May 11, 2017 Lada.Online 137 300 10

MD tuning stands for throttle modernization. There are quite a few ways to modify the throttle assembly, but this article will discuss the most popular scheme proposed by the American engineer Ron Hutton. According to him, correct MD tuning can increase engine power and reduce fuel consumption by up to 25%.

MD throttle tuning, myth or not?

| It is believed that the inventor of MD (Modern Throttle) tuning is the American engineer Ron Hutton. According to him, this modification of the throttle assembly allows you to change the state of the air flow (create turbulence), which allows you to increase engine power and reduce fuel consumption by up to 25%. Is it really? |

How to make MD throttle tuning with your own hands

Great accuracy does not play a role here.

The cutting depth should depend on the wall thickness, usually 2-3 mm (no more than 5 mm). To remove any burrs that have formed, you can use fine sandpaper. The process is not complicated and does not require ECU firmware. How to do MD tuning is shown in the video (watch from 8 min 46 sec):

If the tool is powerful enough, the work will not take more than 15 minutes. At service stations they charge from 7,000 rubles for such tuning of the throttle valve.

Reviews about MD tuning

After such modernization of the throttle assembly:

- + The gas pedal becomes more informative (more responsive).

- + Increase in power from 1000 to 3000 rpm.

- + Reduced fuel consumption.

- ─ Loss of elasticity.

To find out whether there is an effect from MD tuning, an experiment was carried out (look at the video above from 12 minutes 30 seconds):

- The car's tank was filled to maximum.

- We drove about 20 km by car.

- We filled the tank to the maximum (consumption was 2.01 liters).

- A modernized throttle assembly (diameter 46 mm) was installed.

- We drove the car along the same section of the road.

- We filled the tank to the maximum (gasoline consumption was 1.61 liters).

Thus, fuel savings amounted to about 20%. In addition, an increase in low-end power was noted.

If, after upgrading the throttle assembly, problems with idle speed appeared, then most likely the tightness of the closed throttle valve was broken (too large recesses were made).

What reviews can you leave about MD tuning?

Causes

The most common reason for an adaptation to be made is the consequences of throttle valve maintenance. As a result of operation, a large amount of deposits forms in this unit, therefore, after flushing, the position of the throttle valve changes, and the ECU continues to send signals about its condition until maintenance.

Over time, natural wear occurs on the resistive layer of the sensor potentiometer and the moving elements of the throttle valve; in this case, after adaptation, it will most often require replacement. It is necessary to conduct training if changes are made to the ECU settings (chip tuning), especially if operations have been performed to increase engine power.

The procedure is performed using special programs on computer equipment or without them (a strictly defined procedure, which will be discussed below) depending on the brand of car. Auto electricians must take into account the features of the model, year of manufacture, and type of ECU installed on the vehicle.

Cleaning the throttle valve of a VAZ 2114

There are two cleaning methods: - Without removing the unit; — And accordingly with its dismantling.

Which method should I choose? It all depends on the degree of pollution. If the mileage has been up to 25 thousand since cleaning or replacing the throttle. Then, most likely, it is possible to limit ourselves to superficial cleaning and prevention without removing the part. In other cases, it is recommended to completely dismantle the unit for deep, thorough processing, cleaning and gaining access to hard-to-reach places.

We will describe in detail the process of complete removal after which the first option will not be difficult to complete. So, let's begin:

To begin, unscrew the cap of the expansion tank with antifreeze. This is necessary in order to “relieve” the pressure and avoid antifreeze leaking out of the hoses.

Next, we need to unscrew and loosen all the clamps that tighten the hoses attached to the throttle block. The same applies to the air pipe. To carry out the work, we will need a 13mm wrench or socket. After removing the clamps, we disconnect the hoses themselves. We disconnect the pipe from only one side and, for convenience, move it to the side.

Now remove the throttle cable from the throttle drive selector.

Turn off the power to the sensors.

Take the 13mm head, unscrew the two bolts and remove the throttle assembly. Remove the old gasket.

