The end of the 90s for the domestic automobile industry was marked by the appearance of the VAZ 2112 engine. It was a completely new power unit in its design, which included the use of 2 camshafts, as well as 16 valves (4 for each cylinder). The engine joins the tenth family of front-wheel drive cars.

It was introduced in 1997, and if you look at the facts, it turned out to be the manufacturers' first engine with 16 valves. Therefore, this particular engine is the ancestor of all subsequent versions with two camshafts. Thanks to this solution, manufacturers were able to increase performance and improve technical characteristics.

Characteristics

| engine's type | Petrol |

| Power | 92.5 l. With. |

| Torque | 128 Nm at 3700-3900 rpm |

| Volume | 1.5 l (1499 cc) |

| Design | in-line |

| Fuel type | petrol |

| timing belt | DOHC |

| Compression | 10.5 |

| Cylinder diameter | 82 |

| Piston stroke | 71 |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Petrol | AI-95 |

| Cylinder operating order | 1-3-4-2 |

| Weight | 120 kg |

| Maximum speed | 175-185 km/h |

| Years of manufacture | 1998 — 2006 |

| Fuel supply | injection, distributed injection |

| Ignition system | coils/plugs |

| Cylinder numbering | from the crankshaft pulley |

| Cylinder head | Aluminium alloy |

| Cylinder block | cast iron 28 kg |

| Inlet | polymer manifold with receiver |

| Release | pipe with neutralizer |

| Camshafts | 2 |

| Ring material | steel, cast iron |

Maintenance

The ergonomic design of the internal combustion engine allows you to service the 2112 engine with the following frequency:

| Maintenance object | Time, year or mileage, 10,000 km (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1/20000 km |

| Valve clearance | 2 /20000 km |

| Crankcase ventilation | 2 /20000 km |

| Belts that drive attachments | 2 /20000 km |

| Fuel line and tank cap | 2 /40000 km |

| Motor oil | 1/10000 km |

| Oil filter | 1/10000 km |

| Air filter | 1 – 2/40000 km |

| Fuel filter | 4 /20000 km |

| Heating/Cooling Fittings and Hoses | 2 /40000 |

| Coolant | 2 /20000 km |

| Oxygen sensor | 1.5/100000 km |

| Spark plug | 1 – 2 /20000 km |

| Exhaust manifold | 2/40000 km |

Unlike coolant, oil partially settles on the walls of the lubrication channels, so with a volume of 3.5 liters, 3.2 liters of a semi-synthetic product is actually required.

Modifications

Let's consider models of internal combustion engines. First, the basic design of the VAZ 2112 15 16v engine was created. In this model, there is free space inside the block and cylinder head, which is a disadvantage, therefore, after the release of the first model of the 21120 engine, other improved modifications began to be produced. In model 21124, the engine was increased to 89 hp. and increasing the volume of the internal combustion engine to 1.6 liters.

In model 21126, the engine design was improved, as a result of which the engine acquired a volume of 1.6 liters, and the power indicator of the design was increased to 98 hp. Model 21128 has the largest combustion chamber volume, which is 1.8 liters. At the same time, the power characteristics of the engine of this car model were increased to 105 hp.

In these modifications, major repairs are carried out less frequently, and the valves do not bend. The first modification was made to increase engine capacity and achieve world quality standards. Changes in these modifications were made by increasing the block height to 197.1 mm and increasing the piston stroke.

In the next modification, engineers created the greatest resource for various system components. For this purpose, cylinder honing was used according to the Federal Mogul method. In design 21126, the number of sets of liners and pistons is reduced to 3 pieces. In this case, the step between them is 0.01 mm. Model 21128 is produced not by the AvtoVAZ production association, but by another manufacturer, Super-Avto CJSC.

ICE performance has been improved:

- engine capacity - 1.8 l;

- power characteristics increased to 75 kW;

- torque is 162 Nm.

The cylinders have a diameter of 82.5 mm; a new crankshaft was created that provides a piston stroke of 84 mm; The width of the rings is increased to 2 mm in oil scraper models. The throttle cross-section has increased and is 51 mm.

The new model has Siemens injectors installed, which have high performance. Model 21127 was released in 2013. In it, the torque is increased to 148 Nm, the volume is increased to 1.6 liters, and the power characteristic is 106 hp.

