Pump diagnostics and repair

The importance of maintaining the fuel pump in a constant working condition is that if it does not work correctly, constant breakdowns of other components of the GAZelle 405 car will begin, and the injector may not work correctly or even fail.

You need to start repairing the fuel pump by determining what exactly the problem is, that is, diagnosing it. The first alarm bell that the fuel pump is not working correctly is that the GAZelle 405 injector moves unevenly, as if in jerks. If this particular symptom appears, then do not be discouraged - repairs are possible on your own. Also, if the GAZelle 405 engine takes a long time to start, and the injector usually always starts with half a turn, this is another bad sign that the fuel pump is starting to fail, although it is still far from complete failure

You need to start repairing the fuel pump by determining what exactly the problem is, that is, diagnosing it. The first alarm bell that the fuel pump is not working properly is that the GAZelle 405 injector moves unevenly, as if in jerks. If this particular symptom appears, then do not be discouraged - repairs are possible on your own. Also, if the GAZelle 405 engine takes a long time to start, and the injector usually always starts with half a turn, this is another bad sign that the fuel pump is starting to fail, although it is still far from complete failure.

You can check the fuel pump using a special indicator, which can be bought at any spare parts store for the GAZelle 405 injector. This device is installed on the gas pump and you can do it yourself, the main thing is to strictly follow the instructions and not make mistakes. The check takes place with the engine turned off; the device itself will do everything. If a significant decrease in pressure in the fuel network was noticed in less than 10 minutes, this means that the fuel pump is working properly, and either the pressure regulator or the injectors of the GAZelle 405 injector are to blame.

Tips for motorists

In the operation of the submersible electric fuel pump on a Gazelle car, the following take part: the main relay, the fuel pump relay, the electronic control unit, and fuses protect this electrical circuit. In addition, if the car has an anti-theft system installed, then another relay will be added to the circuit, which will cut off the voltage supply to the fuel pump terminals.

And those Gazelle cars that run on gas will still start on gasoline and in their electrical circuit of the fuel pump, an additional relay will also be installed that will turn off the operation of the gas pump at the moment the engine switches to gas.

Therefore, when troubleshooting problems associated with a non-working gas pump on a Gazelle, you need to start by checking the integrity of the fuses. You also need to check the condition of the contacts for oxidation. Next, we check the operation of all the relays that are used on this vehicle in the electrical circuit for supplying voltage to the fuel pump terminals. If this does not help, then you will have to check the wiring and connections from the electronic control unit to the main relay and the fuel pump relay.

Another common cause of fuel pump failure is oxidation or burning of the negative contact located on the fuel pump inside the tank. There is a white block there, but please do not confuse it with the block that is located on the surface of the gas tank. Typically, this malfunction initially manifests itself by periodically turning the fuel pump on and off. If this problem occurs, then these contacts will have to be periodically cleaned by removing the module or connected directly once and for all, bypassing the terminal.

Unfortunately, the driver is not always able to independently find faults associated with the failure of the submersible fuel pump on a Gazelle car and has to look for a competent auto electrician to solve this problem.

Posts: 1

January 9, 2013, 15:48 #1 123

Good afternoon everyone. Evening is already approaching, and in the morning I can’t start the gas 3110 d406i yesterday, but today it’s silent when starting (the gas pump doesn’t work), the fuse is intact, the relay contacts were cleaned, they tried connecting directly to the relay socket. The gasoline pump connected to the battery works. What could be the problem?

- Posts: 95

- From: Moscow Region, Chekhov

January 10, 2013, 21:37 #2 123

is there an alarm?

- Posts: 95

- From: Moscow Region, Chekhov

January 10, 2013, 21:39 #3 123

Does the check light come on when you turn on the ignition?

Posts: 1

January 25, 2013, 16:35 #4 123

Hello everyone. I have exactly the same problem. I got home, it won’t start in the morning. There’s no power to fuse 9. I got it from a neighbor, the pump started working, but the alarm won’t start. I called, please help me with advice

Posts: 4

March 31, 2013, 14:03 #5 123+ 2

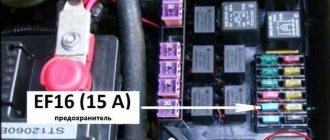

Guys, hello everyone! I have gas 3110 ZMZ 406. There was a problem with the electric fuel pump! The relay works, there is no power, in short, everything is as described above! I figured it out. The thing is this: Neither the alarm system nor anything else like that has anything to do with it! Remove the right fuse block (which contains the fuse for the EBN 15A). Then remove 1 of the 4 small fuse blocks, again the one with the EBN, and carefully look at all the wiring coming out of it, there are 6-7 of them. Review all twists and connections! It’s twisted there, it’s dark, believe me. I had a barely noticeable break in one of them! good luck to all! If anyone wants to discuss anything else about the Volga, write to me by email

- Posts: 10185

- From: Angarsk

- Lada Niva 2131M Nissan Patrol

March 31, 2013, 15:37 #6 123

lubludorogu, March 31, 2013, 14:03, #5

It’s better here so that it’s accessible to everyone. Maybe it will come in handy

Gazelle car fuses

The vehicle's on-board circuit (except the starter circuit) is powered through two fuses.

