VAZ-2106 is a true classic of the Soviet automotive industry. The car was produced for a long time after the collapse of the Union, which is explained by its incredible reliability. In addition, it stands out from other domestically produced cars due to its amazing maintainability of literally every component, availability of spare parts, and unlimited possibilities for modernization.

An important advantage of the VAZ-2106 is the engine used in this car. This four-stroke unit, equipped until 2002 with a carburetor and then with an injection fuel ignition system, can run on even the lowest quality gasoline, rarely fails in extreme cold, and can be operated successfully in almost any conditions. Any of its problems are eliminated even without the participation of a specialist - any more or less experienced car enthusiast can easily cope with routine repairs.

How much does the VAZ weigh?

Perhaps one of the most popular cars in the post-Soviet space was, is and remains the VAZ. This car has captivated many generations. However, how did it all begin? When was the first VAZ car produced and how much did it weigh? You will learn the answers to these and other questions from this article.

The first VAZ car was produced by the Volzhsky Automobile Plant on April 19, 1970. The make of this car was VAZ-2101 Zhiguli. Its production was carried out according to the analogue of the Fiat concern. Moreover, VAZ owes its appearance to this particular brand of Fiat 124, produced in 1966. Here, in fact, is it:

As a result of some design improvements, the first domestic car, the VAZ 2101 of 1970, was produced:

The weight of this car was 955 kg. Moreover, of this mass the engine weighed 114 kg.

It has not lost its popularity to this day. In 2000, it was recognized as the best car among eighty thousand car enthusiasts surveyed in the CIS countries and Russia. It was named the best car of the century, VAZ 2101. At the time of its production, it was considered the most comfortable, reliable and modern domestic car. Its presence was a sign of wealth and prosperity!

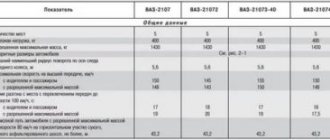

But the Volzhsky Automobile Plant did not stop there. He created entire collections of this car. Each of them differed in its configuration, as well as its total weight. Therefore, now we will compare some VAZ models by their weight.

- VAZ 2102 has a weight of 1010 kg .

- VAZ 2103 has a weight of 965 kg .

- VAZ 2104 has a weight of 1020 kg .

- VAZ 2105 has a weight of 1060 kg .

- VAZ 2106 has a weight of 1045 kg .

- VAZ 2107 weighs 1049 kg .

- VAZ 2108 weighs 945 kg .

- VAZ 2109 weighs 915 kg .

- VAZ 2110 has a weight of 1020 kg .

- VAZ 2111 has a weight of 1055 kg .

- VAZ 2112 has a weight of 1060 kg .

- VAZ 2113 weighs 975 kg .

- VAZ 2114 weighs 985 kg .

- VAZ 2115 has a weight of 1000 kg .

- VAZ 2116 weighs 1276 kg .

- VAZ 2117 has a weight of 1110 kg .

- VAZ 2118 has a weight of 1110 kg .

- VAZ 2119 has a weight of 1110 kg .

- VAZ 2120 has a weight of 1110 kg .

- VAZ 2121 has a weight of 1550 kg .

- VAZ 2122 has a weight of 1122 kg .

- VAZ 2123 has a weight of 1300 kg .

In what models was the VAZ used?

Improved engine characteristics made it possible to equip them with VAZ cars of the following models:

- 2103 Lada sedan;

- 21054 Zhiguli sedan (only for the FSB, the Ministry of Internal Affairs and the State Traffic Safety Inspectorate);

- 2106 Lada sedan;

- 21074 Lada sedan;

- 2121 Niva carries a 5-door station wagon or a 3-door hatchback.

Due to the following difficulties in the production of some parts, the 2106 engine was considered economically unprofitable by management and was discontinued.

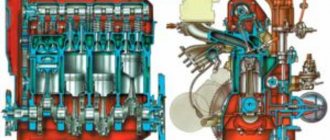

What does a VAZ engine consist of?