To treat contamination, you can use carburetor cleaner and a clean rag or rag. If the degree of contamination is very high, then you can use a toothbrush with hard bristles. Just before cleaning, disconnect the idle air control. Apply the product to the contaminated surface. Using progressive movements, remove carbon deposits from the metal surface. If you are not satisfied with the result, repeat the operation again until complete cleansing

It is very important to clean or blow out the channels that are in the product. A lot of dirt accumulates there

It is most convenient to carry out purging using compressed air. To do this, you can use a regular car pump. If the sensor socket and the sensor are clogged, be sure to clean them too. Do not forget to carefully clean the junction of the throttle assembly and its internal cavity. To do this, apply some cleaning product to a rag. Distribute evenly on the inner walls of the parts. Take a brush and clean the problem areas. After finishing the treatment, wipe the cleaned areas with a damp cloth and remove any remaining dirt. After washing the unit, it is recommended to clean and blow out the disconnected pipes. We expect a short amount of time. We install a new gasket at the junction of the throttle assembly. We attach and secure the knot in place. We connect the IAC sensor. We pull the hoses onto the fittings of the cooling system and connections to the adsorber. We put on the throttle body pipe. We fix the cable on the drive. Tighten the clamps of all attached elements. We connect the sensor chips. Close the cap of the expansion tank with coolant. We start the car and test its operation.

Cleaning the throttle valve VAZ 2114, 2115, 2110

The non-removal method is somewhat similar to the one we described earlier. The only difference is that we will only remove the air duct pipe and nothing else. The work steps are as follows: — Remove the pipe; — We repeat point number 10 of the previous method. — We connect and secure everything in the reverse order, not forgetting to replace the old gasket with a new one.

Keep in mind that this method is most suitable for preventative, light, superficial cleaning. If malfunctions or incorrect operation of the engine occur, use only the removal method. Now we know how to clean the throttle valve on a VAZ 2114 using two different methods, quickly and without much difficulty.

Helpful advice

Please note that if you do not have a carburetor cleaner available, you can use other cleaning products, for example the well-known WD-40

Need for maintenance

The prophylaxis procedure should not be carried out in the absence of obvious reasons. Before starting, you need to carefully evaluate the condition of the throttle valve. If there are no obvious signs of tar deposits and areas of coking, then the reason for unstable operation may lie elsewhere.

Also consider the mileage of the car. Experts recommend resorting to flushing no earlier than after 100 thousand km. But on some cars, for example, a Ford Focus, it may be necessary to flush it after 30 thousand kilometers.

You should know how to clean your throttle body to achieve the desired result. This requires a special carburetor cleaning solution, for example, Abro Carb & Choke Cleaner or similar products. The assembly must be dismantled; only in this case can the maximum effect be achieved, otherwise carbon deposits will remain inside the tubes. Disconnect all pipes from the throttle valve to gain good access to the inlet part of the assembly.

Remove carbon deposits delicately using a clean rag or soft brush. Do not use excessive force; you may damage the valve. The internal elements are coated with a thin layer of molybdenum, which novice car enthusiasts mistake for harmful deposits.

The consequences of zealous cleaning can be different: the moving part of the damper will begin to bite, or vice versa, in the closed position it will begin to let air through. In this case, it will not be possible to do without repairing the throttle valve.

How to check and replace TPS?

The VAZ throttle position sensor (TPS) is part of the engine throttle assembly. Therefore, when checking the TPS, check the IAC at the same time (see the article How to check the IAC (Idling Air Sensor)?. Because in certain situations they have similar symptoms of a malfunction:

- uneven idle speed;

- Unstable engine operation (the engine stalls after releasing the gas);

- no idle speed;

- the car moves jerkily when the gas pedal is pressed at a certain level;

- low vehicle dynamics (in addition to a malfunction of the sensor itself, low engine dynamics can be the result of many reasons:

- low compression in the engine (How to measure engine compression correctly?);

- wear of the camshaft cams. or incorrectly aligned timing belt marks;

- cylinder head valves are leaking or burnt out;

- the engine power supply system is faulty;

- the air filter is dirty;

- brake cylinders jam;

- the clutch slips;

- the fuel filter is clogged;

- exhaust system is faulty).

It is worth noting that this sensor is not available on new samara-2 models due to the use of an electronic gas pedal.

How to check TPS?

To check the throttle position sensor, we will need the following tools: a multimeter (ohmmeter, voltmeter), pieces of wire.

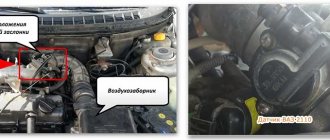

- Having opened the hood, we find the sensor we need (we look for it on the throttle assembly next to the IAC).