The lighting circuit is protected by a 40 A fuse, the remaining circuits are 60 A. Both fuses are installed in a block mounted on the bulkhead in the engine compartment.

In addition, each circuit of all electricity consumers is additionally protected by fuses with a lower operating current.

They are located in two blocks under the instrument panel on the driver's side. The rated current of the fuses and the circuits they protect are indicated in the table.

Fuses are numbered from left to right, 8 A - black; 16 A – green.

The starter circuit is designed for short-term high current and does not have a fuse.

When repairing the electrical system, disconnect the battery. Do not use oversized fuses or homemade fuses - this can lead to failure of the electrical consumer and possibly a fire.

Circuits of cars manufactured before 2003, protected by fuses

| Electrical circuits protected by fuses |

| Upper fuse box |

| Fuse no. |

* For buses and cars with two rows of seats. ** Installed on car parts.

GAZ 2705 | Checking the fuel pump relay

Checking the fuel pump relay

The fuel pump activation relay is located in the relay box located in the right rear of the engine compartment. It is used to control the operation of the electric fuel pump. In particular, the relay breaks the pump power circuit if the engine stops with the ignition on.

To turn on the fuel pump when the engine is stopped, you need to remove the relay and close contacts 30 and 87 on the connector with a short wire with a diameter of 1.5 mm. The fuel pump relay is brown on the 520i/525i/524td and orange on the 530i/535i.

Attention: when checking the fuel pump activation relay, the battery must be charged. • Check fuse No. 23

• Check fuse No. 23.

• Remove the relay.

• Connect a voltmeter to pins 30 (*) and 85 (-) on the relay connector. The voltage should be around 12V.

• If this is not the case. connect a voltmeter to pin 30 and ground. If the voltage is about 12 V, check the electrical diagram to see if the brown-green wire is broken. If it is intact, check the red wire and replace if necessary.

• Turn on the ignition. Connect a voltmeter to pin 86 (+) and ground. The reading should be around 12V Otherwise, check the electrical diagram to see if the red/white wire is broken and replace it if necessary.

• Check the presence of a signal at the output of the crankshaft speed/angular position sensor (to do this, contact a service station).

• Connect a short jumper to pins 30 and 87. If the pump starts, replace the relay. Otherwise, check for an open and replace the green-violet wire if necessary.

• If the wire is OK, replace the fuel pump.

Fuel pump relay: device and main faults

The fuel pump relay is not the fuel system component that often fails. Often, problems with this relay are discovered only in a service center, although faults could be easily identified without even leaving the car. We will figure out how this relay works, how the fuel pump relay circuit works, as well as how this device works and why it is needed in general.

Starting from afar

It is not at all surprising for the modern automotive industry to use an ECU - an electronic control unit. This unit is installed under the dashboard in the car interior and performs many functions. The main function is to control the operation of actuators and sensors installed in the vehicle. The ECU also “monitors” the operation of the fuel pump relay.

The heart of the electronic control unit is the microcontroller . We will not understand the features of various controllers, but will only say that the newer the car is, the more complex and advanced microcontroller its ECU is likely to use. However, different microcontrollers have common elements. For example, input/output ports.

As you might guess, they are needed so that the controller can receive and send signals. In datasheets, these ports are designated as the letters A , B, C , and so on. The beauty is that it is the firmware, aka the program, that will determine which of the ports will play the role of incoming and which - outgoing.

The firmware will also determine the operating parameters of the car’s sensors and actuators.

Key functions of the fuel pump relay

So what is a relay for? One of its main tasks is to create something like a buffer cascade between the current consumer in the on-board electrical network and the electronic control unit. The fact is that fuel pumps are equipped with DC motors, and very powerful ones at that.

And a large load cannot be connected to the ECU output. And it is the relay that allows you to create control circuits to which a small current will act. This is clearly applicable to automotive electrical circuits, which include low-current control circuits and power wires to which pumps, optics, etc. are connected.