At its core, the VAZ 2106 engine is a modernized 4-cylinder Troika engine that has received more power. From now on, the car boasts 75 horsepower, which produces a torque of 116 Nm. However, the developers did not stop at just one variation, presenting several of the following modifications to the attention of car enthusiasts:

- classic car with 1.6 liter internal combustion engine;

- a product with a 1.3-liter engine, as well as a modified carburetor, the piston stroke length is 1.4 cm shorter;

- 1.5-liter engine with modified parameters of connecting rod and piston elements and block.

All variations without exception are popular, but the most popular are still models with an engine capacity of 1.5 liters. This VAZ 21061 is quite unpretentious in operation and fails less often than other modifications. In total, regardless of the design options, the VAZ 21061 - 21063 engine includes the following:

- cylinder and crankcase, at the bottom of which a special pan is usually installed;

- a piston and adjacent compression rings located directly inside the cylinder;

- the crankshaft that moves inside the crankcase bearings.

For those who are accustomed to repairing a car themselves, no difficulties arise during the operation of the “six”. It’s a completely different matter if the driver is thinking about how to increase the power of a VAZ engine. Then the process will require an order of magnitude more knowledge and, possibly, specialist consultation. Of course, if the owner really wants to improve his car, and not cause irreparable harm to it.

Advantages of the VAZ 2106 engine over its contemporary competitors

This unit is very successful compared to its predecessors. Its development was based on then modern technical solutions. The engineers were faced with a difficult task - it was necessary to significantly improve the existing engine models of the VAZ plant.

- Thanks to improved cylinder operation and increased unit volume, overall power has been significantly improved.

- The diameter of the cylinder block structure has changed upward.

- Since the cylinder head remained the same, to change the cylinder diameter it was necessary to introduce other gaskets.

- There are cylindrical holes. Each piston heats up evenly and gradually during operation. Thanks to this, the issue of thermal deformation was resolved. The plates that regulate heat are made of high quality steel.

Typical faults and features

If you know the features of the motor used in your personal car, you can significantly extend its service life and maintain good performance. Therefore, we will consider the most typical aspects that relate to this unit.

Warming up . In winter, the engine needs to be warmed up. You need to wait at least five minutes until the speed increases to 1500 rpm. Once the idle starts to hold up well, you can hit the road.

Oil . As for oil, problems often arise due to excessive savings. Owners of the “six” often buy low-quality oil or do not replace it in a timely manner. This leads to the fact that after a mileage of 60 thousand kilometers, the cylinders may increase in diameter. Also, sometimes situations arise that the engine begins to consume too much oil - more than 1 liter for every thousand kilometers. This indicates that it is time to measure the compression. This will let you know if there is a problem with the rings or valves.

Knocks and sounds . After only 7-10 thousand kilometers, loud knocking noises often begin to be heard in the engine at idle. This indicates that the valves need to be adjusted.

If engine detonation begins, you need to pay attention to the following points:

- What fuel is used? The use of low octane gasoline may cause detonation.

- Is there carbon deposits in the combustion chamber?

- Is the ignition installed correctly?

If the engine knocking is accompanied by metallic sounds, then it is time to go to a service center. It is most likely the connecting rod bearings or piston pins that require attention.

If the sound occurs during warm-up and resembles the sound of hitting pottery, then the pistons have “moved”. You need to immediately, but very carefully and slowly go to the service center.

If, when you hear a knock, the oil pressure also drops, then there are problems with the main bearings. Such a motor cannot be loaded with work. You urgently need to turn off the engine and tow the car to a service station.

If the car makes an unpleasant squeaking sound from the engine, then it’s time to work on the timing chain tensioner or damper.

If you hear grinding and knocking noises, then it’s time to change the pump bearing.

