At the end of the 70s of the last century, the classic Zhiguli family of the Volga Automobile Plant reached the peak of its popularity, and despite the fact that such cars were still inaccessible to the bulk of the population of the USSR, they had already become familiar. Moreover, the concept of a “classic” (both design and constructive) began to gradually become outdated, so the concern decided to develop a fundamentally new car that would be a breakthrough. Thus, the project of a car with front-wheel drive and a defiant appearance was born, which would receive a real embodiment and become known as the “Eight”.

The history of the VAZ 2108 begins in January 1978 - it was then that the presentation of the future Soviet compact took place in Togliatti. However, already at the stage of the premiere of the pre-production model of the model, disputes arose regarding the imminent launch of the car into production.

The reason for the dispute was that the Eight, launched into series, could compete in the same niche with another Soviet car - Moskvich-2141, which the AZLK management did not want at all. Therefore, the serial production of Lada 2108 was postponed until 1984. It is worth noting that the decree on the launch of the compact into production was signed by L.I. himself. Brezhnev, who was partial to the products of the Volga Automobile Plant.

At the time it went on sale, the Lada Sputnik (later this name would be replaced by “Samara”) was a technological breakthrough, but not everyone aroused positive emotions.

Some criticized the front-wheel drive (mostly due to the inability to drive it), while others were very skeptical about the design of the new product - the deliberately angular shapes caused bewilderment. However, in fairness, in terms of appearance, it kept up with the times and could compete with foreign opponents.

Brief overview of the Soviet automobile industry in the post-war period

The Great Patriotic War dealt a strong blow to the economy of the Soviet Union, because after a hard-won victory the country was on the verge of famine, and industry worked for the army. By the mid-50s, the situation improved, the famine subsided, economic recovery began, including the construction of new automobile factories, because the country needed transport. At first, the emphasis was on trucks, and passenger cars were produced in minimal quantities, sufficient to cover the needs of government agencies.

By the mid-60s, the Council of Ministers and the Central Committee of the CPSU decided to create an automobile plant, the products of which would be competitive on the world market, but there was no own project for a passenger car that met these requirements. Therefore, the USSR entered into an agreement with the Italian company Fiat, according to which it not only built a car plant, but also helped in the development of a passenger car, the basis of which was the popular Fiat-124 model. Together with the Italians, Russian (Soviet) designers made hundreds of changes to the basic car to adapt it to the conditions of the USSR.

This is how the legendary “Kopeyka” appeared (this was the name given to the VAZ 2101), which became the ancestor of the VAZ classics, that is, the “Zhiguli” family (VAZ 2101–2107). Cars with a classic layout were equipped with rear-wheel drive, because it was much simpler to implement, and therefore cheaper. But, since the mid-70s, when engineers and technologists managed to finalize the front suspension design called the “MacPherson Strut” or “Swinging Candle,” the global auto industry switched to front-wheel drive. By this time, the new models of the classic series could no longer compete even with budget foreign cars, because at a comparable price they showed worse handling.

Since the early 70s, when the tendency of the global automobile industry to switch to front-wheel drive became clear, VAZ engineers, at their own peril and risk, tried to develop their own car of this type, but things did not go further than creating a prototype. The shift occurred in 1978, when VAZ designers showed a prototype to the government commission. The new car with an unusual appearance impressed officials and leaders of the country, so they approved the technical specifications for such a vehicle. After this, the development ceased to be a private initiative, becoming a state strategy for the development of the domestic automobile industry.

But in the USSR there was no design school for front-wheel drive passenger cars, and the old developments with which they created the legendary Lada Niva SUV were not suitable for a city car. However, in 1979, comprehensive testing of the first prototype of the Eight began, which within 5 years would become the dream car for the residents of the USSR.

VAZ 2108

Chassis

On the VAZ-2108, the front wheels were not only steered, but also driven. It was possible to organize this thanks to the use of front independent suspension. The main component of the front suspension of the VAZ-2108 are MacPherson struts, which, in addition to their main function, also served as steering knuckles. They consisted of a housing, a shock absorber and a spring, assembled into a single structure. The racks were attached to the body with levers at the bottom and supports at the top. The left and right struts were united by a stabilizer bar.

Related link:

Replacing a CV joint on a VAZ-2108 car

At the rear, a torsion bar suspension was used, the design of which included a beam with mounting brackets, a shock absorber and a spring.

