Print this article Font size 16

The mechanical method of measuring the speed of a car is long gone. Today, this function is taken over by a speed sensor, whose operation is based on the Hall effect.

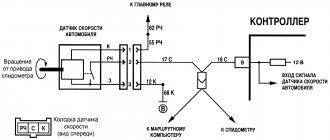

The sensor transmits pulses (electromagnetic) to the controller, and based on them, the controller calculates at what speed the car is moving at a given moment.

Appearance of the device

Speed sensor VAZ 2109 Repair VAZ 2108 2109 21099

Carburetor models VAZ 2108 2109 21099 have a mechanical connection between the gearbox and the speedometer: a cable. When the car moves, the cable rotates and turns the gear in the speedometer, from which the speedometer needle deviates and shows the speed of movement. Injection models have an electronic speed sensor, the operating principle of which is based on the Hall effect. The electronic sensor is installed in the same place as the old mechanical cable. The sensor also has a roller that is inserted into the gearbox and, when rotated, rotates the Hall sensor drum. The speed sensor is connected to the electronic engine control unit. When the drive part of the sensor rotates, it begins to send impulses to the control unit. The higher the frequency of the pulses, the higher the speed of the vehicle; the lower the frequency of the supplied pulses, the lower the speed of movement. When moving at a speed of 1 m/s, the sensor sends 6 pulses per second. When driving at a speed of 10 m/s, the sensor sends 60 pulses per second, the ECU processes these pulses, converts them into km/h and displays them on the speedometer.

speed sensor VAZ 2109

Naturally, if non-standard tires are installed on a VAZ 2108 2109 21099, the speed will be displayed incorrectly. For example, if R14 tires are installed, the speedometer will underestimate the readings. If, on the contrary, low-profile R13 tires are installed, then the speedometer will show a speed higher than it actually is. The controller firmware has special conversion factors that must be changed when installing non-standard wheels. Three versions of the speed sensor were installed on the VAZ 2108 2109 21099: - GM, American standard with a round connector and article number 311.3843. - With a flat connector and a plastic roller. Due to the plastic bead, this sensor is unreliable.— With flat connector and metal bead, article number 344.3843. This sensor is reliable and it is better to take it. There is also a nuance with the number of pulses per revolution, nine-speed sensors have 6 pulses per revolution, but on sale you can find sensors marked 10 pulses per revolution. If the speed sensor fails, then the light should light up CHECK. But this does not always happen, the fact is that it is difficult for the controller to diagnose the speed sensor, since it is unclear whether the car is driving or standing still. Only in powerful modes, with high air flow from the mass air flow sensor and fuel consumption, the controller can determine a faulty sensor. The cost of a speed sensor for the ninth family is 300-400 rubles.

Practical advice

The operation of an injection power unit, and in particular the maintenance of its electronic components, is fundamentally different from carburetor engine systems.

Owners of converted cars must learn a few basic rules:

- Before dismantling the injection control system components, be sure to disconnect the negative cable from the battery terminal;

- Do not start the engine if the terminals of the wires on the battery have poor contact. Be sure to check how tightly they are tightened;

- Do not disconnect the battery while the vehicle engine is running. This is guaranteed to lead to failure of the ECU;

- Monitor the ECU temperature. It is not allowed to overheat (65°C when the car is running and above 80°C, for example when drying in a paint booth). If such a process is unavoidable, remove the ECU from the vehicle for the duration of the work;

- It is also necessary to remove the ECU or disconnect it from the vehicle’s on-board system when carrying out welding work on body parts.

Verification methods

Fuel level sensor FLS for VAZ 2108, 2109, 21099 cars

The first thing that needs to be done is to make sure that a voltage of 12 V is supplied to the DC contacts. Because the operation of the DC is based on the Hall effect, the test is carried out by torsion. The voltage in this case varies between 0.5-10V.

Nowadays, three main methods are used to check the performance of the speed sensor. The first two require the use of a multimeter. Which one to choose, decide for yourself. We will carefully talk about all 3 methods of checking DS.

