Causes and symptoms of malfunction

The appearance of air jams is a common problem for experienced car enthusiasts, which they often encounter. But before you remove air from the cooling system, it is still advisable to know the cause of the malfunction.

There are several of them:

- Errors when adding coolant or replacing it.

- Suction at the junction of pipes.

Similar problems in 90% of cases occur in winter, when the fittings decrease in size under the influence of low temperatures.

As a result, microcracks or other types of damage appear, through which excess air leaks;

- Atmospheric valve defect;

- pump depressurization;

- the appearance of leaks in radiators (cooling or heating);

- damage to the gasket under the cylinder head (white smoke appears from the exhaust pipe, oil leakage from under the cylinder head becomes noticeable);

- thermostat failure;

- mechanical defects or clogging of radiators (pipes connecting them).

The presence of an air lock in the cooling system can be easily diagnosed; the engine takes a long time to warm up or, conversely, does not reach the required temperature at all.

It's easy to explain. Due to strong airiness, antifreeze (antifreeze) cannot normally enter the cooling radiator. As a result, the engine temperature constantly increases.

The consequences can be catastrophic, especially in winter. The heater (stove) does not work. In this case, the coolant no longer enters the heater radiator and, as a result, it does not warm up.

In any of the above cases, it may be necessary to remove air from the cooling system. But how to do it right?

Improvement of the heating system

The design of the VAZ 2107 stove is far from perfect. Therefore, car owners modify it in a variety of ways. First of all, attempts are being made to improve the tightness of air ducts, especially at joints. This allows you to slightly increase the efficiency of heating the interior.

VAZ 2107 owners modify the heating system in a variety of ways

Fan replacement

Often, to improve the operation of the stove, car enthusiasts replace their original fan with a more powerful one, used in other VAZ models (for example, VAZ 2108). The factory fan motor is mounted on plastic bushings, which wear out quickly. As a result, shaft play appears, and a whistling noise becomes audible in the cabin when the fan is operating. Repair and lubrication of bushings in this case, as a rule, do not bring the expected effect. The VAZ 2108 fan electric motor is mounted on bearings. Therefore, installing it in the VAZ 2107 stove will not only increase the efficiency of heating the interior, but will also make the operation of the fan more reliable.

Usually, along with the fan electric motor, a number of other elements of the stove control unit are also changed . The rotation speed of the VAZ 2107 factory fan at a current of 4.5A is 3000 rpm. The VAZ 2108 electric motor consumes 14A at a frequency of 4100 rpm. Therefore, when replacing, you should install the appropriate fuse, resistor (usually from a Niva) and speed switch (for example, from a Kalina).

Video: modification of the VAZ 2107 stove

To dismantle the fan you will need:

- flat and Phillips screwdrivers;

- keys for 7 and 10;

- round nose pliers.

The fan is removed in the following order.

- The instrument panel, shelf and glove box are dismantled.

- Use a 7 key to loosen the casing of the air damper control cable. The cable loop is removed from the lever.

- Use a 10mm wrench to unscrew the nut securing the heater housing.

- Use a flat screwdriver to remove the left and right air ducts from the heater body.

- Use a flat-head screwdriver to remove the latches that secure the fan to the stove.

- The wire terminals are disconnected.

- The fan is removed from the stove body.

- The impeller is removed. If necessary, use pliers.

The size of the new fan (from VAZ 2108) is slightly larger. Therefore, its installation will require some changes in the design of the stove. If only the motor is changed, it will be necessary to make an additional hole in the grille through which warm air enters the lower part of the cabin. If this is not done, the motor housing will rest against the grille.

Replacing the stove body

When installing a fan from a VAZ 2108, you will need to make a new frame, usually from plexiglass. This is quite labor-intensive and will require certain skills.

The material for a homemade frame when modifying the stove can be plexiglass

When making a new frame, all dimensions must be strictly observed. The slightest inaccuracies can lead to vibration or failure of the new fan. Having assembled the structure, you should lubricate the joints with sealant and install the new housing in place. After this, the noise level in the cabin usually decreases, and the stove begins to heat the air better.