The steering of this car is of the rack-and-pinion type with tie rods for connection to the steering knuckles. No power steering was provided. The brake system was dual-circuit, with diagonal position of the circuits, hydraulic drive and vacuum booster. Disc brakes were installed on the front wheels, and drum brakes were installed on the rear wheels. The hand brake is a mechanical type with a cable drive and acts on the rear mechanisms.

This design of the VAZ-2108 chassis is quite successful and was used not only on models of the Sputnik family, but also on all subsequent VAZ vehicles.

Birth of "Chisel"

The design of a front-wheel drive car was very different from a rear-wheel drive one, so the new Lada from the Zhiguli received a minimum of parts, everything else had to be developed from scratch. After all, even the classic engine did not meet the new requirements, and no one knew how to make it more modern; there were no appropriate design schools in the USSR, so we had to turn again to foreign engineers and technologists. In addition, it was necessary to reduce the empty weight of the car as much as possible, because the lighter it is, the lower the production costs and the lower the fuel consumption.

This time the choice fell on UTS, which is a subsidiary of the USSR's long-time partner, the Italian company Fiat and the German company Porsche, which created tanks during the war, and after its end produced modern passenger cars. Foreign and Soviet designers created the G8 from scratch, because it inherited almost nothing from the classic Zhiguli. But, to produce such a machine, components and assemblies were required that USSR factories did not produce, which is why it was necessary to look for suppliers abroad.

The entire process of giving birth to a new car took less than six years, but considering that the Chisel was created from scratch, it is incredibly fast. Even in the 21st century, the process of creating a new concept car from scratch takes 6-10 years, and even during the Soviet Union, with a sluggish planned economy, such a speed of appearance of a light small-class car of a new concept was akin to a miracle.

To create what would in the future be called the “VAZ 2108”, licenses were purchased for various components and assemblies, from rack and pinion steering to the carburetor and suspension. This was a forced but inevitable step, because a car with parts from obsolete Zhiguli cars would not have received recognition on the world market, and such recognition was the goal of the entire project. Therefore, the choice fell on those companies that at that time were leaders in their industry.

The history of the legend: how the famous “eight” was created

The decision to write an article about the VAZ-2108 did not come immediately. What to write about a car that almost everyone seems to know about! For all its shortcomings, the G8 was a revolutionary machine for the USSR. And the point here was not even about the newfangled front-wheel drive or aerodynamic design, the philosophy of the car itself was different. For the first time, a Soviet person was allowed to have a three-door car of a non-trivial design with a sporty character. And how much scope for tuning the Samara family gave its owners in the nineties! Everything changed - from the headlights to the exhaust system. Having appeared back in 1984, this car seems to have no intention of leaving the city streets. “Samara” changed its status from a prestigious Soviet car to the first car of a Russian student, but did not lose its relevance. Today we will talk about, perhaps, the most beloved and hated, the most spectacular and the most controversial, but without a doubt, the most scandalous production car of the USSR - VAZ 21083 “Sputnik/Samara”...

In the previous review, we talked about the development of the first Soviet “front-wheel drive” at ZAZ. However, as you know, Tavria was able to enter the market only in the late eighties, when Samara was already traveling in full force along the country’s roads. The creation of a new model of a passenger car in Tolyatti was officially announced by the Minister of Automotive Industry V.N. Polyakov in his speech at the XXVI Congress of the CPSU in February 1981. He said that in the eleventh five-year plan, VAZ would create a car with front drive wheels, not related in design and technology to the classic Zhiguli cars produced.

It must be said that, despite the beginning of the spread of front-wheel drive throughout the world, Soviet automakers were very skeptical about it at first. Debates arose at both technical and technological levels. Will Soviet industry even be able to master, for example, constant velocity joints, necessary for the production of a car of this class? It was also obvious that the promising family needed a fundamentally new body; the classic family was rapidly becoming outdated, even when modernized to version 05/05/07. By the way, below are the search models of the VAZ 2101 modernization, created by the factory designer V. Pashko. Pay attention to the spectacular American styling of these samples - we will see many of the solutions used here in Samar modifications.

By the way, the name Samara was originally intended for the Western market; for the domestic market the name Sputnik was invented, but it “didn’t work”, and soon all the cars of the family received “Samara” nameplates on the back door. Because the machine was revolutionary in many ways, it was decided to involve Western partners in its creation. Negotiations were held with several companies, but ultimately the German Porsche was chosen as the main partner.