Verification method

Your actions

- Remove the sensor;

- Use a multimeter to check which pin does which function. It is necessary to find a pulse contact;

- Connect the positive probe of the multimeter to the pulse contact, and the negative probe to the engine, or, in other words, the car body. It will be a mass;

- Put a piece of tube on the DS axis and start turning it at low speed;

- Immediately check how the voltage changes;

- As the speed increases, the pulse frequency and voltage should increase

- There is no need to dismantle the device;

- Use a jack to lift one of the front wheels of the car; Connect the multimeter to the sensor wires, as in the first method;

- Spin the wheel with your hands and watch the multimeter readings;

- If impulses occur immediately, the DS is working normally. In this case no, it is out of order and needs to be replaced

- This test method does not require the use of a multimeter;

- Instead, a control lamp is taken, or an ordinary 12-volt light bulb;

- Disconnect the impulse wire from the DC;

- Turn on the ignition and use the test lamp to find the plus and minus;

- Raise one of the front wheels using a jack;

- Connect the test light to the signal wire and spin the wheel;

- If the minus light on the control lamp lights up, this indicates the normal state of the sensor;

- If you don’t have a control, take any 12V light bulb. On a VAZ 2109 you can find one in the turn signal. Connect the signal contact and the plus of the battery with a wire. The functionality of the sensor is indicated by the lamp starting to blink.

If checking the DS shows that everything is fine with it, be sure to check the functionality of the sensor drive. It is necessary to hang up the front wheel and find the DS drive by touch. Now start rotating the wheel with your foot and check with your hand whether there is rotation in the drive and how stable it is. The help of a partner will not hurt you here.

If problems occur when installing a new panel

A “twitching” needle during ignition indicates that power is coming to the speedometer. Possible problems could be:

- incorrect connection of wires;

- there are breaks in the wiring - check the integrity of each wire separately;

- There are problems in the device itself - burnt out tracks or the speedometer drive.

By the way, the mere fact of replacing the sensor does not yet indicate its performance. VAZ sensors often turn out to be “dead” immediately after purchase. Ideally, ask your friends for a similar sensor that is known to work.

Speed sensor VAZ 2109

The speedometer operating system is quite simple. The speedometer sensor produces a signal. Further along the wiring it is duplicated and simultaneously goes to the ECU and the dashboard. Next, along the tracks on the dashboard board it gets to the speedometer mechanism - the arrow rotates to the desired angle.

The malfunction may be in any of these elements

Always pay special attention to the chips (contacts oxidize, measure with a tester, spray with a wedge, bend if necessary)

Just like any other old car, there are problems with the wires - they burn out, break under the insulation (check with a continuity tester). You can use a multimeter or a universal probe that “can” find plus, minus and absence of a signal. A 12V screwdriver, which detects only power, is an inferior assistant.

Similar

| Digital portable anemometer ap1m irsha. 402131. 001 Tu is intended...Purpose: digital portable anemometer AP1M Irsha. 402131. 001 Tu is designed to measure the average speed of directed air… | Instructions for use en. 401 ReConnecting en4, en6, ez6 sensors to on-board monitoring controllers of the “Autograph-gsm” series 84 |

| Instructions for use en. 401 ReConnecting en4, en6, ez6 sensors to on-board monitoring controllers of the “Autograph-gsm” series 84 | 1. Requirements for technical means of controlRequirements for the subject of purchase: for the right to enter into an agreement for the supply, installation, calibration and activation of Mercury ta-001 tachographs... |

| The program must periodically poll the internal memory of the electronic...The general diagram of the system is shown in Fig. 1 and should consist of temperature sensors (1), pressure sensors (2), sensor power supply... | Application of a Doppler meter to determine the speed of moving railway unitsOts of radar Doppler speed meters. The possibility and scope of their application in railway transport is considered.... |

| 5. Operation of the filtration deviceCheck that the diffuser holders (26) and manifold (13) are in perfect condition, as well as the air duct connection to... | Technical description and operating instructions for the speed control device UX-1MU. The speed control device UX-1M, hereinafter referred to as UX, is designed to control the speed of transport equipment of mills, elevators... |

| Manual for installation, operation and calibration of aviation electronic... Monitoring and setting the minimum speed value is carried out by the minimum speed indicator ims-1M (hereinafter referred to as the “indicator”) during... | Algorithm for checking access speed... |