Unsustainable work. If the engine runs unsteadily, this most often indicates that it is time to clean the carburetor jets. If the engine starts to stall while idling, you need to check the idle speed and choke adjustment. If the problem with a stalling engine appears on the Oda, then it’s time to look into the ignition or power system.

Excessive heating of the unit. This may indicate that a poor quality thermostat is being used. The radiator may be clogged or air may have entered the cooling system.

The VAZ engine is tripping. Many newcomers who purchased a VAZ 2106 for the first time believe that this is an inevitable problem that is no longer worth paying attention to. However, there may be reasons for this problem, the elimination of which allows the engine to operate properly. For example, tripling may indicate that:

- Valve adjustment required

- Some valve burned out

- The cylinder head gasket needs replacing.

This may also be due to the use of low octane gasoline. If none of the above applies, you need to check the carburetor adjustment and ignition system.

Heavy smoke from the engine. Perhaps it's time to take your car in for repairs. This may indicate a malfunction of the oil scraper rings and valve seals.

Motor vibration. Vibration is caused by engine mounts wearing out over time. Also, one of the possible causes is an imbalance in the driveshaft and crankshaft. The service center will be able to diagnose and identify the exact cause of the malfunction.

Where is the engine number located?

An important identifying characteristic of any motor is its number. On a VAZ 2106, the number is stamped in two places at once (for the convenience of the driver and supervisory authorities):

- On the left side of the cylinder block.

- On a metal plate under the hood.

Each number is stamped as clearly as possible, since an ambiguous interpretation of the number cannot be allowed

The engine number is assigned at the factory; corrections and interruptions of numbers in the number are not allowed.

What engines can be installed on the VAZ 2106?

The best solution is to leave the one you have. However, some craftsmen install other units. You need to remember that the hood of this car is small in size. Therefore, VAZ 2106 engines with a cylinder diameter of 79 ml will feel most comfortable. You cannot install units that are too powerful, since neither the brake system, nor the axle, nor the suspension will be able to service them. It is recommended to install the following models:

- from Fiat 124

- from BMW 536, BMW 326, BMW 746

- model Lancia Thema (834)

- Alfa Romeo model (06476)

- Fiat Croma model (154)

In any case, it will be necessary to make some modifications related to the design features of each model.

Tuning rules

The main goal of high-quality tuning is improved engine performance. And the desired result can be achieved using the following methods:

- boosting the engine;

- chip tuning;

- replacing the ignition system with a more powerful one.

The most difficult and one of the most expensive procedures is increasing the diameter of the cylinders and the piston stroke. The weight of the VAZ car does not change, but the output power increases significantly. The best solution in this case is to replace the cylinders, which will be both easier and cheaper to install. The overall dimensions of the components will change very slightly and will not affect the ride quality in any way. Dimensions make themselves felt only when the vehicle is overcrowded or faulty.

Another effective tuning method is to improve the dynamic performance of the engine, achieved in the following way:

- the weight of the crankshaft and connecting rod-piston system is reduced;

- adjustment of gear ratios;

- adjustment of electronic systems.

The torque of the car will not change much from such actions; the power will increase, but only slightly.

Radical methods can come to the rescue, allowing those who wish to carry out in-depth tuning.

It consists in selecting a special crankshaft to replace the factory unit. This will allow you to change the car, practically reduce the ground clearance, and increase power. After all the necessary elements have been replaced, the vehicle as a whole is repaired and debugged.

Chip tuning is a relatively new modernization method that allows you to change parameters without mechanical intervention using special software. How much the engine weighs and when it was produced does not matter. The system will cope with any, even the most difficult, circumstances.

Replacing the ignition system belongs to the category of progressive tuning techniques. The best solution is a block called non-contact and allows you to significantly gain in power.

Experimenting with your own car is, of course, good, however, when deciding on the next modification, you need to think about whether they will be the last thing that the vehicle will finish off . The range of experiments is wide, so there is no need to rush. It’s better to think carefully and choose what will really come in handy.