This is how the chief designer of VAZ in 1975 – 1996 describes the decision to cooperate. Georgy Konstantinovich Mirzoev in the book “The Flame of High Thought”:

In 1975, President E. Fuhrmann met with V. Polyakov, then already the Minister of the Automotive Industry of the USSR. And in the conversation he noted that the German state caused a lot of trouble to the Soviet Union by starting the Second World War, and that this must be compensated in some way. As a result, an agreement was born between VAZ and under the auspices of the State Committee for Science and Technology (SCST) of the USSR. The work was designed for three years - from 1976 to 1978, at 500 thousand Deutschmarks per year. During this period, the following were developed and manufactured: a version of the Niva car with aluminum attachment parts; engine running on lean gasoline mixtures; running layout of the modernization of the VAZ-2103 car in interior and exterior. For two and a half years, a group of our specialists was constantly at Porsche, regularly updated, which allowed engine engineers, bodybuilders, and designers to “get smart.” When choosing a technology consultant, our technologists had a clear opinion: to use FIAT, since they had a better understanding of VAZ technology, equipment, and layouts than we did. But, since FIAT itself refused to cooperate with us on front-wheel drive, it offered its subsidiary UTS, specializing in technological developments.

So, as we see, VAZ itself, the German Porsche and the Italian UTS worked on the creation and development of the Samara, but there were also dozens of enterprises that supplied components throughout Europe! We can say that the project was global, but the stakes were high. VAZ's last conquest in Europe at that time was the completely revolutionary Niva, which sold more than 500 thousand copies worldwide. Perhaps these are not very large numbers for the giants of the automotive industry, but for one single Soviet model, this was a true achievement, and the new model should not have “lost its face.” It should be noted right away that, unlike the “stuffing,” Western experts had nothing to do with the design of Sputnik. The image was born gradually, and at the stage of sketch development, the style of the front part even resembled the American Pontiacs of those years.

The 1978 sample and the team of its creators.

Pay attention to the door handles recessed into the sides - this decision was later abandoned. There was even a legend that a certain Russian emigrant from Porsche gave our engineers a handle from the 924 model. However, such legends are not without foundation. In addition to the obvious advantages that cooperation with the global engineering giant provided, our bureaucratic system often “failed” and gave rise to unpleasant precedents.

Tester Konstantin Kukushkin recalls:

The sparks of good decisions (no worse than branded ones) were quickly extinguished by our bureaucratic machine. The company offered us solutions, we had to evaluate them within a certain period of time and issue a conclusion on their suitability in our conditions. We usually did not meet the required deadlines, but in order not to lose face and not show our inability to work quickly, these proposals were approved in advance. Later, when it became clear that what was proposed was unacceptable to us, we had to look for a new solution. The company readily offered another option - just pay. When fine-tuning the body, during testing, we came up with good solutions, sometimes even better than those offered by the company. But our bureaucracy completely rejected them. Contract! So that my statements do not seem unfounded to anyone, I will give two specific examples from personal experience. Thus, the side door design proposed by the company did not want to fit into the norm. V. Filimonov and I struggled with the sagging of the door for a long time, reworking several options. The result of the search was a door that meets all standards, and at the same time is 200 g lighter. Relevant reports and “forgangs” were written about this. But we were still forced to “torment” the design developed by the company. When it was finally completely rejected, the company offered a new one - ours, made by us a year ago, polishing it and refining the inner panel. The door was accepted as an offer from the company! A similar situation occurred with the battery pad. During a frontal impact, the battery did not want to stay on the platform (or the platform did not want to hold the battery). I made a platform that was 100 g lighter than the German one and easier to manufacture. She passed the test, but was not accepted. She was sent to a Porsche. She passed the test there too. The company representative, Mr. Getzer, when testing my site, said: “Gut.” But branded is better. The company's site was accepted - it was calmer. What happened, happened. You can't erase a word from a song.

There were also funny situations. Porsche specialists suggested putting the appropriate inscription on those parts to which they had a hand. However, the Soviet side refused. The magazines wrote: ... “With the participation of German specialists.” Any European manufacturer would be honored to have Porsche nameplates on the parts of their car, but “the Soviets have their own pride”...