| Terminology in the technical literature Automatic transmission is driven by the output shaft and creates pressure proportional to the speed of the vehicle; in fact, Governor is a hydraulic... | The operating manual contains technical data, description...Measurement of parameters, regulation and configuration of a single-limit sensor |

| Product Name Vector control algorithm combines fine speed calculation and self-emission function of motor parameters. This achieves... | Instructions for complex setup and testing of the Mercury-115 cash register. The instructions apply to the Mercury-115 cash register with software - 115UZ107 for the following version of the cash register. |

| “Monitoring the opening speed of the Top 100 websites in Russia” This informational...Creation of a system for constant monitoring of the opening speed of popular web pages and prompt identification of resources (hereinafter referred to as the System),... | Operating manual for usd mercury 250 Part Software manual During the setup and operation of usd mercury 250, the following types of software are used |

Speed sensor device, malfunctions, check, repair

Manual, instructions for use Instructions, instructions for use

Symptoms of speed sensor failure

The driver must react in time if the speed sensor fails by replacing it with a new one. If this is not done, the engine will not perform optimally and its components will suffer additional wear and tear. The following symptoms indicate a speed sensor failure:

- The engine is unstable at idle;

- In the usual operating mode, the engine began to consume more fuel;

- The speedometer erroneously displays information about the vehicle's speed. If the sensor is completely out of order, it may not report it at all;

- The car began to accelerate worse.

In many modern cars, error information appears on the on-board computer when the speed sensor fails. The Check Engine light may also come on.

Air flow sensor

The mass air flow sensor, also known as MAF, is probably the most famous and most recognizable sensor of all the sensors in a car. Its purpose is to count the air entering the engine. Air counting is necessary to create the air-fuel mixture in the correct proportions.

Location

The VAZ 2109 air flow sensor is located on the intake corrugation between the throttle valve and the air filter housing.

Signs of malfunction:

- Idle speed fluctuates;

- The car does not pull well;

- The engine stalls spontaneously;

Replacement

If you have a desire to save money and want to try and repair an old speed sensor first, we hasten to disappoint you.

We remove and change

The speed sensors installed on the VAZ 2109 (as well as on other cars) cannot be repaired or restored. The only way to solve the problem is to replace the device.

Take a pair of keys for 21 and 10. Disconnect the negative from the battery to de-energize the car. Disconnect the connector going to the speed sensor. Unscrew the sensor itself

Another time the rod may break, so you will also have to remove the drive. Be sure to be careful when removing the drive, otherwise you risk dropping a broken rod into the gearbox. After removing the device, change the drive, if necessary, and screw the new speed sensor into place. The drive rod should be inserted into the DS bushing, and the rubber seal ring should be treated with oil. All that remains for our client is that you can quietly screw the device into the socket.

We got to DS

How to connect a speed sensor to a VAZ 2109.

After completing the repair, be sure to reset the error that was generated by the electronic control unit on the on-board computer. Otherwise, the system will assume that the sensor is faulty. Therefore, even its presence in the socket will not allow the DS to start working.

Symptoms of a problem

If the speedometer needle remains stationary regardless of the speed of the car, then this symptom of a malfunction is the most specific for a breakdown of this type. The malfunction of the element can also significantly affect the odometer readings, which either completely stops counting the kilometers traveled, or its operation becomes inconsistent. Arrow problems can also occur from time to time. In such a situation, the speed sensor is not always to blame. Insufficient contact of the connected wires to the terminals often manifests itself in this way.

If a signal is sent from the sensor to the engine ECU, then symptoms of a malfunction of this part may manifest itself in the form of unstable operation of the power unit. Dips in engine operation will be especially noticeable during sudden acceleration. There may also be an increase in fuel consumption and unstable engine operation when driving at low speeds. Difficulties starting the engine and idling can also be a sign of a malfunction of the VAZ 2109 DS.

Speed sensor Lada Kalina Car Hobby

I encountered the following problem - the speed sensor on Kalina quickly failed. More specifically, in about a year and a half I replaced 3 speed sensors. Moreover, the latter did not work even a day. This arrangement of events did not suit me and, to be honest, I was a little fed up. I decided to figure out the reason for such a quick “demise” of the sensors.

