After replacing the struts, supports, steering and ball bearings, the knocking noise when driving on rough roads did not disappear. And then the other day I crawled under the car and noticed the damaged silent blocks.

I went online to see how this whole thing is changing and someone on Drive found a post about replacing silent blocks and rubber bands, or popularly known as “Daisies.” After studying the material, I finally decided to change them.

We bought silent blocks, front suspension extension joints (“Daisies”), as well as stabilizer bushings and anti-roll bar struts (popularly “Eggs”).

We drive the car into the pit and fix it. Safety comes first. First, I recommend filling all the bolts and nuts with WD-40 and letting them sit.

Next, we tear off the nuts of the lever, brace and “eggs”. If you can’t unscrew the nut of the extension, you can unscrew the crab and unscrew the extension later, in more convenient conditions. Next, we raise the car, remove the wheel, unscrew the 2 ball bolts, unscrew and remove the “egg”, unscrew the extension nut, the lever bolt and remove the lever.

So, now you need to get rid of the old silent block. There are several options: 1. Burn it with a torch. 2. Drill out. 3. Use a special puller. 4. Be smart.

Since I didn’t have a drill, a torch, or a puller, I chose the 4th point. I cut off one side of the silent block with a knife and knocked it out with a hammer.

Afterwards, it is necessary to clean the seat from rust and dirt, otherwise the new silent block will not be pressed into place.

Here. Now you need to press the new silent block into place. There are also several options here: 1. Use a special puller. 2. Using a vice. 3. Be smart.

Here, too, I chose the 3rd point. Using my ingenuity, I assembled this puller.

Next we look at how to use it in the photo:

Before assembly, lubricate the lever eye and silent block with liquid soap or detergent. You cannot use grease, lithol or oil, because... The rubber is not oil resistant and will quickly become rough and crack. To press the silent block in, use a screwdriver to push the collar into the hole. It may not work out the first time, you will have to suffer.

By tightening the bolt, we press the silent block in and somewhere halfway it will rest against the puller washer. And then the puller was modified:

To put the silent block in place you need to use some kind of thread and tube. The inner ring of the wheel bearing caught my eye (see photo above). It fits just right. We press the silent block in completely, not forgetting to lubricate it with soap.

Now we change the daisies. We knock out the old ones with a chisel. For me they fell apart into 2 parts.

We clean the seat, lubricate it with lithol and hammer new ones into place.

We put the lever in place. We tighten all the bolts, tighten the ball bolts at once.

ATTENTION! IT IS STRICTLY PROHIBITED TO TIGHTEN THE BOLTS WITH THE MACHINE RAISED. OTHERWISE, WHEN LOWERING THE CAR, THE BUSHING BLOCKS MAY TEAR.

We put the wheel on, lower the car and tighten all the bolts. Along the way, we change the stabilizer bushings and install the “eggs”.

After repair, it is recommended to do a wheel alignment.

I think this post will be useful to someone. Thank you for your attention_)).

Today we will talk about how to replace silent blocks on a VAZ 2110.

The suspension is one of the most loaded devices of a car, since it constantly absorbs all the oscillatory movements of the wheel that are transmitted to it from the road surface.

Suspension design features

A feature of the suspension design is that many of its elements should not be rigidly connected, otherwise it will transfer all the vibration to the body.

How does the VAZ 2110 suspension work?

Therefore, some composite suspensions are connected by means of rubber bushings and rubber pads with metal bushings inside, i.e. silent blocks.

So, in the front independent suspension of the VAZ-2110 the following are connected to each other through silent blocks:

- Lower arm;

- Stretching;

- Anti-roll bar.

Each of these elements plays an important role in the suspension design.

The lower arm prevents lateral movement of the wheel, the extension prevents the wheel from moving longitudinally relative to the body, and the anti-roll bar prevents the body from swaying when performing maneuvers or when driving over uneven surfaces.

Read also: Volume of a dump truck body in cubes

But the loads on these elements coming from the wheels are very large, so their displacement, although small, must be provided in order to partially absorb the loads and partially absorb them, and not transfer them to the body.

The possibility of displacement of suspension elements relative to each other and relative to the body, as well as partial damping of vibrations, is provided by silent blocks and rubber bushings.