As for other tasks of the fuel pump relay, there are quite a few of them:

- Lambda probe heating. In some systems, the heating was turned on when the fuel pump was turned on, while on others a separate transistor was installed for similar tasks;

- Fuel pump control. Or rather, putting the pump into operation. So that when the engine is turned on, the pressure in the fuel line immediately increases, the relay turns on the fuel supply pump for just a couple of seconds. Next, the operation of the gas pump is “monitored” by more powerful units;

- Monitoring the operation of the starting nozzle. This is relevant for the operation of a still cold engine. When the engine is “cold” the starting nozzle can work for 8-10 seconds, while on a well-warmed engine the starting nozzle can work for a few fractions of a second;

- On vehicles with automatic transmission: control of the Kick-Down function.

On some cars, the fuel pump relay also performs several other functions. For example, the device can perform the tasks of a crankshaft speed limiter. If the internal combustion engine is too high, the relay starts working to turn off the electric pump . Another interesting feature: the relay turns on immediately when the driver's door is opened. This allows you to create pressure in the fuel supply system in advance, which facilitates the quick start of the power unit.

As you can see, a relay is a small but quite important component that increases the stability of several automotive systems. Relay malfunctions negatively affect the operation of the fuel pump, up to its failure and the inability to start the car. However, it should be noted that the high survivability of this element is due to well-developed circuit design - complete failure of the relay and at the same time the fuel pump is observed quite rarely.

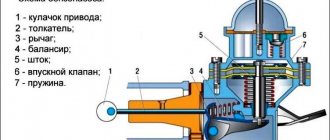

Advantages of the old ZMZ-402 over modern engines

If someone happened to own a UAZ, Volga or Gazelle car from early years of production, he would definitely come across the ZMZ-402 engine or its Ulyanovsk analogues.

Once upon a time in our family there was a UAZ 469 produced in 1976, just the same with a ZMZ-402 engine for 76-80 gasoline, a working volume of 2445 cm3, a power of 76 l / s, with a compression ratio of 6.7 and torque of 160 Nm. Since then I have had the opportunity to drive different cars, including foreign cars. But the further I moved away from the 402, I realized how good it was.

To some, words of praise dedicated to the old engine, and some highlighted advantage over modern engines, may seem stupid, but it depends on how you look at it.

ZMZ-402 was produced from 1968 to 2022, periodically undergoing light modernization. As a result, 6,125,136 of them were produced.

The declared engine life is 250 thousand km before major repairs, but many owners of cars with a similar engine talk about 300 - 400 thousand km. In fact, this engine is eternal, as it has 5 repair sizes of the cylinder-piston group. By the way, the pistons with a diameter of 92 mm are exactly the same as on the V8 Gas-53.

In general, I would like to highlight the main advantages of the 402:

1. Relatively light. This reduces the overall weight of the vehicle and the load on the front axle. Thanks to the fact that the cylinder block and cylinder head are made of aluminum, its weight is only about 170 kg.

2. Very repairable. Due to the fact that the sleeves are removable, major repairs can be carried out right in the yard without any special skills. No special tool needed. Most operations can be performed with ordinary wrenches, with the possible exception of removing the crankshaft hub - you will need a puller.

3. Simple and clear design. Which cannot confuse you in any way. Knowing the general principles of operation of a four-stroke engine, you can easily find the cause of a particular malfunction yourself.

4. Good resource capacity. Especially when comparing modern engines, whose service life is comparable to the 402, they are usually thrown away and bought “contract”.

5. Your timing belt will never break, and therefore your valves will never bend. Because there is simply no belt. The camshaft is driven by a silent textolite gear directly from the crankshaft. The gas distribution mechanism itself is quite reliable. Periodically, only adjustment of the thermal gaps is required.

6. Grassroots motor. At the maximum possible 4400 rpm. the character of the engine is appropriate. The car starts easily at low speeds. Works great at medium speed.

7. Smooth operation in all modes. There is no “diesel” effect, as on the same Kalinas.

The disadvantages include: increased fuel consumption, not very stable idling, poor elasticity, low power and corresponding throttle response. Those cars that had this engine under the hood were quite heavy, so they all had an extremely low power-to-weight ratio. Overtaking and climbing are difficult.

Otherwise, this engine will take you home in any case. Even if on two cylinders, it will never die completely.

Source

Replacing the fuel pump motor

The reason for replacing the fuel pump module motor is low gasoline pressure or sudden changes in pressure, which is recorded by a pressure gauge during the diagnostic process. Also, the imminent failure of the motor is indicated by the fact that the fuel pump is humming or whistling.

In this case, it is often possible not to change the pump assembly, which will save money. The device must be removed (similar to the situation with cleaning or replacing the mesh filter), after which it is disassembled. The motor itself is replaced and can be purchased separately. The housing and fuel level sensor can be left from the old fuel pump. At the same time, it is recommended to replace the gas pump gasket and other rubber seals, which are not designed for re-installation after removal, that is, they are disposable. Do you often face the problem of limiting access to your favorite entertainment? Then you simply must save a link in your browser to the working mirror of the AZINO website so that the best slot machines of our time are available 24/7, regardless of regional restrictions. Play and win real money, as much as you want, whenever you want!