The air intake should ALWAYS be from the street, especially in winter, otherwise the windows will sweat (and freeze in winter). Air intake from the cabin is done only when the air conditioning is turned on (in the seven this issue does not arise). The fact that one “sleeve” is not blowing is possible: a) when tampering with the stove, the sleeve did not fit into the right place and the stove is blowing somewhere under the panel, b) some kind of crap got into the nozzle (foam rubber or something like that ).

Anakin

https://forums.drom.ru/russian/t1151720023.html

When making a new frame for the motor, all dimensions must be strictly observed.

Other stove tuning options

Sometimes the design of the air ducts is modified. Additional holes are made in the stove body into which plumbing hoses are inserted. Through these hoses, connected to the side and bottom air ducts, when the engine is running, an additional flow of warm air is created onto the windows and into the legs.

Often the cause of poor interior heating is a clogged heater radiator. The coolant begins to circulate more slowly or completely stops circulating through the heating system, and the efficiency of air heating decreases noticeably. Usually in these cases the radiator is replaced with a new one.

A clogged heater radiator leads to a decrease in the efficiency of heating the interior.

Three methods for removing air from the cooling system

Let's look at the main and most effective ways to solve the problem.

Method number 1 . Proceed in the following sequence:

Remove the plastic casing that is installed on the engine. To do this, you will need to unscrew the cap on the hole for adding oil. After this, remove the cover (once the casing has been removed, the cover can be returned to its place to prevent dirt and dust from getting inside the power unit).

Find the pipes that are responsible for heating the throttle assembly. (see Cleaning the throttle body). Select any one and pull it off. Unscrew the cap from the hole in the expansion tank that contains the antifreeze and cover the hole with a clean rag.

Blow inside the tank. In this way, pressure is created that squeezes out the air. As soon as coolant comes out of the pipe, you have successfully gotten rid of the air.

Return the handset to its place (the sooner you do this, the better). Otherwise, you can catch a portion of air again.

Method number 2. This option is much simpler and you don’t need to blow anywhere. Vent the air as follows:

- Warm up the engine for 10-15 minutes and then turn it off;

- the cap on the expansion tank remains screwed on;

- also (as in the previous method) remove one of the pipes on the throttle assembly;

- wait until coolant comes out of it.

As soon as this happens, immediately return the tube to its place and secure it tightly with a clamp.

When performing this operation, be very careful, because the temperature of antifreeze (antifreeze) can reach 80-90 degrees Celsius.

Method number 3. We cannot mention another simple but very effective method of getting rid of air in the cooling system.

Proceed like this:

- Find a steep hill and stand on it so that the front of the car is the highest point;

- put the car on the handbrake and place stands under the wheels to prevent accidental rolling;

- unscrew the plugs from the radiator and expansion tank;

- start the car and let it warm up for 10-15 minutes;

- Press the accelerator pedal periodically and add coolant to the reservoir as needed.

Continue adding until no bubbles appear at all. Only in this case can the work be considered completed.

Now you know how to remove an air lock from the cooling system quickly and without special financial costs.

At first glance, this problem may seem minor, but in the long run it can lead to a whole host of problems.

So, when the first symptoms of airiness appear, ruthlessly expel the air pockets and open normal access for coolant circulation.

Good luck on the roads and of course no breakdowns. Don’t forget to share your personal experience in repairing VAZ cars in the comments.

Step-by-step instruction

The next method of how to blow out the stove on a VAZ-2107 will be discussed step by step. So:

- Unscrew and pull out the top pipe. This pipe goes directly to the stove, and this is the highest point where air can accumulate.

- We insert the pipe into place without twisting it.

- Fill the antifreeze tank full. It’s better to play it safe and pour antifreeze through a cloth to prevent debris from getting into the heating system. This is a rather tedious and time-consuming process, but it is necessary so as not to damage the system.

- We start the engine and bring it to 80 degrees. Now you need to let the air out through the highest pipe.

- To do this, we take it a little and move it.

- We carry out this procedure until the antifreeze flows out. If the antifreeze has poured out, it means that almost all the air has already escaped.

- If a small air bubble remains, it will then come out through the expansion tank.

This is one of the most effective ways to blow out the stove on a VAZ-2107. With the help of these instructions you will cope with this problem and be sure to restore the operation of the stove!