On the VAZ-2110, silent blocks and bushings are installed in the front suspension:

- Lower arm (two silent blocks - through one it is attached to the body, and through the second a stretcher is connected to it);

- Stretch bar (one silent block through which it is attached to the crossbar);

- Anti-roll bar (it is connected to the lower arm through a strut with two silent blocks, and to the car body through brackets with rubber bushings).

Since the VAZ-2110 has a dependent rear suspension, so many silent blocks are not required, because it is structurally simpler.

At the rear of the entire suspension there are only two silent blocks installed - through which the rear beam is attached to the body brackets.

Why silent blocks fail

When encountering failures of silent blocks for the first time, it is quite difficult to imagine what can happen to these products after long-term use. Over time, the rubber begins to tear, resulting in the need to replace the hinge.

There may be several reasons why a product becomes unusable:

- High mileage of the car, the consequence of which was the drying out of the rubber, loss of its elasticity and the appearance of cracks and tears.

- Contact of chemicals with the rubber of the silent block. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of the rubber.

- Incorrect installation. Fastening the bolts of the levers should only be done after the car is installed on the wheels and not hung on a lift. If tightened incorrectly, the rubber of the silent block becomes strongly twisted, which leads to rapid failure of the product.

Consequences of consumables malfunction

It should be noted that silent blocks and bushings are consumables.

Due to heavy loads, it is possible that the rubber part of the silent block may be pressed through, detached from the metal bushing, and the rubber itself may delaminate. As a result, they are no longer able to work properly.

This results in knocking from the suspension, the appearance of creaks, when driving, especially over uneven surfaces, the car can throw from side to side, and the more wear on the silent blocks, the stronger the tossing will be.

Also, due to worn silent blocks, the angles of the wheel position - camber and toe - change, because of which the car will no longer hold the road, it will begin to drift in any direction, the tires will quickly wear out due to incorrect angles.

So, the condition of all rubber elements of the car suspension must be constantly monitored, and if signs of malfunction appear, they must be promptly replaced.

With certain knowledge and the availability of tools, you can replace silent blocks yourself without contacting a service center.

It should be noted right away that even if damage to one or two silent blocks is detected, it is better to completely replace all rubber parts of the suspension, and not just the damaged ones.

Also, all elements are replaced immediately on the left and right sides of the car.

How to understand when it's time to replace

Before you set out to press in these parts, you should first of all inspect them thoroughly to make sure that they really require replacement. Check for holes and any deformations, for swollen rubber on the hinges and for cracks. Manipulate the components, determining the presence of backlashes. If the permissible norm is exceeded, then replacement of parts is inevitable. It is not recommended to delay the pressing procedure. Over time, this problem will only get worse and can lead to suspension arm failure.

The main indicators that indicate the failure of one part or several:

- Driving the car has become much more difficult.

- When overcoming bumps, the suspension begins to knock loudly. Tires wear unevenly, which has not been observed before.

- It has become much more difficult to adjust wheel alignment.

Tools and accessories

There are not so many tools that will be required to replace all consumables, but some of them are specific.

- Set of keys, heads, knobs;

- A set of new oil seals and bushings;

- Device for pressing out and pressing in silent blocks;

- Puller for ball joint;

- Jack;

- Stops;

- Vise;

- Hammer and wooden spacers;

- Soap solution.

Device for pressing out and pressing in silent blocks.

You can buy it or make it yourself.

The simplest homemade device consists of a long bolt with a nut, pieces of pipe with different diameters and several thick washers.

The principle of operation of such a device is very simple.

To press out the silent block, take a bolt and put a washer on it, the size is slightly smaller than the diameter of the rubber part of the silent block.

The bolt is passed through the bushing of the silent block. On the other hand, a piece of pipe with a diameter equal to the diameter of the seat, for example, a lever, is thrown onto the bolt.

That is, the pipe will have to rest against the circumference of the seat in the lever.

Next, another washer is put on the bolt, its circumference larger than the diameter of the pipe, and then the nut is screwed on.

Pressing out is done like this: the nut, when screwed on, will pull towards itself the washer resting on the silent block.

The installed tube will allow it to come out of the seat and not rest against another washer.

Pressing is done in exactly the same way, with the only difference that it is not necessary to use a piece of pipe, since the silent block will rest against the thrust washer when it sits in place.

You can even press-fit without using a device; it is enough to have only a vice, between the jaws of which a new silent block and lever are installed, so that it and its seat are on the same axis.

