Strictly speaking, devices that hold the hood or trunk lid open are not shock absorbers. These are gas springs that use the properties of gases to accumulate energy when compressed. But since certain damping abilities are present there, and the device itself is very similar in appearance to a regular automobile telescopic shock absorber, the not entirely accurate designation has taken root and is actively used by everyone except manufacturers.

Car trunk shock absorber

Shock absorbers, like most other car parts, can be divided into subtypes. They are: Each type has its own advantages and, of course, disadvantages, which can be insignificant, or, conversely, unpleasant in some situations. Gas shock absorbers are the lightest, since the weight of the entire part is almost equal to the weight of the body.

On some sports cars, a few grams removed from the total weight of the car often pleases its owner, but in practice this is practically unsuitable. The main advantage of gas shock absorbers is their durability.

Most likely, with proper use, they will last the entire life of the car without any problems.

This is the most resistant type of spare parts to weather conditions, dirt and improper care.

Hyundai Elantra HD (automatic transmission) › Logbook › Furniture gas struts (shock absorbers) in the trunk

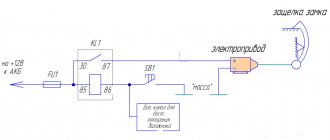

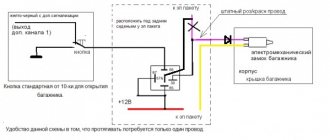

I decided to implement a spectacular automatic trunk opening and implemented it in a budget way.

Fortunately, you can find anything you want on the Internet; I liked the idea of using furniture gas stops or shock absorbers to effectively open the trunk at the touch of a button. I would like to note that my car is designed to automatically open the trunk, but given that there is no such thing as a license plate, apparently the Korean engineers don’t realize that you can’t drive a car without license plates. The 80 Newton stops themselves were bought a long time ago at a hardware store for 100 rubles.

There are some pitfalls during installation, but more on that below.

A little about the trunk supports

The trunk lid, as well as the hood of the vehicle, can treacherously drop at the most inopportune moment, causing injury to the motorist. The description of such a nuisance was reflected in many jokes and even movies, but it never promised anything good to the car owner himself. Automakers have found a simple and elegant solution - to install special shock absorbers that simplify access to the trunk or engine compartment, and also guarantee safety during operation. They have several names: the most common “shock absorber”, the often used “stop”, “torsion bar”, less often “gas spring”. The most correct name is “pneumatic-hydraulic stop”, although both buyers and sellers use it very rarely.

Conclusion

Although the shock absorbers of the trunk and hood are resistant to mechanical stress, they fail on average once during the entire life of the car. Luckily, finding a new shock absorber is easy. Good analogues can be found in the catalogs of companies such as LUK, Finwhale, Blue Print, Monroe, Kraft, Magnetti Marelli. Inexpensive options of medium quality can be found at, Sampa and FPS. There are quite a few options, but we still recommend buying shock absorbers from the most well-known companies, whose products are never cheap - here high quality is truly reflected in the high price.

Gas trunk shock absorbers

Installation of shock absorbers (stops) for the luggage compartment. Demonstration of installation of shock absorbers (stops) of the Lada Vesta trunk (art.

AB-LD-VS00-00) from upory.ru https://upory.ru/shop/122/desc/lada_vesta_bag.

Gas stops for the trunk lid on the Lada V. Opening the trunk with a button on the Lada Vesta. Stops: https://lada-vesta-shop.ru/shop/dopolnitelnoe-oborudovanie/gazovie-upory-bagazhnika.html. Trunk lid shock absorbers for BMW E-3. You can buy shock absorbers here - https://ali.pub/w9onf Cashback service from 7% on AliExpress products - https://epngo.bz/cashback_index/f54q68. trunk lid shock absorber 2109.mp4 It was interesting what was inside and why it was written “do not open” Installation of shock absorbers (stops) for the trunk.

Demonstration of installing trunk shock absorbers (stops) for Hyundai Solaris (art.

