The smooth operation of a vehicle largely depends on the quality of the fuel used.

Any fuel contains impurities to a greater or lesser extent that negatively affect engine performance.

Therefore, it must undergo unconditional multi-stage cleaning.

- 2 Types of fuel filters

- 3 Purpose of fuel filters

- 4 Coarse filters

4.1 Design and principle of operation of the coarse settling filter

- 5.1 Types of fine filters

- 7.1 Cleaning the fuel filter

- 10.1 Video: replacing the fuel filter

Fuel filter device

The fuel filter is responsible for removing impurities from the fuel supplied to the engine cylinders.

It usually comes in the form of a filter paper cartridge.

The basis of the fuel filter is usually a cartridge with filter paper

The fuel filter cannot be restored or repaired, but is replaced at certain intervals.

The filter housing with inlet and outlet fittings is made of heat-resistant material.

High-quality ten-micron paper is used as filter material.

The fuel filter design is quite simple.

Modern cars usually have two fuel filters:

- Coarse filter (FGO), which retains impurity particles larger than 0.1 mm.

- Fine filter (FFO) that retains particles smaller than 0.1 mm.

Two-stage cleaning provides reliable protection of the engine from the ingress of fuel with impurities into it.

Purchasing a new item

When choosing this element, be sure to pay attention to the following parameters:

- filtration level. If it is insufficient and large particles nevertheless penetrate into the system along with the fuel, this will very quickly lead to engine failure;

- the area of the filtration element, as well as the presence of a rubber seal that covers the entrance to the filter itself. If there is none, this part will be very problematic to replace.

Depending on the fuel system, fine filters are divided into:

- carburetor, permissible degree of purification is 15-20 microns (smaller particles will pass into this system, but will not harm the fuel delivery system to the engine);

- injection, finer degree of purification, 5-10 microns (in such systems, the requirements for the maximum size of permissible contamination are higher, i.e. the injector can become clogged with larger particles, so the holes in the filter are smaller);

- diesel engines are capable of retaining not only very small solid particles (less than 5 microns), but also removing moisture, and this is very important for a diesel engine.

When purchasing, it is important to tell the seller the make and year of your car in order to choose the right filter. For the most part, if there is no product specifically for your case, then you can choose something interchangeable. But there are cases where this is not possible, so check your vehicle's manual for this information.

Purpose of fuel filters

Modern cars are extremely sensitive to fuel quality. The fuel sold at gas stations already contains foreign impurities.

In addition, water, rust from the walls of steel tanks, dust and dirt from the refueling nozzle get into gasoline or diesel fuel.

Modern cars are sensitive to fuel quality

In injection systems, mechanical impurities in the fuel can cause premature wear and, as a result, failure of the injectors and fuel pump.

The filter removes condensation and contaminants before fuel enters the system, thereby preventing unpleasant consequences.

Moreover, the combustion efficiency of purified fuel is noticeably higher. As a result, engine power increases.

As a result of untimely replacement or failure of the fuel filter:

- there are problems starting the engine;

- blockages form in the fuel lines;

- individual elements of the injection system wear out;

- the carburetor becomes clogged;

- fuel consumption increases.

Is a filter really necessary? What does it affect?

First of all, the purity of gasoline is important for the injectors of an injection engine: their thinnest holes become clogged with deposits of paraffins, sulfur, dust, dirt and other “goodies.” This is followed by deterioration in engine performance (after all, the required amount of fuel does not enter the cylinder and is not dissipated properly), loss of power, “triple”, when an injector in one of the cylinders fails, and after that - expensive repairs. For systems with a fuel injection pump (high pressure fuel pump), cleaning is carried out before fuel enters the pump: the fine fitting of the parts does not withstand foreign impurities. Buying a new pump also costs a considerable amount.

Clogged injectors

If we compare the quality of European and Ukrainian fuel, the latter will be far from winning: the purity of our gasoline is such that the service life of good imported filters is exhausted almost 2 times faster than the manufacturer expected. Impurities in gasoline appear both at the manufacturing stage (manganese to increase the octane number, sulfur and paraffins due to insufficient purification) and at the transportation stage (dust, dirt). The level of the plant itself will also be an important factor: gasoline purification is a delicate matter and requires modern, expensive equipment. You can evaluate the quality of the fuel yourself by disassembling the old filter after replacing it, as many car owners like to do. All the dirt that has collected in the filter could end up on the pistons, injectors and engine walls.

But, be that as it may, fuel filters are installed on absolutely all cars all over the world: no matter how clean the gasoline is, additional protection will not hurt. We have a good filter - not a precaution, but a vital necessity.