This is interesting: What is a drive belt for?

Main technical characteristics of the six engine

As mentioned above, the VAZ 2106 power unit is the result of a refinement of the VAZ 2103 engine. The purpose of this modification is clear - the engineers tried to increase the power and dynamics of the new model. The result was achieved by increasing the cylinder diameters to 79 mm. In general, the new engine is no different from the VAZ 2103 engine.

On Six engines, the pistons have the same design as on previous models: their diameter is 79 mm, while the nominal piston stroke is 80 mm.

The crankshaft was also taken from the VAZ 2103, the only difference is that the crank was increased by 7 mm, which was dictated by the increase in the diameter of the cylinders. In addition, the length of the crankshaft was also increased and amounted to 50.7 mm. Due to the increase in the size of the crankshaft and cylinders, it was possible to make the model more powerful: the crankshaft rotates at maximum loads at speeds of up to 5400 rpm.

Since 1990, all VAZ 2106 models have been equipped with Ozone carburetors (before this period, Solex carburetors were used). Carburetor power plants allow you to create a car with maximum vitality and productivity. In addition, at the time of release, carburetor models were considered very economical: prices for AI-92 were quite affordable.

The design of the Ozone carburetor is considered quite complex, as it consists of many small parts

All models of “six” carburetors since 1990 have a displacement of 1.6 liters and a power of 75 horsepower (74.5 hp). The device does not have large dimensions: it is only 18.5 cm wide, 16 cm long, 21.5 cm high. The total weight of the entire assembled mechanism (without fuel being poured) is 2.79 kg. The overall dimensions of the entire motor are 541 mm wide, 541 mm long and 665 mm high. The assembled VAZ 2106 engine weighs 121 kg.

The working life of engines on the VAZ 2106, according to the manufacturer, does not exceed 125 thousand kilometers, however, with careful maintenance of the power unit and periodic cleaning of the carburetor, it is quite possible to extend this period to 200 thousand kilometers or more.

Technical features

Characteristics of the VAZ 2106 engine:

- The cylinder block is made of cast iron

- Can work with both carburetor and inverter type power systems

- The engine cylinders are in-line

- There are 4 cylinders in total

- There are 2 valves on the cylinder

- The distance from the lower to the upper position of the piston is 80 millimeters

- Each cylinder has a diameter of 79 millimeters

- The compression ratio of the unit is 8.5 atmospheres

- The power of the VAZ 2106 engine is 75 horsepower

- Engine displacement – 1,569

- You can use AI92 gasoline

- For every 100 kilometers on the highway, consumption averages 7.4 liters, and in the city - 10 liters

- For every 1000 kilometers, 700 grams of oil are consumed

- The following types of oil can be used: 5w-30, 5w-40, 10w-40, 15w-40

- When changing oil you need to use 3.5 liters

- According to factory data, the unit can travel up to 125,000 kilometers. In fact, it works up to 200,000 kilometers

- Installed on both VAZ 2106 and VAZ 21074, as well as VAZ 2121, VAZ 21053, VAZ 2103.

- Candles should be used of the following type: A17DVR, A17DV-10, FE65CPR

- The weight of the VAZ 2106 engine is 121 kilograms

Which oil to choose and how to replace it correctly

Among the large and varied selection you can find synthetic and mineral oil. They differ from each other in that the latter is capable of flushing out all unnecessary and excess deposits from the engine.

But in cars of this brand, spare parts are made of nitrile rubber, which can dissolve in high-quality synthetic oil. To completely prevent this process, it is necessary to replace all rubber parts with similar acrylic parts. They will work with any synthetic oil.

After all components have been replaced, you can switch to a synthetic analogue of oil.

Changing the oil in the VAZ 2106 engine is carried out independently or at a service station, where the technicians will simply drain the old mineral oil and fill in new one; or a specially designed detergent for washing (in case of heavily soiled parts).