A little about electronic trunk shock absorbers

Electronic trunk dampers can be found on some two-box vehicles rather than the more common gas and oil filled units. Their main advantages: ease of installation and increased comfort. The main disadvantages: high price, low prevalence and average service life of the entire system (the shock absorber must be installed together with a number of other elements). The Electronic Stop Installation Kit includes the following:

- The shock absorber itself;

- Special control unit;

- Key control button;

- Opening and closing buttons installed in the interior;

- Sensor;

- Touch strips.

There is no point in talking about the buttons - they are needed to control the shock absorbers

But the sensor strips cannot help but attract the attention of the car enthusiast. They play the role of additional protection against possible pinching

The special sensor included in the kit is an integral part of the system, so if it fails, it will simply be impossible to get close to the trunk. The installation of an electronic trunk shock absorber can be carried out by the car enthusiast himself. All the necessary information is in the manual that comes with the kit. However, if there is a problem with installation, you can turn to professionals. The same electrician will cope with the task of installing such a shock absorber, and will also check the operation of the mechanism and, if necessary, make adjustments.

Replacing stops - step-by-step instructions

Open the trunk and support its lid with some strong wooden beam. It is advisable to replace both stops with bars so that it is convenient to work with them from either side. After installing the safety stops, parts are replaced. It is quite simple and takes no more than 10 minutes. The hinged ends are secured with some kind of clamp. Typically, either a flat clamp or a C-shaped clamp is used. The latter should slide through the bottom of the cracker, and then under the ball

Only in this case will the fastening be reliable. It is important to push out the old shock absorber correctly. Some car enthusiasts do this by using a screwdriver, inserting it between the ball joint and the metal, and then pulling like a lever.

For this purpose, it is better to use needle-nose pliers or a small screwdriver, with which you should carefully lift the clamp from the cracker. Then all that remains is to pull the cracker off the ball. The same manipulations should be repeated with the second end of the stop. Installing the new part will be made easier by applying a small amount of silicone grease to the inside of the cracker. To do this, the clamps are installed in a half-open position. Then you need to pull a new cracker onto the ball and snap the clamp. It also happens that the hinge joint does not have a clamp, and the ball joint is screwed to the body panel. In this case, it is recommended to use a hex wrench to remove the old ball joint. You can screw on the new heel using an open-end wrench. If the stop is mounted on a rigid mount, you just need to unscrew the bolt holding it in place. The fastening on the pin should be disassembled using a locking spring washer or pin to prevent the stop from slipping off the pin. To release the lock washer, it must either be pushed or pulled in a specific direction. In some cases, it is enough to push it slightly with the tip of a screwdriver. You can also grab the end of the washer with needle nose pliers and pull it out. After this, the old hood or trunk lid stop must be removed, a new one installed, and the lock washer smoothly returned to its place until it snaps into place. Usually the piston column has a coating that is resistant to external influences. However, when working, you still need to act carefully so as not to damage it. It is also important to install the new part correctly. If the old stop was with the piston down, the new one should have the same position. A device containing nitrogen or hydraulic fluid will operate more smoothly if the rod end is pointed down. After installing the new shock absorbers, you can remove the wooden block holding the hood or trunk and enjoy the convenience of the system.

We continue to replace

Please note that old pneumatic-hydraulic stops must be removed as carefully as possible so as not to damage the fasteners. To do this, we insert a flat-head screwdriver between the ball joint of the torsion bar and the metal, using it as a lever. The clamp is first removed from the cracker and then from the ball. The process is similar with the second rack.

An important detail - many drivers change one rack at a time. This is wrong, because for normal operation it is necessary to perform pairwise replacements. If you leave one old shock absorber, then most of the load will fall on the new shock absorber, therefore, it will quickly fail. This also applies to the hood, and many components in the car. Well, now let’s move on and briefly consider the process of installing new racks.

Recommendations for installing trunk supports

To ensure that the lid closes and opens smoothly in any weather, you can adjust the trunk and wrap the torsion bars with electrical tape. If the door begins to open too much and touches the roof, it is better to attach a gas strut travel limiter. It is easy to make from nylon rope.

