Very often, after replacing the timing belt, owners of Renault and Lada Priora cars are faced with a problem: a rhythmic noise is heard in the timing belt area. In today's article we will figure out where this noise can come from, where to look for the cause of the problem and how to fix it without resorting to the help of specialists.

The GDS system stands out for its extremely complex structure. In order for it to periodically function in the correct mode, it is necessary to timely check and replace certain parts

Reasons for whistling

The timing belt is made of cord covered with an outer layer of rubber. The inner surface is equipped with teeth for better adhesion to the crankshaft pulley. From it, the drive transmits torque to the camshaft, ensuring timely supply of fuel and air for optimal ignition of the mixture.

If the timing belt whistles, then this is a reason to worry, since the rubber element may fail, leaving the car immobilized.

There are 5 main reasons why the timing belt starts to whistle.

Tooth wear

Depending on the make and model of the car, the estimated service life of the rubber element in the gas distribution unit is 60–120 thousand km. With use, the teeth gradually wear out, so a gap appears between the counter protrusions and depressions on the crankshaft pulley. When unwinding, air gets into the voids, which causes an unpleasant squeak or howl from the right side of the engine compartment.

Tooth wear and cracks

Ingress of technical and other liquids

Another common cause of the problem is contact with technical fluids on the element. For example, if the cylinder head gasket is leaking, machine oil may drain onto the belt. If the cooling system pipes pass nearby and the clamp is loose, antifreeze often drips. Sometimes brake fluid sprays out of a leaky circuit when the pressure suddenly increases. Often there is an air duct above the timing belt, where fuel vapors enter and it “snotts” at the connections. Oil and other substances make rubber-to-metal contact unreliable, causing the timing belt to whistle.

If the plastic fender liners and lower protective elements are missing or damaged, then when driving through puddles, water may be thrown under the hood by the wheels. It gets on the timing belt and causes squeaking or squeaking. Some car owners note the occurrence of unpleasant symptoms in humid weather and spontaneous disappearance after a few days in a dry climate.

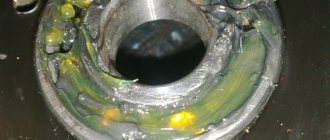

Roller surface wear

The next reason for the belt whistling lies not in the belt itself, but in a neighboring part. For optimal tension of the element, a roller with a rubber coating and sides is used. Sometimes it is simply machined from steel. The barrel with sides prevents the belt drive from slipping at high speeds. Another part of the design serves as a tension element, since the timing belt is the longest belt in the car, and the remaining pulleys are not adjustable in distance from each other. When the surface of the tensioner wears out, the drive begins to “walk”, producing excess noise.

Roller bearing wear

Problems sometimes arise even with a normal elastic roller coating, since the cause of belt whistling is a worn bearing. Additional space is formed between its holder and the steel balls, which leads to distortion of the part. When working with a small axial displacement, friction begins where it is not provided for by the manufacturer, which causes a squeak.

Checking the tensioner roller for play

And this problem does not arise due to high mileage - simply low-quality parts with a low resource. In 90% of cases, the timing belt whistles after replacement precisely because of the tensioner bearing, which is left as an old one or purchased from an unverified manufacturer.

Poor tension and cold engine

For some, the timing belt whistles when starting the engine, and then the unpleasant sound disappears. This misleads the car owner and he thinks that everything is fine since there is no howling during the trip. But the problem still exists and requires a solution. The fact is that the rubber transmission element has stretched. While the engine is cold, all clearances in the assembly are increased. Then linear expansion of the metal and rubber occurs, which “tensions” the parts to the desired state. Therefore, at startup the problem appears, and then disappears.

Weak tension

Related problems with the generator and pump

It is important for car owners to be aware of other possible problems that cause the whistling noise so that they do not go down the wrong path when trying to fix them. For example, when starting up, the whistle may come from the generator or pump. They are also located to the right of the engine in the engine compartment and the howl is approximately the same. To exclude the generator, you will need to disconnect the drive from the crankshaft with the engine off and start the engine.

To remove the pump, remove all tensioning elements and turn its shaft by hand. If you feel biting or the axle wobbles excessively, this may be the cause. When the rotation is unimpeded, they begin to look for a problem in the gas distribution part.