Coarse filters

FGOs trap only large particles of impurities in fuel. They are usually made in the form of a metal (brass) mesh, which can be removed, washed and returned to its place.

In carburetor systems, several coarse meshes with cells of different sizes are used.

- A mesh with large cells is installed on the neck of the gas tank.

- A mesh with smaller cells is installed on the fuel intake.

- The inlet fitting is equipped with a mesh with the smallest cells.

Coarse filters are made of brass mesh

In the case of an injection engine, the FGO with a mesh is built into the fuel pump of the gas tank.

Diesel units are usually equipped with a sediment filter. This, however, does not exclude the use of grids.

The diesel fuel coarse filter has a number of advantages over screens, reliably protecting the engine from condensate drops getting into it.

Diesel FGO is not disposable. It can be washed and reinstalled.

Design and principle of operation of the coarse settling filter

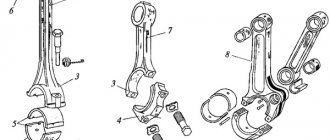

The settling filter consists of the following elements:

- housing with lid;

- a filter element made of aluminum plates 0.15 mm thick with protrusions of 0.05 mm - located on a sleeve in a glass attached to the body;

- threaded bushing screwed into the body;

- distributor pressed by bushing;

- sealing paronite gasket between the glass and the body;

- damper located in the lower part of the body.

Diesel engines are usually equipped with a sediment filter

The settling filter works according to the following scheme:

- Through holes in the distributor, diesel fuel enters the filter.

- The fuel moves lower into the damper - large particles of mechanical impurities and condensate remain here.

- Then the fuel goes up to the mesh of the filter part, on which small particles of impurities remain.

- Fuel enters the engine through the fuel outlet.

Design and principle of operation

A diesel fuel filter, like its “brothers,” performs one main function – filtering the fuel entering the engine and fuel system. According to the principle of organizing fuel purification, all diesel cars are quite similar. The general principle of this procedure is as follows:

- The fuel enters the tank, where some of the large impurities remain at the bottom as sediment, and the other is filtered using a special coarse mesh located at the outlet (less often, at the inlet) of the gas tank.

- Then the fuel is sent through fuel lines further along the highway, after which it enters a coarse filter, which filters the fuel from moisture and impurities of at least 0.5-1 mm in size.

- After undergoing coarse cleaning, the diesel enters the fine filtration filter, which, in turn, brings the fuel to the cleanest possible state, clearing it of a number of small impurities. How clean the fuel will be when approaching the engine is determined based on the size of the filter element cells. On a diesel engine, it is measured in microns and, as a rule, is as small as possible in order to ensure high-quality fuel purification.

On different car models with diesel equipment, fuel filters have different designs and work arrangements. The most popular types of fuel filters are the units arranged:

- or as a single piece, that is, both the fine filter element and the coarse filter element are combined into one module;

- or two different units, that is, a fine and coarse filter - separate parts from each other;

- or as an integral part of other elements of the fuel system of a diesel car (fuel pump, fuel level sensor, etc.).

It is worth noting that, regardless of the method of organization, the fuel filter for a diesel engine has a significant difference from similar parts on gasoline engines. It consists in the fact that diesel fuel filters have a special container in which all filtered moisture condenses and requires periodic cleaning by the car owner. This feature is largely due to the fact that diesel fuel contains much more moisture than gasoline, so the moisture content in it is quite high and, if it gets into the fuel distribution mechanisms or even the engine, it can cause irreversible damage. In addition to a container for collecting moisture, special heating elements are often installed in the diesel filter, which in cold weather protect the filter element from freezing due to the considerable amount of moisture contained in it.

We recommend: Selecting and changing the fog lamp bulbs yourself

Important! Excessive moisture in a diesel fuel filter can cause engine detonation, so if signals appear on the dashboard or you personally detect a large amount of moisture in a special container, it must be eliminated immediately.

Fine filters

The main purpose of the FTO is to clean fuel from small foreign particles that were not caught by the coarse filter.

Its design is practically no different from the FGO, and the mesh consists of smaller cells.

Types of fine filters

There are non-separable (disposable) and collapsible (reusable) fine filters.

The former are made of fabric or paper that is folded into a spiral or star shape to form a filter curtain.

The spiral shape provides better cleaning due to the increased surface of the filter material by 1.8 times - the contact of the fuel with the filter becomes longer.

Non-removable filters last quite a long time

Non-removable filters are usually installed on the fuel line section in front of the fuel pump.

There is no pressure in this place, and the likelihood of leakage is reduced.