Sometimes it happens that shock absorbers are sold without mounting bolts. In this case, the missing elements must be removed from the old stops. If the model is not designed for disassembly, you will have to cut the body of the old stop. To connect an old bolt to a new part, you must:

- Remove the spring from the ball pin.

- Insert the bolt inside until it stops. It is necessary that it catches on the retaining ring. A characteristic click should be heard.

- If the parts were able to be attached, install the spring in its old place.

Installation in 15 minutes

It is advisable to use silicone lubricant. It is needed so that the new shock absorber fits into place more easily. The cracker is treated with lubricant from the inside, and the clamp is installed in the half-open position. Then the cracker is pulled over the ball and the clamp is closed. If the fastening is somewhat different, for example, the ball end is attached directly to the car body, then in this case you will need a hex key. With its help, the old ball joint is unscrewed and a new one with an open link is installed.

You may also encounter rigid mounting of the stop. It is quite rare, but still sometimes comes across. In this case, it is necessary to unscrew the fastening bolt and remove the pin or spring washer. Be careful not to let the stop slide off the pin. There must be a lock washer. It needs to be pulled in a certain direction, after which it will be possible to install a new stop. Approximately in this sequence you can change the trunk shock absorber on Kalina and some other domestic cars.

DIY rear door shock absorber repair

In the vastness of the forum, there are different ways to relieve pressure from the rack before disassembling, but there is not a single detailed one. Write down who does it and how, in detail, so to speak “competitively”, so that later you won’t be offended by the repair you just made, or worse, by a damaged eye.

A thin drill bit and a drill at low speed. True, I was dismantling a shriveled gas strut. Otherwise, the GP from the office chair was understood in the same way. Drill so that the future hole is located above the oil level. If you are afraid for your eyes, put a protective shield cut out of cardboard over the drill. However, I drilled without anything and there was nothing but zilch.

Why be wise? Drilled and pricked with a needle. If it didn’t puncture, I still drilled it. Drill 1-1.5 mm. I used to drill with a 0.25 drill bit, but it's difficult without breaking it. It drills where it is cut. And so, my grandfather sawed such a stand on the balcony, using a file in a circle. Then he told how someone fired a gun at him and showed off the bruise. It’s good that he at least said what he did, otherwise I might have believed it.

Where is the sealing ring located on the rod plug? I ask because it is necessary to maintain the maximum length of the pipe. Where should I drill? Here are two photos:

Honestly, I don't remember. I was drilling a stand that was already leaking, there was a little oil in it, a cube at most. You let it lie down in a horizontal position so that as much oil as possible drains off the top wall. Once the air is released, the oil will no longer flow, it will only ooze. Cover the pipe with rags if you are afraid of getting something dirty, but I don’t think they will be useful. I can’t tell you where to drill - I drilled in the middle, I was just curious what was inside

Yes, they drilled her hole and that’s it. There is no more than a couple of cubes of oil. Don't be afraid of it, while you're drilling it will all flow down. The hole definitely won't have it.

Judging by the photo, the stand is stretched, made of a round coin, like a 12 gram can. This means the walls are a little thicker, but not by much.

Drilled. It turned out “the devil is not so scary.” “The drill was really dull, I didn’t sharpen it, I drilled for about 3 minutes, and at the same time I was watching a movie on TV, when it “bumped” I didn’t even have time to get scared - I was distracted. By the way, the “zilch” is similar to what happens if you hold the fitting of a car pump with your finger, pump and release the fitting, that is, the sound is quite quiet and nothing is splashed with oil. If anyone is interested, after complete disassembly I will post a photo of the giblets, if not necessary, I will destroy the thread.

This shriveled stand (it was easily pressed in) was removed using a dirty but safe method - the rod in the place number “1” was ground off with sandpaper, then it was pressed against the floor with the rod and pressed. I naturally bleed it down the machined rod along with the oil =) well, this was all done in the garage using old rags. I disassembled the next one by FINISHING it with a hacksaw in the place numbered “2”. file the current at one point (and not in a circle.) or it’s even easier to drill with a thin 1mm drill. when it hisses, don’t get scared and don’t throw it away (if it’s in a vice, you can cover it with a rag and step aside. If you’re drilling on the floor, you can put the stand in a thicker pipe, leaving only the tip into which you’ll drill), otherwise it will turn over and splash oil =)

Be sure to use safety glasses.