List of internal combustion engine modifications

Five modifications have been developed for the ZMZ 405 engine. The first version, 4052.10, appeared in 2000. The base was the 406 engine. The basis was modified first to meet the environmental requirements of Euro-2, and then to Euro-3 and 4. In 2013, a new engine model with a turbo engine appeared under the designation 4054.10.

Injector

All ZMZ 405 engine models are equipped with an injector. Modifications differ in power, requirements for environmental standards and adaptability to the class of machines:

- 4052.10 is installed on the Volga. The engine power is 152.5 hp, torque is 210 Nm. Meets Euro-2 class. Equipped with Mikas ECU;

- 40522.10 - similar to the basic version, but adapted for installation on GAZelle and Sobol trucks and minibuses;

- 40524.10 has been modified for GAZelles and Sobols for Euro 3 and 4 classes. Engine power is 140.5 hp, torque is 214 Nm. To improve ventilation, the design included valves that maintain a constant vacuum in the crankcase. An electronic gas pedal E-Gas has also been added;

- 40525.10 is installed on Volga of Euro-3 class weighing up to 2.1 tons. Engine power is 143.8 hp, torque is 213.5 Nm;

- 4054.10 is equipped with a petrol turbocharger and air cooler. Engine power is 195 hp, torque is 343 Nm. The cylinder size was reduced to 92 mm, the piston stroke became longer - 94 mm. The engine is installed in special vehicles for military and security services.

Carburetor

Among the ZMZ 405 engine models, carburetors are not found. However, the predecessor, the 406 engine, was carburetor. The prototype for development was the Swedish SAAB engine. The engine was in production from 1997 to 2008.

ZMZ 406 is a gasoline 4-cylinder 16-valve internal combustion engine, built according to the DOHC scheme with two camshafts. Engine capacity - 2.3 liters. Power - 100 hp, torque - 177 Nm. 92 gasoline is suitable as fuel. Despite the weak characteristics, drivers speak positively about the engine.

Resistor

If we talk about the resistor of the Gazelle stove, then it is responsible for the operation of the heater at speeds 1 and 2. For this purpose, a special resistance is provided that reduces the voltage, thereby allowing the electric motor to rotate at a lower speed. Since the last maximum mode has a direct connection, bypassing additional resistance, if the resistor fails, the stove starts working only at maximum speed. At speeds 1 and 2 the heater will not turn on.

Gazelle heater resistor

There is nothing complicated about replacing the heater resistor on a Gazelle. To do this, you will need to perform several sequential procedures:

- Lift the lid of the upper glove compartment located on the dashboard. Everything unnecessary should be removed from there, otherwise things will interfere with the dismantling procedure.

- There are 4 screws under the cover. They are the ones holding the glove compartment. Unscrew them one by one and set them aside for now.

- Since this is a Gazelle 3302 and not a new Business version, access to the electric heater fan, to which the resistor is connected, is much easier. There is another panel missing, due to which half of the torpedo has to be disassembled.

- Removing the upper glove compartment, you will see a plastic housing for the electric fan underneath. It is not necessary to remove it, although getting to the additional resistance block will not be so easy. For this it is worth saying thanks to the GAZ designers.

- Prepare a new resistor immediately. Before replacing the old element, it would be a good idea to make sure that the current resistance unit has failed.

- To the right of the driver on the motor is the required heater resistor.

- Squeeze your hand into the hole near the electric fan and remove the resistor connection chip.

- Disconnect the connector from the old resistor, take a new resistance and connect the chip to it. Now start the stove itself. If it turns on at speeds 1 and 2, the reason was definitely the additional resistance.

- It will not be possible to completely remove the old resistor in this position. You will have to halve the electric fan housing. To do this, you need a long head of 8. Using the tool, unscrew 2 fasteners.

- Now the electric fan housing can be pulled out from its seat.

- On the right side of the fan you will see a resistor that has completely failed, as proven by a recent test.

- Unscrew one screw that holds the additional resistance or speed control.

- Pull out the old resistor, and then install a new one in its place.

- Connect all the chips and assemble the unit in reverse order.

At this point, the replacement of the resistor or speed controller on the Gazelle 3302 can be considered successfully completed.

Resistors and fuses on Gazelle cars can break, burn out and fail. This doesn’t happen very often, but sometimes it’s worth starting the check with these elements. Access to them is relatively simple, plus replacing them will require much less effort and money than removing the same electric fan or dismantling the heater control unit.