- Disconnect the wire block from the sensor.

- Take a multimeter and set it to voltmeter mode. Volts negative terminal (on the engine). We connect the positive terminal of the voltmeter to the sensor wire block to terminal “A” (the pin numbering is indicated on this wire block).

- Turn on the ignition and check the voltage: the voltmeter should show a voltage of around 5 volts. If the voltage is not supplied, or it is much lower than 5 volts, then the problem is either an open circuit or a malfunction in the electronic engine control system (in the brains). But if the voltage is normal, then, accordingly, the TPS is faulty.

Conclusion: If the sensor is faulty, then there are two options to solve the problem:

- Repair the sensor (How to repair the TPS?). Most often it is easier to replace the sensor with a new one, because The cause of failure is most often normal wear of the part.

- Replace the sensor with a new one.

How to replace TPS?

To replace the throttle position sensor we will need:

- Unscrew the 2 screws securing the sensor to the throttle assembly (see picture).

- Remove the sensor from the damper axis.

- We install the new sensor on the damper axis so that its leads are directed towards the partition of the engine compartment.

- Rotate the sensor relative to its axis until the mounting holes align.

- We wrap the sensor.

- We regulate TPS.

- We connect the sensor contacts.

- Reset the battery terminals for 5 minutes.

How to adjust TPS?

We open the damper by turning the sensor drive sector or pulling the accelerator cable. If this operation fails, the sensor is not installed correctly. In this case, you need to remove the sensor and reinstall it at an angle of 90 degrees relative to the damper axis.

As for manual adjustment of the damper position, the sensor is not adjustable.

The controller automatically uses the sensor's low idle voltage as a reference point. But it happens that after replacing the sensor, the controller uses the values for the old sensor, which causes the throttle valve to open a few degrees. In this case, you need to reset the controller parameters either through the on-board computer or remove the battery terminal for 5 minutes.

Removing the damper

In order to understand how to remove the throttle valve on a VAZ 2114, you need the following tools:

- Screwdriver regular and Phillips

- Pair of M13 bolts

Remove it in case of washing, replacing with a new one, replacing the gasket of the throttle assembly, replacing the IAC sensor. Many people advise draining the antifreeze before work, although not much liquid is lost in the process (that’s what the container is for), it’s easier to pour it back later.

Important point: cool the engine before operating the damper! And now the process of how to remove the throttle valve:

- We opened the hood, removed the protection (especially for the 1.6-liter fourteens)

- Open the cap of the expansion tank and reduce the pressure in the cooling system to zero

- See the throttle valve pipe on the VAZ 2114 - it must be removed. It comes from the air filter, such a thick, black plastic pipe.

- Then, we move to the gas pedal cable and disconnect it

- We remove the contact system from the throttle assembly sensors - IAC and TPS

- Using a cross, we unscrew the throttle pipes; these are two hoses along its edges. One is slightly thicker than the second, it contains antifreeze, you need to put a container under it so that it does not spill past. Then we take those same M13 bolts and plug the unscrewed pipes so that they don’t leak.

- Between these two hoses there is a third one - it comes from the adsorber - it also needs to be disconnected.

- Now the throttle assembly, we unscrew its fasteners with a 13 mm spanner, it is attached to the intake manifold.

- That's it, let's take it out.

Another way to make sure that the antifreeze doesn’t go anywhere: we start with the middle hose coming from the adsorber, then loosen the fastening of the antifreeze pipes. Without removing them, unscrew the fasteners of the throttle valve assembly and pull it out along with the antifreeze pipes. And only after that we plug each one with bolts prepared in advance.

Now you can clean the throttle, replace it with a new one, check the condition of the gasket (for a 1.5 engine) or the seal ring (for a 1.6 engine). We remember about the container with antifreeze and add the rest back into the pipe.

The main thing is that when you remove your used spare parts, do it carefully. There is a risk of damaging the surface of the assembly (aluminum is a soft material and requires gentle handling).

Before installation, all surfaces that come into contact with the gasket and manifold must be cleaned. Washing the unit is quite simple: you need a cool WD solution. Just don’t wash the TPS! As well as a valve for controlling air flow at idle. Otherwise, you will damage the devices.

