Along with other options for improving the units and systems of the VAZ 2107, a non-contact (electronic) ignition system (BSI) is being considered instead of the standard one. This modernization makes it possible to provide stable increased voltage on the spark plugs, which, in turn, makes it easier to start the engine and increases spark energy.

Installing and adjusting a contactless ignition system is quite a difficult task, so if you do not have sufficient skills in working with automotive electronics, it is better to entrust this work to specialists. If you feel that you are able to install the BSZ kit on a VAZ 2107 yourself, then carefully study these instructions and get to work.

To work you will need the following set of tools and materials:

- Key to 8;

- Key for 10;

- Key to 13;

- Phillips screwdriver;

- Two self-tapping screws;

- Drill with a drill of the same diameter as the self-tapping screws;

Naturally, in addition to all this, an electronic non-contact ignition system must be purchased, or rather a set of its components: a coil, a switch, a distributor and wires for connecting all the elements together.

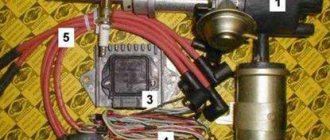

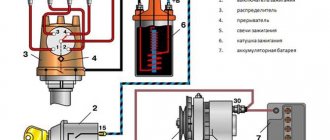

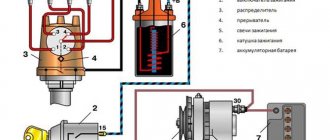

Below is a schematic diagram according to which the contactless ignition system for the VAZ 2107 is connected.

Setting the ignition timing with advance

This setup is completely easy to do. Even a beginner can cope with this task. To do this, prepare a 13 mm wrench and a special 38 mm crankshaft wrench in advance.

If your car is started, be sure to turn off the engine, since you can only turn on the ignition when the engine is turned off. First, the piston of the first cylinder is installed at the top dead center of the compression stroke, that is, in the ignition position. Before doing this, remove the candles and plug the hole from them with cotton.

You need to align the mark on the crankshaft and the front engine cover. To do this, use a wrench to start turning the crankshaft clockwise. During this action, the air compressed there should push out the cotton wool, thereby indicating the compression stroke. Continue turning the shaft slowly until the marks on the timing belt pulley and cover line up.

Please note that there are 3 marks on the cover:

- The first indicates ignition advance by 10º;

- the second – by 5 º;

- the third is equal to zero.

Since a VAZ 2107 engine with a carburetor runs on 92 or 95 gasoline, we need to set the ignition for these types of fuel. That is why you should select the second mark, which will indicate an ignition advance of 5º.

Once the required parameters match, put the spark plugs in place and remove the wires. The system is ready for use.

Spark plug

Plugs are used to ignite the fuel-air mixture in the engine cylinders when high voltage is supplied from the ignition coil. The main elements of any spark plug are a metal body, a ceramic insulator, electrodes and a contact rod.

Spark plugs are necessary to generate a spark and ignite the fuel-air mixture in the engine cylinders

Checking spark plugs for VAZ 2107

There are many ways to check spark plugs. The most popular are the following algorithms.

- With the engine running, remove the high-voltage wires one by one and listen to the operation of the engine. If after disconnecting the wire no changes occur, then the corresponding spark plug is faulty. This does not mean that it necessarily needs to be changed. In some cases, you can get by with cleaning it.

- The spark plug is unscrewed and a high-voltage wire is put on it. The spark plug body is leaned against a mass (for example, a valve cover) and the starter is cranked. If the part is working properly, the spark will be clear and bright.

- Sometimes spark plugs are checked with a special tool - a gun. The spark plug is inserted into a special hole and checked for the presence of a spark. If there is no spark, the spark plug is faulty.

- Candles can be checked with a homemade device made from a piezo lighter. The wire from the piezo module is extended and attached to the tip of the candle. The module is pressed against the spark plug body and the button is pressed. If there is no spark, replace the spark plug with a new one.

Video: checking spark plugs

Selection of spark plugs for VAZ 2107

Various models of spark plugs are installed on VAZ 2107 carburetor and injection engines. In addition, the parameters of the spark plugs depend on the type of ignition system.

The choice of spark plugs for the VAZ 2107 is determined by both the ignition system and the engine type

Auto stores offer many types of spark plugs for the VAZ 2107, differing in technical characteristics, quality, manufacturer and price.