A speed sensor can break down mainly for 3 reasons - the first, and most common, is liquid (water or antifreeze) getting on the sensor contacts. This occurs due to leaking pipes or driving through a large puddle. The second reason is transmission oil getting inside the sensor. This is due to the design features of the sensor itself. And third, the speed sensor chip may begin to melt; no one knows for sure why this happens.

The first time my speed sensor failed was due to antifreeze getting on it. I fixed the leak (the pipes leading to the stove were leaking, just above the sensor) and replaced the sensor. The second time the speedometer stopped showing after a trip in rainy weather, although it didn’t seem to drive through puddles. The third time I didn’t understand at all why it stopped working.

Through my own experiments and reflections, I came to the conclusion that the reason for such rapid breakdown of sensors is their quality. The last two times I bought a sensor with the number 1118-3843010-04 approximately “StartVolt”

Pay attention to its shape - it’s all square

For the third time I bought a speed sensor-1118-3843010-02 (Kaluga). It looks better quality when you pick it up and it's noticeable. It has an oval shape. The bottom of the sensor is not made of plastic, but is filled with a substance like epoxy resin (I don’t know exactly). I originally had the same sensor. Why I didn’t buy the same one right away, I don’t know.

Speed sensors for Kalina have three varieties 1118-3843010-00 (02, 04). That is, they differ only in the last two digits. Sellers at the market claim that you only need to install the one that was there before. But actually it is not. All of them are interchangeable (personally verified).

So this is what I'm getting at, buy high-quality sensors (I recommend Kaluga). Come to the AvtoVAZ branch and ask for a speed sensor, they will offer you a branded, high-quality sensor. And you don’t need to run around the market, shops, check numbers, listen to the persuasion of sellers and end up buying crap, excuse the expression.

Another reason could be rotting of the contacts on the connector itself or a break in its wires.

In this case, you will have to buy a new connector. Changing it is quite simple - cut off the old one and screw (solder) a new one in its place. Be careful with the wires, do not mix them up.

Replacing the oil pressure sensor is a simple and easy-to-do procedure at home.

1. First of all, you need to remove the decorative plastic engine cover.

2. The Kalina oil pressure sensor is located on the back of the engine, it is screwed into the cylinder head socket on the right.

3. By pressing the block latches, disconnect the wire block from the DDM.

4. Using the key at “21”, unscrew the sensor.

5. Prepare the new pressure sensor for installation and install it in the socket.

6. Clamp everything properly, put the wire block back in place, install the decorative cover and check if the problem has disappeared. If after starting the light goes out after a few seconds, we can conclude that the fault was in the DDM, so its replacement was not in vain.

That's all for me, thanks for your attention.

IMPORTANT! In addition to the sensor itself, the contacts suitable for it also break, and very often, because are in free flight. During removal, do not drop the rod into the box, otherwise you will have to read: How to remove the gearbox?

Causes of failure

There are several main circumstances due to which the DS may stop working:

- There has been a break in the electronic circuit. Therefore, we first recommend checking the condition of the wiring and contacts. They could become dirty or oxidized. They are easy to clean. Additionally, we recommend treating the contacts with Litol.

- Break near the connector. Here the wiring is often bent and chafing occurs. Don’t forget to also check the condition of the insulation of the wires that are located near the exhaust manifold. Often they melt under the influence of temperature, which leads to short circuits.

- The speedometer cable is worn out. After some time during the operation of the car, the cable becomes covered with burrs, cracks, and breaks. As a result, the speed sensor stops working perfectly.

Replacing the speed sensor

, how to correctly change the speedometer sensor Signs of malfunction: Unbalanced.

Description of DS

As we have already said, the main purpose of the speedometer drive sensor is to accurately determine the speed of the vehicle. Thanks to this device, the model can always know at what speed his car is moving. As for the varieties, DS can be of the contact or non-contact type. Today, most of our compatriots prefer contactless options. Contact DS, despite all the advantages, have one significant drawback - they are prone to contamination, which in turn will lead to inaccuracy of the displayed readings.

Design and principle of operation

Structurally, according to the diagram, this part consists of:

- speedometer drive;

- housings;

- as well as the controller itself with a connector for connecting to the on-board network.