Reviews about MD throttle tuning

Advantages of MD tuning:

- The gas pedal becomes more informative (more responsive).

- Increase in power in the range from 1000 to 3000 rpm.

- Reduced fuel consumption.

Disadvantage of MD tuning:

- Loss of elasticity.

1.

Checking the effectiveness of MD tuning in practice (cable):

- The gas tank was filled to maximum.

- We drove about 20 km.

- Once again we filled the tank to the maximum and got a consumption of 2.01 liters.

- We did MD tuning on a throttle body with a diameter of 46 mm.

- We drove along the same section of the road.

- We filled the tank to the maximum (gasoline consumption was 1.61 liters).

Thus, fuel savings after modification of the throttle assembly amounted to about 20%. During the experiment, an increase in low-end power was noted. Watch the experience in the video above from 12 min 30 sec.

2.

Testing the effectiveness of MD tuning in practice (E-Gas):

A similar experiment was carried out on a car with E-Gas. Fuel economy in this case was about 9% (was 1.5 liters, now 1.37). There is a faster response to the gas pedal. See also how to adjust E-Gas.

ps If after MD tuning there are problems with idle speed, then most likely the tightness of the closed throttle valve was broken (the chamfers were made too deep).

Have you modified your car this way? What feedback can you leave about MD tuning?

Let us remind you that we previously talked about other modifications that can improve engine performance. For example, installing a PCV valve in the crankcase ventilation system, as well as installing capacitors in the car’s ignition system.

Additional disadvantages of the procedure

As for the disadvantages of MD tuning, there are quite a lot of them. These include:

- loss of throttle elasticity;

- high cost of the service;

- low quality of work;

- nonlinear response to the gas pedal.

In addition, if you make chamfers that are too deep, due to which the seal of the closed throttle valve is broken, the car begins to act up at idle.

Such modifications to the car can only be done when you want to get sharp feedback at the bottom and feel that the vehicle is driving itself, but this is all an illusion. If you are satisfied with the performance of the feedback when pressing the pedal, then you should not waste money and make this useless upgrade.

Engine tuning methods

Every motorist invents different ways to increase engine power: it all starts with installing additional equipment and ends with a complete rework of the engine itself. The most well-known way is to increase power through the exhaust system and air filter.

Method 1

To change the exhaust system, you need a straight-through muffler, which will be larger than your standard one. This will help you increase the performance of your engine and increase the load capacity and reduce exhaust gas emissions. In other words, with an increase in the release time of used gases, we will be able to add several horses.

These changes will require you to change some more parts of your engine. So, you will need to replace the air filter so that air can flow more freely. It is best to purchase an exhaust with a 3-inch muffler. Additionally, you can install a second air filter – a sports one.

The next change you'll need is some additional cooling equipment for the intake air, as hot air rushing in like a hot blast will reduce engine efficiency.

Check your wiring and spark plugs to ensure they are good and resistant to these power fluctuations. There is no need to skimp on spark plugs; good spark plugs will ignite fuel better.

Method 2

But there are other ways to increase engine displacement. You can try boring out the rings on the engine cylinder. Or replace the crankshaft. However, these changes are costly and time-consuming.

In the first case, you will need to bore the cylinder and buy new rings and pistons. In the second case, you will have to search long and tediously for a crankshaft that will have a larger stroke. If you do find the crankshaft you need, replacing it will not be easy.

Do-it-yourself ring boring

Method 3

Good gasoline can also add power to your engine. When more fuel enters the cylinder, your engine will increase in performance. To increase the scale of filling the cylinders with fuel, you can try to reduce the aerodynamic resistance of the intake and exhaust systems.

Method 4

A very popular way to increase speed is to increase fuel compression. To do this, craftsmen grind off the surface of the heads or change the gasket to a thinner one. However, it is worth remembering that the head can get used. Therefore, it is better not to take risks with this matter.

But before you make any changes under the hood, check the engine for errors. Perhaps something is malfunctioning, which leads to a decrease in power and creates dull sounds and rumble. Very often there are breakdowns of the cylinders themselves. The rings are worn out or the cooling system is clogged.

What to do additionally

After modernization of this type, it is necessary to perform a number of additional manipulations:

- Rechip the ECU, since using a new part the old program will not work adequately. It will not be able to properly control the ratio of air and fuel in the mixture.

