to target the Western market, where the “injector” had long ceased to be a curiosity, but had become commonplace on commercial vehicles.

In addition, VAZ even then considered a multi-valve head with four valves for each cylinder as the optimal solution for the VAZ-2110, and it was almost impossible to optimize the combustion processes in such an engine with a conventional power system. All in all, it came down to the fact that introducing electronically controlled fuel injection at the launch of the next model is one of the main tasks. Moreover, it was decided not only to switch to an “injector” version with a 16-valve head, but also to equip a conventional 1.5-liter eight-valve engine, known as VAZ-21083, with injection.

Do not forget that in those “golden” years, the export of VAZ cars sometimes reached 40% of the total output - and this, as you know, is income in the form of such a desirable currency for the plant, and the upcoming tightening of environmental standards in Europe would be easy for VAZ destructive. It’s not for nothing that since the mid-eighties, export modifications have been equipped with systems for reducing exhaust gas toxicity – including those with a catalytic converter. However, the “cat” itself was not very effective, because even with additional electronics, a conventional carburetor turned out to be the “weak link” of the system for a simple reason - it prepared the mixture less accurately and stably than required.

Collaboration

The leading players in the market for the development of injection systems at that time were three companies - Bosch, Siemens and General Motors. Preliminary negotiations ended with the conclusion of a contract with GM for a simple reason - GM had more experience and could offer the maximum range.

Lada Baltic was the first to try on the 2111 injection engine. GM components are distinguished by the distinctive design of the mass air flow sensor between the air filter housing and the intake manifold.

What were General Motors specialists supposed to do as part of the contract? Firstly, to develop and adapt fuel injection for VAZ engines that would meet Euro-1 and US-93 standards. Secondly, for export cars, “Dzhiem” had to supply more than half a million (!) sets of power systems. And, finally, the result of the work was supposed to be the acquisition of the appropriate licenses with the subsequent production of components at Soviet (and in the new realities, Russian) factories.

The type of power system on the Lada Baltic was emphasized by the original “injection” nameplate, located on the left rear door under the inscription “LADA”

Already in 1993, GM began supplying central injection kits (the so-called monoinjector) for Zhiguli and Niva, and subsequently, distributed injection systems for Lada Samara. Alas, for objective economic reasons, in a difficult time for the new country, in six years it was possible to put on the assembly line only 115 thousand sets instead of the initially planned 540 thousand.

At that moment, VAZ realized that it was impossible to rely on just one foreign partner and decided to sign a contract with Bosch in 1995. This made it possible to master both the development and production of another power system, later known as the “Boshevskaya”. Of course, work on a fundamentally new power system required long stays on foreign business trips for VAZ specialists leading on the project, some of whom worked on this topic in the United States for three or four years in a row.

Early “injectors” had imported GM controllers

During the work on the “injector”, they tried to convert such exotic modifications as the 1.1-liter VAZ-21081 engine . However, subsequently it was decided that small-capacity modifications should not be touched, and VAZ designers, together with foreign specialists, focused on engines with a volume of 1.5-1.6 liters - both Zhiguli and chisel engines. And the 16-valve engine 2112 was supposed to be the first in the history of VAZ, a design that was initially “tailored” only for an electronic power system with distributed injection.

Even during early experiments on classic engines, it turned out that the installation of a catalytic converter greatly worsens the engine’s performance in terms of power and torque, so the power system had to provide maximum efficiency in order to minimize “environmental” losses of power supply, inevitable in any case.

In Samara, with the so-called low panel, the injection controller was placed on a shelf under the glove compartment

Electronically controlled fuel injection was a common (yet modern) concept. The electronic control unit received information from a couple of dozen sensors, on the basis of which the correction of the fuel-air mixture was based, as well as other parameters - the opening time of the injectors, the ignition timing, the amount of air and fuel supplied to the cylinders, and so on. The main “work” was done by several important sensors - for example, the crankshaft position sensor (without it the engine will not start at all!) and the mass air flow sensor.

The most important advantage of VAZ injection, like most similar systems, is “survivability”. If the electric fuel pump or the “strategic” DPKV sensor has not failed and the ECU controller or ignition module has not burned out, then the system, at the very least, will work even if several sensors fail, going into emergency mode and working according to alternative control algorithms using some “averaged” » indicators built into the program.