It must be said that for the domestic automotive industry the project developed at an incredibly fast pace. If in 1975 a fundamental decision was made to cooperate, then already in 1978 the first model was built, and in 1984 the car went into mass production. Interestingly, there was an incident with this first sample. The car was assembled exactly on December 31, 1978, but it was not possible to start the engine then. However, already on January 2, 1979, the designers began testing again. The car was developed according to the accepted German system. The project was given the name “Gamma”, and each new sample was given a series with two zeros - 100, 200 and 300. The first number of the series reflected the readiness of a particular sample for mass production. It should be taken into account that the coordination of three engineering sites: Tolyatti, Stuttgart and Turin was carried out without the use of modern data transmission technologies. Seconded specialists from different companies were constantly “cruising” between the three cities. One of the first front-wheel drive VAZ cars, Ladoga project.

Search sketches and the VAZ 2101 restyling project allow us to judge the overall high level of design at VAZ in those years.

Plasticine model of VAZ 2108

Plasticine model of a VAZ 2109. Noteworthy are the door handles a la Moskvich 2141 and the huge rear window

At the same time, in addition to developing the car itself and putting it into production, there were still a lot of organizational problems to be solved in relation to suppliers. As we know, the problem of high-quality Russian components at the plant has not yet been resolved, and then it was necessary to literally knock on the thresholds of departments and factories in order to persuade enterprises to produce this or that type of product of the appropriate quality and the required configuration. Below is one illustrative example.

Technologist A. Zevakin recalls:

There were many difficulties with the production of glazing for new VAZ-2108 cars at the Bor Glass Factory. The windshield and tailgate glass were accepted for production without any major objections. But the development of sliding glass doors and sidewall windows met strong resistance from glaziers. Of course, there were plenty of technological difficulties. Cylindrical (concave) glass is a new thing for them, but at first they didn’t even want to try anything. And this is understandable - why do they need an extra headache? And only thanks to the intervention of G. Mirzoev, who managed to come to an agreement with their Moscow Main Command, the plant agreed to produce a test batch of glass. The work was headed by the chief engineer of the glass factory, A. Zhimalov, and deputy chief technologist, V. Tarbeev. The UGK sent me. Everyone together inspected and selected furnaces and presses, onto which we then installed our stamps, having previously wrapped them in fiberglass. The fact is that the stamps were made of wood, and they had to work in contact with hot glass. Many plant specialists came to the first pressing. Later I understood all the difficulties that glass specialists foresaw. Out of 60 processed blanks, only 11 usable glasses were obtained - 7 right and 4 left. The rest are fights or marriages based on fit. But only two shifts were spent on preparation, not counting the fact that the entire module was stopped for our needs. Then there were many trips to the glass factory with V. Unzhakov, Yu. Shevelev, V. Kuznetsov, D. Khusainov - to fine-tune the working equipment and manufacture glazing. Each such trip, although difficult, made it possible to ensure the assembly of prototypes in a timely manner.

There were such problems with literally everything! Rubber seals for glass, shock-absorbing bumpers made of glass-filled polyurethane - everything was given “with a fight.” Soviet industry in many areas reached a new level of production with the G8, but this level was very difficult...

By the way, initially, the family was supposed to include models with two body types (three- and five-door hatchback) and three engines of 1.1, 1.3 and 1.5 liters, but later the need to develop a sedan became clear, which stretched right up to 1990 ...

Competing cars. Seat Rondo (1982-1986)

Scoda Favorit (1987-1995) - an analogue of the “nine” even in appearance

Finally, in 1984, a pilot batch of cars was produced. Of course, the Za Rulem magazine could not help but note such a significant event and dedicated several of its issues to the G8. A detailed article about the new car appears in two New Year's magazines:

“Actually, the VAZ 2108 is not just a new car, but the first model of a family of cars that is fundamentally new in design. When its technical specifications were approved in 1978, preference was given to a layout with front driving wheels...” “As comprehensive tests and operation in different climatic and road conditions have shown, the VAZ 2108 not only differs sharply in its consumer qualities from other common us cars. It is not inferior to the best foreign analogues of its class. The machine is well adapted for use in our country and in these conditions, we can safely say, it is superior to foreign models.”

In 1989, “Behind the Wheel,” “with some abbreviations,” cites a test from the English magazine “Car,” which tested the Ford Escort and the G8.

Here you can read the original test in decent resolution. And here is a test from the Motor magazine from the page diecast43

Since the VAZ 2108 was not only a car for the domestic market, but also for the external one, it required a serious advertising campaign. To promote the new model, the all-powerful Autoexport used the most advanced technologies - advertising in automobile publications, the creation of videos and, of course, the formation of a sporty image of the brand. This is worth dwelling on in more detail.