Table: characteristics of spark plugs depending on the type of VAZ 2107 engine

| For carburetor engines with contact ignition | For carburetor engines with contactless ignition | For injection 8-valve engines | For injection 16-valve engines | |

| Thread type | M 14/1.25 | M 14/1.25 | M 14/1.25 | M 14/1.25 |

| Thread length, mm | 19 mm | 19 mm | 19 mm | 19 mm |

| Heat number | 17 | 17 | 17 | 17 |

| Thermal enclosure | Stands for spark plug insulator | Stands for spark plug insulator | Stands for spark plug insulator | Stands for spark plug insulator |

| Gap between electrodes, mm | 0.5 – 0.7 mm | 0.7 - 0.8 mm | 0.9 – 1.0 mm | 0.9 – 1.1 mm |

You can install spark plugs from various manufacturers on VAZ cars.

Table: manufacturers of spark plugs for VAZ 2107

| For carburetor engines with contact ignition | For carburetor engines with contactless ignition | For injection 8-valve engines | For injection 16-valve engines |

| A17DV (Russia) | A17DV-10 (Russia) | A17DVRM (Russia) | AU17DVRM (Russia) |

| A17DVM (Russia) | A17DVR (Russia) | AC DECO (USA) APP63 | AC DECO (USA) CFR2CLS |

| AUTOLITE (USA) 14–7D | AUTOLITE (USA) 64 | AUTOLITE (USA) 64 | AUTOLITE (USA) AP3923 |

| BERU (Germany) W7D | BERU (Germany) 14–7D, 14–7DU, 14R-7DU | BERU (Germany) 14R7DU | BERU (Germany) 14FR-7DU |

| BOSCH (Germany) W7D | BOSCH (Germany) W7D, WR7DC, WR7DP | BOSCH (Germany) WR7DC | BOSCH (Germany) WR7DCX, FR7DCU, FR7DPX |

| BRISK (Czech Republic) L15Y | BRISK (Italy) L15Y, L15YC, LR15Y | CHAMPION (England) RN9YC | CHAMPION (England) RC9YC |

| CHAMPION (England) N10Y | CHAMPION (England) N10Y, N9Y, N9YC, RN9Y | DENSO (Japan) W20EPR | DENSO (Japan) Q20PR-U11 |

| DENSO (Japan) W20EP | DENSO (Japan) W20EP, W20EPU, W20EXR | EYQUEM (France) RC52LS | EYQUEM (France) RFC52LS |

| NGK (Japan/France) BP6E | EYQUEM (France) 707LS, C52LS | MARELLI (Italy) F7LPR | MARELLI (Italy) 7LPR |

| HOLA (Netherlands) S12 | NGK (Japan/France) BP6E, BP6ES, BPR6E | NGK (Japan/France) BPR6ES | NGK (Japan/France) BPR6ES |

| MARELLI (Italy) FL7LP | MARELLI (Italy) FL7LP, F7LC, FL7LPR | FINVAL (Germany) F510 | FINVAL (Germany) F516 |

| FINVAL (Germany) F501 | FINVAL (Germany) F508 | HOLA (Netherlands) S14 | HOLA (Netherlands) 536 |

| WEEN (Netherlands/Japan) 121–1371 | HOLA (Netherlands) S13 | WEEN (Netherlands/Japan) 121–1370 | WEEN (Netherlands/Japan) 121–1372 |

Adjusting the ignition timing

For subsequent actions, use a 13 key to loosen the fastening nut of the distributor (ignition distributor). Connect one wire from the light bulb (it will act as a voltmeter, that is, indicate the presence of voltage) to the low-voltage terminal that the coil has, the second to ground.

Now turn on the ignition. Slowly and carefully rotate the distributor body clockwise, stopping immediately when the light goes out. The sparks that appear will indicate the moment of ignition. Move the distributor counterclockwise until the contacts are disconnected and the lamp lights up again. Everything is in order, you can safely tighten the distributor, the setup is complete.

Checking the ignition coil

The coil is checked based on two indicators: the presence of a short circuit and an open circuit. Before diagnostics, the ignition coil must be disconnected. After this, one probe of the device is connected to the central contact of the coil, the second to the body (ground). If the display shows resistance equal to infinity, there is no short circuit.