Difficulties

But it was smooth only on paper. Mastering such a complex system, when the industrial giant of the USSR had already fallen asleep, became a difficult task for VAZ. However, with the intellectual support of foreign partners, they completely coped with it - at least, by the end of the nineties, the “injector” had become not just a workable, but also a completely serial power system for VAZs.

The mass air flow sensor is one of the most expensive components of a power supply system with distributed injection.

Of course, a lot went wrong. Attempts to attract the defense industry to production ended in nothing, and the work in the States was completed back in 1994 - before injection was put on the assembly line. In addition to the injection version of the 1.1 liter engine, in the end it was not possible to master the 16-valve version of the Samara, although the adaptation of the 2112 unit to the 21093 body was carried out in the early stages of the injection work. Only much later did the multi-valve engine fit under the hood of Samara in a factory version - more precisely, “near the factory”, from.

A special device is provided to absorb fuel vapors - an adsorber.

Some components had to be left imported - for example, the oxygen sensor, injectors and mass air flow sensor. Blocks were produced to order at Bosch, and over time, domestically produced controllers were also introduced. The remaining components (sensors, intake, exhaust and fuel supply system from the tank) were mastered almost independently.

VAZ 2109 injector controller

The controller receives the necessary information from the sensors, then makes calculations: based on them, it independently issues commands to the actuators. This device is quite reliable. One problem: it is afraid of large surges in on-board voltage. This can happen when the generator malfunctions or the starter sticks while the engine is running; sometimes the process of “lighting” another car or the use of a low-quality starting charger is to blame.

As soon as malfunctions occur, the controller immediately detects them, notifies the driver with the above-mentioned lamp, and stores the codes. Under his control, the injectors try to work smoothly, as does the ignition system.

The injectors turn on in pairs, but this depends on the type of controller itself. An interesting fact is that pairs of injectors tend to turn on alternately, approximately 180° from the crankshaft rotation. This is called double synchronous injection, but sequential operation is possible. An idle spark is provided for the system: 16-valve engines are an exception. They are already equipped with personal ignition coils for each spark plug.

This process occurs as follows: high-voltage pulses are applied to a specific pair, and the formation of a working spark occurs in the cylinder on the compression stroke and on the exhaust stroke. Otherwise, an idle spark will form. In this case, a small amount of energy is required for the cylinder during the exhaust stroke, and the rest of it is used during the compression stroke. This is how the process of ensuring normal sparking and unhindered ignition of the fuel mixture occurs. The whole process can be repeated if the cylinders decide to switch roles unexpectedly.

The controller controls not only the fuel supply, but also the energy accumulation time and ignition timing. This concerns the crankshaft rotation speed in idle mode, the uninterrupted operation of the electric fuel pump, the tachometer and the warning lamp, which is located on the VAZ instrument panel, the cooling system, and the cabin air conditioning compressor clutch. The device generates certain speed signals to the trip computer, regulates fuel consumption, and maintains the required stereochemical ratio (gasoline-air as 1:14.7).

VAZ 2109 injector does not start

Problem: the car worked fine all day and drove dozens of kilometers around the city. I stood in the garage resting for several hours. The owner decided to go out again on business, but could not start it. It seemed like something was catching, but then it died out. I had to unscrew the candles, which were thoroughly wet, and put the ones I had just bought in their place. And again a bummer! I had to check the timing belt: it turned out to be normal, I removed the battery and examined it for a failure. I checked the fuel pump: it is also ok. There is a return line, there is fuel too, but the car just doesn’t want to start.

Tips: heat the spark plugs, screw them in hot, try to start them. If the result is negative, then we can assume that the fuel was filled with low-quality gasoline; blow out the engine with the module turned off, and add a little oil to the cylinders; carefully inspect the wire near the sensor: it often breaks in this place. The terminal area is a vulnerable spot. Try to touch it, a spark should jump out.

Sensors VAZ 2109 injector

The VAZ 2109 injection system includes a certain set of sensors that collect information about the state and mode in which the engine is operating. Let's get to know them.