Model 21129 has a volume of 1.8 liters. It has a phase shifter installed. Various engine configurations have been created (LI, GLI, SLI), in which additional options can be installed, such as electric windows, door locks, and an immobilizer.

- Comparison of modifications

- cylinder head

Maintainability

Like all VAZ engines, the VAZ-2112 has high maintainability. The simple design and interchangeability of many parts with other brands of engines do not cause difficulties during restoration.

There is no need to look for spare parts for repairs - they are available in any specialized store. The only danger when purchasing is not to run into a fake. The market is literally flooded with counterfeit spare parts for VAZ engines. The quality of parts from Chinese manufacturers is especially low.

In most cases, internal combustion engine repairs are carried out by car owners themselves, in the garage. As a rule, restoring an engine using this method is much cheaper, and sometimes even better, than at a service station.

VAZ-2112 is a reliable, economical and easy-to-maintain and repair engine. With timely maintenance and proper operation, it is able to please its owner with many hundreds of thousands of kilometers, exceeding the resource declared by the manufacturer.

Design Features

A new version of the VAZ 2112 engine with increased power was created by AvtoVAZ together with specialists from Porsche and General Motors.

Motor 2112 has the following design changes:

- a separate drive has been created for the exhaust tract; the intake valves are controlled by the cams of their intake pipe camshaft;

- steel connecting rods 121 mm long were created;

- holes were made in the instrument block for attachments;

- improved: distribution mechanism, cylinder block assembly, crankshaft, lubrication system, spark plugs, torque, maximum speed of the internal combustion engine;

- special hydraulic pushers were created that saved owners from periodically adjusting the valves and choosing their number;

- improved control of the operating temperature of the fuel in the internal combustion engine;

- a floating landing of the piston is performed;

- Oil channels are created inside the cylinder head.

What cars was it used in?

Only three VAZ models using the 2112 engine left the assembly line of the manufacturer's plant:

- 21103 – sedan;

- 21113 – station wagon;

- 2112 – sedan, GLI luxury and Standard versions.

VAZ-2112

Since the characteristics of the engine 21124 and internal combustion engine 21128 are not too different from the original, it was mounted on the same VAZ Lada. The modification of the 21126 engine was equipped exclusively with Prioras.

Malfunctions and repairs

The new generation engine, subject to operating conditions, operates for quite a long time. The basic modification was created jointly with the German company Porsche, which is considered the most advanced in the creation of engines.

A small disadvantage is the use of a toothed belt drive, which requires the installation of high-quality spare parts, which cannot always be found in car repair shops.

At the same time, some motorists do not carry out regular maintenance in a timely manner, which leads to a reduction in the service life of the device.

Malfunctions that may occur in the operation of the internal combustion engine, and methods for eliminating them:

- Adjusts the engine. The fault lies in the cylinder head distribution unit, spark plugs or wires.

- The engine is idling unsteadily. In this case, you need to check the crankshaft sensor, throttle plate and control device. If this does not help, then the mass air flow sensor may have failed.

- At idle or when the vehicle is moving, the drive stalls. Such a problem may result from contamination of the throttle assembly, its sensor or IAC.

- If the engine does not catch when starting. If the battery and starter are working properly, then the problem has occurred in the power supply or ignition system.

- Hydraulic compensators are knocking. The breakdown consists of a decrease in oil pressure in the engine.

- The engine warms up slowly. You should check the presence of coolant, connecting rods and thermostat operation.

- The internal combustion engine does not pull well, operation is accompanied by vibration. In case of such a malfunction, it is necessary to diagnose the engine.

- Oil pressure is insufficient. There can be many reasons for this phenomenon. This can happen due to untimely replacement of lubricant in the motor. Over a long period of use, the oil pump may break down.

- If the indicator turns on, this indicates that there is no oil pressure. In this case, you need to stop to find out the reason. If necessary, call a tow truck.

Weak spots

Unfortunately, the VAZ-2112 is not without them. The most important one is the timing belt. If it breaks, a meeting with the valves is inevitable. And this is already a serious repair of the cylinder head. A pump leak can cause a breakdown, causing the belt to become splashed with coolant, become wet and lose its properties.

Leaking camshaft oil seals cause the belt to become oily, which is no less dangerous. Wearing the shafts also does not bring any benefit. The fact is that in this case the belt gets slightly distorted. Its presence is indicated by the appearance of a grinding noise when the engine is not warmed up.

