The problem of lubricant boiling inside the internal combustion engine is quite common and usually occurs in the spring and summer, when excessive heat can provoke an additional increase in temperature inside the power plant. However, this disease cannot be ruled out even in severe frost conditions. Let's talk today about what boiling point is set for motor oil, what can cause the liquid to boil and what consequences its combustion can lead to.

Optimal oil temperature parameters

During operation of the motor, increased pressure and a fairly high temperature are created in its housing, which negatively affect the main parts. To combat these negative loads, oil is poured into the power unit, which must maintain optimal temperature conditions inside the unit. According to reference literature, the normal temperature of the lubricant should be 90-105 degrees. Even a slight deviation can significantly affect the normal operation of the power unit.

The situation is especially serious if this threshold is exceeded, when there is a risk of oil boiling. The likelihood of the above material flaring directly depends on the presence of certain additives and ranges from 180 to 195 degrees. The boiling process is accompanied by the appearance of bubble formations and an increase in evaporation.

All types of lubricant are characterized by one main parameter - the flash point of the oil. The reference books indicate that a flash is possible at +230-240 degrees, but according to experienced motorists, this situation can arise as early as +150 degrees and is directly related to the volume of accumulated vapors.

Refrigerant Application

The quality of the coolant greatly affects the thermal conductivity, operating and maximum operating temperature

To determine the boiling point of antifreeze, you need to pay attention to quality. For example, the boiling point of antifreeze “A 40” is 108-110 degrees

Sometimes car enthusiasts come across a low-quality liquid that boils even earlier than water. The only way to reduce the likelihood of buying a counterfeit is to purchase a brand of antifreeze or antifreeze that has already been used.

For any antifreeze, the boiling point depends on pressure. As a rule, with increased pressure, the upper limit shifts upward. The coolant freezes at forty to sixty degrees below zero. Typically, antifreeze is changed after two to three years or every eighty thousand kilometers.

Water and antifreeze

In the first car models, ordinary water was used to cool engine systems. But at one hundred degrees the liquid boils, so under conditions of increased loads it is very ineffective. And besides, water freezes when the thermometer is zero. This fact has more than once caused various car breakdowns in the winter.

Chemists and engineers thought about the problem for a long time and found a solution. The new liquid - antifreeze - has a boiling point of 108-125 degrees Celsius. Of course, the spread in the value is quite large, but the figure depends on the type of additives in the composition, the pressure in the system and the overall quality of the liquid.

The cheapest antifreeze is produced in violation of traditional technology, which affects the composition and properties. Sometimes drivers complain about liquids that boil at eighty-five degrees. Undoubtedly, this is dangerous for the car. Sometimes it is better to pour distilled water into the tank rather than an incomprehensible mixture. You shouldn’t save too much on antifreeze, because car repairs can ultimately cost much more.

Pressure dependence

At atmospheric pressure, high-quality antifreeze boils, reaching 180-110 degrees. But increased pressure in the system also increases the maximum permissible value for boiling liquid.

If the system is working properly, the upper limit for antifreeze can be shifted to plus 130 degrees. Of course, the system must be completely sealed. The antifreeze tank must be tightly closed. This largely depends on the serviceability of the valve on the expander cap. A leaky cooling system causes the antifreeze to quickly overheat. Under pressure, antifreeze increases the engine's resistance to overheating.

Main signs of an oil flash

According to the observations of experienced motorists, there are four main signs of a lubricant flash:

- Sudden change in thermostat readings. Each car is equipped with a special indicator that monitors the heating level of the lubricant. With a normally warmed-up engine, the instrument needle points to the average value. If the arrow begins to approach the red line, then this indicates that there is a problem with oil exchange.

- Characteristic sound of boiling. When the lubricant boils and then flashes, the motorist may hear a characteristic sound.

- Smoke appears. If smoke comes from the engine compartment, then most likely there is a boiling and flash of the lubricant.

- The appearance of black smoke from the exhaust pipe. This sign indicates that the problem with excessive lubricant temperature has reached an unpredictable level.

If any of the above symptoms appear, you must immediately begin troubleshooting the problem.

The influence of low temperatures on engine starting stability

When purchasing a lubricant, you need to familiarize yourself with the winter parameters of the fluid, since they determine the quality of starting the internal combustion engine in the cold season. If you are using a 5W-40 class lubricant, then subtract 35 from the number 5 (this is a constant number for all types of oils). We get -30 - this is the minimum temperature at which the lubricant can start the engine without problems.

Low temperature parameters

It is necessary to take into account not only the ambient temperature, but also the power unit, since the operation of the engine is determined by the vehicle’s mileage and loads.

There are low-temperature properties of the working fluid, which include:

- Pumpability. This parameter means a state in which the substance is pumped without problems through the channels of the lubrication system.