Mass air flow sensor - mass air flow sensor

It is installed on the air filter housing. Measures the amount of air sucked in by the engine from outside. Parameters – kg/hour. This device is considered reliable, but has an enemy - moisture, which is sucked in along with the air. A violation of its operation is indicated by inflated readings at low speeds, by approximately 15 - 25%.

Such actions lead to fluctuations in engine operation only at idle. But a stop is also possible after triple power modes or problems with starting. But underestimated readings lead to complete “dullness” of the engine or increased fuel consumption. If by default air consumption at idle should be within 10 kg/hour, then at 3000 rpm in 1 minute no more than 32 kg/hour.

Throttle position sensor

This device is installed on the side, on the throttle pipe, approximately on the same axis with the drive. Its job is to read the gas pedal. The main enemies of this sensor are considered to be engine washers, as suppliers of unnecessary moisture. The service life becomes unpredictable when exposed to water. Violations appear when roars and dips begin at idle, even under light loads.

Coolant temperature sensor

Located between the thermostat and the block head, it has 2 contacts. Do not confuse it with the single-pin temperature sensor located next door. The main function is to determine the engine temperature: the colder it is, the richer the fuel mixture.

Such a device is also called a thermistor or resistor, the change in resistance of which depends on many factors. Coolant temperature affects engine control characteristics. Despite the fact that such a device is reliable, it sometimes suffers from a number of malfunctions: a breakdown in the electrical contact inside the sensor itself, a breakdown of the insulation, or a break in the wire next to it or the throttle cable.

Coolant temperature sensor failure - If the fan is turned on when the engine is cold, the device may fail. In this case, you will experience difficulties when you need to start a warm engine or fuel consumption will be slightly higher than planned.

Knock sensor

Placed on the engine block, directly between cylinders 2 and 3. Manufacturers offer a choice of 2 sensor options – broadband (tablet) or resonant (barrel). Reliable, but requires constant cleaning of the connector.

The operating principle is similar to piezo ignition: stronger impact - greater voltage. His job is to track detonation knocks in the engine. Failure or possible breakage of the device manifests itself in the fact that the engine is “stupid” and fuel consumption exceeds reasonable limits.

Oxygen sensor

Manufacturers found a place for it on the exhaust pipe of the muffler. This is a serious, very reliable electrochemical device that can determine the presence of oxygen residues in exhaust gases.

The principle is simple: if oxygen is present, then the fuel mixture is lean, the oxygen mixture in the “No” mode is rich. Based on the sensor readings, they judge what adjustments should be made to the fuel supply.

It is strictly forbidden to use leaded gasoline. If the oxygen device fails, then expect high fuel consumption with a simultaneous increase in harmful emissions into the atmosphere.

Speed sensor

Designed for pulse formation, when the number of pulses should not exceed the limit allocated for the speed limit of the car per unit of time. Installed on top of the gearbox. These six-pulse speed sensors inform the controller about the current vehicle speed at a certain moment.

Reliability is average due to constant oxidation of the connector or wires. Failure usually results in a slight deterioration in driving performance.

Crankshaft position sensor

It is required to generate a specific electrical signal if the angular position of the toothed disk, which is installed on the oil pump cover near the crankshaft of your 2109 engine, has changed. Its readings control the operation of the cylinder during the supply of fuel and spark.

It looks like a piece of magnet with a coil of thin wire. Quite durable, works together with the crankshaft toothed pulley. If the device fails, wait for the engine to stop or rev limit.

Phase sensor

This auto phase sensor is designed to detect the degree of camshaft angle. On an eight-valve engine it is installed at the end of the cylinder head, not far from the air filter, and on a sixteen-valve engine - near the first cylinder there.

In units produced before 2005, our sensor is completely absent. This means only one thing: the injectors open in paired and parallel mode. Failure to operate switches the fuel supply to synchronized mode, which is highly undesirable, since you will have to constantly fill the tank with fuel.

Air temperature sensor

Directly fits into the mass air flow sensor. Began production in 2005. Since then it has been modernized several times, differs in the number of (5) wires. If there are fewer of them, then this is not the device in question.