Next, the vice compresses and the consumable itself falls into place. But in this way you can install silent blocks only on the lever and stabilizer struts, but on the cross member you will still need a device for replacement.

How to replace silent blocks on a VAZ 2107

Replacing the silent blocks of the front levers on VAZ 2101 - 2107 cars is not an easy task.

However, they still need to be changed from time to time, and most car enthusiasts have learned to do this without much difficulty. A special universal puller will help to significantly simplify this work. It is with its help that both the upper and lower silent blocks are replaced. So, you have come to the conclusion that it is time to replace the silent blocks. You should start by purchasing them. Today there are many domestic and imported products on the auto parts market. They differ from each other in price, quality, and service life. Experts recommend installing polyurethane ones as the most reliable and durable, however, due to the fairly high price, they are not affordable for everyone.

For the replacement process itself, it does not matter at all whether the silent blocks are polyurethane or rubber; they are changed on the VAZ 2107 in exactly the same way. From the tool you will need:

- Silent block remover;

- Ball joint remover;

- Keys for 13, 22, 24;

- Hammer;

- Chisel;

- Mount;

- Penetrating lubricant (eg WD-40).

You should start by hanging the front end on a jack and removing the front wheel. Next, we proceed directly to the replacement procedure. For the upper and lower front arms of the VAZ 2107, the order of work is different, so we will consider both options. To simplify the work, it is recommended to pre-treat all threaded connections of the levers with penetrating lubricant.

Removing front suspension elements

First, we will describe the sequence of actions to restore the front suspension.

It is better to perform all work in an inspection hole, so you need to place the car on it and immediately loosen the front wheel fastenings.

The front of the car is jacked up on both sides. First, they lift one side, install supports under it, and then lift the second side with a jack and also fix it with supports, after which the wheels are removed.

Read also: Is molybdenum magnetic or not?

The first control arm to be removed from the car is the lower control arm. To do this, unscrew the nuts securing the extension, stabilizer strut and ball joint from it.

The lever is removed from the ball joint using a puller.

The last thing to unscrew is the nut securing the lever to the bracket on the body, the bolt is pulled out, and the lever is removed.

Next, the stretch is removed. Since it is already disconnected from the lever, all that remains is to unscrew the nut securing it to the cross member.

The last thing to be removed from the car is the stabilizer.

The stabilizer is attached through the struts to the levers on both sides, so you can either first dismantle it on the other side and start removing the stabilizer, or simply unscrew the nut securing its strut, and dismantle the lever itself and the brace later.

Having disconnected the stabilizer mounts to the arms, to remove it, all that remains is to unscrew the nuts securing the body brackets and remove the stabilizer along with the bushings.

Independent removal and installation of new parts on the upper arm

Work on replacing silent blocks on a VAZ 2107 without a specialized puller begins by placing the car in a room with a flat floor, and placing stops under the rear wheels, lifting it on a jack and removing the front wheel, after which:

- It is necessary to remove the front bumper, which is attached from the inside of the lower skirt of the engine compartment with four bolts. This is done because the bumper will not allow you to remove the upper arm mounting bolt completely, and in this case it will not be possible to change its silent blocks.

- Having removed the bumper, a stop is placed under the lower arm, after which the car is slightly released from the jack, and the nut of the upper arm fastening axis is unscrewed, then the nut on the ball joint is unscrewed and, using a puller, the ball joint is removed from the steering knuckle. Next, by removing the bolt securing the lever, it can be dismantled.

The removed lever is clamped in a vice and the old silent blocks are pressed out of it, replacing which new ones are installed. This can be done either with a specialized puller or with the help of a hammer; the silent block is driven through the spacer with gentle blows into its seat in the lever.

- After installing new parts, the upper arm is mounted in the reverse order. At this point, all work with the upper levers is completed and work begins on the lower ones. The important point here is that the nut on the axial mount of the upper arm is fully tightened only after the car is removed from the jack on all wheels; this is done to avoid excessive twisting of the polyurethane filler in the silent block, which can cause its rapid breakdown.

Replacing consumables, eliminating axial play

Having dismantled the suspension elements, you can begin to press out the worn silent blocks and install new ones.

Using a special device prepared in advance, old silent blocks are removed from the crossbar, levers and racks and new ones are pressed into their place.

To facilitate installation, new consumables can be moistened with soapy water.

But the use of petroleum-based lubricants is not recommended, since they have a negative effect on rubber elements.