- Install a sports receiver. But before installation, be sure to consult with specialists or simply contact a car service center for help.

- Replace existing camshafts with more advanced ones.

Refining the throttle assembly is a serious procedure, there are a lot of different disputes regarding it, those who have tried such tuning in practice praise the result, but theorists swear. But the opinion of practitioners still prevails, and the fact that after modernization fuel is saved by 30% is already a proven fact.

A little theory

Using a standard throttle valve, air consumption measurements showed that the engine consumes approximately 14 kg at idle, and about 22 kg at 3000 rpm. All this, of course, only applies to a fully functional engine. If we take measurements with a modified damper, then consumption at idle speed remains the same, but at the same 3000 revolutions it increases from 22 to 33 kg. This means that the increase in power is only felt at rpm of 2500 and above.

In a word, such tuning of the throttle valve on the VAZ 2110 takes place if the car often moves along the highway. In the city you won’t be able to experience all the delights of the modification.

Adjustment in your garage

Even a novice car enthusiast can adjust the throttle position sensors; the main thing is to strictly follow the instructions given below. Moreover, this operation does not depend on the operating principle of the TPS - non-contact or not. So, first we carry out the preparatory work. We disconnect the corrugated tube through which air passes and thoroughly rinse it with alcohol, gasoline or another strong solvent. But one liquid is not always enough; to achieve a better effect, you should also wipe the tube with a soft cloth. We carry out the same operation with the damper itself and with the intake manifold. In addition, do not forget to carry out visual inspection, especially for the damper.

So, no mechanical damage was detected? Then we proceed directly to adjusting the throttle position sensor. First, take the key and loosen the screws. Then we raise the damper and sharply lower it all the way, keep in mind that you should hear a blow, otherwise repeat the operation again. Loosen the screws until the part stops “biting.” And only then can the position of the fasteners be secured with nuts. Next, unscrew the bolted connections of the TPS and rotate the device body. Next, we set the throttle position sensor so that the voltage changes only when the valve opens. The setup is complete, all that remains is to return everything to its place, tighten the bolts and enjoy driving your favorite car.

Flushing the throttle "tens"

Often, VAZ 2110 owners confuse a malfunction of the throttle assembly with an ordinary clogged valve. The main symptoms of the latter include:

- when you release the gas pedal, the engine does not immediately switch to low speed;

- the engine is difficult to start in severe frost;

- after starting, the engine vibrates for a few minutes;

- The engine jerks regularly at low crankshaft speeds.

To clean the throttle valve, carefully remove the plastic decorative trim that covers the top of the engine. Next, disconnect the ventilation system hose and drain the oil from the air pipe. After this, unscrew the cap from the expansion tank and disconnect the fuel tank ventilation hose. Having done this work, we get free access to the throttle valve of the “tens”.

The part itself must be cleaned using aerosol products such as Wynn's or WD-40. The procedure for washing the part should be repeated with a short pause of 15 minutes. At the first stage, we treat the part with an aerosol and wipe it with a damp cloth. The second time, an aerosol is also needed, only you need to wipe the part with a dry piece of cloth. During the cleaning process, it is strictly forbidden to use brushes for working with metal, as they severely damage the surface of the throttle assembly.

When cleaning the throttle valve, you should also pay great attention to the crankcase ventilation duct. This part of the assembly is most susceptible to contamination.

To wash the internal channels of the damper itself, unscrew the idle speed sensor. If during the process of dismantling the sensor you find play, the part should be replaced. You also need to pay attention to the condition of the gasket in the throttle assembly. It's best if you replace that too.

Repair work

Now to the question of how the cleaning procedure is performed. For everything to go smoothly and without problems, it is enough to prepare all the necessary materials and tools in advance, place everything at hand and get to work.

VAZ 2110/2112 cleaning the throttle valve

To clean the throttle you will need:

Throttle position sensor DPZ

- Screwdriver Set;

- 13mm wrench;

- Throttle valve cleaner.

Specialized preparations made from appropriate components are sold specifically for these purposes. Do not spare money on their purchase, since the funds will last for a long time. This is more profitable than changing the damper every time.

Cleaning with special means

Preparation

Let's start with the preparatory activities that will ultimately allow you to get to the throttle body and more and clean it properly.