Source

An air lock forms in the engine cooling system.

It would seem that the formation of an air lock in the cooling system of an internal combustion engine is such a simple problem, but its presence seriously affects the current and future operation of the engine. Many drivers have encountered such phenomena as boiling antifreeze, antifreeze and water, failure of various sensors, seething - all this indicates that there is air in the system channels, which is stopping circulation. It also happens that after starting the engine the car does not heat up. When the first signs of air appear in the engine cooling system, prompt elimination of the causes is required.

General recommendations for prevention

The first thing you need to pay attention to is the level of antifreeze in the cooling system . Always monitor it and top up if necessary. Moreover, if you have to add coolant very often, then this is the first call indicating that something is wrong with the system, and additional diagnostics are necessary to identify the cause of the malfunction. Also check for stains from antifreeze leaks. It is better to do this in the inspection hole.

Try to use the antifreeze recommended by your car manufacturer. Make purchases in trusted, licensed stores, minimizing the likelihood of purchasing a counterfeit. The fact is that low-quality coolant can gradually evaporate during repeated heating, and instead of it, an air plug forms in the system. Therefore, do not neglect the manufacturer's requirements.

Instead of a conclusion

Finally, I would like to note that if the described signs of airing in the system appear, it is necessary to carry out diagnostics and check it as quickly as possible. After all, an air lock significantly reduces the efficiency of the cooling system. Because of this, the engine operates under conditions of increased wear, which can lead to premature failure. Therefore, if you detect airing, try to get rid of the plug as quickly as possible. Fortunately, even a novice car enthusiast can do this, since the procedure is simple and does not require the use of additional tools or devices.

Source

Signs of an air lock in the cooling system

You can determine the presence of air in the engine refrigeration system by conducting independent diagnostics and eliminating the causes. We carry out diagnostics based on the above criteria.

- Checking the system for leaks. Over time, clamps weaken, oxidize, or break completely. The hose also has shock absorption; over time, it bursts and cracks; either heat or cold gradually destroy the rubber.

- Problems with the thermostat. If the engine heats up very quickly after starting, that is, the cooling fan has already turned on, and the temperature sensor shows that it is about to push the needle into the red scale, then this indicates a non-working thermostat or the presence of air in the pump discharge pipe. In this case, the thermostat valve will be in the closed position, the coolant will move in a small circle. The opposite may also happen. The engine takes a very long time to warm up after starting. This means that the thermostat valve is fully open or there is an air lock in the thermostat. In all cases, you will have to remove air from the engine cooling system.

It’s easy to check the thermostat yourself; you need to do the following:

- start the engine;

- after a couple of minutes, touch the radiator pipes (the top one should be warm first, then cold, the bottom one should be cold);

- when the engine temperature reaches operating temperature, 80-90 degrees, the thermostat should open and the lower pipe should heat up.

It's also easy to check functionality. It is determined by the noise level (it is not worth using a noise sensor and determining the level in decibels (dB)), by the sound you can already feel how the pump is working. The vibration of the pump is also checked. The pump bearing may have fallen off.

The main clue is that air has appeared in the engine cooling system in the heater. If the engine is hot and the heater is blowing cold air, then there is an air lock.

Folk way

This method of deflation came to us from the people. That is, in a logical way, drivers came up with the idea of parking the car at an angle so that the air bubble would come out of the heating system during certain actions.

So, you need to find a hill with a slight slope. An overpass will also do. Drive the car onto it so that the front is as high as the rear as possible. The plug will go away if your engine idles for a couple of minutes. However, this method does not always help. However, this method is the cheapest and easiest, so it makes sense to try it. If it doesn’t help, read on to learn how to blow out the heater on a VAZ-2107.

Reasons why air appears in the cooling system

Air appears in the system due to malfunctions, actions or inactions on the part of the driver. The following reasons are identified:

- The tightness of the system is broken. This could be a loose clamp, fitting, or cracks in the hoses.

- Work has been carried out to replace or top up the coolant. This is, as a rule, the most common reason for air getting in, because not everyone knows that it should be poured in a thin stream. If you pour in a thick stream, a funnel is formed that swirls the air.