The tension pulley of the Priora timing belt 16 valves is noisy

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

the sound is similar to that of the author of the topic https://autolada.ru/viewtopic.php?p=7171345#7171345 The next question is, there is a trip to a distance of 2 thousand km.

(1 t.km+1 t.km). Departure in 4 days. There is practically no time to buy and replace a roller. How critical is this condition of the roller? Seryoga_ukr

If there is no time at all, for 8th grade I would take with me a set, a belt, a roller and drive the car to carry it. at most you can change it on the road

what about the video? take the tube wider or make a tube out of your palm, put it to your ear and point it at possible sources. where it is louder is the culprit

I'll add more. The roller is stock. Passed 51 thousand.

If the source of the sound is a video, what is the worst thing that could happen to it? I've been carrying the belt with me for about 5 years now.

I changed the pump 2 thousand ago. I also look askance at the pump (after reading the threads on the forum). But I hope not her.

Another such moment. A couple of days ago I tightened the alternator belt a little, without fanaticism. Today this sound appeared. At random, I decided to loosen the tension a little (the middle between “before” and “after”). The sound is gone. It didn't show up within 5 minutes. Then I drove into the garage, tomorrow I will listen and listen to the source. I mean, it's kind of a coincidence.

This is from the “no time” series. Real options AvtoVAZ and VPZ.

The circle narrows to AvtoVAZ and Samara Bearing. Which one is better?

A couple of days ago I tightened the alternator

, without fanaticism. Today this sound appeared. At random, I decided to loosen the tension a little (the middle between “before” and “after”). The sound is gone. It didn't show up within 5 minutes. Then I drove into the garage, tomorrow I will listen and listen to the source. I mean, it's kind of a coincidence.

Maybe a pump? Then your movable property can turn into immovable property.

The coolant does not go away and stays at the level. There was no sound this morning. As I already wrote, after a slight loosening of the alternator belt, it did not appear, and today it did not (may be a coincidence). I thought about the roller, because after poking around the forum, I read that people change rollers almost every 30 thousand or fill them with lubricant almost once a year. My video (native) was 51 thousand and 6.5 years old. I changed the pump at the beginning of May (about 1.5 thousand ago). The old one didn't leak. There was sluggish (virtually absent) pressure from the heater pipe. When I took it off, there was no play and the impeller held perfectly. But I installed a new one. The sound was heard yesterday with the car warmed up at idle speed.

Source

How to eliminate timing belt whistling: step-by-step instructions

Trying to eliminate the whistling problem, some car owners use silicone lubricant or WD-40, which increases the elasticity of the rubber element and makes the fit tighter. At the same time, it displaces oils that cause slippage.

But this is not the most effective method - and it can even be dangerous if the teeth jump due to lubrication.

The cause of the whistling can be completely eliminated only by replacing the belt and roller, and the spare parts must be genuine and from a trusted manufacturer.

Popular brands:

Audi A8, BMW 7-Series, Mercedes-Benz C-Class

The actions take place in a car with the engine turned off in the following sequence:

- On most models, it is recommended to remove the air pipe to allow more room for manipulation.

- Next, the protective casing is dismantled. Most often, a 10mm socket is suitable for this.

- The generator is mounted on two bolts that are adjustable in the grooves. Both clamps are loosened and the generator is moved towards the engine to relieve tension.

- Its belt is dismantled. To do this, the right wheel of the car is jacked up, gear is set to 5th and, by rotating the tire, the drive is removed.

- Using a socket head, the bolt holding the tensioner is unscrewed and the latter moves to the center of the internal combustion engine.

- The old timing belt is removed and a new one is put on. In this case, it is important to pre-align the pulleys according to the marks (the specific position of the marks is indicated in the operating instructions for the car) to ensure synchronization of air compression in the cylinders and the supply of fuel with a spark and fresh air. If tension cannot be achieved, the crankshaft is turned by the jacked wheel.

- Then use a roller to tighten the timing belt until it stops and fix the position.

Important! To begin putting the timing belt on the lower shaft first, and then on the upper.