As for the principle of operation, it is based on measuring the frequency level of signals from the controller, which is located on the gearbox housing or transfer case. At the output of the device, while driving, rectangular pulses are formed, the minimum value of which should be at least 1 volt, and the maximum value should be at least 5 volts.

According to international standards, the controller must generate about 6 thousand such pulses over one kilometer. The pulses themselves are subsequently converted into current, which is measured by a magnetoelectric device. It should be noted that the current value directly depends on the number of signals supplied per certain unit of time. That is, this value will be directly proportional to the speed of the vehicle.

In addition, thanks to the electronic circuit installed in the dashboard, the operation of the stepper motor is ensured by counting incoming signals. The latter is designed to rotate the counter reels, after which it displays the relevant information on a small screen, where the total and daily mileage of the car is shown. If we are talking about daily mileage, then this value can be reset to zero if necessary.

Symptoms of a problem

If the DS for some reason fails, this will lead to the control unit being unable to determine the speed of movement. However, this is not the only problem, since malfunctions in the performance of the power unit may also occur.

We suggest that you familiarize yourself in more detail with the signs of a malfunction, by which you can determine the failure of the DS:

- the speedometer on the dashboard has either stopped working altogether or displays incorrect readings;

- malfunctions appear in engine operation, in particular at idle speed;

- fuel consumption increased;

- engine performance has deteriorated, the power unit cannot reach the required speed;

- the engine may stop spontaneously while idling, in particular when the driver tries to press the clutch to change gear;

- if the car is equipped with an on-board computer, a Check indicator may appear on the dashboard;

- if the car is equipped with an electric power steering, this unit may also fail;

- in some cars, for example, Lada Kalina, failure of the diesel engine can also lead to increased sensitivity of the fuel level controller in the gas tank (the author of the video is the Autoelectrics HF channel).

As for the reasons, as a rule, they are caused by damage to the car's electrical wiring, so checking the functionality should begin with diagnosing the condition of the contacts and electrical circuits. Perhaps the problem lies in oxidized or dirty contacts, so they will need to be cleaned and treated with a lubricant, for example, Lithol. A broken wiring should be looked for first of all near the connection connector, since in this place the wires are bent and usually frayed.

Also, the cause of the malfunction may be a violation of the integrity of the wiring insulation in the area where the exhaust manifold is installed. At elevated temperatures, the insulation may melt, causing the device to short out. Also, the DS may transmit incorrect readings due to a worn speedometer cable. Over time, cracks and tears form on it, which contributes to the failure of the controller.

Verification methods

The first thing you need to do is make sure that a voltage of 12 V is supplied to the DS contacts. Because the operation of the DS is based on the Hall effect, the test is performed by torsion. The voltage in this case varies between 0.5-10V.

Nowadays, three main methods are used to check the performance of the speed sensor. The first two require the use of a multimeter. Which one to choose, decide for yourself. We will carefully talk about all 3 methods of checking DS.

Verification method

Your actions

- Remove the sensor;

- Use a multimeter to check which pin does which function. It is necessary to find a pulse contact;

- Connect the positive probe of the multimeter to the pulse contact, and the negative probe to the engine, or, in other words, the car body. It will be a mass;

- Put a piece of tube on the DS axis and start turning it at low speed;

- Immediately check how the voltage changes;

- As the speed increases, the pulse frequency and voltage should increase

- There is no need to dismantle the device;

- Use a jack to lift one of the front wheels of the car; Connect the multimeter to the sensor wires, as in the first method;

- Spin the wheel with your hands and watch the multimeter readings;

- If impulses occur immediately, the DS is working normally. In this case no, it is out of order and needs to be replaced

- This test method does not require the use of a multimeter;

- Instead, a control lamp is taken, or an ordinary 12-volt light bulb;

- Disconnect the impulse wire from the DC;

- Turn on the ignition and use the test lamp to find the plus and minus;

- Raise one of the front wheels using a jack;

- Connect the test light to the signal wire and spin the wheel;

- If the minus light comes on on the control lamp, this indicates the normal state of the sensor;

- If you don’t have a control, take any 12V light bulb. On a VAZ 2109 you can find one in the turn signal. Connect the signal contact and the plus of the battery with a wire. The functionality of the sensor is indicated by the lamp starting to blink.