- The air valve is out of working order. This valve is located in the coolant reservoir cap. During natural heating or by installing and starting an autonomous engine preheater, the volume of liquid increases, the pressure in the tank increases and excess air must be discharged through the valve in the lid. This is also a common reason. This is the first place to look for the reasons for airing in the cooling channels. This cover costs 100 rubles for modern VAZ cars. Whoever changes it, when he has already double-checked all the reasons, even after replacing the cylinder head, it turned out that the reason was precisely the non-working cover.

- Problems with the pump (pump). The seals and fibers in the pump may be faulty, causing air leaks.

- There is a leak through a bolt in the cooling radiator (not available on all models). If there is a leak of antifreeze, antifreeze or water, the lost volume is filled with air.

- Burnt cylinder head gasket. If the engine has already been overheated, then there is a possibility that the cylinder head gasket has burned out. When it burns, coolant is released either into the crankcase or into the exhaust system. Seething and boiling begins when the volume of coolant (coolant) has decreased and the entire void is filled with air. In this case, repairs and replacement of the head gasket will be required; for this you need to know what types of cylinder head gaskets there are.

If coolant gets into the engine crankcase, it is easy to check with the oil level dipstick; the level will be higher than expected. If water is used as coolant, the engine oil will turn white. Sometimes air gets into the brake system, in which case the system also needs to bleed air. And for this you need to know the diagram, which wheel to start with and what exactly to do to bleed brakes with ABS and how to bleed brakes without ABS. If the entire fuel fluid has leaked or you want to replace it, then such work also has its own nuances. In particular, you need to know which brake fluids can be mixed and how much brake fluid is needed for replacement.

Device

The first place where the fluid begins its flow is the radiator. On VAZ 2106 models, two types of radiators were installed - copper and aluminum. The first one is of higher quality, and if cracks appear on its surface, they can easily be welded. In contrast, any crack on an aluminum part is its certain death.

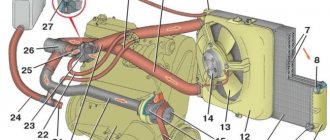

The radiator figuratively consists of three parts: the upper barrel, the cooling honeycomb and the lower barrel. The upper tank has a filler neck for adding coolant. During operation, hot liquid that has gone through one cycle is collected in this tank. Further, it descends into the lower barrel, through the honeycombs, simultaneously being cooled by a fan. And in the lower tank, the liquid is already completely cooled and ready for use.

Tubes are connected to the radiator from above and below: two wide and one narrow. A narrow tube connects the radiator to an expansion barrel, designed to allow excess liquid to enter it during heating and expansion. The upper wide tube connects the part to the thermostat, which, in turn, uses a valve to regulate the flow of coolant. Fluid can flow from the thermostat either back to the engine cylinder block or to the radiator.

For forced circulation, the system includes a pump that pumps antifreeze, creating pressure inside the block. Between the cylinders, a specially made void is provided, where this liquid enters.

How to remove air from the engine cooling system.

The process of removing an air lock on cars is almost the same, be it Kalina, Priora, Granta, Hray, Vesta, VAZ 211(0-5), 2101-2107, Opel, Daewoo Matiz, Nexia, Nissan Almera, Gazelle Business, Audi 80-100 , BMW E39, Peugeot, Chevrolet Cruze, Skoda, Mazda, Mitsubishi Lancer, Suzuki Grand Vitara, Niva, UAZ, Volkswagen, Ford, Renault Duster, on Chinese Lifan and even on premium class cars.

There are several options for removing an air lock from the cooling system:

Timing for replacing coolant in VAZ 2107

The purpose of the coolant in the VAZ 2107 is to remove excess heat from the car’s engine. Indeed, during operation, many parts of an internal combustion engine reach temperatures of 300 degrees C. If the engine is not cooled in time and sufficiently, it will fail. Coolant solves this problem; it is supplied to a running engine, flows through the channels, thus taking away excess heat from the internal combustion engine.

After heating, the coolant goes into the central radiator, which is constantly blown by the fan. After cooling in this unit, the liquid returns to the engine cooling channels. This is the procedure for continuous liquid cooling of the VAZ 2107 engine.