The basis of the dismountable FTO device is a brass or ceramic mesh filter element.

These filters can be removed, washed and cleaned.

The most convenient are filters with a transparent body, as they allow you to visually assess the degree of contamination of the filter material.

The transparent housing allows you to visually assess the degree of filter contamination

Choice

The correct strategy for choosing a fuel filter is to follow the recommendations of the car manufacturers. They are designed taking into account the needs of the engine. You should not experiment by installing an unsuitable filter just because it is cheap.

Some motorists try to compensate for poor cleaning quality by frequently replacing the fuel cell. This is the wrong approach. The main task of the filter is to prevent foreign particles larger than a certain size from entering the fuel equipment and cylinders. Filtration fineness is one of the characteristics that does not change during operation. Neither old nor new element, which is not able to retain small particles, will protect the engine from breakdown.

Filtration fineness is one of the filter characteristics that does not change during operation.

Filters with similar parameters are produced by different companies. Well-known brands Mann, Knecht (Mahle), Bosch, UFI, Delphi and others occupy a leading position in the market, as they produce high-quality products that car manufacturers install on new cars. To select a suitable filter, use online catalogs. Choose only those models whose description contains a direct recommendation for your car.

Bosch filters are some of the cheapest among well-known brands Mann offers the widest range of filters for various purposes Delphi is one of the few companies that has mastered the production of filters for Common Rail diesel engines Knecht-Mahle is a prestigious German brand The Italian company UFI supplies filters to the Volkswagen assembly line

We recommend: How to make a heated steering wheel with your own hands?

Fuel filter location

The location of the FTO depends on the type of transport and the characteristics of its fuel system.

In any case, it will definitely be located between the gas tank and the engine.

The FTO can be located under the bottom or under the hood of the car. There are options for installing it in the gas tank together with a coarse filter and a fuel pump.

Cleaning of large contaminants must occur before fuel enters the fuel system.

Therefore, the FGO is most often located in the gas tank. Sometimes it can be located under the bottom of the car in the engine compartment.

In this case, the fine filter will be installed between the carburetor and the fuel pump.

The installation location of fuel filters depends on the fuel supply system.

- In carburetor systems, coarse fuel cleaning is carried out in the gas tank. In this case, the FTO is located directly in front of the carburetor. It is usually built into the fuel supply line to the fuel pump. It is easy to recognize by its transparent body.

- In injection engines, the FGO is located under the bottom of the vehicle, and the FGO is usually located in or near the gas tank. If it is not near the tank, and the fuel line comes from the tank under the hood, then the filter is definitely located in the gas tank.

- In diesel engines, the fuel filter has impressive dimensions. It is installed between the engine and the fuel pump. You can find it through the fuel lines - the pump inlet pipe is always directed away from the filter. The location of the FGO depends on the car model, and the fine filter is always installed near the injection pump and injectors.

You can find the fuel filter by looking at the fuel lines

Mesh filters are always installed in standard places, and they are quite easy to find.

In any case, the sediment filter will be located near the gas tank. It can be easily found by the pipes coming from the tank.

Subtlety of elimination

Screening fineness is an indicator of the number (as a percentage) of particles of a certain size that the filter retains.

The level distinguishes between average, nominal and absolute screening fineness with specification of particle size.

- Medium means that the filter captures 50% of particles of a certain size;

- Nominal – screening out 95% of particles;

- Absolute – complete screening, the filter retains 100% of particles.

In the characteristics of the filter, this indicator is indicated as follows: “Nominal screening fineness 15 microns,” and this means that the filter retains up to 95% of particles up to 15 microns in size.

Modern filters are developed in accordance with strict environmental standards, and their nominal screening fineness can be 6 microns, 4 microns or less. Such filtration is important primarily for diesel engines, which are more sensitive to fuel purity, and at the same time more hazardous to the environment than gasoline engines. The better the fuel purification, the less harmful emissions.

Procedure for replacing the fuel filter

Timely replacement or cleaning of fuel filters is necessary for all types of engines.

- In the case of a gasoline carburetor engine, the need to clean the fuel is dictated by the fact that the fuel channels in the carburetor are often clogged due to low-quality fuel. Moreover, individual carburetor elements may be damaged or destroyed due to the abrasive properties of impurities.

- Injection systems are even more demanding on the quality of fuel, since it is supplied to the cylinders in small doses under high pressure. Fuel is supplied using injectors consisting of high-precision elements (precision pairs). Mechanical impurities in the fuel can damage the surface of these elements, and the injector will fail.