At one time I drilled into a stud along its axis. A small spritz and a drop of oil. All!

Popular shock absorber models

As you know, today products from several manufacturers are entering the market. Let's take a closer look at the models and find out their strengths and weaknesses.

DELLO from Germany

DELLO is a manufacturer of various spare parts for Volkswagen, Audi and other European cars. It is a brand from the first letter in Hamburg, as well as throughout Germany. The products, including shock absorbers for the cargo compartment and hood, are very popular in Russia.

It will be useful to know that some of the DELLO assortment is produced by third-party companies, but under a patent. Such products are sold under the AutoMega brand.

Spare parts from this German company are unrivaled, but sometimes unflattering reviews are heard. According to experts, if you take into account the cost of products, DELLO shock absorbers are a very profitable option with good quality. On the other hand, to be completely honest, the quality of the products somehow reaches 3 on a 5-point system.

MONROE

A very well-known manufacturing company in Russia. The design of Monroe products is always based on special technology. It is always head and shoulders above its competitors.

It will be interesting to characterize one of the manufacturer’s models:

- The buoyant force of the model from Monroe ML5809 is 410N.

- The internal working component is gas.

- The length of the cylinder is 19 mm.

- Product length – 536 mm.

The cost of this model rarely exceeds 700-800 rubles, although in some areas of the country they can be more expensive.

In general, if you ask the users of Monroe products themselves, they will call the price of shock absorbers quite affordable. But the most important thing that attracts people from Monroe products is the ability to modernize them. For example, if you need to repaint the fasteners so that they do not glow with the shine of chrome or for other reasons, this can be easily done.

Nakayama

A Japanese manufacturer that produces products at very low prices. Shock absorbers for the lid from Nakayama at one time could even be bought for 100 rubles.

Many motorists, owners of VAZ models, manage to install products from Nakayama along with springs from the trunk. As a result, this combination gives an amazingly effective result. The lid is fixed very securely at any angle.

On the other hand, even without the VAZ spring, the Nakayama shock absorber functions excellently, although the cargo compartment lid of some car models will only be securely fixed at the highest point.

Not all models are listed above, and not only the best. They are simply often more in demand than products from other manufacturers in Russia.

Features of operation of shock absorbers

The very first selection criterion is the frequency with which we use this or that device. Some drivers more often climb under the hood of a car than into the trunk, while others do the opposite. This factor plays a fairly significant role when choosing shock absorbers. Based on this, you need to think about what kind of wear resistance is best to choose for the hood or trunk.

It is worth noting that before purchasing shock absorbers for the hood or trunk lid, you must carefully study the technical literature of the vehicle. All technical characteristics of the parts used on this vehicle must be given there. The same applies to shock absorbers. An incorrectly selected system may not work correctly and therefore quickly fail.

There are cases where drivers mistakenly install shock absorbers on the hood of a rather short length. Thus, the owner of the car was unable to check the oil level, since the dipstick did not come out all the way. The same applies to the trunk of a vehicle. If it does not open high enough, you can safely forget about large cargo that will not fit into the trunk of the car.

When using such a shock absorber in the cold season, do not sharply open the car hood, trunk lid or rear door without making sure that it has completely warmed up. This should be done as smoothly as possible to allow the liquid inside to flow more slowly. It is worth noting that the trunk shock absorbers should be slightly tighter than the hood shock absorbers. This is due to the fact that during the loading process, the trunk can suddenly close and, having a higher fall speed, as well as higher weight and possible hands-on occupation, cause quite serious damage.

How to make the right choice

Before you buy a trunk lid shock absorber, you need to understand a little about the range on the market and what is right for you. The first important point is the frequency of operation. A lot depends on this parameter. After all, the more often the trunk or hood lid is used, the greater the load the shock absorber is subjected to. Accordingly, the more the hood or trunk weighs, the greater the pushing force the rack must have.