The general principle of operation of the VAZ 2107 cooling system can be studied using the diagram below.

How to understand what kind of coolant is required for a VAZ 2107 - antifreeze or antifreeze? Since we are talking about Russian cars, we should distinguish between concepts such as antifreeze and antifreeze to clarify concepts.

It should be noted that such division and differentiation is accepted only in the Russian Federation. To answer this question, you must first understand: what is coolant?

So, the basis of the coolant is ethylene glycol, less often propylene glycol. Special additives are added to it, which protect against corrosion. Each manufacturer adds different types of additives.

Let us differentiate the coolants available on the modern market according to additive production technologies:

- traditional, in which additives are made from salts of inorganic acids: silicates, nitrites, amines, phosphates;

- carboxylate, additives are made from organic carbonates;

- hybrid, consists of a mixture of organic carbonate additives and inorganic salts (in smaller quantities, including phosphates or silicates).

So, the main difference between antifreeze and antifreeze is that coolant made using traditional technology is called antifreeze, while coolant made using carboxylate technology is called antifreeze.

Advantages and disadvantages of using antifreeze

Pros:

- protective film. Thanks to the inorganic salts contained in antifreeze, a protective film is created on the surface of the cooled parts, protecting them from corrosion. The film reaches 0.5 mm. In the picture below you can see how antifreeze creates a protective layer, the disadvantage is that it interferes with heat removal;

- color change. If the driver forgot to change the coolant, a clue to the need for the procedure will be the color of the liquid, which is easy to notice just by looking into the car's expansion tank. The changes are that as the antifreeze loses its useful properties it becomes darker, and completely unusable antifreeze cannot be distinguished from tar;

- affordable prices. Coolant produced using traditional technology is 3 times cheaper than antifreeze.

Disadvantages of antifreeze:

- replacement frequency. Antifreeze has a short lifespan, becoming unusable after 50 thousand kilometers;

- negative impact on aluminum parts. The additives used to create antifreeze negatively affect the aluminum surfaces in the main radiator (which significantly reduces its service life);

- due to the tendency to form condensation, it negatively affects the water pump of the VAZ 2107, as a result - premature wear of its impeller.

Let's look at the advantages and disadvantages of using antifreeze

Pros:

- service life is longer - 6 liters of antifreeze is enough for 150 thousand kilometers;

- temperature selectivity - due to the presence of carbonate additives, antifreeze more actively protects the engine surface that is heated the most;

- antifreeze does not interfere with heat dissipation, and also protects corrosion areas with the help of local layers;

- long engine operation due to temperature selectivity and timely engine cooling with antifreeze;

- there is no condensation, which means antifreeze cannot damage the radiator and water pump of the VAZ 2107.

The disadvantage of antifreeze is obvious - its high cost. In terms of price, it is on average 3 times higher than antifreeze.

Protection against air lock formation in the cooling system.

In all matters related to malfunctions and subsequent repairs, the easiest way is to prevent the occurrence of breakdowns; in this case, it is necessary to prevent the appearance of an air lock. It is advisable to learn how to fix simple breakdowns and perform preventive maintenance yourself, then you won’t have to contact a car service center.

One of the main preventive measures for the formation of an air lock is not to bring the coolant to a boil (do not overheat the engine). If antifreeze is poured in, it can withstand higher temperatures than antifreeze, and even more so than water. When the coolant boils, steam is formed, which is pressed into the most inaccessible corners of the ignition system. In such cases, certain types of breakdowns appear.

An air lock in the cooling system leads to disruption of heat removal from areas of increased heat generation: pistons, cylinders, intake and exhaust manifolds. Such unstable operation of the engine cooling system can cause overheating. Prolonged operation of a car with an air lock can result in serious repair costs.

How to prevent the problem from recurring

At least there is a guarantee for the car service work.

The surest way to avoid unnecessary problems with your car is to trust the service to professionals. The structure of a car and an engine in particular is constantly becoming more complex. A modern cooling system consists of many irregularly shaped parts, tubes and hoses located at different angles. In a word, there are many places where air can accumulate in the cooling system. Professionals know all the intricacies of filling the antifreeze system and can easily replace the old fluid with a new one.