The primary winding of the coil for a break occurs differently. The probes of the device must be connected to the right and left contacts. The resistance between them should be within 3-3.5 Ohms.

If the resistance of the primary winding does not correspond to the norm or there is a short circuit in the coil to the housing, it must be replaced.

Installation of electronic ignition

Electronic ignition makes engine operation smoother and softer, makes it easier to start in the winter, and reduces fuel consumption. If you, having a carburetor engine, decide to switch to contactless (electronic) ignition, we will tell you how to correctly install it on a VAZ 2107 car.

An electronic system for a car with a carburetor should not be too expensive or cheap. It is best to opt for a product in the mid-price category, so that later you don’t have to change anything after a while.

Before work, prepare a drill and a set of keys.

For an overview, first read the included instructions carefully and open the carburetor type engine kit. It includes:

- ignition coil;

- distributor;

- switch;

- 4 candles;

- connecting and high-voltage wires.

The system is easy to install. First of all, remove the negative terminal from the battery and turn the crankshaft until marks numbered 3 and 4 align, that is, the highest dead center.

Now you can begin the main steps. The coil should be disconnected from all wires, remove it and install a new one. The coil can now be connected to the central high voltage wire. Connect 2 brown wires to contact “K”, and 2 blue wires to contact “B”.

Now remove the distributor cover. Please note that the slider must be set exactly as shown in the picture. Mark this place with a marker on the block to correctly install the new distributor. Now you can unscrew this part and put it to the side.

After opening the cover of the new distributor, place the slider perpendicular to the engine and insert it into the hole in the cylinder block. Align it with the mark on the block. Next, put on the cover and connect the wires.

Decide where the switch will be located, since there is no space for it in the VAZ 2107 car. We recommend installing it next to the washer reservoir. Secure it with self-tapping screws and install the connector.

Don't forget the candles. To replace them on a VAZ 2107 car, you will need a spark plug wrench, which you should use to unscrew the old spark plugs from the cylinders and put new ones in place.

Instructions for installing a contactless system on the seven

Manipulations for converting the ignition system on a VAZ 2107 from contact to contactless are carried out according to the following principle:

- First, you should turn off the power to the car by disconnecting the minus terminal from the battery.

- Disconnect the armor wires from the spark plugs.

- The spark plugs are unscrewed, after which the crankshaft should be turned with a key set to “36”. This is done in order to set the piston of the 1st cylinder to TDC. To determine that the piston has reached top dead center, use a screwdriver. The notch on the crankshaft pulley must be on the cylinder block.

- The steel latches of the switchgear cover must be snapped off and then removed along with the wires.

- A mark must be placed on the engine valve cover next to the moving contact of the slider.

- All wires are disconnected from the distributor along with a thin tube connecting the device to the carburetor fitting.

- Using a wrench, you need to loosen and unscrew the nut, which is used to press the distributor skirt to the BC.

- The old distributor must be removed, and at the same time pay attention to the gasket so as not to lose it.

- The wires from the coil are disconnected, remembering their locations. The coil mount is unscrewed and the device is dismantled.

- The next step is to install the mounting block.

- Make holes to secure the switch.

- The cover is removed from the new distributor and the gasket is installed. The distributor must be placed in the mounting hole of the cylinder block, and this should be done so that the moving contact is located at the level with the top dead center, which is drawn on the valve cover (the slider should point in the same direction as on the old distributor).

- The distributor skirt is fixed.

- The coil is placed in place of the old device, and terminals with wires from the ignition switch, as well as the tachometer and switch are connected to it.

- The wire from the EB of the first contact must be connected to the coil terminal marked “K”.

- The wire from the fourth contact is connected to terminal “B”.

- The spark plugs are screwed into place, after which the armored wires and the wire suitable for the coil can be connected.

- At the final stage, all that remains is to attach the vacuum tube and proceed to the stage of adjusting the ignition.

This is interesting: Practical tips and recommendations for replacing the fog lamp on a Renault Logan car

At this point, the installation of electronic ignition on the VAZ 2107 is completed, and before testing the device, you will need to make preliminary adjustments.