It works in conjunction with other devices, its purpose is clear from the name. If the history of the VAZ 2109 brand began a little earlier, then you shouldn’t judge the designers for the fact that someone did an excellent job of driving without additional funds.

Engine crank mechanism

The design of the cylinder block of the VAZ-2111 engine is identical to block 21083. It is cast from cast iron, the cylinder diameter is 82 mm, and if the piston group is replaced, it can be increased by:

- 0.4 for the first repair;

- 0.8 at the second.

Crankshaft

The crankshaft is located at the bottom of the block and rotates on five main bearings that have removable covers, which are secured to the block with bolts. The covers are not interchangeable and are marked with marks on the outside. The middle support of the main bearing has slots into which support half-rings are installed, eliminating axial displacement of the crankshaft. The front half-ring is made of an alloy of steel and aluminum, the rear half-ring is made of cermet. If play in the crankshaft appears, the half rings must be replaced.

The bearing shells - support and connecting rod - are thin-walled, made of steel-aluminum alloy. There are grooves on the inside of all the upper main bearings, with the exception of the third bearing bearing.

The design of the crank (engine crankshaft) is as follows: it is cast iron, has four connecting rods and five main journals. Eight counterweights are cast together with the shaft. Channels are drilled inside the shaft, closed with plugs and having a dual purpose:

- they supply oil to the connecting rod journals from the main ones;

- they clean the oil, since centrifugal force throws all mechanical impurities that are not retained by the filter towards the plugs.

The latter circumstance must be taken into account when overhauling the engine, and when removing the crankshaft, and especially when balancing, it is necessary to clean the channels from accumulated deposits. After cleaning, the plugs are replaced with new ones.

The camshaft drive pulley is attached to the front part of the crankshaft, and to it is the generator drive pulley, which also works as a damping device, thanks to the elastic element between the outer and inner parts of the pulley. A cast iron flywheel is attached to the rear end using six bolts. It has a ring gear designed to start the engine using a starter. In addition, there is a conical mark on its surface, designed to determine TDC after the engine is assembled.

Piston group

The connecting rods are made of steel and have an I-section. The covers are processed together with the connecting rods, and therefore are not interchangeable. The cylinder number is stamped on them and on the connecting rods.

Piston pins are steel tubes. They float freely in the piston bosses, in which they are fixed using retaining rings.

Piston design: the pistons are made of aluminum alloy and have three grooves in the upper part for piston rings. The set of rings for each piston consists of two compression rings and one oil scraper ring. Compression rings prevent gases from entering the crankcase, and the oil scraper removes oil from the cylinder walls and carries it to the bosses to lubricate the piston pin.

Slightly lower are the holes for the piston pin (boss). There is a recess in the bottom of the piston designed to prevent bending of the valves in the event of a break in the timing belt. In the VAZ-2109 with an engine capacity of 1.3 liters, it is flat, so a broken belt inevitably led to failure of the entire piston group and gas distribution mechanism, and as a result, to expensive repairs.

VAZ 2109 injector diagram: how it works

In 1997, they began producing 2109-20 cars, which are equipped with an engine with a distributed injection system (injector). This improves their efficiency, environmental and traction performance. Distributed injection is so called because fuel is injected directly into each cylinder by a separate injector.

Such a system makes it possible to somewhat reduce the toxicity of exhaust gases, as well as improve the driving performance of the 2109 car. Today, there are injection systems without feedback and with feedback. Both presented systems can include domestic and imported components. Each of the systems has its own design, repair and diagnostic features. I would just like to note the main principles of the design, normal operation, engine repair (if necessary) and subsequent diagnostics of the fuel injection system (the VAZ 2109 injector diagram is presented below).

The automotive fuel injection system, which has feedback, is used mainly on export VAZ 2109. The exhaust system of these cars is equipped with a catalytic converter for exhaust gases and an oxygen sensor. It provides feedback. Using an oxygen sensor, the oxygen concentration in already exhaust gases is monitored.

Next, the electronic control unit (ECU) of the vehicle, according to its signals, maintains the appropriate ratio of fuel and air, that is, one at which the special converter works extremely efficiently. The injection system, in which there is no feedback, is not equipped with a converter and an oxygen sensor.