The operating instructions usually indicate the type of shock absorber and its characteristics. At the very least, there should be markings by which you can understand what it costs and with what parameters. But there is one caveat. For example, many cars from Japan, the USA and other countries cannot withstand our harsh climatic conditions. Therefore, many components are not designed for temperature fluctuations. But the VAZ-2110 trunk shock absorber tolerates cold well, so sometimes it makes sense to install it on foreign cars.

Restoring struts: collapsible and non-dismountable shock absorber

A simple automobile shock absorber has the following design:

- lug body;

- rod with casing and mounting eye;

- piston, compression and return valves, rings;

- cylinder with valves;

- seals and fastening nuts.

First of all, the main problem of the shock absorber is leakage of oil or boost gas. As a result, the rack leaks, a knocking sound is heard during operation, and deformation of the rod is also possible. Violations of tightness and defects lead to changes in characteristics (partial or complete loss of performance). As a result, the car handles and brakes poorly, rolls, and does not hold the road, since the struts do not dampen the vibrations and sway of the body.

The main malfunctions include: free movement of the rod in the pipe, play during compression or rebound (workout in the rod or cylinder), damage to the shock absorber valves. It is also impossible to exclude external damage (case cracks, dents, etc.).

To repair, you need to remove the strut, remove the spring and release the shock absorber. Next, you should understand whether the shock absorber on the car is collapsible or non-dismountable. If the body is solid, then such a rack cannot be repaired. It is officially prohibited to open the body and try to weld the shock absorber after repair. If there is a nut or retaining ring in the place where the rod enters the pipe, this stand allows for repairs or maintenance.

To repair a gas and gas-oil collapsible shock absorber in a garage, you will need a compressor for supplying air (you can use a bicycle pump), a fitting for supplying compressed air, and a pressure gauge

Please note that you will have to work with high pressure, you should protect your eyes, hands, and face in advance

Repair of a collapsible type rack begins with the rack being clamped vertically in a vice, washed of dirt, and the entry point of the rod is also blown with air. Next, disassembly of the shock absorber begins and the protective cap of the rod is removed. Then you need to fill the shock absorber under pressure; for this you need a pressure gauge.

The shock absorber can be filled with nitrogen, carbon dioxide and compressed air. In the garage, it is optimal to use compressed air for repairs. First, the rack is disassembled, cleaned, the O-rings are checked, and the condition of the inner wall of the pipe is assessed.

If the shock absorber has damage to the rod, seals or valves inside the strut, you can buy a repair kit for dismountable shock absorbers, remove “live” parts from another strut, etc. The main task is to install all functional parts to obtain complete tightness, while cleanliness is extremely important during assembly (debris and shavings will quickly damage the restored rack).

By the way, it is always better to replace the oil seal with a new one, even if the existing one does not cause any complaints. Next, all that remains is to pump oil or air into the shock absorber, after which the strut needs to be pumped.

Shock absorber bleeding is required

Please note that shock absorber repairs must be done in pairs, just like replacements. In other words, repairing rear shock absorbers or repairing front struts involves manipulating both the right and left sides, that is, you need to restore both struts on the same axis

Now let's move on to how to disassemble a shock absorber and how to repair a non-dismountable shock absorber. Let us note once again that such parts are not officially repaired. However, repairs are possible, but they require skills and special equipment. In fact, usually non-separable shock absorbers are simply converted into collapsible struts.

If there is equipment, the repair comes down to the fact that it may be necessary to change the main part of the rack (cartridge), it may be necessary to replace the rod (sometimes to install a reinforced one), oil seals, seals, etc. In general, the process is reminiscent of repairing struts with your own hands in the case of collapsible shock absorbers.

In fact, it all comes down to replacing worn components, reassembling and pumping gas/oil. The main difference is that you need to remove the “cover”, which is not removable. There are many ways, from drilling holes to converting the rack from permanent to collapsible by installing a rod protection cap.

In any case, such repair of the shock absorber strut (if it is successful) allows you to restore performance, but it is difficult to guarantee the reliability and service life of the repaired strut. The main reason is that, in fact, it is necessary to make changes to the design, since the restoration of non-separable type shock absorbers involves disassembling and subsequent reassembly of the body, which initially does not provide such a possibility.