In the latter case, the 2106 engine will be started for ten minutes so that the filled liquid can wash away all residual deposits from the use of outdated mineral oil.

Important:

- This operating process is necessary to ensure that the new synthetic oil does not mix with particles of used mineral oil.

- Otherwise, you may encounter blockage of the oil channels. To change the oil in VAZ 2106 engines you need to have certain knowledge. Otherwise, such intervention will lead to engine damage.

- If the vehicle has been in use for quite a long time, combustion deposits will form on the liners and gaskets. The holes in oil seals and head gaskets can become clogged.

- Particular attention should be paid to the general condition of all internal parts, especially check the seals and gaskets.

- When excessive pressure is observed inside the system when the supply tube is clogged, an oil leak can be expected.

- Therefore, to change the oil, you need to buy a high-quality brand that has been tested for decades.

VAZ for scrap metal

The First Scrap Metal Company is no longer alone in accepting old cars. By concluding a deal with us, you will not have to tediously wait for your funds. We work around the clock and are ready to accept your order immediately.

Please note: scrapping a car is not only a profitable decision, but also the right one from the point of view of protecting the environment.

How we are working

To begin with, the car is sent to a plant that processes metals. This is where they begin to separate old batteries, rubber and wiring from the car. After this, the parts are sent to the dismantling workshop. If there is any remaining gasoline in your car, it must be poured into a canister designed for this purpose. A completely disassembled car is just a pile of metal that will be sent to metal crushing equipment.

Everything that remains of the car is melted down. Recyclable materials will be simply an excellent source for making bodies for new cars. If you decide to sell your VAZ 2106 for scrap metal, you can:

- earn;

- clear the area around you of debris;

- contribute to improving the environmental situation;

- help in obtaining recyclable materials.

Documents needed to scrap a car:

- you must have a civil passport with you;

- passport of the car that is about to be scrapped;

- document authorizing disposal from the traffic police.

If you cannot deliver the car to the collection point yourself, then we will do it for you using special equipment for its delivery. We have a fleet of special vehicles for this!

The most frequently asked question is how much does a VAZ cost for scrap metal?

— We answer:

| VAZ model | Car weight | Blockage | Metal weight |

| 2101 | 955 kg | 30% | 668 kg |

| 2105 | 955 kg | 30% | 668 kg |

| 2106 | 1045 kg | 30% | 731 kg |

| 2107 | 1060 kg | 30% | 742 kg |

| 2109 | 945 kg | 30% | 661 kg |

| 21099 | 950 kg | 30% | 665 kg |

All data given in the table are approximate. For more information, please contact our manager.

Prices at the First Scrap Metal Company will be the most favorable for customers. Our company is official and takes great responsibility in determining the cost, which consists of the following factors:

- how much does the car weigh;

- what is the quality of its metal;

- Are the machine parts available?

- the shape of the machine itself.

The presence of an engine greatly increases the value of a car, because it contains a significant percentage of steel. Cast iron and steel are present in significant quantities in the chassis of the car. Nickel and copper are found in car electronics. In this regard, we can say that a more complete set of your car will bring more money upon delivery.

Why is it profitable to cooperate with us?

It is our company that will pay a high price for your scrap metal! We will come to you at exactly the agreed time, because we value our time and the time of our clients. The First Scrap Metal Company is distinguished by its integrity and works seven days a week and on holidays. Our specialists are highly qualified and experienced in similar work. Contact us to sell your VAZ 2107 for scrap! We will prepare the necessary accompanying documentation and pay instantly on the spot.

Design

I would like to note that this power unit was installed on many cars. It does not require much attention during maintenance and costs during repairs.

- It is based on a simple four-cylinder 2110 engine equipped with a direct injection system. The latter allows fuel to be injected into each cylinder of the engine to produce maximum power. The material is quite simple, high-strength cast iron with the addition of some elements. This combination allows for a very durable structure that can withstand shock and temperature changes.