Sometimes the motor starts to “trouble”. As a rule, the cause of this phenomenon must be sought in the electrics (ignition module, high-voltage wires, spark plugs) or in the throttle valve, idle air control. The culprit may be various sensors (DPKV, DPS, DMRV).

The thermostat does not shine with quality. As a result of its failure, the engine may overheat, or, conversely, the inability to reach operating temperature.

The car owner is often bothered by various unauthorized noises. They are worth paying close attention to. Knocks can be caused by faulty hydraulic compensators, connecting rod or main bearings.

If any malfunctions are detected, the best solution would be to go to a service station to diagnose the engine.

Service

When servicing an internal combustion engine, you need to know the brand of fuel, what kind of oil needs to be filled, and how much oil is needed for a given design. You also need to know the service life of your car’s engine and the presence of a timing belt.

Change engine oil in 2 ways:

- With engine flush. In this case, after draining the liquid, you need to add flushing liquid or the oil that will be filled into the engine. Then turn on the engine. It should run for 10 minutes. Then drain the oil.

- No engine flushing. After the old oil is drained, new oil is immediately poured in.

Let's look at the procedure for changing the oil. For this you will need:

- capacity 4 l;

- key to 17;

- oil filter remover.

Place the car on the inspection hole. Remove the cap from the oil filler neck. This will make it easier for the fluid to drain out because there is no vacuum forming at the top of the engine. Then remove the oil pan plug.

Drain the oil. Do not allow hot liquid to come into contact with the skin. The draining continues for 10 minutes. When changing the oil in engine 21124 to another brand of oil, the engine must be flushed.

For this purpose, fill in the flushing liquid to the bottom mark of the dipstick. Turn on the engine. It operates at idle speed for 10 minutes. Drain the liquid.

When replacing the lubricant, the filter must also be replaced. Unscrew the oil filter head cover using a screwdriver or a puller. Before installing a new filter, fill it halfway with oil and lubricate the O-ring, which will prevent air locks.

Screw the drain plug onto the crankcase. Then they install the oil filter. After this, the volume of lubricant is monitored using a dipstick. To prevent oil overflow, it must be poured slowly and the level must be monitored. Then tighten the plug and return the dipstick to its place. Turn on the motor. When the oil pressure warning light goes out, the engine will stop. Check the oil level. If necessary, it needs to be topped up.

Reliability

Despite complaints from some car owners, the internal combustion engine of the VAZ-2112 can be confidently called a reliable power unit. The whole problem of reliability lies in the attitude towards it on the part of the car enthusiast himself.

With timely and high-quality maintenance and compliance with all manufacturer’s recommendations, the engine practically does not cause any complaints. With this attitude, the engine resource increases significantly.

The only direct defect of the manufacturer of this motor is the possibility, or rather the guarantee, of the valves bending when the belt breaks. But, with a careful, caring attitude towards the engine, this problem can be reduced to an absolute minimum. It is enough to replace the belt not after 50-60 thousand km, as the manufacturer recommends, but much earlier. For example, after 30-40 thousand km. Financial costs will be much less than when repairing the cylinder head.

Tuning

Before starting tuning, you need to take into account the design features of the 2112 engine. One of the frequently used tuning options is boring the cylinders for piston 21128 by 5 mm. Chipping is not used. You can replace the throttle with 54-56 mm. The exhaust tract with a 4/2/1 “spider” is being installed. You can install STI-2, STI-3.1 or Stolnikov camshaft.

If piston chip tuning and crankshaft modification are performed, which increase the piston stroke, then the valves must be replaced together. ICE 2112 is considered the 5th generation of engines with a 4-stroke cycle. In the initial version, the design was not fully developed, as the valves bend. In later models this defect was corrected.

If you change the cylinder head and install a wide-phase camshaft, the power characteristic will be 130-140 hp. If you install a crankshaft with a long crank measuring 37.8 mm, then modification of the combustion chamber and the use of T-shaped valves will increase the power characteristics to 150 hp. Some car enthusiasts, in order to increase power, mount ICE 2112 on rear-wheel drive VAZ 2105-2107 cars. To install the engine under the hood, car owners cut off part of the partition of the internal combustion engine compartment.