Let's talk about recovery

Objectively, the most correct move on the part of a car owner who is faced with a breakdown of the shock absorbers on his vehicle is to replace them.

I don’t argue that in the case of collapsible elements, it is possible to carry out repairs. The video clearly shows how to do this. But what about the non-separable ones?

The concept of recovery is increasingly being applied to such shock absorbers. Theoretically, and sometimes practically, it is possible to restore shock absorbers of a non-separable type. But this method has a number of pitfalls. The restoration guarantee is 6-12 months, and most often this is no more than six months. Plus, operating a car with such shock absorbers is not 100% safe and reliable. In any case, the design of the unit is violated. All this provided that the restoration of the non-disassembly was carried out by an experienced craftsman and using professional equipment. What can we say about the quality and reliability of attempts to restore it with your own hands in a garage.

Shock absorbers are not those elements of the car on which you can and should save. They directly affect your own safety. Think about this when the thought arises of restoring or repairing old shock absorbers that have served their purpose. Maybe it’s better to buy new ones?!

Subscribe, write your opinion in the comments, ask questions on the topic! Don't forget to tell your friends about us!

Selection of shock absorbers for the hood, rear door and trunk

Hello, dear car enthusiasts! We are accustomed to the fact that the word “shock absorber” is most often used in relation to the chassis (suspension) of a car.

Initially, shock absorbers were intended specifically for damping, that is, artificially suppressing vibrations of suspension elements and the vehicle body.

With the development of the automotive industry, shock absorbers began to be used in other elements of the car. And if in the recent past, conventional stops were used to open the hood or trunk lid, today many car models use hood, trunk, and rear door shock absorbers.

And, although the requirements for them are not as stringent as for suspension shock absorbers, the choice of shock absorbers for the hood, trunk lid or rear door has its own characteristics. So let's together consider the question of how to choose shock absorbers correctly. So that they perform their functions as long as possible and as efficiently as possible: convenience and comfort of car operation.

We begin the selection of shock absorbers by studying the operating features

The seemingly identical hood shock absorbers and rear door or trunk lid shock absorbers serve their purpose in different ways. This depends on a number of reasons.

First of all, it depends on the intensity of use of various elements of the car. After all, you cannot argue with the fact that we climb under the hood of a modern car less often than into the trunk. Therefore, in addition to the general requirements for the selection of shock absorbers, the intensity of operation of the mechanism must also be taken into account.

Of course, before choosing shock absorbers for a particular body element, you need to open the operating manual for your car and read the manufacturer’s recommendations: on the type and brand of shock absorbers, and on their technical characteristics.

When choosing a hood shock absorber, it is advisable to ensure that it is not short. Let’s say that in order to check the engine oil level or the brake fluid level, the opening height of the hood lid is sufficient.

But when at a car service center you need free access to the “insides” of the engine, you will hear everything that the master thinks about you. Therefore, it is advisable to choose a hood shock absorber with a long rod stroke.

When choosing shock absorbers for the trunk, consider the intensity of their use. If you look into the trunk very often, then a gas trunk shock absorber will be just for you. Although they are not cheap, they last a very long time and are reliable.

A general important rule when using shock absorbers for the rear door, hood, and trunk: in the cold season, do not try to open the hood or trunk with a sharp jerk. This way you will help the shock absorber fail much earlier than the time specified by the manufacturer. In winter, the hood or rear door should be opened smoothly, helping the shock absorbers

This is due to the fact that at low temperatures the shock absorber working substance becomes more viscous

In winter, the hood or rear door should be opened smoothly, assisted by the shock absorbers. This is due to the fact that at low temperatures the shock absorber working substance becomes more viscous.

When selecting a rear door shock absorber, select a mechanism with greater buoyancy force than for the hood shock absorber.

General Information and Concepts

It is necessary to understand that a shock absorber that dampens vibrations from the road surface and one installed on the hood or trunk are two different things. The latter is a rather fragile and, so to speak, delicate mechanism, the operation of which must be periodically checked. Of course, there is nothing critical about the failure of the trunk lid shock absorber, but it can hit you on the head or fingers, and this is also not very pleasant.