- Cooling is carried out throughout the unit, evenly. This move completely eliminates overheating of the power unit and its failure.

- As for the cooling jacket, it is slightly open towards the cylinder head and cylinders. The lower part of the block is equipped with crankshaft bearing supports, which have special fastenings.

- The crankshaft itself is made of high quality cast iron. This was not done by chance, because only cast iron is able to withstand colossal temperatures and loads. No other material can produce such results. All connecting rod bearings are lubricated through oil valves that are drilled along the entire length of the crankshaft. This is very convenient and practical, especially in the summer.

- The power unit also has a vibration reduction system. It consists of several dozen counterweights located on the crankshaft. Due to this, the 2110 motor will not vibrate while moving.

- In front of the crankshaft you can see the oil pump with a timing belt pulley. At the rear there is a flywheel made of high-quality cast iron.

- All connecting rods are made of high-quality steel using forging. A small feature is the caps on the heads. There is a liner in the lower part, and a pressed-in bushing in the upper part.

- All pistons are equipped with three rings: two for compression, one for oil control. As for the material of the pistons, it is simple aluminum.

- On the bottom, the designers made special recesses for the combustion chamber. On top of all this is installed a cylinder head made of an alloy of steel and aluminum. Due to this, the 2110 motor is very durable and practical.

- At the bottom of the cylinder block you can find special channels designed for coolant circulation.

- A small feature of the VAZ 2110 engine is that the camshaft is located in the upper part of the power unit on supports. To reduce wear of parts, they are subjected to heat treatment. Thanks to this, the parts will not lose their properties during long-term operation.

- I would also like to note that the 8-valve engine has two valves per cylinder: intake and exhaust. They allow the fuel mixture to enter and exit the cylinder, thereby completing operating cycles. In addition, they are equipped with special springs. It is very convenient and practical. In addition, the engine from the VAZ 2110 receives good power and torque.

- The guide bushings and all valves are completely pressed into the cylinder head.

- The camshaft is driven by a simple timing belt from the crankshaft.

- I would also like to say something about the VAZ 2110 engine cooling system. The fact is that there is a fairly powerful electric fan installed here that turns on at a temperature of 115 degrees. It turns off when the power unit cools to 95 degrees.

- The power supply system is equipped with the following components:

- Fuel tank;

- Fuel lift pump;

- Air filter;

- Fuel lines;

- The carburetor itself.

It is worth noting that the fuel pump is located on the cylinder head itself and is driven by a pusher from the eccentric to the camshaft. All electronics of this type of car are focused on a simple controller. In simple words, an electronic control unit.

From the technical data sheet it is clear that the lubrication system has a combined system:

- By spraying;

- Under high pressure.

This system helps protect the power unit and mechanisms from damage and poor lubrication. All mechanisms will receive a sufficient amount of oil, which is very good. You don't have to worry about this. The VAZ 2110 engine with 16 valves is characterized by good durability and ease of maintenance.

In conclusion

“Kopeyka” is rightfully called a legend of Soviet automobile production. People appreciated this car for its reliability, practicality and affordability. This modification has not been produced for a long time, but it can be purchased on the secondary market. There are quite well preserved copies. In addition, the VAZ-2101 represents a limitless field for tuning. Craftsmen “put their hand” to literally all parts of the car, from equipping the interior to modifying the body and power unit.

Repairing a VAZ engine is quite possible to do on your own

Engine 2103 1.5l

The design of this power unit is quite simple. Accordingly, many car enthusiasts can do all engine-related repairs themselves. This option helps to save a certain amount due to the absence of the need to pay for the work of the craftsmen. There are a number of signs that indicate the need for repairs. Among them are:

- increased fuel and oil consumption;

- smoky exhaust with a clear bluish tint;

- uneven operation of the engine in idle mode;

- the appearance of soot on candles;

- clearly decreased power and sluggish dynamics;

- tripling;

- “sneezing” of the carburetor;

- “shots” in the silencer;

- constant overheating.