- Diesel units place even higher demands on fuel purification. Here, precision pairs are installed not only in the injectors, but also in the pump, which can also fail.

Manufacturers claim that the diesel fuel purifier or its filter part needs to be changed at least once every 30 thousand km.

The fuel filter completely loses its original properties after 30,000 km.

The frequency of replacing the fuel filter is determined by:

- car model;

- operating conditions;

- the quality of the filter itself.

All fuel filters can be divided into two groups:

- submersible, located in the housing of the pump immersed in the gas tank,

- main, located on the fuel line between the tank and the power unit.

By type of fastener there are:

- fuel filters that can be removed by hand;

- filters installed by the manufacturer on specific fasteners (to dismantle you have to buy a special tool or contact a service station);

- filters replaceable using a standard set of tools.

To replace the fuel filter yourself, you will need the following tools:

- standard set of wrenches;

- screwdrivers;

- protective gloves;

- container for draining fuel from the filter;

- pump or compressor.

The fuel filter is replaced in accordance with the following algorithm.

- The non-separable FTO on a carburetor engine is secured with clamps in the fuel line. To replace it, loosen the clamps, replace the filter with a new one and secure it.

- In the case of injection systems, access to the FGO (and sometimes to the FTO) is possible through a hatch in the tank. The fine filter, located outside the tank, is changed after loosening the gas line clamps. To do this you should:

- remove the rear seat;

- open the hatch;

- remove the fastening nut;

- disconnect the hoses;

- remove the fuel pump power connector;

- disassemble the fuel system housing.

- The most difficult thing to replace is fuel filters on a diesel engine. If a sediment filter is built-in, it is first disconnected from the power system. Then it is disassembled using wrenches, and the fuel is poured into a previously prepared container. The filter is washed and blown with compressed air, and the filter material (if any) is replaced with a new one.

The collapsible FTO is changed in the same way as the filter element of the coarse filter, and the non-separable filter is removed and replaced with a new one.

Most often, it is impossible to visually assess whether a filter needs to be replaced - usually the filter elements are not visible.

The exception is some models for carburetor engines.

The main symptoms of a dirty fuel filter are as follows.

- The engine stalls periodically.

- The engine stalls when the speed decreases.

- The car has a hard time picking up speed, especially on an incline.

- The engine is difficult to start in the morning.

- Fuel consumption increases.

- The motor power gradually decreases.

- When you press the accelerator pedal, the car moves jerkily.

After replacing the filter, you should once again check the reliability of all connections and tighten if necessary.

There should be no leaks or holes where the filters connect to the fuel lines.

Cleaning the fuel filter

Cleaning is possible only for dismountable types of fuel filters. In general, the procedure for washing is as follows.

- The filter is removed and wiped with a dry cloth.

- The cover securing bolts are unscrewed and the cover is removed.

- The filter element is pulled out.

- The inside of the case is wiped with a dry, lint-free cloth.

- The filter and plug are washed with acetone and blown with compressed air.

- A new sealing ring is put on the filter.

- The filter is put in place and connected to the fuel lines.

- Gasoline is poured to the edges of the filter.

- The lid is screwed on.

- The plug closes.

It is necessary to clean or completely replace the fuel purifier in gasoline cars every 60–100 thousand km.

On carburetor engines, coarse filters are serviced as follows.

- The mesh is pulled out of the fuel neck.

- If the mesh is clogged with dirt, it is washed in gasoline and blown with a stream of compressed air.

- The fuel intake comes from the gas tank.

- The mesh removed from the fuel intake is cleaned in the same way as the mesh from the fuel neck.

- The carburetor inlet fitting is unscrewed.

- The mesh from the carburetor inlet fitting is washed and blown.

After cleaning and installing the filters in place, you should start the engine and let it idle for about a minute.

After this, it is necessary to inspect the filter connections for fuel leaks.

What will happen when driving with an old filter?

If clogged, the filter will lose its ability to perform its main function - to clean the fuel, so the fuel mixture injection nozzles and the entire power system will become clogged, and the required amount of normal fuel will not flow into the engine itself.

Fuel that has not undergone proper cleaning will burn out not evenly, but in fragments, and will begin to settle on the pistons, cylindrical partitions, and spark plugs. A fuel mixture containing heavy metals and other particles, as a result of combustion products entering the exhaust system through accelerators and a lambda probe, will begin to gradually reduce the service life of all these elements.

It cannot be said that a clogged filter directly affects fuel consumption. However, the increase in fuel consumption, which is observed in this case, will lead to a decrease in power. As a result, for normal use of the vehicle you will have to press the gas harder, which, in fact, requires more gasoline or diesel. Therefore, a clogged filter for the fuel mixture, without directly affecting gasoline consumption, leads to an increase in this parameter.