- Remove the casing that is installed on the power unit.

- Unscrew the cap on the expansion tank. This will allow you to relieve excess pressure from the cooling system.

- Slightly loosen the tension on the mounting clamps, then remove the forced ventilation tube.

- Examine the current condition of the air pipe, which should also be removed and, if necessary, replaced.

- If there are significant traces of oil in the pipe, then you can be 100% sure that the throttle is definitely clogged.

- The problem is most likely in the forced ventilation duct. This is explained by the fact that contaminants in the form of gas from the crankcase and oil particles have no other way than through the ventilation branch.

- Next you need to remove the damper heating tubes. To do this, just loosen the clamps with a screwdriver.

- For a while, come up with plugs for them from improvised means - old spark plugs, some kind of non-hollow rubber bands. In short, anything that fits the diameter of the hole.

- Remove the fuel tank ventilation system hose. To do this, you must first unscrew the clamp, remove the cable and unscrew the throttle mounting nuts.

- Be sure to remove the connectors from two sensors - idle speed and throttle position. They are located on the unit being repaired, so there will be no problems with the search.

Cleaning

There is nothing difficult about cleaning the throttle valve. This procedure can be easily done with your own hands, without involving specialists from car services and without spending extra money.

- Using the purchased throttle cleaner, clean the channels and the entire disassembled assembly;

- Rinse the engine's forced crankcase ventilation duct especially carefully, since this is where the largest amount of pollutants comes from;

- Use sharp objects if you want to carry out the work responsibly and as thoroughly as possible. A simple knitting needle will do;

- Remove the idle air control. To do this, simply unscrew a couple of bolts;

- Be sure to wash the unit thoroughly;

- Check the condition of the rod. If it is heavily soiled or there is play, the element is easiest to replace. It's not expensive;

- Inspect the current condition of the gasket. If the gasket is damaged, be sure to buy a new one. Even if it is in satisfactory condition, we advise you to make a replacement once you have begun to dismantle this unit;

- After washing the throttle assembly elements, return all its components to their places, proceeding in the reverse order.

How to adjust the throttle cable on a VAZ 2110-VAZ 2112?

Note! A lot of engines were installed on cars of the tenth family, ranging from carburetor 1.5 to injection 16 valve engines. Let us immediately warn you that carburetor engines from the Samara family were installed on dozens, and we already have information on adjusting all the valves on carburetor Samaras and it is posted in two article, the first is called: “Adjusting the throttle valves”, the second: “Adjusting the air damper”, so if you have a carburetor, then go straight to them, because in this article we are talking only about injection cars and we will not touch on carburetor cars!

Note! Let's say a few words about the adjusting screw, the most important thing is not to confuse it with any other screws (For example, with screws A, by the way, they cannot be turned out at all), it stands on the side, for clarity, in the photo below it is indicated by an arrow with the letter B!

Additional video: Using the example of a Renault Logan car, look at how the cable is adjusted, it applies to 16 valve cars; on dozens with a 124 engine, this adjustment is done almost exactly the same way.

Theory and design testing

The essence of the modification is to install special rings or a swirler with blades in front of the throttle. Allegedly, such interference swirls the air in a special way, and thanks to this, the process of mixture formation is improved, the engine runs better, and fuel consumption is reduced.

Actually, a friend of mine who tested this modification assured me that, according to the readings of his on-board computer, fuel consumption was reduced from 0.6 l/h to 0.3 l/h

. This reduction looks more than significant. I didn’t believe this and decided to try it myself.

First of all, I decided to make sure that the air really swirls before entering the throttle assembly. A smoke generator made from a cigarette helped me with this. Having put on the cut-off bottle, I clearly saw that the air flow went straight without interference, but with a cylinder with blades inside, it began to twist in a spiral.

That is, in theory, the air should really mix better with the fuel, which will ensure its more complete combustion, and, accordingly, an increase in power.

Md Tuning It is the same “refinement of the Throttle Unit”

#1 Kyoto

- Active Member

- 857 messages

- Gender: male

- City: Vladimir

- Vehicle: EA5A 6A13

The information was taken from an Internet resource.