Their function (regulating the concentration of CO in already completely exhausted gases) is performed by a CO potentiometer. They also do not use a gasoline vapor recovery system.

Injector

VAZ 2109 with injection engine

As in the case described above, there are advantages and disadvantages here. If I may say so, then all the advantages of the “carburetor” are the disadvantages of the injector and vice versa.

Peculiarities

They are as follows:

- An injection engine has lower emissions of harmful substances and is more suitable to modern requirements than a carburetor engine;

- Torque is the opposite situation with the “carburetor”. Here at low speeds there is insufficient performance, but at high speed such a motor almost gets a second wind;

- Servicing the injector will cost a little more;

- The injector must be filled with clean fuel (otherwise the injectors will clog), while almost everything that gets into the carburetor flows into the carburetor;

- Malfunctions of the injector are shown by diagnostics, for which, again, you have to pay a tidy sum;

- The injector has lower fuel consumption, especially on the highway (6-7 l/100 km). This advantage is easy to explain: the injectors on such an engine are controlled by a computer that supplies a strictly measured amount of fuel.

Advice. The amount of fuel supplied depends on the ECU firmware. And if your VAZ 2109 with an injector consumes more fuel than normal, perhaps these are errors in the software.

- There is no need to use any “suction” or anything similar when servicing an injection engine. All unit speeds will be electronically regulated;

- Today, many owners install 4th generation gas equipment on cars. It is much easier to install such a kit on a VAZ 2109 than on the version with a carburetor.

VAZ-2109 does not start - what to do?

In general, diagnosing malfunctions of the controller (computer) and control system sensors, as well as the VAZ-2109 injector itself, is not much different from similar work for other cars. But due to the peculiarities of the “nine” control system, experienced owners of this car recommend the following solutions.

Most often, the injection “nine” does not start in winter. In this case, it is advisable to warm up and even recharge the battery - perhaps due to loss of capacity due to low temperature, it is not able to spin the engine shaft well.

Another “folk” method that helps is supplying air to the engine filter through a hairdryer. At the same time, heated air will flow into the cylinders. Many people claim that the VAZ starts right away.

Another possible reason: as a result of prolonged unsuccessful attempts to start, the spark plugs were filled with gasoline. In this case, it is recommended to try to start the car with the gas pedal pressed all the way to the floor - the spark plugs should dry out and the car will start. If this does not help, then unscrew the spark plugs and check for the presence of a spark. If it is not there, then either the spark plugs or the ignition system are faulty.

History of the VAZ 21093 - how did a domestic car with an injector appear?

Serial production of VAZ 21093 cars began in the late 80s. At that time, the VAZ was produced only with a carburetor engine. The main difference between this car model and its predecessor, the VAZ 2108, was the presence of 5 doors, which is why it began to be considered a family car.

The production of the VAZ 21093 with an injector began in 2000, when the so-called electronic brains appeared - primitive on-board computers that control all electronic processes in the operation of the car. The presence of connectors allows a car service center to diagnose the car and determine faults without delving into the insides of the car. The on-board computer can see malfunctions of sensors, turn signals, headlights, ignition systems, and problems with engine operation.

Since 2012, the VAZ 21093 has received another advantage - an electronic gas pedal, which is a pleasure to press! The driver does not need to make almost any effort - just put his foot on the pedal for the car to start.

Checking injectors and timing belt

When there is a spark and its color is bright bluish, check the fuel supply: turn out the injectors and turn the engine shaft with the starter. The fuel should be sprayed from the nozzle in a uniform cone-shaped “torch”. If instead the injector pours gasoline or splashes it, then it is clogged.

If the tested components are working, then look at the timing belt. Owners of the injection “nine” have more than once encountered the situation of the belt slipping by several teeth. In winter, this can happen when starting a cold engine when the camshaft rotates heavily. To check, look at the timing mark. If it matches, check the crankshaft sensor and its wire (sometimes it comes off). Then the remaining sensors are checked.

Diagnosis of sensor failure

Let's consider deviations in engine operation and the corresponding possible causes. Unstable operation at idle, difficult starting or stopping the engine after driving in high power mode can be caused by malfunctions of the mass air flow sensor (MAF) - it will give the controller at low speeds readings that are 15–25% higher. If there is excessive fuel consumption or the engine response has decreased, the mass air flow sensor gives underestimated readings.