Regarding the stabilizer struts, before pressing out, they will need to be knocked off the stabilizer, since they are tightly seated on it.

When knocking down, it is better to use a hammer and strike through a wooden spacer.

Also, after removing the struts, the rubber bushings are pulled off the stabilizer and new ones are installed in their place.

Often a phenomenon called axial play occurs at the lower arm.

It is formed when the body bracket to which the lever is attached, for one reason or another, loosened and a gap appeared between it and the metal bushing of the silent block, which is why the silent block itself was able to move along the fastening bolt.

This axial play negatively affects the performance of the suspension, so it should not exist. But if it appears, then there are two ways to eliminate it.

You can try to compress the bracket. But this is very difficult to do, since it is better not to apply impact with a hammer, even through a spacer, and using clamps or a vice is not very convenient.

It is much easier to get rid of axial play using washers that are placed between the bracket and the silent block.

But according to the manual, it is recommended to replace the entire lower control arm with joints

After replacing all consumables, the removed suspension elements are installed in place.

After replacing all the silent blocks on the front suspension, the vehicle must have its wheel alignment angles adjusted.

How to press in a silent block - execution details

Andrey-45 Blog Replacing Silent Blocks with Your Own Hands on a VAZ-2131 Niva

A silent block (rubber-metal hinge) is two metal bushings with a rubber insert between them. This unit is used to connect suspension parts. Due to the fact that there are elastic inserts (most often polyurethane) between the silent block bushings, these elements dampen vibrations transmitted from one unit to another. For example, a knock in the front suspension may well be caused by a faulty silent blocks, since they bear the heaviest load. Silent blocks must resist the deformation that the car's suspension receives. To figure out which silent blocks are better and how to replace VAZ 2107 silent blocks, it is best to contact specialists. Indeed, replacing such a unit requires appropriate knowledge and qualifications, so if you doubt your own abilities, entrust the repair to professionals.

By the way, there are certain signs by which you can determine the need to replace a given unit. So, if the rear silent blocks of the front levers or the front silent blocks are worn out, the car will pull away at speed. Uneven tire wear may also occur. Although, if such a problem occurs, it may be necessary not only to replace the silent blocks, but also to carry out some repair work related to the suspension. It should be remembered that any intervention in the operation of the car suspension (including if you replaced the silent block of the lever) will require restoration of the toe and camber angles of the wheels. As for purchasing new silent blocks to replace worn ones, today the most popular are fulcrum silent blocks, which are products with polyurethane gaskets.

Replacing the silent block

It is clear that when, say, the rear silent blocks are replaced, the worn parts need to be removed and new ones installed in their place. It seems that there is nothing complicated, but many car enthusiasts are racking their brains over how to press out the silent block, since it may not fit into the lever. However, all this is completely solvable if you choose the right set of tools. So, how to press in a silent block without any problems:

Before starting manipulations, it is necessary to carry out a thorough visual inspection of all structural parts to ensure that they correspond to each other in size; pressing in the silent block at home should be done using a vice. This tool can ensure reliable fastening of the part; the lever must be thoroughly cleaned of all existing contaminants, after which the inner walls of the hole must be generously lubricated with machine oil; the metal outer sleeve must be lubricated in the same way; the lever must be clamped perfectly evenly in a vice, after which it is strictly perpendicular a silent block is installed for him

It is very important to avoid distortions when carrying out this operation, since in this case you will get unstable operation of the entire car, and the polyurethane hinge will not work for a long time in such conditions. The next step is to drive the hinge into the lever, using two short metal pipes for this. One of these pipes must have the same diameter as the outer bushing of the silent block

In order to drive in the hinge, it is necessary to hold the lever with one pipe and place the other directly on the silent block so that when working with a hammer the part is not damaged. By performing such simple manipulations, you can easily press in the silent block and thereby provide your car with suitable conditions for comfortable operation. If, however, any difficulties arise during the installation process, the optimal solution to the problems would be to contact a car service.

Replacing rear suspension silent blocks

Now let's look at how to replace silent blocks on the rear suspension of a VAZ-2110.

Although there are only two of them, replacing them is not very easy, since the rear beam on which they are installed will not be removed from the car.

You won't need a lot of tools:

- A set of keys;

- New silent blocks;

- Device for pressing-pressing;

- Soap solution;

- Hammer and wooden spacer.

The car is placed on a pit and its rear is jacked up. First, replace on one side.