If checking the DS shows that everything is fine with it, be sure to check the functionality of the sensor drive. It is necessary to hang up the front wheel and find the DS drive by touch. Now start rotating the wheel with your foot and check with your hand whether there is rotation in the drive and how stable it is. The help of a partner will not hurt you here.

KEY-DOP

Functions

It is incorrect to assume that the DS serves solely to transmit information regarding the current speed of the vehicle. In fact, this device has several tasks.

- Transferring information to the dashboard, namely the speedometer, about the speed of the car.

- Supports optimal functioning of the idle air control.

- Transferring data to the electronic control unit in order to maintain optimal speed depending on the travel mode.

The DS is connected to the speedometer and controller using a mounting block located in the engine compartment. And inside the car, directly on the heater fan relay, there is a sensor fuse.

https://youtube.com/watch?v=7drLW_Qlgj4

Errors and symptoms

If the device starts to work incorrectly or breaks down, you should pay attention to the on-board computer screen. Diagnostics of errors will determine that the DS has stopped functioning properly and measures should be taken to eliminate the breakdown

| Error code | What does it mean |

| P0500 | This error indicates that the computer does not receive a signal from the speed sensor. |

| P0503 | This error code informs about the receipt of an unstable signal from the DS, which is intermittent. |

If these error codes appear on the dashboard, you should definitely inspect the electrical circuit for oxidation or damage to the integrity of the contacts. Often it is because of this that the DS stops transmitting information.

But there are other signs by which you can determine that the DS is out of order:

- On the dashboard, the speedometer shows incorrect speed data or the needle does not move at all;

- With a slight acceleration, the speed floats, the engine switches off on its own;

- Fuel consumption increases;

- Engine power is noticeably reduced.

These signs may be signals of problems with other systems. But if you find one of the characteristic signs of a DS failure, plus one of two error codes appears on the on-board computer, then the problem lies precisely in the speed sensor.

Functionality check

Do not rush to replace the device until you are sure that the faulty sensor is the culprit of the problem.

The check is performed in several ways. Decide for yourself which one you prefer.

Before doing this, be sure to check the condition of the wiring and contacts. If they are oxidized or rusted, or there are breaks in the circuit, then the DS itself may well be operational. You just need to return the wiring and contacts to a functional state. If the check shows that everything is intact and there are no problems with the contacts, then diagnose the speed sensor.

- If you don’t want to remove the DS, then place the car on a level surface, secure it with blocks and lift the left front wheel with a jack. Connect the voltmeter to the contacts of the sensor and begin to rotate the wheel with your hands. At the same time, look at the voltmeter data. If the voltage increases with frequency in proportion to the increase in wheel speed, the DS operates normally.

- Another method also does not require removing the measuring device. But for this you will need a test lamp. Use a jack to lift the left front wheel and connect the test lamp to the DC contacts. After this, manually rotate the wheel. If the lamp lights up, the sensor is working well.

- The third method involves dismantling the sensor and then checking the input and output voltage. The device for measuring the indicators will be a voltmeter.

- The fourth method is actively used by those who prefer to repair their car with their own hands. Here you have to check the sensor drive. To do this, lift the wheel using a jack and remove the sensor. Feel for the DS drive, and then begin to rotate the wheel. You can feel with your fingers that the drive rotates. If there are no jams, everything rotates evenly, then the drive is in good condition.

If a malfunction of the DS is detected, the only correct solution is to remove it and replace it with a new sensor.

Having determined that your DS has already served its purpose, you can begin the replacement procedure.

Replacement

If you have a desire to save money and want to try and repair an old speed sensor first, we hasten to disappoint you.

We remove and change

The speed sensors installed on the VAZ 2109 (as well as on other cars) cannot be repaired or restored. The only way to solve the problem is to replace the device.

Take a pair of keys for 21 and 10. Disconnect the negative from the battery to de-energize the car. Disconnect the connector going to the speed sensor. Unscrew the sensor itself

Another time the rod may break, so you will also have to remove the drive. Be sure to be careful when removing the drive, otherwise you risk dropping a broken rod into the gearbox. After removing the device, change the drive, if necessary, and screw the new speed sensor into place. The drive rod should be inserted into the DS bushing, and the rubber seal ring should be treated with oil. All that remains for our client is that you can quietly screw the device into the socket.