- Product rotation. This value indicates the dynamic characteristics of the viscosity of lubricants, as well as the temperature at which the lubricant becomes most liquid. In this state, starting the engine will be easier. The cranking temperature is always 5 degrees higher than the pumping temperature.

User Vlas Prudov made a video in which he talked about choosing a high-quality fluid for a machine engine.

Freezing

The value of the pour point is determined by the loss of mobility and fluidity properties of the liquid. When the viscosity parameters increase sharply, this leads to the beginning of the wax crystallization process. Oil operating at low temperatures will be less mobile. The lubricant hardens, which leads to an increase in ductility as a result of the release of hydrocarbon substances. The pour point of the motor fluid corresponds to the minimum circulation parameter. If the oil begins to solidify, starting the engine is possible, but it will be very difficult.

Solidification temperature

The solidification temperature is 3-5 degrees lower than solidification. When it gets very cold, the fluid base becomes harder, making it impossible for it to pass through the channels of the lubrication system. Accordingly, the driver will not be able to start the power unit. This problem is more pressing for residents of northern regions, who fill their cars with oils that do not meet the viscosity class for use in such conditions.

Loading …

What to do when the grease boils

- The car engine will immediately turn off.

- Minimize the load on the power unit by reducing speed.

- Turn on the car furnace for the maximum possible airflow, which will allow you to effectively and quickly remove superheated air from the working part of the car engine.

- If there is such an opportunity, then it is advisable to drive along a coasting road to quickly cool the engine compartment.

- After stopping the car completely, you need to wait at least 5 minutes and only then turn off the engine.

Friction modifiers.

For modern engines, they are increasingly trying to use oils with friction modifiers, which make it possible to reduce the coefficient of friction between rubbing parts in order to obtain energy-saving oils. The most well-known friction modifiers are graphite and molybdenum disulfide. They are very difficult to use in modern oils because these substances are insoluble in the oil and can only be dispersed in the oil in the form of small particles. This requires the introduction of additional dispersants and dispersion stabilizers into the oil, but this still does not allow the use of such oils for a long time. Therefore, at the moment, oil-soluble esters of fatty acids, which have very good adhesion to metal surfaces and form a layer of friction-reducing molecules on them, are usually used as friction modifiers.

Reasons for this problem

1. The main reason for this problem is the low quality of the lubricant used. If, in pursuit of cheaper oil, after some time problems arise with the car’s lubrication system, then this is not anything unexpected. After all, low-quality oil cannot cope with regular fluctuations in the temperature level inside the unit, thereby provoking it to evaporate and ignite. 2. Unfortunately, this situation can also arise when using high-quality material after it has aged. 3. The occurrence of a problem in the cooling system, such as a pump breakdown, a malfunction of the fan fluid coupling.

Good to know: Which motor oil is not counterfeited in Russia, list of the best

Standards and Specifications

SAE J300

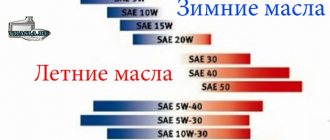

The classification of viscosity-temperature properties of lubricants SAE J300 was developed by the American Society of Automotive Engineers Society of Automotive Engineers. The system divides oils into two types: summer and winter (marked W - winter). For materials intended for operation at low temperatures, the limits of pumpability (MRV test - Mini Rotary Viscometer) and crankability (CCS - Cold Cranking Simulator) of the crankshaft are additionally regulated. For summer varieties, shear strength under extreme heating is determined (HTHS test - High Temperature High Shear Rate). The SAE J300 viscosity grade indicates the operating temperature range of a particular brand of engine oil. The designation of all-season varieties combines two indicators: winter and summer. For example, 5W-40.

Viscosity grades of winter motor oils SAE J300

| Low temperature viscosity | High temperature viscosity | ||||

| Class viscosity SAE | CCS, MPa-s. Max, at temperature, °C | MRV, MPa-s, Max, at temperature, °C | Kinematic viscosity, mm2/s at 100 °C | HTHS, MPa-s. Min at 150 °C and 10L6 s-1, | |

| Min | Max | ||||

| 0W | 3250 at -30 | 30000 at -35 | 3,8 | — | — |

| 5W | 3500 at -25 | 30000 at -30 | 3,8 | — | — |

| 10W | 3500 at -20 | 30000 at -25 | 4,1 | — | — |

| 15W | 3500 at -15 | 30000 at -20 | 5,6 | — | — |

| 20W | 4500 at -10 | 30000 at -15 | 5,6 | — | — |

| 25W | 6000 at -5 | 30000 at -10 | 9,3 | — | — |

What is the danger of high lubricant temperature

- If the above-mentioned indicator exceeds + 105 degrees, then a decrease in viscosity is guaranteed to occur, which will cause the destruction of the protective layer and overheating of the working parts of the engine.