French advertising of Samara

Advertising photo by V. Khetagurov

Funny French commercial Based on the G8, several truly unique racing cars were developed, including rally cars for intra-Union competitions with a classic layout and real mid-engine monsters: Lada Eva, Lada Samara T3, VAZ 2108 Rally 4x4.

The first such car was the VAZ 2108-Rally, created in the accelerated testing bureau of the Office of the Chief Designer of VAZ. Basically, it had a converted “eight” body, in the center of which a 150-horsepower 16-valve engine was installed, driving the rear wheels. Later, an all-wheel drive modification of the VAZ-2108-RALLI 4x4 was created, and in 1987 a heavy-duty Eva was built in Vilnius.

VAZ 2108 Rally 4X4

Here I tried to portray a “collective” image of rally Ladas of that time. Of course, they were not yellow, but had “advertising” colors. “Chandeliers” on the bumper were hung as needed.

Development of the VAZ 29081. According to the project, the car was supposed to have a three-hundred-horsepower engine

In fairness, it is worth noting that the Lada Eva only had doors, a windshield and head optics left from the G8 - the rest of the body, made of fiberglass, was of the original design. By the way, the aerodynamics of the car were improved by specialists from the Prenai Experimental Plant DOSAAF sports aviation.

Even the engine used was different - a block from a VAZ-2106 with a volume increased to 1860 cubic centimeters, with a sixteen-valve block head, Lucas distributed fuel injection and turbocharging, producing 300 hp. Moreover, the internal combustion engine was located not in the front, but in the rear (behind the seats), and drove the rear wheels. The chassis also underwent significant changes - the front and rear double wishbone suspensions were supported by tubular subframes attached to the central part of the body. Eyewitnesses claim that in terms of dynamics and handling, the prototype was in no way inferior to the then queen of rallying, the Lancia Stratos.

But the creation of sports cars based on the VAZ-2108 has not stopped, because in addition to Group B rally there are other competitions - for example, the famous Paris-Dakar. Unfortunately, in the early 1990s, in the seemingly indestructible Union, some friction was already emerging and the Vilnius Experimental Plant (the new name of the VFTS) did not undertake the preparation of the G8 for the Dakar, and therefore the company took up the development of the cars POSH is a distributor of LADA cars in France. On the LADA SAMARA T3, even less of the VAZ remained - even the engine was no longer Soviet, but... a German boxer Porsche with a volume of 3.6 liters, developing power up to 400 hp! Plus an all-wheel drive transmission from the Porsche 959, a suspension designed by the Tupolev Design Bureau based on the suspension used in fighter aircraft chassis and a body consisting of a space frame-frame and ultra-light cladding made of composites... LADA SAMARA T3 took seventh place in the Paris-Dakar rally in 1990 year, fifth in 1991. In addition, second place in the Tunis Rally in 1990 and first place in the Pharaoh Rally in Africa a year later.

Rally Lada

Lada Eva

You can see a large number of photographs of Eva here

Lada Samara T3

Full-scale production of the VAZ 2108 began in 1985, in 1987 the “nine” was released, and only in 1990 – the “ninety-nine”. In the same year, VAZ “front-wheel drive” vehicles lost their famous terrible “beak” in the design of the front end and received so-called “long” front fenders and a calmer radiator grille. Also in the early nineties, the “low” dashboard was replaced by a “high”, more refined one, from the VAZ 21099 model.

One of the options for designing the front end of a VAZ 21099. An analogy immediately arises with the restyling project for a penny in the seventies. The name on the front end does not contradict the truth. Before the advent of the “tens” project, this name was assigned to a sedan.

In 1990, at the Brussels Motor Show, the permanent dealer of Soviet cars in Europe, Scaldia-Volga, presented a stylish Lada Natasha convertible prepared for small-scale production. In Brussels, and later in Bratislava and Prague, small production facilities are opened, where new cars are produced in small batches. The bulk of them are exported to France and Spain, where these machines enjoyed enormous success.

Lada Natasha

Lada Carlota

Experimental Lada with original targa body

Another concept car, this time with a coupe body. She also didn’t make it into the series.