Engine overheating can be prevented with regular maintenance

There is no need to allow the engine to overheat, bring the antifreeze to a boil. At this moment, the coolant turns into steam, which, under high pressure (the system is closed) fills all the most inaccessible corners of the cooling system. In this case, the engine itself is at great risk of serious damage. It also takes a lot of skill and experience to remove air from your car's cooling system.

If you do not remove the air lock from the cooling system in time, there is a chance that the engine will incur significant costs for repair and restoration. So the question “how to remove air from the cooling system” must be taken seriously.

Possible consequences of an air lock in a car's cooling system

The presence of air in the coolant leads to many unpleasant consequences. The normal circulation of antifreeze (antifreeze) is immediately disrupted and the main purpose of the cooling system begins to suffer:

- heat removal from the components of a running engine occurs unevenly;

- heating the air in the cabin does not provide the necessary comfort.

An experienced driver will immediately notice the twitching of the coolant temperature gauge needle and its boiling in the cooling system. An air lock in the coolant causes:

- overheating of engine parts and components at idle speed, which leads to temperature jumps;

- incorrect operation of the sensors - this causes malfunctions in the temperature indicator readings;

- inaccuracies in the operation of the thermostat, which can cause engine overheating;

- insufficient heating of the stove will cause fogging of the windshield and side windows, which will lead to limited visibility and the creation of an emergency situation on the road.

Preparation

The 11183 engine has a plastic casing that can be removed by simply pulling the part up. You can first unscrew the oil filler plug.

Motor “11183” and its protective casing

The temperature regulator in the cabin is moved to the right position. Without this, all actions will be useless.

Using method 1, the engine is first warmed up. For methods 2 and 3, the engine is left without warming up.

Causes of air accumulation in antifreeze

General diagram of a liquid cooling system

Closed liquid cooling systems are designed to maintain constant excess pressure (up to 100 kPa). The increased pressure made it possible to raise the boiling point of the liquid to 120 degrees. Since cars are used all year round, a concentrated, special non-freezing coolant was specially developed for them - antifreeze (antifreeze is the most popular). It consists of ethylene glycol, distilled water and anti-corrosion, anti-foaming, antioxidant additives. Antifreeze provides optimal thermal operating conditions for the engine of 80–100 degrees in any weather. The main causes of air locks are as follows:

- Air suction through insufficiently tight connections of pipes, hoses, fittings, tubes. This happens because when antifreeze moves through the system, a reduced pressure is created near the walls of the tubes, which draws in outside air in places with loose connections.

- Air is trapped in the cooling system when a wide mouth funnel is used to add or change coolant. A powerful flow of antifreeze blocks the path of air to the top. Antifreeze is always poured into the expansion tank or radiator in a thin stream.

Antifreeze circulation diagram in the engine cooling system Modern cars use a forced closed cooling system. Its main task is to ensure stable operation of the engine during the transition from cooling mode to heating mode and vice versa. This is not easy to achieve, since when the antifreeze is heated, its volume increases and excess pressure arises, and when it cools, the volume and pressure in the system decreases. The increased pressure compresses the air at the highest point of the system - the expansion tank. There is an air valve in the filler plug of the tank that operates in two directions. When the pressure increases, it bleeds excess air out; when the pressure decreases, it lets outside air into the system. It is the air valve that maintains constant excess pressure under any thermal conditions. If this device does not work correctly, excess air will begin to constantly accumulate in the cooling system.

Video: How not to air out the cooling system when filling with antifreeze

Reasons for airing

The air that has penetrated into the system is collected into one bubble, moving through the channels to a certain place. Having reached the highest point or narrowing, it stops and blocks the flow of antifreeze (antifreeze). Practice shows that most often an air lock occurs in a large circulation circuit, including the main radiator. Although the opposite situation also happens, for example, airing of the heat exchanger of the cabin heater (in common parlance - the stove).

How air enters the cooling system of a car engine:

The main task solved during the process of filling antifreeze is to simultaneously expel air from the cooling system. If you perform the operation in a hurry and do not follow simple rules, the formation of an air lock is guaranteed. Quick filling allows air to enter the system along with the liquid through the funnel, and then collect into one bubble.