Place the timing belt first on the lower shaft, then on the upper

After this, you should immediately try to start the engine (even before connecting the generator - the battery charge is enough for several minutes of engine operation) to see if the synchronization is correct. While everything is open, it is easier to correct something in case of an error. If the internal combustion engine does not start or runs on several cylinders, it is worth checking the position of the pulleys and starting again. When everything is normal, the belt drive is connected to the generator and the protective casing is installed. The generator is moved away from the engine with a pry bar to create tension, and its bolts are tightened.

Label option

Replace or tighten

Some people don’t want to spend money on a kit, and they hope to get by with a timing belt tightening. If it is not worn out and was indeed tensioned incorrectly to begin with or has become loose later, this may solve the problem.

But pulling up will only help if the problem is not with the support roller. If the latter is skewed, the whistle may even intensify when the pressure becomes even greater.

In this case, tightening should only be used to prevent the timing belt from being too loose, to prevent it from jumping one or more teeth. After a temporary measure, you should visit a service station as soon as possible.

AVTOVAZ recommendations for eliminating noise and rattling in the timing drive area

During operation of Lada Granta, Kalina and Priora cars equipped with 8-valve engines, the discrepancy “Noise, grinding noise during engine operation, in the timing drive area” may appear. The cause of the noise is the contact of the camshaft pulley with the rear protective cover of the timing belt 21116-1006209-01 due to deformation of the cover. This is described in information letter No. 12-19 dated 02/06/2019.

If the owner contacts the LADA dealership with this problem, the auto center specialists will eliminate extraneous noise in accordance with the factory recommendations. Additionally, when dismantling the rear protective cover, the condition of the site for installing an automatic timing belt tensioner on the cylinder head will be monitored.

Consequences for the car

If you ignore the whistle and continue to drive with a worn timing belt or a skewed tensioner, you may encounter a drive failure. This will create a desynchronization in the movement of the piston system and the cylinder head valve mechanism. They will begin to converge and disperse chaotically. The internal combustion engine will definitely stall and it will be impossible to start it. You will have to tow the car to the service station, calling a friend on wheels or a taxi.

Bend valves

But that is not all. In some engine models, this means that the pistons and valves will literally meet. Since the connecting rods are more powerful, the valve stems bend during a collision. The nickels themselves may break off and parts of them will fall into the cylinders. For repairs, you will need to completely remove the cylinder head, oil pan, crankshaft, connecting rods and check each cylinder for metal debris. Then buy new valves and restore the broken seats in the block head. To do this, they are welded with argon, then sharpened and ground. Therefore, you should not ignore the whistle and it is better to immediately contact the service.

GRS mechanism: operating principle

Let's start with the basics. The GDS system stands out for its extremely complex structure. In order for it to periodically function in the correct mode, it is necessary to timely check and replace certain parts.

To understand why the noise appeared, we need to delve into the structure of the system in more detail.

So, the GDS mechanism is a device that ensures the admission of the fuel mixture into the cylinders of the power plant, and is also responsible for the subsequent elimination of gases.

Considered to be an extremely complex internal combustion engine device, the GDS mechanism is responsible for the proper functioning of the engine valves. Moreover, everything must be carried out strictly within certain periods of time. The functioning of the system must be combined with the operation of other mechanisms.

How does the gas distribution mechanism work?

You can understand how the system works this way. For example, while driving, the driver presses the accelerator pedal to increase the speed of the car. As a result of this, the fuel mixture begins to flow into the internal combustion engine in larger quantities.

A motor is an even more complex device consisting of valves, actuators, shafts, etc. The task of the valves is to open and close in due time, and the drives are to create conditions for the automatic rotation of the shafts along the intended path and with a specific amplitude.

The camshaft pulley is located directly above the BC of the power plant. Valves and special pusher devices are also located here. Outside the cylinder head you can find the cam pulley disc.

Note. To prevent engine lubricant from being knocked out of the cover, the engineers provided a special oil seal.

It is important to understand that the new belt, which suddenly began to make noise, is put on the camshaft disc and receives its movement when the crankshaft flywheel rotates.

For good, or rather, correct belt tension, rollers are used. We must always monitor their normal functioning, just like the belt, they must be changed in a timely manner.