At the auto show, in addition to the aforementioned Lada Natasha, the company also presented a restyled version of the G8 Lada Carlota and a “charged” Lada Samara RSI, created in the VAZ sports car department. The plastic body kit was manufactured by the German company Pichler, and the tuning company Mangoletti adapted the “racing” injection system to the forced 1600 cc engine, providing two options - 100 and 130 hp. With the first “Miss Russia” Masha Kalinina as the hostess of the Scaldia Volga stand, AvtoVAZ products gained unprecedented popularity abroad. After the success of Scaldia, Volga and other exporters of VAZ cars begin to develop restyled versions of the “chisel”. For example, the Norwegian, following the example of Lada Carlota, produces the Lada Konelia model. She equipped her Ladas with alternative optics. By the way, take a closer look at the design of the front end and compare it with Pashko’s early sketches. Doesn't remind you of anything?

However, time did not stand still, and if the 1978 G8 model in the photograph still looks very modern, then by the early nineties, AvtoVAZ’s advanced model began to become obsolete, losing export markets.

If in 1988 AVTOVAZ supplied 306,641 cars abroad, then in 2008 106,562 units were exported. However, this statistics is “from the evil one”, because up to 80% of supplies come from the countries of the former USSR, which, for obvious reasons, were not previously considered export markets.

Attempt to resume export. Lada Baltic. One of the examples of a very successful and laconic restyling

In 2004, the Lada-113 replaced the VAZ 2108 in production. This ended the official history of the first mass-produced Soviet passenger car, but its road history did not end. Thousands of eights continue to run around the cities and towns of our country, some are completely “killed”, some are in excellent condition. No matter how much they scold him, the “chisel” continues to enjoy popularity and love among novice car enthusiasts and experienced tuners, and even rally drivers. However, the moment will come when the “eights” will take their rightful places in automobile museums and people will look at them with undisguised affection - after all, this was a good page in the history of our automobile industry...

By following this link, you can see the G8's competitors in the 1993 rally.

During testing on cobblestones, the rear suspension fell off. Early eighties. instead of the front end there is a camouflage lining

Another camouflaged prototype. Testers recalled that drivers sometimes looked at the monster with such interest that they flew into a ditch

The famous “beak” and a plastic mask, which later had to be abandoned. The process of adjusting the plastic turned out to be too labor-intensive

Why does the Eight look the way it does?

Since the appearance of the VAZ-2108, debates have not subsided about which model its appearance was taken from, because the Eight car looks similar to such popular contemporary models as:

- Volkswagen Golf II.

- Fiat Ritmo.

- Opel Cadett.

- Ford Escort.

- Renault 14.

Fiat Ritmo

The reason for this similarity lies in the features of the hatchback body, which differs:

- strongly sloping back;

- a single space, that is, the trunk is separated from the passenger compartment only by a seat and a decorative shelf;

- slightly sloping front.

The first car with such a body was the Renault 16, which appeared back in 1964 and since then the popularity of the “hatchback” has only increased. However, world fame came to him only with the advent of the Volkswagen Golf, which marked the beginning of a separate class of cars, to which the Eight belongs. It was the Golf that managed to become the second people's car, taking the palm from the Volkswagen Käfer (Volkswagen Beetle) and showing noticeably higher sales.

Soviet designers took the idea of a hatchback body, as well as interesting, technologically appropriate interior elements, then created the image of a car that, a few years later, would be given the nickname “Chisel.” Indeed, in appearance, the “Eight” really resembles a chisel - a pointed nose, a powerful middle and a heel beveled from hammer blows. In addition, by this time the three-door hatchback was no longer something new; many manufacturers used this body type. Therefore, contrary to rumors, the appearance of the VAZ-2108 was not bought or stolen from other models, it was a domestic development, an adaptation of the world's best solutions.

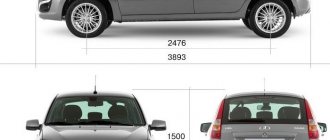

Weight and dimensions

Finally, about the load-bearing part. The Eight had a three-door hatchback body. Afterwards, the 5-door hatchback VAZ-2109 and the sedan VAZ-21099 were released on its basis.

The dimensions of the VAZ-2108 were: length - 4.006 m, width -1.75 (including one side mirror), height - 1.402 m. Ground clearance - 170 mm.

The curb weight of the car is 920 kg, and when fully loaded, the Eight weighs more - 1370 kg.

Despite the fact that the model has not been produced for a long time, it still remains popular and is in demand. Moreover, this car is an excellent field for experiments to improve its appearance and technical characteristics.