Distributor

The sequence of work that must be performed in order to install a set of new parts on a VAZ 2107 does not make much difference. Therefore, we can start by replacing the distributor. Remove the distributor cover to access the slider. To simplify the task of further adjusting the BSZ, you should immediately perform some preparatory measures: installing the distributor slider in a position that will be easy to repeat when installing a new distributor; mark on the block opposite the middle mark on the distributor scale, which is used to adjust the ignition.

Using a 13mm wrench, completely unscrew the nut securing the distributor and then remove it. Disconnect the high voltage wire connecting the ignition coil and the distributor. We install a new non-contact sensor distributor, and you need to set the slider so that it matches the position of the old one. The body of the new distributor needs to be aligned according to the marks, the middle one opposite the one previously left on the engine body. We put on the distributor cover and a set of high voltage wires.

Coil

Next, you need to replace the ignition coil. Using a size 8 wrench, unscrew the nuts securing the wires to the coil contacts. Using a 10mm wrench, unscrew the mount of the coil to the body. Installing a new coil requires special attention - you should take into account the possible discrepancy between the locations of contacts “B” and “K”. For convenience, you can rotate the new electronic coil relative to the fastener, thereby placing the contacts in the same way as on the old one.

Having secured the coil, we connect old wires to its contacts (usually one blue, the other brown), and new ones, with connectors for connecting to the distributor and switch. They usually have the same colors as the standard ones. Typically, in a VAZ 2107, brown wires are connected to contact “K”, and blue wires are connected to “B”. It remains to connect the high-voltage wire that connects the coil and the distributor.

Switch

The last element in the circuit, the presence of which is required by a contactless electronic ignition system, is a switch. The ideal place in which it can be installed in a VAZ 2107 is between the washer reservoir and the left headlight. There is a flat area on which we will install the switch, with the radiator facing the body. Having leaned the switch, we mark the places for drilling holes in the body, through which we fasten it with self-tapping screws; in this case, you need to screw the black (neutral) wire from the connection block under one of the screws.

After completing all the work described above, you should once again carefully check the connection of the wires according to the circuit diagram. If everything is done correctly, you can try to start the engine. Usually there are no problems with this; all that remains is to adjust the ignition to ensure the most efficient operation of the engine.

Checking correct ignition

After completing the steps, it is necessary to check the operation of the ignition system.

To do this you need:

- start the car and drive off;

- Accelerate the car to 50 kilometers per hour, engage fourth gear and sharply press the accelerator pedal. Then, engine detonation will appear, which will decrease (and then disappear altogether) as the speed of the car increases.

There can be two types of problems:

- Engine detonation occurred, but did not disappear as the vehicle speed increased (it is assumed that the ignition was turned on earlier ). In this situation, the switchgear must be turned half or one division to the right.

- Detonation did not occur at all - ignition was delayed . To eliminate this problem, you need to turn the switchgear half or one division to the left .

As you can see, setting the ignition on the VAZ 2101 is quite simple. However, if difficulties or additional questions arise, it is better to contact certified car services for advice.

Replacing the starter relay

Another common problem on VAZ 2107s with a carburetor is a malfunction of the starter relay. When you turn the key in the lock, the system makes a click, but the retractor relay does not operate. Replacing the relay is very simple.

First you need to remove the starter from the relay. Unscrew the 2 bolts that secure it. Slide it to the right and take it out, turning it backwards. Unscrew the nuts securing the starter and relay.

Turn it to the side.

Remove the 2 bolts securing the relay to the starter.

Install the new one in reverse order.

If you follow these simple steps, your VAZ 2107, which has a carburetor system, will serve you for many more years.

Vehicle dynamics, fuel consumption, exhaust toxicity and starting reliability on a carburetor “seven” depend on the correct setting of the ignition timing. The outdated “contact” system requires periodic maintenance and adjustment. Ignition adjustment on a VAZ 2107 with an injection engine equipped with a contactless ignition system is not required. But owners of outdated modifications of the VAZ 2107 have to go to a service station for adjustments or perform the operation themselves. This is not difficult to do.

Installation and connection of additional elements

Many cars do not have hood, trunk, or fuel filler door sensors. You can purchase limit switches, connect them in parallel and connect them to the control input. This is how, for example, they install the hood button:

One subtlety must be taken into account - the “open” position must correspond to a closed state. Installation is carried out in the following sequence:

- Secure the switch body;

- Additional wires are passed through the seal where the hydraulic corrector tubes pass;

- Connect the sensor, and at the same time the siren.