To begin, remove the hand brake cable from the beam. Then the nut securing the beam to the body bracket is unscrewed and the bolt is removed.

The beam is pulled down so that it is possible to reach the silent block.

To fix the beam in this position, a wooden spacer is driven between it and the body.

Next, the worn-out consumable is removed from the beam using a device, and a new element is installed in its place using the same device.

By the way, axial play may also occur in this connection, so it is important to ensure that there is no play after assembly and, if necessary, eliminate it using washers.

Next, the beam is put in place and tightened with a bolt and nut. Replacing the second silent block is done in the same way.

Using these methods, the silent blocks of the suspension of a VAZ-2110 car are replaced.

After the work is completed, the car will regain smooth running.

However, these consumables cannot serve long on our roads, so it is advisable to replace them approximately every 20 thousand km.

For garage handicraftsmen, it is a pleasure to make various devices for repairing automotive components. You can make pullers with your own hands to remove silent blocks, to remove wheel hubs, etc. All you need is desire, materials and time to make.

Read also: Power steering is hard to turn

Independent removal and installation of new parts on the lower arm

Removing the lower silent blocks on a VAZ 2107 begins with the following steps:

- The anti-roll bar mounting bracket is unscrewed and through the upper stud of its mounting, it is moved to the free position.

- The two nuts securing the lower arm axis are unscrewed, after which the ball joint is removed, unscrewing its nut and using a puller or hammer, it is removed from the steering knuckle.

After replacing the silent blocks on a VAZ 2107 with your own hands, the car is completely lowered onto all wheels, and under a standard load on the suspension, all axle nuts are finally tightened. Also watch the video of the work in progress:

What is a silent block

A silent block is a rubber-metal hinge (RMH) - an element that connects two suspension parts, in this case, a car. Consists of metal and rubber. Rubber serves to dampen vibration, smooth movement, and eliminate wear caused by metal-on-metal friction.

Silent blocks or RMS - receive and dampen axial, radial, torsion and cardan vibrations. Withstands radial vibrations up to 300 kN (kilo Newton), that is, up to 300 kg.

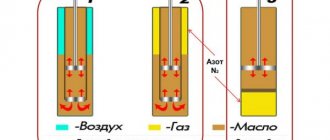

Classification of rubber-metal silent blocks that work in torsion:

- with outer ring;

- from the inside;

- double cage;

- eccentric.

Silent blocks of this type are installed in car suspensions so that the levers and springs can move.

Classification of RMSs that work in compression with bending:

- supports;

- pillows.

Hinges of this type are installed under the engine (mounts, cushions) to dampen vibration oscillations of a running and moving engine. Protects the body from vibrations.

Replacing silent blocks

Depending on the driving style (careful or sporty) and the quality of the roads, the lifespan of silent blocks differs. They can wear out in one summer, or they can last for several years.

Also, the service life of the RMS depends on how they were installed. In the absence of a puller, some people hit them with a hammer. If you plant silent blocks with a hammer, the rubber may be damaged and the metal bushing may move.

The average resource of silent blocks is from 100 to 150 thousand kilometers.

What is a puller for installing silent blocks?

This is what a RMSH puller looks like, which you can make yourself. In order to make it yourself, at home, you will need the following materials and tools:

- Bolt with nut. The diameter and pitch of the thread are at your discretion. If the thread is small, you will have to turn it longer, but it will work easier and smoother.

- We select a cylinder with a diameter such that the silent block fits into it.

- Washers. Some. One washer should tightly cover the cylinder hole. You can even weld the washer on one side. We take the remaining washers with a smaller diameter than the diameter of the silent block.

A RC puller is needed not only for removal, but also for installation, so as not to damage the new silent blocks. And when removing with a puller, there is no need to hit with a hammer and there is no risk of damaging the paws (levers). If you knock out rubber-metal hinges with a hammer, microcracks may appear on the lever.

On cars with 4-link suspension, the wheel alignment angles may be disrupted if the levers or new silent blocks are damaged. In this case, you will have to change the rubber-metal bushings and, possibly, the wheels again.

In terms of cost, pullers for automobile silent blocks can be purchased at prices ranging from 800 rubles to 30,000 rubles (a set of different pullers). But, it is easy to make from improvised means. The principle of operation of a mechanical puller is that when the nut is tightened, the silent block itself is squeezed out of the eye of the lever. Hydraulic ones are more complex in design, they are more powerful, but it is better to buy them when necessary; it is impossible to make them from scrap materials.