Design and technical characteristics

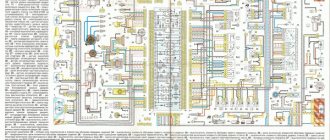

The “Eight” is equipped with an all-metal monocoque body without a frame, equipped with reinforcements and stiffening ribs. The front suspension is MacPherson type, the rear is semi-independent, with an elastic beam. This combination ensures low production costs and high steering quality, as well as good stability on any road. Front-wheel drive also increases stability and, to some extent, improves handling on all types of road surfaces.

The steering is rack and pinion, without amplifiers, thanks to a well-chosen gear ratio, a balance is maintained between the force that must be applied to turn the wheel and feedback, that is, the transfer of force from the wheels to the steering wheel. The ignition is contactless, transistorized, and in the first years Russian (Soviet) switch units caused a lot of criticism due to unreliable base elements, the power transistor often failed.

Front brakes are disc, rear drum. The abandonment of front drum brakes increased the handling of the Eight, making it safer. The engine was initially carburetor, with a displacement of 1.1–1.5 liters and a power of 54–70 hp, and models with a 1.1 liter VAZ 21081 engine were mainly exported to countries where the amount of transport tax directly depended on the volume and power of the power unit.

The VAZ 2108 engine with a volume of 1.3 liters, due to insufficient power, quickly lost the palm to the power unit 21083 with a volume of 1.5 liters and a power of 70 hp. This motor was installed before the transition to injection engines, that is, until the mid-90s of the twentieth century. At the same time, any power unit was installed transversely, which distinguished the Chisel from any classic car in which the engine was mounted longitudinally.

Eight

All engines of this family are designed the same, therefore they differ only in the diameter and stroke of the piston. The camshaft is mounted on top, the timing drive is belt driven, and instead of archaic rocker arms, cylindrical valve tappets with adjusting washers are installed. This design has been preserved to this day and has been adopted by all engines produced by AvtoVAZ. The only exception is one of the engines received from the Renault concern, which became the owner of the Russian auto giant.

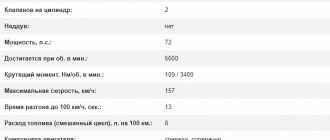

Here are the main technical characteristics of the G8:

three-door body, “hatchback” type;

- empty/curb weight 915/940 kg;

- length 4004 mm;

- body width 1650 mm;

- ground clearance 160 mm;

- load capacity 425 kg.

At the time of its appearance (1984), such characteristics were quite at the level of budget foreign cars.

Transmission

Next, let's look at the technical characteristics of the VAZ-2108 transmission. This car used a three-shaft type gearbox (4 or 5-speed) and with a differential installed in the crankcase. It was controlled by a lever installed in the cabin. But since both the power plant and the gearbox were located transversely, gear shifting was carried out not directly (as in classic models), but through remote traction. The amount of oil in the VAZ-2108 gearbox was: 4-speed version - 3.0 liters, 5- fast - 3.3 liters. Transmission oil was poured into the VAZ-2108 gearbox. The clutch was single-plate, dry type and cable driven.

New transmission

Despite the differential installed in the crankcase, the dimensions of the VAZ-2108 gearbox were smaller than those of the classic versions.

Related link:

Description and installation of the “Lunfey” heater on a VAZ

Both types of gearbox were installed only on the 1.3-liter version. The 1.1-liter engine was not equipped with a 5-speed gearbox, and all 1.5-liter modifications were not equipped with a 4-speed gearbox.

It is noteworthy that the characteristics of both boxes are identical, and the difference comes down only to the presence/absence of 5th speed.

The gear ratios of the VAZ-2108 gearbox of both versions up to 5th gear are the same, and they are all shown in the table:

| Gear ratios of the VAZ-2108 gearbox | |

| Speed | Meaning |

| 1st | 3,636 |

| 2nd | 1,95 |

| 3rd | 1,357 |

| 4th | 0,941 |

| 5th | 0,784 |

| Rear | 3,53 |

The drive from the box to the drive wheels was carried out using two drive shafts, each of which in its design had two ball-type equal angular velocity joints.

Next is the dynamic and speed characteristics of the VAZ-2108 car with different technical equipment. Naturally, the weakest according to these data is the 1.1-liter version. Its maximum speed is only 140 km/h, and it accelerates to 100 km/h in 22 seconds. Its average gasoline consumption is 7.9 liters.