- Such negative processes will provoke a decrease in the thermal gap between parts.

- In addition, increased temperature conditions will negatively affect the quality of the lubricant, causing its oxidation and accelerated aging.

- A fire in the engine of low-quality lubricant will be accompanied by the accumulation of various deposits, which can trigger a detonation explosion.

- Thanks to the oxidation process, an oil film is formed in the power unit, which, under the influence of high temperature, is baked on the surface of the main parts of the lubrication system.

- When engine oil ignites, a fire can occur that can destroy the entire vehicle in a matter of minutes.

Good to know: Anti-friction additives in motor oil

Application of paraffin:

Paraffin is used:

– for making candles and matches,

– as a lubricant for rubbing wooden parts (drawer guides, pencil cases, etc.), bicycle chains, lubricant for sliding cross-country skis, alpine skis and snowboards, etc.,

– in cosmetics for the production of Vaseline,

– as food additive E905 in the food industry,

– in paraffin therapy in medicine and cosmetology,

– as an effective neutron moderator and proton “generator” in nuclear physics and technology,

– in the manufacture of containers and packaging materials,

– for the production of rubber products,

– for finishing fabrics,

– for the production of household chemical goods,

– for the production of synthetic fatty acids and α-olefins in the petrochemical industry,

– as an electrical insulating material,

– as a component of greases,

– as an additive to lubricating oils.

Note: Photo //www.pexels.com, //pixabay.com

Site Map

Demand factor 6,231

The difference between the terms of properties, classification and characteristics of motor oils.

It is curious that upon requesting “motor oil characteristics,” Yandex dumps a bunch of articles where, after the traditional SEO play on the key phrase, in half the cases the text goes towards classifying oils according to API, ACEA, SAE and all other standards for assessing quality and applicability.

For those who need this, I can advise you to read the article on the classification of motor oils. The other half begins to talk about the properties inherent in oils, which is also close, but has a slightly different meaning. Here is an article about the properties of motor oils. In my understanding, characteristics are a quantitative expression of the properties of an oil. So to speak, properties expressed “in parrots”, i.e. physical quantities or coefficients having a numerical expression. For example, viscosity is a property of oil. And the value of kinematic viscosity at 100C (equal to, say, 14) is already a characteristic. In the public domain we can see several characteristics of motor oils; as a rule, they are indicated in the so-called TDS (Technical Data Sheet). These are the characteristics:

- kinematic viscosity

- dynamic viscosity

- viscosity index

- sulfate ash content

- base number

- pour point

- flash point

- density

Total.

So to speak, the conclusions from the article in brief:

- Characteristic is a quantitative expression of a particular property of the oil. You can measure it and compare it with other oils.

- Viscosity - winter, characterizes the ability of the oil to ensure engine starting in cold weather (dynamic viscosity) and working (NOT summer) (kinematic viscosity), tells us about the quality of engine lubrication. Thicker is better. Viscosity index is the change in viscosity with temperature. The number is larger - the change is smaller - better.

- Ash content is bad for catalysts and particulate filters in diesel engines; the alkalinity number means the oil’s resource for neutralizing acids.

- The pour point, like the flash point (and density), has no practical significance, but allows you to draw some conclusions about the composition of the oil.

Sulfated ash content, alkaline number.

These characteristics tell us about the chemical composition of the oil. First, let's look at sulfate ash content. There is an opinion that this characteristic indicates the amount of additives in the oil and, accordingly, its quality. Strictly speaking, this is not true, since there are now many ashless additives. But in fact, this number indicates the amount of inorganic salts (ash) remaining after the combustion/evaporation of the oil. It’s not necessarily sulfates, it’s just that they (read “sulfur” in their composition) scare aluminum engines with coatings that are afraid of sulfuric acid. In short, ash spoils particulate filters in diesel engines and catalytic converters in gasoline cars, but this is if the car consumes oil. In any case, the amount of sulfur in fuel is much more critical than in oil. For full-ash oils, the ash content is >1% of the total mass. For low-ash oils it is 0.5 - 0.9% (they, in turn, are divided into low-ash and medium-ash oils with a border of about 0.5 - 0.6% by mass). The total alkaline number is a characteristic of how long the oil can neutralize acids. Physically, this is the amount of potassium hydroxide (KOH) equivalent in neutralizing effect to the additive package in this oil. Those. If the TBN (Total Base Number) of an oil is 7.8, then the additives it contains have the same neutralizing ability as 7.8 mg of KOH per gram of oil. The higher this number, the longer the oil will resist oxidation processes (you can drive longer before changing the oil).