Jerks and dips when switching from idle to operating speeds, even in the case of light loads, means that the operation of the sensor that reads the throttle position has been disrupted. Difficulty starting a warm engine or slight excess fuel consumption - the coolant temperature sensor has failed.

The engine picks up speed poorly and does not develop the required power, or there is a large excess fuel consumption - the knock sensor has failed or the wire from it has broken. In the event of a noticeable overconsumption of fuel with a simultaneous increase in the amount of harmful emissions in the exhaust gases, the oxygen sensor has failed.

A slight decrease in throttle response and deterioration in other engine performance characteristics means a failure of the speed sensor or oxidation of the contacts of its wires or connector. Limiting engine speed or stopping it indicates a failure of the crankshaft position sensor. Large excess fuel consumption - the phase sensor has failed. Minor deterioration in engine performance or difficult starting means the temperature sensor of the air entering the engine has failed.

If all of the above devices and sensors have been checked, but the injection VAZ-2109 does not start, then the processor may have failed and it does not properly control the entire starting system. In this case, diagnostics at a car service center is required.

Description

The technical characteristics at that time were standard: a 1.1-liter engine, a carburetor in the mechanisms, a maximum power of 54 horsepower.

After some time, models of this car with an improved engine began to appear on sale. The main changes include a larger engine volume, increased to 1.5 liters, and an engine temperature sensor, and in the early 2000s, models with an injector entered mass production. It is also possible to perform engine tuning in the VAZ 2109, which allows you to obtain improved performance for relatively little waste.

The main advantage of this machine was its fairly cheap maintenance, which was typical for any of the production machines.

Even after the end of the warranty period, keeping the car in good condition was quite simple and did not require any special expenses, the main thing was to change the oil regularly. And thanks to the prevalence of this range of models, it is quite easy to find replacement parts for broken ones both in car repair shops and in the hands of motorists.

Due to the simplicity of the design, many owners thought about what kind of engine they could install to improve the car’s performance. In order to repair or tune a VAZ 2109 engine, you do not have to be a car mechanic.

Almost any driver can do all the work with his own hands. That is why most owners of this car want to drive this model, which is cheap both to repair and to operate, for as long as possible. Tuning the VAZ 2109 engine is also easy.

Candles

First of all, find out if there is a spark at all. The weakness of the latter allows you to start the engine while it remains hot, but it does not work when it is cold.

Unscrew the spark plug, place it against ground and crank the starter. If there is a spark, then there is probably a problem in the fuel system. We will tell you about it later.

It is necessary to do otherwise when the unscrewed spark plug works properly, but it turns out to be wet. Here you should check the timing belt. The latter sometimes jumps off, which disrupts the correct gas distribution and, accordingly, the VAZ engine does not want to start.

If you see that the spark plugs are filled with fuel, then perhaps this very circumstance is preventing you from starting the engine. Dry them with a burner or on a gas stove burner. When they turn out to be wet again during the next attempt, you will have to find out why this happened.

If there is no spark, the cause is sought further. It often lies in problems:

- crankshaft pulley or sensor that controls its position (DCPV);

- computer.

In most cases, the VAZ model 2109 injector does not want to start precisely because of the failure of the DPKV. Failure of other sensors does not prevent the engine from starting, it will simply not work correctly.

First, check whether the connector leading to it is intact and whether the wires are in good condition. It is the destruction or contamination of these elements that most often interferes with the normal operation of the DPKV, while the device itself is reliable.

To test the sensor, just hold a piece of metal close to it and measure the output voltage. It will fall if the piece of iron is taken away, and rise when it is brought close.

Another reason why a VAZ may not start is the crankshaft pulley. The disadvantage of this unit is that its teeth are partially made of rubber, which means they can come off or even scroll. This affects the sensor readings, and the computer, guided by them, does not want to supply voltage to the spark plugs. It’s not difficult to check - remove the casing from the timing belt (inspect it at the same time), and then examine the pulley.