Important point! An obvious sign of airing is a critical rise in coolant temperature at any engine operating mode.

The inclusion of an electric fan depends on the make and model of the car: if the temperature sensor is in the cylinder head, forced airflow will definitely work.

If the meter is located differently (in the main radiator, on the pipe), the fan may not start due to the sensor being in a stagnant zone. How will air get through leaks in a pressurized system, you ask? The algorithm is simple:

- During the heating process, the antifreeze increases in volume and displaces the air layer from the expansion tank through the plug valve.

- After the engine stops, the coolant cools and compresses to its previous volume, and the valve lets the air back in.

- As the antifreeze cools and contracts, leaks in the system elements will turn into sources of additional air leaks.

Similarly, airing of the cooling system occurs due to the jamming of the bypass valve. Cooling and shrinking antifreeze provokes the formation of a vacuum, which is not replenished by air flow from the outside. Then suction occurs in the weakest connections.

How to determine if there is a problem: symptoms, signs, diagnosis

Diagnostics are designed to help find the cause of malfunctioning cooling system. If antifreeze constantly disappears somewhere, boils, boils strongly in the cooling radiator, and the interior does not heat up, all this needs to be dealt with. If the antifreeze level regularly drops, air will take its place, which over time will form an air lock. In this case, you need to check the tightness of all connections of the engine cooling system. To do this, carry out a careful external inspection of the interfaces of rubber parts (hoses, pipes) with tubes and fittings with a warm, running engine. Pay special attention to the radiator pipes, water pump, thermostat and heater hoses. If a leak is detected, it must be eliminated by replacing the pipes or tightening the steel clamps.

Checking the hoses

The second way to expel air from the VAZ-2107 stove is to find the hoses from the cooler under the hood and move them. It is quite possible that such a mechanical effect will provoke the release of an air bubble.

You need:

- Open the car hood.

- Find the radiator outlet, bypass and supply hoses.

- Press your hand three times on each of the hoses.

After the completed manipulations, check the operation of the heater. If warm air comes out, then the problem is solved. If everything remains as it was, it’s time to try the next method of airing.

How to bleed air using the VAZ model range as an example

VAZ models have a design advantage in the arrangement of cooling system components - a convenient position of the cooled throttle assembly (carburetor), which is the highest place in the cooling system. The procedure for a Lada Kalina car is as follows (the only tool you need is a Phillips screwdriver).

Fully open the heater switch (to the highest temperature);

Remove the valve cover protective screen;

Disconnected heating outlet hose from the throttle fitting

Remove the cap from the expansion tank

Video: How to remove air from the expansion tank

The second method of releasing air differs from the first only in that you do not need to force air masses into the neck of the expansion tank with your mouth. All operations are performed with the engine normally warmed up and turned off. This method does not involve any manipulations with the expansion tank cap. Immediately remove one of the two heating hoses from the throttle fittings. If coolant leaks, the hose is inserted into place and tightened. It may not work out the first time, then the operation must be done again. This method requires care and caution, since the antifreeze is heated to a temperature of 90 degrees and is under increased pressure.

The third method does not require any disassembly of the cooling system. True, its effectiveness is not very high. The car drives its front wheels onto an embankment so that the radiator cap becomes the highest point in the cooling system. The radiator and expansion tank caps are removed. The engine starts, the antifreeze temperature is brought to operating parameters. When reducing the volume of coolant, it must be constantly added to the amount recommended by the manufacturer. It is necessary to expel the air lock until bubbles stop coming out of the neck of the radiator or expansion tank.

Articles

- 21110-1008650-00 – plastic screen (only for 11183);

- 21120-1008658-00 – rubber screen pin;

- 21080-1311065-00 (-01, -03) – expansion tank plug;

- 21080-1311067-00 – gasket for the plug.

Do you only need distillate?

We tried to expel air from the system, but on the VAZ-2114 the entire “plug” takes up 100-150 ml. This means you don’t have to add anything at all to the tank. You can also add regular distilled water.

It is easier to find a 100 ml package of distillate at a pharmacy or battery store.