Now let’s add movement control to the car, that is, the alarm will “know” whether the car is actually moving.

Connecting to the speed sensor

Let's talk about the "Seven" with an injection engine. Then the speed sensor is installed and connected from the factory. It will be easy to find the contact of this sensor:

As you can see, you need to make a tap connected to one ECU terminal (1/59). Here we are talking about the control unit, that is, the standard engine controller.

Not every alarm system has a separate input connected to the speed sensor. But if the connection is still made, take care of good contact with ground. Under the “dashboard” there are two copper studs connected to the body. One of them is located near the ECU, and it is better to connect to it (see figure).

It would seem that the speed sensor is a fairly simple additional device. And if this element is missing, you can buy it and install it yourself:

The sensor housing must cover the hole in the gearbox housing. Everything looks simple, and you can do the installation yourself, but the tightness of the assembly will then be broken. In general, it's better not to take risks.

Subtleties of engine control

If autostart is not used, the alarm should not read data from the engine. Otherwise, it is necessary to implement control that allows you to turn off the starter at the right time. The control itself is usually carried out like this:

- The signal can read the value of the supply voltage;

- The cord from the generator is connected to the terminal of the VAZ-2107 tidy - the control cable can be connected to this terminal;

- It is best to control the launch using the tachometer, for which the alarm will still need to be configured.

The third option is preferable. The cord is not connected directly to the tachometer terminal, but through a capacitor and resistor:

Direct connection is used for “generator” control.

In practice, only one control method can be used. First, installation and connection are performed, then the system is configured.

Handbrake control

The dashboard diagram of the VAZ Seven looks like this:

The cord from the handbrake limit switch goes to terminal 8 (connector X2). Connect to this contact unless the instructions indicate that a diode must be installed. Otherwise, use terminal 4.

Connecting to the 4th terminal if the diode is not specified in the basic diagram is incorrect. Remember this and be careful.

https://youtube.com/watch?v=2ug2Eu6ajLM

What is “ignition timing”

Ignition advance means the air-fuel mixture ignites before the piston reaches top dead center (TDC) during the compression stroke. This factor has a great influence on engine performance. A certain amount of time passes between the moment the spark occurs and the moment when the gas pressure in the cylinder reaches its apogee. Although this period of time is extremely short, due to the high speed of the crankshaft, during the time the mixture is ignited, the piston can travel a long way from the moment of sparking to the explosion of the mixture. When the advance angle is correctly set, the mixture explodes at the moment when the piston is at TDC and ready to move down. If the mixture ignites earlier (“pre-ignition”), it explodes during the lifting phase of the piston and interferes with the movement of the piston (the engine detonates). This leads to premature wear of parts and deterioration of engine performance. If ignition is done late (“late ignition”), the mixture explodes after the piston has left TDC, which leads to fuel burning out already in the exhaust manifold, a decrease in gas pressure in the cylinder and, therefore, loss of power and reduced efficiency. Therefore, installing the ignition on a VAZ 2107 is an important and necessary procedure. Sparking should occur at the most appropriate moment, which depends on the position of the gas pedal and crankshaft speed.

What is needed to install BSZ on the seven

The first BSZ kits, which were installed on injection engines, had an unreliable switch that often failed. At the same time, there was a need to replace it until the manufacturers improved the system. As a result, the weakest part of the contactless ignition module is only the Hall sensor.

To install the BSZ on the seven, you need to first prepare not only a set of necessary equipment, but also tools. These tools include:

- Screwdriver Set.

- Open-end wrenches for “8”, “10”, and “13”.

- Pliers or pliers.

- Spark plug wrench for replacing spark plugs.

- A drill for drilling holes in the body, with the help of which the switch will be secured.

- Key set to “36” to rotate the crankshaft.

When all the tools are ready for modification, we begin work. It is worth noting that installation is not difficult and can be done independently at home.

How to choose contactless ignition on a VAZ 2107?

As a result of the fact that VAZ 2107 cars were equipped with different engines, the BSZ system must be installed taking into account the design of the distributor. For power units with volumes of 1.3 and 1.5-1.6 liters, different distributors are purchased. In 1.3-liter internal combustion engines, a unit with a shortened shaft is installed, while in other engines the pulley has the same length.