Conversion of an 8-valve engine to a 16-valve engine

This alteration is carried out by modifying the bolts securing the head. To upgrade, you need to change the head. In order for each screw to fit into the hole in the head, it must be adjusted in length and diameter. The holes in the gasket also need to be modified.

Then they change the pistons, connecting rods and adjust the wires. It is necessary to take into account the difference between sixteen-valve pistons and 8-valve pistons. The placement of the sensors is also excellent. Leave the ignition system and connect the unit using high-voltage wires.

Increase in engine displacement

The working volume of the internal combustion engine depends on the piston diameter and stroke. In the factory version, the displacement is increased by installing a higher block and a crankshaft with a crank radius that will increase the piston stroke to 75.6 mm. The displacement can be increased to 1580 cm³ by installing a crankshaft with a crank radius increased by 1.9 mm, which will provide a piston stroke of 74.8 mm.

Spider exhaust manifold

To install the “spider” manifold, the exhaust system unit is dismantled: the intake pipe, the exhaust manifold of the internal combustion engine. Instead of a standard exhaust manifold, a “spider” is installed. It must fit precisely onto the cylinder block and not touch the wiring.

Installing a zero resistance filter

A zero-resistance filter is installed in the engine instead of a standard air filter. It allows you to reduce inlet resistance without reducing filtering capacity. Thus, it increases the power characteristics of the motor. Thanks to the installation of a zero filter, you will not have to change the filter device every 10,000 km. The zero filter can be washed with a special composition, this will restore its functions. After installing it, the engine torque increases.

You can do the installation yourself. First, remove the standard filter housing. Then the selected design of a zero-resistance cone filter is installed on the pipe that fits the air flow sensor. The filter brand must be selected according to the diameter of the installation site.

Description

In 1997, a new internal combustion engine under the designation VAZ-2112 was developed and put into production. The VAZ-2110 was taken as the basic basis. The changes affected the system for supplying the working mixture to the cylinders, and, most importantly, the cylinder head. Engine production continued until 2004.

The VAZ-2112 is an in-line four-cylinder petrol unit with a volume of 1.5 liters and a power of 93 hp. s and a torque of 128 Nm.

Under the hood of the VAZ-2112

The engine was installed on VAZ cars:

- 2110 (1997-2007);

- 2112 (1998-2004);

- 2113 (2000-2004).

The VAZ-2112 replaced the aging “eighth” engine. The laid down requirements for increasing power, environmental standards and increasing efficiency can be achieved in two ways - installing turbocharging or changing the power system with the transition to a multi-valve cylinder head.

VAZ engineers took the second path and created a fundamentally new engine using positively proven components and mechanisms of the old one.

The cylinder block remained traditionally cast iron. The cylinder head mounting has changed. Additional oil channels have been created to lubricate the crankshaft main bearings. The cylinders are not lined, they are bored directly into the block.

The crankshaft is made of cast iron and is mounted on five bearings. The main and connecting rod bearings are made of steel and aluminum. The crankshaft has a special design and is not interchangeable with shafts of similar engines (VAZ-2110, 2111).

The connecting rods are steel. A steel-bronze bushing is pressed into the upper head.

The pistons are made of aluminum alloy and have a complex shape (the skirt is conical in the longitudinal section, oval in the transverse section). There are three piston rings, two of which are compression, one is oil scraper. The piston pin is of a floating type, fixed with retaining rings.

Aluminum cylinder head. At the top there are two camshafts and 16 valves. The valve seats are metal-ceramic, the guide bushings are brass.

The valves are steel, with hydraulic compensators. They have a V-shaped arrangement.

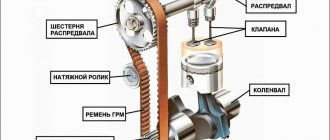

Timing belt drive. When the belt breaks, the valves bend.

VAZ-2112 cross-section

The ignition module includes two high-voltage coils and two electronic units. Not dismountable, cannot be repaired. The manufacturer recommends using AU17DVRM spark plugs.

The power supply system is phased distributed injection. Controlled by ECU (Bosch, GM or “January”).

Combined lubrication system. Gear type oil pump. To improve cylinder lubrication and piston head cooling, special oil nozzles are installed.

Oil nozzles

The cooling system is forced, closed type.

Despite the presence of many original parts, some are identical to parts from other VAZ engines.