According to the type of damping, shock absorbers are divided into two types:

Actually, if we talk about a more suitable option, then these are dynamic trunk shock absorbers. True, they cost slightly more than hydraulic ones, but this is fully justified by their reliability.

Tips for long-term use of shock absorbers

Sometimes motorists complain about squeaks when opening the lid. To avoid such problems, you can try lubricating the stops and hinges. But in most cases the reason is the low quality of components or their obsolescence. At low temperatures, the viscosity of the working substance increases. Therefore, in winter, when operating in northern regions, you need to open the trunk with a smooth movement.

Often, after replacing one shock absorber, you have to apply more force when closing the door. Therefore, some drivers decide that one stand is enough. In fact, the load will be distributed unevenly, and the mechanism will begin to wear out faster. To avoid having to replace it again soon, it is better to install two shock absorbers at once.

If the shock absorber no longer holds the door, it is not necessary to throw it away. You can make simple repairs to temporarily put off buying a new part for a while. Before you begin restoration work, you need to prepare tools - a cordless drill and a metal drill.

When carrying out a simple repair, you will first need to pull the piston out and drill a hole in the housing

In this case, it is important to get into the area located in front of the piston. Then you need to wait until the air comes out from inside

The oil is also drained through the hole.

The drilled hole will allow you to determine the position of the piston. You need to drill a second hole, which will be located exactly under the piston. It is made end-to-end.

A nail on a string is tied to the stop with electrical tape. After lifting the trunk, a nail is inserted into the hole, so the lid is fixed. To lower it, the nail is removed.

Inserted nail in repaired stop

Do-it-yourself repairs should only be done as a last resort and, if possible, new components should be supplied as quickly as possible. No maintenance required after installation

In order for gas struts to last as long as possible, it is important to check that the trunk lock is closed before traveling. Otherwise, the lid may open along the way, resulting in damage to the glass and the stops breaking out.

Trunk shock absorber

TRUNK SHOCK ABSORBER First, you need to decide where the mechanism will be mounted, because The operating principle of different shock absorbers is different.

It is also necessary to take into account the frequency of its use: for example, the trunk opens much less often than the doors. Often the type and all necessary characteristics of the shock absorber are recommended in the instructions by the car manufacturer itself. The length of the shock absorber is a very important parameter when selecting it for the hood, because

sooner or later you will need to have good access to the internal contents of the engine. If you are going to use the trunk frequently, then it would be preferable to purchase a reliable and durable gas trunk shock absorber. A mechanism that has a high pushing force is required for installation on the rear door.

Whatever shock absorber you choose, there are the same rules for all, one of which recommends opening the doors, trunk or hood smoothly, without sudden movements, which will significantly extend the life of the mechanism.

Let's sum it up

So we figured out what kind of trunk shock absorbers there are, how to remove and install them. In principle, there is nothing complicated. But it is necessary to take into account some nuances. For example, try not to damage the fastenings and not lose anything. In addition, the new stops must be used carefully.

The best option is to open the trunk and see what shock absorbers are currently installed. Use the electronic catalog to search and order a suitable option or a high-quality substitute. If the old stops are with the piston down, then it is advisable to install new ones in the same position. It is this placement that will make their work as efficient as possible. Also try not to suddenly open the trunk or hood lid at sub-zero temperatures. This can kill the shock absorbers within a few years. It is also better to avoid racks that are too cheap, as they are unlikely to turn out to be good.

Source

Reasons for replacing old shock absorbers

It is impossible not to notice that one of the racks is broken. Most often, the door stops locking when lifted, which causes inconvenience for the driver. If you do not replace it in time, you may be injured when using the roof rack. Typically breakdowns occur for the following reasons:

- Inaccurate operation.

- Temperature changes combined with moisture entering the mechanism.

- Natural wear and tear.

Trunk shock absorber

If the shock absorber is working properly, when lifted, the cover moves up on its own to its original position. The door should not rise any further, even if you push it. Faulty stands usually do not hold the lid at all. Also, a broken door may not lift all the way or move beyond its original position when lightly pressed by hand.