Do-it-yourself pressing and pressing of silent blocks: description of work, materials and methods

Everyone who has a car is familiar with the problem when there is a need to press out or press in silent blocks. You don’t always want to turn to specialists, and doing it yourself is much more pleasant.

Thanks to this article, you will learn what silent blocks are, why they are needed, and most importantly, how to press them in and press them out at home using different methods.

This word is of foreign origin. Translated from English, silent means silence, and block means detail.

A silent block, or simply “silent,” is a rubber-metal component; in ordinary words, these are two bushings that are connected to each other by a layer of durable rubber.

This invention, in addition to guaranteeing comfortable and silent movement in a car, has a number of advantages that will be listed below.

Purpose and functions

Silent blocks perform the following functions:

- Protect components from wear and tear by damping vibrations .

- They dampen vibrations that come from the chassis of the wheels, thus providing a comfortable and soft ride.

- Prevent vibrations and beatings that appear during the movement of the car between different elements of the chassis and engine compartment.

And these are just the main advantages; in fact, there are many more.

How to understand when it's time to replace

Before you set out to press in these parts, you should first of all inspect them thoroughly to make sure that they really require replacement. Check for holes and any deformations, for swollen rubber on the hinges and for cracks.

Manipulate the components, determining the presence of backlashes. If the permissible norm is exceeded, then replacement of parts is inevitable. It is not recommended to delay the pressing procedure.

Over time, this problem will only get worse and can lead to suspension arm failure.

The main indicators that indicate the failure of one part or several:

- Driving the car has become much more difficult.

- When overcoming bumps, the suspension begins to knock loudly. Tires wear unevenly, which has not been observed before.

- It has become much more difficult to adjust wheel alignment.

To press this part into place at home, you will need the following tools:

- Mount;

- Jack;

- Set of wrenches;

- New hinges.

It is recommended to use machine oil or other types of lubricant as a lubricant.

Among other things, you will need special mandrels designed for pressing silent blocks; as an alternative, you can use a piece of pipe with the required diameter.

You also need to get a press to press in a new rubber-metal hinge . When it comes to home use, an ordinary vice can serve as a press.

In addition, you can stock up on a set of sledgehammers, but with this approach it is necessary to maintain high precision in the work.

Pressing out at home

Replacing these parts is not as difficult as it might seem at first glance. For example, many car owners made sure of this when they replaced parts, using special equipment for self-replacement. It is for this reason that there are many people who have decided to replace silent blocks with their own hands and at home.

First method

First of all, let's learn about how it should be ideally.

The lever in which the rubber-metal hinge needs to be replaced is installed on a special spacer for the press. The old silent will be squeezed onto this spacer. Then another spacer is installed on top - it squeezes out the old bushing. This method is used by service station workers, since they have the necessary set of spacers and a powerful press of 10-20 tons.

Second method

Almost all car owners, naturally, do not have a powerful press, but many have a jack or a good vice in their garage. If you use a powerful vice, you can successfully squeeze out the old bushings according to the principle that is already familiar to us: a spacer for the original bushing and a spacer for pressing on the bushing.

At first glance, it becomes unclear how you can squeeze out the silent tape with a jack? Everything is very simple: you need to weld a frame in the shape of a rectangle from a channel or corner so that its height is slightly higher than the lever and the jack.

The operating principle is as follows: place the jack in the frame, then install the lever eye on top of the rod, as well as the two spacers mentioned above. We create the required pressure, after which the bushing is squeezed out of its seat.

It must be emphasized that most often a jack with a capacity of 3-5 tons is not able to cope with such work, therefore it is recommended to use 10-ton jacks.

Third method

If you have neither a press nor a jack, but still have a strong desire to replace the silent blocks on your own, you can use the third method - using a simple press puller (bolt with nut or stud).

The principle of operation is to create pressure by gradually tightening the nut on the stud; this method can be called an analogue of a vice.

This pin with a washer of suitable diameter is inserted into the eye through the silent block, then on the other side you should put on a spacer with a washer and tighten the nut.

Rotating along the thread, the nut creates the necessary pressure and forces the silent to be squeezed into a special spacer.

This “method” requires the use of a strong, hardened stud and an equally strong nut. If you take a soft pin or nut, you will most likely fail.