MD tuning – technology for increasing power and reducing gas mileage

How it works:

The air that enters the engine through the air pipe in a conventional (unmodified) car flows in a simple even flow; when mixed with gasoline, a truly homogeneous combustible mixture is not achieved. Such fuel does not burn completely and burns unevenly; its residues burn out in the catalyst.

Engineers at Gadgetman Technologies LLC have developed a technology that allows you to spin the existing air flow as strongly as possible, almost to the “Tornado” state - such a strong vortex flow ensures uniform final mixing of air and gasoline, until a truly homogeneous working mixture. This happens, among other things, due to the pressure difference created at the inlet (therefore, the serviceability of the vacuum system for MD tuning is especially important). This allows the same amount of gasoline to do more work due to more complete combustion. At the same time, the air-fuel mixture becomes leaner, approaching the ideal ratio of gasoline to air. These effects provide more power and torque, lower fuel consumption, better dynamics, and a reduction in the amount of harmful substances in the exhaust.

How does a mechanical throttle work?

Any mechanical throttle has a channel for operating the engine at idle speed. And there is an idle speed regulator that regulates the air supply and prevents the engine from stalling. If you do not press the gas pedal, the throttle is closed by the throttle valve. And air enters the engine through the bypass channel. This is idle mode.

When you are driving at speed and release the gas pedal, the idle mode is activated. Engine speed drops, consumption is minimal. The car will begin to gradually lose speed. A car with an automatic transmission will stop. But with a manual transmission, it will start to stall and then may stall if you don’t add gas or shift to a lower gear or engage neutral.

After modifying the throttle, the torque improves and a rolling effect appears. That is, the car starts to idle. On most cars, this effect appears precisely after modifying the throttle.

Car owners note the appearance of some ease of movement of the car. If you release the gas pedal at speed while the gear is engaged, a coasting motion appears. It feels like the car is driving in neutral gear. This effect especially delights car owners with an automatic transmission. For example, on the Lexus LS430 4.3 liters. at a speed of 110-130 km/h, the roll-up is 2 km on a flat road without loss of speed. If you watch various videos on the YouTabe channel “AvtoSila'007“, most car owners talk about the appearance of this effect. The most striking example is on the Hover H3. Until the modifications, he doesn’t want to go downhill at all. And after modification it starts moving at idle. A very useful effect for driving in city traffic jams. Here you can watch a video of how this happens on Lada Largus.

On a car with a mechanical throttle, the appearance of the rolling effect cannot be explained by an increase in the amount of air, since the throttle is closed in idle mode. Then how can you explain that after modification the engine has enough power and starts to roll?! This is explained by the fact that when the valves open, the wave hits the valve and clings to the groove, and also twists from our groove. As confirmation, look at how a regular stock Chevrolet Niva with a mechanical throttle idles.

On cars with electronic throttle, the above described effect also appears. The most interesting thing is that after modifying the throttle on some cars, the idle speed decreases. The electronic throttle has the throttle valve slightly open for idling. But when the engine is running, the damper closes, reducing the passage of air. Thereby moving away from the grooves in the opposite direction by a couple of millimeters. Therefore, it is impossible to explain the better performance of the engine at idle speed by the large passage of air due to the grooves! There is a completely different magic here!

Step-by-step cleaning instructions

If the damper does get dirty, it doesn’t matter; with the help of several cleaning steps, the car’s operation will be restored. Before cleaning, you must remove the throttle assembly according to the following instructions:

- remove the corrugation;

- turn off the power supply to the sensors;

- push out the “weight” that secures the pedal cable;

- disconnect the coolant pipe;

- remove the ventilation hose; unscrew the assembly fastening;

- Unscrew the idle speed control.

To clean mechanisms, special products are required, in most cases aerosol cans. The best solution for this task is a carburetor or brake cleaner.

Dismantling

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Shesnar on the throttles in the classics

When a car enthusiast thinks about tuning an engine, in most cases he expects to slightly increase its volume, modify the cylinder head and install a sports camshaft. More daring ones install a turbocharger or a four-throttle intake system.

To get a noticeable increase in power from the throttles, you need to install an overhead camshaft. Throttles should not impede the movement of air flow before entering the cylinder, and the main benefit from them is required at high engine speeds, when the standard receiver can no longer cope

Here it is very important to correctly approach the precise weight distribution and lightening of the connecting rod and piston group. Indeed, at a crankshaft rotation speed of about 8000 rpm

Every unbalanced gram can cause the entire system to fail. For better performance, you will have to change the exhaust system. Ideally, enlarge the intake and exhaust ports in the cylinder head and install larger valves. If this doesn’t scare you, then it’s worth studying the four-throttle intake in more detail. Therefore, we will first consider existing systems.