Thus, it is necessary to constantly monitor the condition of the fuel filter and, if signs of clogging appear, immediately replace the spare part, since its further use is guaranteed to lead to serious problems with engine operation, the solution of which requires significant material costs.

It should also be noted that the process of replacing the cleaning element itself is not at all difficult; if you have the appropriate skills, you can do everything yourself. You can also always seek help from professionals who will do everything quickly and efficiently.

Features of diesel fuel filters

The main task of diesel fuel purification is to prevent condensation from entering the engine.

In most cases, water is separated from the fuel by a separator filter.

The diesel fuel filter must heat the fuel and protect the engine from condensation.

In addition, the properties of diesel fuel change with decreasing temperature.

Therefore, the filter must be adapted to the cold. This problem is solved by adding a heating system to the filter (for example, a curtain can be paper, capable of conducting current).

This way, the optimal temperature of the mixture of cold fuel from the tank and heated fuel from the filter is maintained.

Some models of fuel filters for diesel engines have a system for separating condensate and sensors that indicate the water content in the fuel.

Review – original or analogue

New MAHLE filter

The auto parts market offers fuel filters for Toyota cars from various manufacturers. Original spare parts bearing the brand of the automaker can be produced by factories specializing in the production of automobile parts. Non-original spare parts are produced by approved companies in agreement with the auto company. Before being released for sale, replacement parts undergo mandatory certification, but they are not an exact copy of the original and may have their own “secrets.” The cost of such spare parts is much lower.

The following manufacturers offer high-quality fuel filters:

- Denso is the official manufacturer of original fuel filters and most spare parts for Toyota vehicles. A high degree of filtration and the elimination of various types of contaminants in fuel to protect the engine is achieved due to the honeycomb structure of the filter fiber. The cost of the original “consumables”, depending on the car model, is 2000-3500 rubles.

- Fram is a global manufacturer of unique fuel filters. Diesel options are capable of capturing up to 95% of particles up to 5 microns in size. For 100% protection, they are equipped with an electric heater and a water level control sensor. You can buy a Fram fuel filter for about 860 rubles.

- Mann offers multi-layer filter elements that perform as well as the original ones. The combination of different materials allows you to choose the best option in terms of service life, degree of filtration and ability to retain moisture. The issue price is 1200 rubles.

- Knecht (Mahle Filter) produces high quality filters, but the company pays special attention to the environmental safety of its products. The cost is 600-900 rubles.

- Sacura is a Japanese supplier. Consumables are tested for compliance with the declared characteristics - performance, service life, pressure drops. You can buy a consumable item for 450 rubles.

- Alco Filter is a German company (with its main production in Cyprus). A fuel filter for Toyota can be purchased for 480 rubles.

- Bosch offers diesel filters assembled and with the ability to replace filter parts. They are able to effectively remove water from fuel and collect it in special storage tanks. The price is 450 rubles.

A fuel filter may differ in thread, filter material, its flow capacity, and the ability to operate under a certain pressure. Regardless of the manufacturer (original or analogue), the selected “consumables” must be designed for a specific car model.

Quality criteria for fuel filters

Cheap, low-quality fuel filters are not able to protect engine parts that come into contact with fuel from premature wear and rust.

The reasons for this are as follows:

- the filter material may tear during operation;

- such filters quickly become clogged and do not allow fuel to pass through;

- cheap filters have low absorption capacity;

- poor-quality filter material will not be able to retain small particles of impurities.

The filter element of a high-quality filter will not tear, and impurities in the fuel will not damage the injectors.

Replacement according to deadline or need

The service life of the filter element directly depends on the fuel used, the quality of which is far from ideal. The actual interval for using a consumable element may differ significantly from the manufacturer's regulations, which recommend replacing the fuel filter every 60-80 thousand kilometers.

Contamination occurs gradually, so a decrease in its efficiency and a possible threat to the fuel system may not be immediately detected. When the filter throughput decreases, the pressure in the fuel system does not have time to restore, resulting in poor atomization of a small amount of fuel and incomplete combustion of the poor-quality mixture. Some peculiarities of “behavior” appear in the operation of the car, by which a malfunction or clogging of the fuel filter can be determined:

- jerky movement;

- “sluggish” acceleration;

- reduction in engine power (in the absence of other reasons);

- increase in fuel consumption.

Regular checking and timely replacement of the fuel filter will avoid clogging of the fuel system and prevent rapid wear of engine parts.