We got to DS

How to connect a speed sensor to a VAZ 2109.

After completing the repair, be sure to reset the error that was generated by the electronic control unit on the on-board computer. Otherwise, the system will assume that the sensor is faulty. Therefore, even its presence in the socket will not allow the DS to start working.

If the panel worked before

The check is essentially the same, but you can exclude an error in connecting the wires from the list of possible faults when switching to a new chip.

If you have a VDO device, on our website you can see how to do its self-diagnosis. If not, purchase a “lace” or have it diagnosed at a car service center. Sources of errors can also show which way to dig.

There is a feeling that in your case the problem lies in the speedometer mechanism itself or the tracks on the panel. Disassemble the panel yourself - call the roads, check the mechanism (continuity, check the integrity of the gears in the speedometer drive or other problems - the unit is quite complex, there are many sources of malfunctions) - or take it to a good electrician.

Also on amateur radio forums you can find diagrams of simulators of the speedometer sensor. Assembling this circuit will be useful for checking the operation of the speedometer. Without it, the dashboard will have to be constantly placed on the car and removed back.

How to connect a tachograph

These devices are required to be installed in long-distance vehicles - regular buses, long-distance trucks, taxis, and so on.

But it is not prohibited to equip any car with such a device at the request of its owner.

This device measures speed, as well as the driver’s physical condition, rest mode, and so on.

The tachograph is connected to the circuit between the speed sensor and the speedometer, due to which the data from the DS enters two devices simultaneously.

When installing this device, you must follow some rules:

- It is not recommended to place the device antenna on surfaces made of metal;

- It is recommended to place the wires in such a way that they are not exposed, since they are quite fragile and can be damaged even by the salt that is sprinkled on the roads in winter;

- If, when installing the tachograph, the speedometer suddenly stops functioning, it may be necessary to connect it in parallel to the DS.

How does he work

The working mechanism is based on the following. For every kilometer traveled, the speed sensor (DS) transmits a certain number of pulses to the controller.

The number of impulses transmitted per 1 km is 6004. The faster the car moves, the faster the impulses are transmitted. Due to this, the controller determines the speed based on the time interval between received pulses.

It is necessary to see that the DS also has an additional function that allows you to partially save fuel for the VAZ 2109. When coasting at a speed of more than 20 km per hour, the controller, focusing on data from the DS, does not open the fuel supply.

Design and principle of operation

It should be noted that the frequency of these pulses directly depends on the speed of rotation of the drive wheels. Thus, for every kilometer traveled by the car, approximately 6004 pulses are sent to its control unit. The vehicle speed and tachometer readings are calculated by the electronic control unit by analyzing the time intervals between received pulses.

Attention! As a consequence of the above, it is necessary to understand that installing wheels with a diameter different from the nominal size directly affects the speedometer readings.

In addition to its informational role, the speed sensor affects the operating modes of the engine itself, since depending on the speed of the vehicle, the control unit changes modes:

- Idle speed, which is slightly increased on a moving vehicle;

- Fuel cut-off when closing the throttle valve;

- Smooth switching to idle, which depends not only on the speed of the car, but also on the engine speed.

Speed sensor VAZ 2109 carburetor, injector location, malfunctions

Why do we need a speed sensor on the VAZ-2109? Let's figure it out. This device is responsible for the correct display of data on our speedometer and tachometer. He does this by transmitting electronic impulses to the electrical control unit. But due to long-term operation and significant load on the speed sensor itself of the VAZ-2109 car (more than 6 thousand pulses are transmitted to the control unit per 1 km), an error occurs during data transfer. Then car owners have questions: how to check the speed sensor? How to change it correctly?

First, let's tell you where the speed sensor is located in the VAZ-2109 car.

As on most domestic cars with front-wheel drive, the speed sensor for the VAZ-2109 is located in the gearbox, or more precisely, on the speedometer drive itself. In order to get to it, you need to open the hood and it is recommended to remove the adsorber to make it easier to replace.

How to find out if our device is faulty

We may not always notice problems right away. This can turn into a huge problem - from a fine for speeding to road accidents and accidents.