Other differences

The engines also differ in their “inhalation” design. The 120th intake consists of two aluminum parts: a manifold (“horn”) and a receiver, connected to each other by rubber corrugations. Unit 21124 is “decorated” by an intake system made of plastic and consisting of a single part.

The ignition system is designed differently. The VAZ 2112 is equipped with an ignition distributor module, and on the 21124, individual coils are installed for each cylinder. Due to differences in intake and ignition systems, valve covers also differ.

The 1.6-liter unit has some other differences from its brother: the pressure regulator has been moved from the fuel rail to the pump, the catalyst is located directly at the cylinder head, there are 2 oxygen sensors (Euro-3) instead of one (Euro-2) for the 1.5 liter. The split timing case design makes it easy to replace the timing belt.

People often ask: where is the serial number of the engine on the VAZ 2112? Indeed, the number located under the air filter is quite difficult to detect. It is located at the rear end of the BC, under the thermostat housing. To find the required numbers, you need to release the air filter mount and tilt it slightly to the side.

If corrosion makes it difficult to read the serial designation, you should use fine abrasive sandpaper and then wash the area with WD-40.

Throttle for VAZ 2112

To increase the stability of the engine and the response of the gas pedal, install 4 throttles. The bottom line is that each cylinder receives its own throttle valve and, thanks to this, resonant air vibrations between the cylinders disappear. We have more stable engine operation from bottom to top, plus this intake is shorter and air gets into the cylinders as quickly as possible.

The most popular method is to install a 4-throttle intake from Toyota Levin on a VAZ. You need to purchase: the unit itself, make an adapter manifold and pipes, in addition to this you need a nulevik filter, injectors, MAP (absolute pressure sensor), fuel pressure regulator and firmware.

There are also ready-made 4-throttle intake kits on sale that are quite suitable for use. It is recommended to install a light piston engine (from Priora, for example), because turning a heavy piston is an additional waste of energy, wide-phase shafts, for example STI-6 or STI-7 Touring Light, a modified cylinder head with light valves and solid pushers, Opel C20XE springs, spider exhaust 4-1 or 4-2-1 at 51, and better than 63 pipe.

With the correct configuration, the 2112 engine produces about 180-200 hp. To completely launch the car into space, at a volume of 1.5 liters, we install STI Sport-8 shafts. There is no point in writing the motor configuration for such shafts; very few people decide to assemble such a thing.

The disadvantages include a reduction in engine life, and this is not surprising, because the engines on the pipes spin at 8000-9000 rpm or more. So you cannot avoid constant breakdowns and frequent repairs of the 2112 engine.

Cylinder block

The 2112 cylinder block is made of high-strength cast iron, and at first glance, is similar to the 21083 block. The main differences are the diameter of the head mounting bolts and holes for them in the block reduced to 10 mm, lugs for the fuel injection system sensors and a completely different technology for honing the cylinders during production .

| Parameter | Meaning |

| Material | Ductile iron |

| Cylinder diameter, mm | 82,0 |

| Intercylinder distance (distance between the axes of adjacent cylinders of the block), mm | 89,0 |

| Block height (distance between the upper plane of the block and the axis of the crankshaft), mm | 194,80 |

| Diameter of boring of crankshaft supports (for main bearings), mm | 54,52 |

| Weight, kg | 28,810 |

For the VAZ 2112 block, five size groups are defined. Size classes are designated by letters: A, B, C, D, E.

Front side of the engine

The front side of the engine is located near the right mudguard. It has a two-piece plastic cover.

Below it are the drives of the gas distribution mechanism and the electric generator. The timing belt includes: camshaft gears, a coolant pump and 2 rollers, one of which regulates the tension of the timing belt. At the end of the crankshaft there is a timing gear, a generator pulley and an oil pump. These components are driven by its rotation.

Piston

On pistons 2112, the wells have a depth of 3.19 mm for the inlet and 3.06 mm for the exhaust.

| Parameter | Meaning |

| Diameter, mm | 82,0 |

| Compression height, mm | 37,9 |

| Volume of internal recess, ss | 0,638 |

| Weight, g | 350 |

The piston pin is steel, hollow, floating type. The outer diameter of the piston pin is 2112–22 mm, the length of the pin is 60.5 mm. The hole for the piston pin is shifted from the center plane of the piston by 1 mm.