There is a high probability that there is no spark due to a faulty ignition. First you should make sure that the connector leading to it is intact. Installing a known-good module on a Lada that does not want to start will allow you to confirm your suspicions.

It is imperative to inspect all wires. A break in them, even with working devices, often leads to the inability to start the engine.

Characteristics

One of the most common cars in the CIS countries, the VAZ 2109, began to be produced back in 1988. Despite the already quite old age of this car model, it is still popular among the population of our country. The main difference between the VAZ 2109 and its predecessor 2108 is five doors instead of four and a more spacious body. The VAZ 2109 engine was also replaced. Thanks to these innovations, this car began to be positioned as a Soviet family car.

Download .xls file

xls

Download picture

Send by email

| OPTIONS | MEANING | |

| Fuel used in VAZ 2109 | Petrol | |

| Power supply to the motor | Carburetor | Distributed injection |

| Cylinder (its diameter in mm) | 82 | 82 |

| Piston stroke | 71 | 71 |

| Maximum compression rate | 9.9 | 9.9 |

| Fuel capacity (engine volume), cm 3 | 1499 | 1499 |

| Engine power, kW/rpm | 68/5600 | 78/5400 |

| Torque - maximum value, Nm at rpm | 100 / 3400 | 116 / 3000 |

| Gasoline standards | AI-92 | AI-95 |

| Waste on gasoline when driving in urban conditions, l/100km | 8.7 | 9.9 |

| Vehicle speed, km/h | 154 | 155 |

| Acceleration of a car to a speed of 100 km/h, s | 14 | 13 |

| Gearbox operation type | With manual control | |

| Transmission levels | 5 forward, 1 reverse | |

| Fuel tank capacity | 43 | 43 |

This motor is suitable for use in VAZ 2108 and VAZ 2109 cars.

Fuel system

If there is a spark in a carburetor or injection engine, it should be assumed that the car does not start due to problems in the fuel supply system.

First make sure that gasoline is flowing into the injectors. If not, then look at the VAZ fuel pump. It is equipped with an electric motor and is located directly in the tank. Normally, when the ignition is activated, it starts to make noise.

It is advisable to find out whether the pressure in the ramp is normal. Measure it with a pressure gauge - there is a special fitting for it. Connect the device to it - if the reading is 4 atmospheres, then everything is in order. Low pressure appears due to a clogged fuel filter; this element will have to be removed and cleaned.

If there is no positive result, move on to the injectors. When they become clogged, gasoline either stops flowing altogether or its volume noticeably decreases. Moreover, it does not spray, but only drips. This problem does not make itself felt while the engine is hot. In frosty weather, the car, even if it starts moving, will still not be able to develop normal power.

In addition, fuel atomization does not occur when the computer does not open the injectors. Make sure they have all the wires and are securely attached.

Car injector breakdowns

Quite often a situation arises when a fuel-injected car starts poorly or does not start at all. The reasons for this operation may be dirty spark plugs from low-quality fuel, problems in the operation of the generator, starter, or insufficient current in the battery. The main malfunction is the low fuel supply to the injector frame; accordingly, an insufficient amount of fuel is sprayed by the injectors.

The fuel pump is responsible for supplying fuel to the injector; it may not produce the pressure necessary for normal operation of the car engine. In this case, it is best to replace the pump. If the reason is not a pump failure, then it will be enough to replace the filter in it. Another common cause of malfunction is the failure of one or more injector nozzles. Low-quality fuel, which sometimes, against our will, enters the system, contains various additives that are deposited on the injectors and interfere with proper operation.

When the injectors become dirty, the vehicle's fuel consumption increases noticeably and the vehicle's traction decreases. If fuel is not supplied in the amount required for engine operation, then the speed on the tachometer begins to fluctuate. In all injection VAZ cars, the average engine speed at idle should not exceed 900 rpm.

Muffler

Sometimes an injection car does not want to start due to shedding of the catalyst in the muffler. It serves to reduce harmful emissions and is installed in accordance with current environmental legislation on all cars.

When the catalyst crumbles, the gases cannot escape normally, which means that the car will not move, since the computer will not allow it to start. It is not difficult to check this possibility - unscrew the muffler mount so that the exhaust comes directly from the resonator. If this helps, then change the catalyst.