The simplest type of engine repair is replacing consumables. In principle, these works can even be classified as maintenance. If you want the engine of your “troika” to serve for a long time, you should change spark plugs, filters, and oil in a timely manner. Every 10 thousand kilometers it is necessary to adjust the valves.

It makes no sense to describe all possible repair options. It would probably be more correct to talk about how the engine is disassembled. Immediately before this, you should remove the engine from the car and wash it thoroughly. Now you can proceed directly to disassembly. We remove the carburetor, having first disconnected the hoses and throttle linkage, then the distributor and fuel pump, coolant temperature sensor. Now you can unscrew the spark plugs. Next comes the turn of all the hoses and pipes of the cooling system.

The oil filter is unscrewed using a special tool. Many Soviet-era car enthusiasts have it in their garages. Therefore, if you don’t have one, ask your friends so as not to spend extra money on the purchase. After unscrewing the filter, you can remove the oil pressure sensor. The next stage is dismantling the crankcase ventilation breather and the entire assembly. Now remove the drain tube clamp and remove the oil separator.

The ratchet can also be unscrewed using a special wrench. Now we fix it from turning and remove the crankshaft pulley. After this, you can begin to dismantle the camshaft drive cover and cylinder head. Next you will need to sweat a little. First, remove the bolts holding the oil pump and camshaft sprockets. Next, remove the chain tensioner and shoe. All that remains is to unscrew the limiting pin and remove the sprockets. That's it - you can pull out the chain.

Now we proceed to dismantling the crankshaft. Here you first need to unscrew the nuts of the studs securing the bearing housing. After this, the latter are removed along with the crankshaft. Next, you need to unscrew the mounting bolts and remove the cylinder head along with the manifolds. From there we remove the oil pump drive shaft, having previously dismantled the thrust flange. Next, we arm ourselves with a special puller and remove the crankshaft sprocket. In order to remove the pistons and connecting rods, first unscrew the nuts of the corresponding bolts. One important point is worth emphasizing here. Experienced car enthusiasts advise to be sure to mark connecting rods, bearings (as well as their caps) and pistons. This is necessary so that when reassembling you do not mix up anything.

After this, you can unscrew the flywheel mounting bolts and remove the washer. Here, in principle, everything is simple. Next, we remove the flywheel itself, after which, using a puller, we pull out the gearbox input shaft bearing from its socket in the crankshaft. However, the last step can be done later. This, as they say, is at your discretion. Now all we have to do is remove the crankshaft oil seal holder, the main bearings (after unscrewing the corresponding bolts), and the crankshaft itself. That's all - engine disassembly is complete.

All you have to do is determine which parts need replacing, buy new ones, and reassemble in the reverse order. As you can see, there is really nothing particularly complicated here. Of course, you will have to spend some time, and not every car enthusiast has the space to carry out such work. Nevertheless, many owners of “threes” prefer to repair their cars with their own hands.

VAZ for scrap metal

- Scrap removal Scrap metal pickup

- Non-ferrous metal scrap

- Paper

Cylinder block

The 2112 cylinder block is made of high-strength cast iron, and at first glance, is similar to the 21083 block. The main differences are the diameter of the head mounting bolts and holes for them in the block reduced to 10 mm, lugs for the fuel injection system sensors and a completely different technology for honing the cylinders during production .

| Parameter | Meaning |

| Material | Ductile iron |

| Cylinder diameter, mm | 82,0 |

| Intercylinder distance (distance between the axes of adjacent cylinders of the block), mm | 89,0 |

| Block height (distance between the upper plane of the block and the axis of the crankshaft), mm | 194,80 |

| Diameter of boring of crankshaft supports (for main bearings), mm | 54,52 |

| Weight, kg | 28,810 |

For the VAZ 2112 block, five size groups are defined. Size classes are designated by letters: A, B, C, D, E.