On conventional cars, the intake system includes the air filter, throttle body and intake manifold. The throttle valve allows air to enter the engine cylinders. Air intake occurs in a certain sequence, depending on which cylinder is currently working for intake. This type of intake manifold is used on serial fuel-injected cars. What is important here is the length of the intake pipes of the manifold, on which the operating mode of the engine depends. Long intake pipes improve performance at low and mid-range speeds, while the use of a short intake pipe leads to increased power at high engine speeds.

The figure shows the design of a conventional intake manifold. Its main disadvantage is that air enters the first cylinder faster from the throttle valve. The amount of air is also proportional to the distance from the throttle, so much less of it enters the last cylinder.

In high-speed engines, a “can” type receiver is used, which is equipped with short pipes inside (“megaphones” or “diffusers”), which is clearly visible in the figure above.

At high engine speeds, it reduces air vibrations and leads to an increase in cylinder filling. Unfortunately, it also has the same disadvantages as the intake manifold. Therefore, it is mainly used in turbocharged engines and when it is necessary to combine all the intake ports.

The ideal option for the engine is a four-throttle intake. In this version, each cylinder is equipped with an independent throttle valve, which eliminates the system from resonant air vibrations that occur between the cylinders during intake. At the same time, throughout the entire speed range, from idle to maximum, the engine operates much more stable.

In VAZ cars with sports engines, a four-throttle intake or, in common parlance, “pipes” is installed, which provide separate air intake. Moreover, they are united by a common channel for the vacuum brake booster, absolute pressure sensor (MAP), fuel pressure regulator (FPR) and idle air regulator (IAC). Please note that when installing a four-throttle intake, air calculations are taken not from the mass air flow sensor (MAF), but from DBP and long-term measurements of engine air flow under different operating modes. So installing a four-throttle intake is not as simple as it seems from the outside.

Options for tuning the throttle assembly, which you can do yourself

To reduce harmful emissions into the atmosphere, many car manufacturers install catalysts on cars and equip cars with various technical means that are controlled electronically. Such a device is an electronic throttle. Since cars with remote control will have to be slightly modernized. But even if the throttle is mechanical, it should also be modified, since the principle is the same and 25-30% of the fuel remains unused, and the power is low.

The throttle valve itself regulates the volume of air entering the gasoline engine and produces the fuel-air mixture necessary for its operation. A simple do-it-yourself throttle tuning in your car can greatly improve performance.

Throttle bore

Stayed after work, planned for a couple of hours...

I worked too diligently and meticulously on the cone and steps, there was little time left for the rod, but it turned out to be very strong, and it was not possible to grind it down completely... I wanted to somehow get home and put the damper in place at night without comme il faut)))

Result: I've been riding for 3 days already, honestly, I haven't really felt any results... Maybe, maybe, etc. at rpm from 2000 to 3000 the car drives a little more lively, but maybe it was the wind at the back, a hillock, etc.))) I think we still need to cut grooves, then maybe we’ll feel the result. And the engine should probably be set to 1.6))) then it will drive more vigorously than 1.4)

But as a matter of fact, there are a lot of reviews on the Internet for these improvements, some for, some against. I just decided to try it because I don’t have to spend money on it, I have the tool, just time. Until you try it yourself, you won’t know what the result will be.

Results after MD tuning

We decided to test the effectiveness of MD tuning. First we conducted an experiment on a machine with a cable. The verification consisted of the following stages:

- Full filling of the gas tank;

- Driving approximately 20 km;

- The gas tank is full again, fuel consumption is 2.01 liters;

- Performing MD tuning on a 46 mm throttle assembly;

- Riding again 20 km;

- The gas tank was full again, fuel consumption was 1.61 liters.

As you can see, the implementation of MD tuning made it possible to save approximately 20% of fuel. Low-end power has also increased.

Next, we decided to conduct the same experiment on a car with E-gas. In this case, the throttle upgrade saved approximately 9% of fuel. In addition, the response to the gas pedal has accelerated.