For example, there are cases when, due to strong pressure, the stud becomes bent, as a result of which the thread on the nut breaks. However, there are thousands of those who managed to change silent blocks using this particular method.

After all, everything depends on the quality and strength of the material used.

The advantage of this method is its low cost, as well as its convenience, if you look at it from the “mobility” point of view. In other words, you don’t need, for example, to completely remove the lever or the entire hub; it will be enough to just have a simple press puller like this.

Fourth method

This method can be classified as drastic decisions or extreme measures. Its principle is to use all popular methods and devices to extract silent from the seat. To do this, you need to knock out the old part using a powerful screwdriver or a thick wedge-shaped piece of reinforcement.

You need to try to hammer a screwdriver or something between the silent block and the bushing, thus deforming the wall of the bushing inside. Now that the bushing is crushed and pushed inward, it is not at all difficult to knock it out.

Before you start knocking out the silent block, you need to squeeze out or burn out the inner sleeve of the part and, if possible, all remaining rubber.

Fifth method

The next method of removing a silent block cannot be called pressing out, since it, like the previous one, does not require the presence of a press: all you need is a metal blade, a hammer and a screwdriver. The principle is simple, but unsafe.

We remove the inner sleeve, then take the blade and start cutting the outer sleeve. Try to cut through the old silent as much as possible without damaging the lever itself or the eye.

It is best to make two cuts, and then using a flat screwdriver, the silent block will be easily deformed and knocked out.

If none of the methods listed above helped, and you still need to do it, there is only one option left - to entrust this work to specialists. To achieve the desired result, take the part and go to the service station, where specialists, using a silent block extractor and other special tools, will qualitatively do all the necessary work “in the blink of an eye.”

We have already talked in detail about how to get the “silents”, now another problem arises - how to press this part? This procedure is difficult because it requires certain skills and abilities. An incorrectly or crookedly installed silent will either not work or break prematurely.

How to make a puller

After preparing the above parts, we proceed to assembling the removable device:

- We close one end of the cylinder with one washer, with a hole for the selected bolt.

- We insert the bolt into a cylinder selected in diameter, slightly larger than the diameter of the silent block.

- After putting it on the silent block, tighten the nut.

Procedure for working with the puller:

- Remove the RMS axle. You can completely dismantle the paw and secure it in a vice, or you can press it out directly in its installed form.

- We install the puller cylinder to the silent block.

- Insert the bolt. We take the bolt of such length that you can throw on a couple of washers and tighten the nut.

- We put the washers on the bolt and begin to tighten the nut.

- Gradually the hinge will begin to slip.

If you remove silent blocks without a puller, you must use a wooden strip to avoid damaging the rods.

Video

This video shows how to make a silent block remover and how to work with it.

How to change silent blocks without a puller.

How to change silent blocks on the “classic” VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107.

How to make a puller for VAZ 2113, 2114, 2115.

How to make a puller for removing and installing rubber-metal hinges on Skoda Fabia, Skoda Rapid, VW Polo Sedan cars.

Do-it-yourself silent block remover: subtleties of the process

It is no secret to any driver that every car contains silent blocks, which play an important role - eliminating vibrations in different components.

It is very important to monitor such a part, since it affects the performance of the mechanism in which it is installed. For example, the front and rear suspension of any car simply cannot exist without a silent block.

In this article, we’ll look at how you can make a silent block remover with your own hands, what tools you may need for this, and how to save a lot on repairs.

Classification of rubber-metal silent blocks that work in torsion:

- with outer ring;

- from the inside;

- double cage;

- eccentric.

This video shows how to make a silent block remover and how to work with it.

How to change silent blocks without a puller.

How to change silent blocks on the “classic” VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107.

How to make a puller for VAZ 2113, 2114, 2115.

How to make a puller for removing and installing rubber-metal hinges on Skoda Fabia, Skoda Rapid, VW Polo Sedan cars.

Quite a lot of car enthusiasts are interested in how to make a silent block remover with their own hands. After all, these vibration-reducing suspension elements have to be changed quite often.

Moreover, this applies not only to domestic cars, but also to many foreign cars. The problem is related to the poor quality of roads.

A sporty driving style also negatively affects the technical condition of silent blocks as part of the suspension. Incorrect installation will not extend the service life.

Many mechanics hammer the silent block with a hammer. In this case, the rubber is damaged and the metal bushing may become dislodged. Therefore, always use pullers; as a last resort, there are completely harmless methods to put the part in place without the help of specialized tools. We will talk about this at the end of the article.