Let's look at the main symptoms of a malfunction:

- It seems to you that the speedometer does not display the speed of your car correctly.

- Faulty idle.

- Lately you have been experiencing increased gas mileage.

- You can hear from the sound of the engine that it is not working at full power.

If we consider the complaints of car owners, then most often problems arise precisely with stopping the engine when the car is coasting, or during gear changes when the clutch is depressed.

The most common causes of failure of the VAZ-2109 speed sensor.

There are two main causes of malfunction:

- There are problems in the wiring: broken contact, wires, contacts are dirty or not connected correctly.

- Your speedometer cable is very worn.

What should be done in such cases

In the first case, we do not necessarily need to change the speed sensor itself. First, we have to familiarize ourselves with the connection diagram of the device and all the electrical wiring. First, let's check the contacts. They need to be cleaned and it is advisable to insulate them somehow - liquid rubber or oil-water-resistant electrical tape are quite suitable. If you don’t have this on hand, you need to at least lubricate them with Litol or some other product that you have in your garage.

Secondly, if the cause has not yet been eliminated after cleaning and sealing the contacts, we carefully review all the wiring, since even minor damage to them will lead to this type of malfunction. Most often, the rupture occurs near the contacts or near the exhaust manifold.

If the integrity of the entire chain does not give you any doubt, let’s move on to the second, more common reason for the speed to not work on the VAZ-2109 – worn out cable on the speedometer. If you look closely at a worn speedometer cable and a new one, you will undoubtedly see the difference. Wear manifests itself in unevenness on the cable, burrs, and micro-tears visible to the human eye. Due to these irregularities, the device fails quite quickly.

If your speedometer cable is brand new and the contacts are intact, you can check the speedometer sensor by removing it and connecting a special device - a multimeter. Since, as we found out, the sensor transmits pulses, the following values should be displayed on the multimeter: 0.5-10 W. If no fluctuations are detected on the multimeter, you should replace your old speed sensor with a new one.

Changing the speed sensor for VAZ-2109

In order to make a replacement, we will need the following: a new speed sensor (the old one cannot be repaired), as well as keys for “10” and “12”. First we need to disconnect the battery, then the speed sensor.

When dismantling a faulty device, you need to be very careful and carefully remove it from the stem to avoid breaking it. That's it, now we can install a new sensor - we'll do all the steps in reverse order. Carefully place the new sensor on the rod, connect it and at the very end, when all contacts are sealed (it is advisable to do this), connect the battery.

But that is not all. In order for our new sensor to display true results, immediately after its installation it is necessary to reset the electronic on-board computer data. Otherwise, do not expect correct data even if a new sensor is installed. Good luck with your installation, dismantling and long-term operation of your car!

How to remove the speedometer drive with your own hands - instructions

VAZ 2110

- We support the anti-rollback shoes of the rear wheel, then we need to jack up the front of the car, and then install it on supports.

- On a model with a cable-driven speedometer, remove the fastening pin and disconnect the cable from the gear drive.

- Unscrew the fastening bolt and remove it together with the heat shield.

- Remove the drive with the gear from the crankcase and remove it from the seal ring.

- The gear can be removed from the gearbox housing; be sure to check the condition of the gear; if defects are detected, it must be replaced.

- If there are signs of wear or damage to the gear, the condition of the gear should be checked.

- To remove the gear, release it from the transmission. Then you need to unscrew the mounting bolt and remove the drive gear housing. Then you should remove the drive gear and remove all the adjusting washers.

VAZ 2107

- Using a “13” wrench, you need to unscrew the bolt of the clamp securing the exhaust pipe of the muffler.

- Take a 10mm wrench and unscrew the drive fastening nut.

- Using a 13mm wrench, unscrew the two nuts securing the cross member.

- Then you need to lower the rear of the transmission.

- The pipe section must be moved to the right and then the speedometer drive must be removed from the crankcase hole.

VAZ 2114

- We unscrew the DS counterclockwise.

- After removing the DS, check the VAZ 2114 speed sensor drive.

- Using a “10” wrench, unscrew the nut and pull it out.

- After removing the drive, you need to check the condition of the ring and, if necessary, replace it.

https://youtube.com/watch?v=rJC6eudWRLA