The speed characteristics of the VAZ-2108 with a 1.3-liter unit and both versions of the gearbox have a maximum of 148 km/h, and this version reaches 100 km/h in 19 seconds. But the presence of 5th speed affects gas mileage. The version with a 4-speed gearbox consumes an average of 8.2 liters, and the presence of an additional speed made it possible to reduce this figure to 7.8 liters.

The 1.5-liter version of the V8 with a different power system and 5-speed gearbox has almost identical performance. The maximum speed of these modifications is 156 km/h, but the dynamic performance and fuel consumption vary slightly. The carburetor version accelerates to 100 km/h in 15 seconds, while the injection version does it 0.5 seconds faster.

As for consumption, the carburetor consumes 8.0 liters on average, and the injector consumes 7.7 liters.

"Lada", "Sputnik" or "Samara"

Cars of the classic series for the domestic market were produced under the name “Zhiguli”, and for a new car a new, loud and modern name was required. At the same time, all cars that were exported were under the Lada brand. Workers and plant management offered various options, including Sputnik. However, the choice of name was a political issue, so the decision on it was made at the highest level. As a result, the names “Lada Sputnik” for the domestic market and Lada Samara (“Lada Samara”) for the foreign market were approved.

However, both names did not catch on among the people, unlike the classic series, the full name of which was transformed into “Bug” and “Zhigulyachka”, and each model was called, depending on the number, “Kopeyka”, “Dvoyka”, “Seven”. But the most popular was 2106, which was called “Six” and “Shokha”.

The same story happened with the VAZ 2108. The name “Lada Sputnik” never entered into colloquial speech, and “Lada Samara” quickly gave way to “Eight” and “Zubil”. These names were familiar even to those who did not have similar cars, but “Lada Sputnik” and “Lada Samara” caused surprise and misunderstanding until the advent of the next generations of the legendary “Eight”, that is, the “Tenth” and “Thirteenth” series .

What do users think about the car?

"Eight", for the most part, has positive reviews from its owners. The domestic compact has earned popularity due to its interesting design and high maneuverability. However, the body of the model is prone to corrosion.

There is one unpleasant fact - at first the car was produced with a gearbox that did not have a reverse gear lock.

And, since the reverse gear is located next to the first gear, often when switching from second gear to first, owners missed the mark and engaged reverse gear, which ultimately led to transmission malfunctions.

Do-it-yourself tuning is very common among car enthusiasts. It is worth noting that the Lada 2108 has some potential in this area, which is what craftsmen take advantage of. The main improvements concern the engine. The craftsmen achieve an increase in its power potential and torque by installing a lightweight connecting rod and piston group, different camshafts, and a new carburetor. An example of tuning can be easily found on the Internet by reading articles on the relevant topic or watching a video.

Further development

Already by the start of production, the Eight turned out to be morally outdated and 10 years behind promising models of the same class, and there was no money in the budget for a full-fledged rework. And the very next year the infamous “Perestroika” began and the financial situation in the country only became worse. Along with the worsening economic situation in the USSR, sales of the Eight in the domestic and foreign markets fell, so the first restyling was carried out in the early 90s.

The short front wings and “beak” were replaced with wings of normal length, which is why the pre-restyling version was called “short-winged”, and the next one “long-winged”. In addition, the conventional instrument panel, called “low”, was replaced with a higher and more comfortable one.

In the mid-90s, AvtoVAZ (as VAZ was called after becoming a joint stock company) stopped producing “Eights” with a carburetor engine and began equipping them with injection engines. The new engines were almost no different from the old ones, the only difference was in the air-fuel mixture preparation and ignition systems.

Discontinuation and legacy

In 2004, the obsolete G8, like the entire Samara-1 family, was discontinued, and their place was taken by more modern 2110–2115. Thus ended the story of the legendary car, which left behind a great legacy and gained many fans and opponents. For its time, the Chisel was very worthy, but the global auto industry moved forward, creating more and more comfortable and technologically advanced passenger cars. But few models can boast of the same fame and popularity in their own country.

The legacy of the Eight was the emergence of new families, up to the modern Lada Granta and Lada Vesta, which retained the general concept of the Chisel, but became noticeably more comfortable and technologically advanced. Therefore, even now the “Eight” car looks recognizable and causes nostalgia and joy in some, and irritation and hatred in others, because the tendency to break down is its integral feature.