How to make a silent block remover with your own hands? Before answering this question, it is advisable to understand what a silent block is. This will make it easier to make a puller.

A silent block is a rubber-metal joint that is capable of dampening vibrations that occur in the suspension.

On passenger cars, a part made in the form of a metal bushing with an elastomer body is more common. The most common option for making a hinge is regular rubber.

But polypropylene hinges can be called the most durable and high-quality. It is recommended to purchase exactly these when replacing.

Licota ATC-2286

The set of silent block pullers is equipped with mandrels and cups of the most popular sizes, which are excellent for working with parts of domestic and foreign production.

Before using the puller, you only need to select a mandrel of the required size, install it on the element to be removed and perform dismantling by rotating the nut. Using the kit, the entire silent block removal process is quick and easy.

Characteristics:

- It is used for both pressing out and pressing in silent blocks.

- Internal mandrels: 34, 36, 38 – 70, 72, 75, 80 mm.

- Outer mandrels: 44, 46, 48 – 80, 82, 85, 90 mm.

- Pins: M10, M12, M14, M16, M18.

- Type: universal puller.

- Weight: 17 kg.

Read also: Welding where to start

Pros:

- It has different attachments, making it suitable for different brands of vehicles.

- All parts are easy to assemble and disassemble.

- Possibility of dismantling and installing silent blocks.

- Convenient case for storing all puller parts.

Minuses:

- Relatively heavy weight.

- High price.

How to press in silent blocks with your own hands?

We have already talked about how to remove the silent blocks, now another problem arises, how to press in the silent blocks? This procedure is complex in that it requires certain skills and abilities. A silent block installed incorrectly or “at awry” will either not work or fail ahead of time.

Method 1

As with pressing out, pressing should ideally be done using a vice. The principle is similar, but exactly the opposite.

Before pressing in the silent block, you need to use sandpaper to clean the seat from rust and remnants of the previous silent block. Then the eye is generously lubricated with soap solution or Litol-type lubricant.

A lever is installed, a silent block is placed on top, after which, through a special mandrel, press pressure is applied to the spacer, which will press the silent block into the seat.

Method 2

When there is no press, you can press in the silent blocks using the above-mentioned vice or jack. The principle is the same as that of the press. A lever, bushing, spacer are placed and, under the influence of a vice or jack, the silent is pressed into the seat.

How to press in a silent block using a vice - video

Method 3

Press puller. If the silent block is small, then you can “put it in place” using the same press puller that was used to press the silent block out of the socket. Again, the principle is the same, only a pin and a thick washer are used as a press.

Method 4

Sledgehammer and brute force. I strongly do not recommend this method for the reason that it is generally considered as purely theoretical, that is, it allows you to press in silent blocks, but it is quite difficult to say what the consequences and quality will be.

The principle is quite simple, we take a lever, put a silent block on it, and then sharply and strongly hit the silent block, causing it to go into the ear of the lever.

The disadvantage is that it is quite difficult to predict the correct movement of the silent block; it can go into the seat awry. It is also possible for the rubber parts to “bite” and damage the silent block or lever itself.

In short, the blow is very difficult to control, and often after such “experiments” you have to go to specialists and redo everything. Therefore, think carefully before using this method.

Method 5

method I know of is to use the weight of the car. The principle is to use the weight of the car, so to speak, for personal gain.

It all looks like this: a hydraulic or screw jack is installed under the car, the wheel is removed, although I think it is already removed if you are changing silent blocks, then a lever with a silent block is installed under the hub, which must be pressed in.

Next, we align everything properly and begin to slowly lower the jack, it is better to have a friend or assistant help you. I think the weight of the car will be enough to press the silent block into the seat.

The disadvantage of this method is that it is inconvenient and somewhat dangerous; in addition, it is quite difficult to control whether the silent block is correctly seated in the seat. However, if you have no other option, then the method is well worthy of your attention.

In principle, that’s it, I don’t know to press out or press in silent blocks If you know any other options worthy of attention, I will be happy to listen to them and publish them.

Share your opinions from what you read and comment, I will be glad to see any constructive criticism. I also remind you that the best way to say thank you to the author of the article is to share this article with your friends on social networks using special social buttons.

networks located just below. Peace and goodness to everyone, see you again at VAZ Repair.