The BSZ system includes:

- Distribution unit. Its catalog number is 38.3706-01 for a 1.3 liter engine. For power units designed for 1.5 and 1.6 liters - marking 38.37061.

- High voltage coil. Its catalog number is 27.3705.

- System control module. Catalog number 36.3734 or 3620.3734.

- Set of connecting cables.

Switchgears for the VAZ 2107 and Niva VAZ 2121 models are similar in appearance, but they are different and are not interchangeable. “Nivovsky” mechanisms have different technical parameters and are not marked as such. If we talk about manufacturers, then products from SOATE have proven themselves on the positive side.

For proper operation of the BSZ, you will need new spark plugs - A-17DVR, they are not included in the package and must be purchased separately. For more efficient operation, it is recommended to install new high-voltage cables, especially if they have not been replaced for a long time.

The channel “ICE Theory” spoke in detail about the work of the BSZ and the features of choosing a system for classic models.

Necessary tool

To perform the work with the tool you will need the following:

- keys for 8, 10 and 13;

- crosshead screwdriver;

- two self-tapping screws;

- drill with a drill of the required diameter for self-tapping screws.

What causes an incorrectly set ignition on a VAZ 2107

An incorrect lead angle causes the following problems:

Engine overheating. Early ignition causes detonation, which changes the temperature regime of the engine. At the same time, the load on the crank mechanism increases, reducing their service life.

Reduced vehicle dynamics. Early and late ignition of the VAZ 2107 leads to the fact that fuel energy is not optimally consumed. The explosion of the mixture must occur exactly when the piston is at TDC.

Burnout of valves. With late ignition, the mixture continues to burn throughout the exhaust phase, causing the valves to overheat and “popping” to occur in the exhaust manifold.

Why turn on the ignition?

Incorrect ignition installation is a rather serious problem that haunts owners of cars with ZMZ-402 engines, but we are not talking about it now. The combustion of the flammable mixture must occur strictly at a certain time. If this timing is incorrect, the engine does not perform as it should.

Correct installation of the ignition on a VAZ 2107 can solve several problems, one way or another related to engine operation:

- Motor overheating. Often ignition too early causes detonation. Because of this, the engine temperature changes. The load on the parts of the crank mechanism increases, and its service life is significantly reduced.

Reduced vehicle dynamics. It does not matter before or after switching on, this malfunction will occur in any case. When an explosion occurs when the piston is at top dead center, all the energy from the explosion is transferred to the crankshaft and converted into torque. Therefore, the engine throttle is at its maximum at this moment.

If you set this earlier, the explosion will occur in the direction of the upward moving piston, which also exceeds the pressure in the cylinder. Of course, this slows down the rotation of the crankshaft, despite the considerable inertia of the flywheel.

- If the moment comes later than necessary, the piston will already fail during the explosion. When the piston reaches bottom dead center, the gases will continue to expand and some will escape into the exhaust manifold. Hence the pop in the exhaust manifold.

Ignition marks VAZ 2107

When adjusting the advance angle, you must focus on the marks marked on the crankshaft pulley and on the front engine cover.

There is a notch on the engine pulley that should align with one of three marks on the cover, depending on the fuel used.

The marks on the lid are of different lengths - short, medium and long. The first corresponds to an advance angle of 10 degrees, the second - 5 degrees, the third - 0 degrees (the mixture is ignited at TDC).

High octane fuel burns faster than low octane fuel. The VAZ 2107 is designed for gasoline with an octane number of 92-95, so the optimal advance for it is 5 degrees.

Distributor

The ignition distributor (distributor) is designed to transmit high-voltage current pulses that come from the coil to the spark plugs. The distributor consists of:

- aluminum body;

- shaft;

- Hall sensor;

- vacuum and centrifugal ignition timing regulators;

- runner;

- covers with four fixed contacts.

In “sevens” with contactless ignition, distributors of type 38.3706 are used.

A Hall sensor is installed on the distributor 38.3706

Table: technical characteristics of distributor type 38.3706

| Characteristics | Indicators |

| Supply voltage, V | 12 |

| Permissible speed, rpm | 3500 |

| Switching on the centrifugal regulator at, rpm | 400 |

| Maximum angle of the centrifugal regulator, o | 15,5 |

| Turn on the vacuum regulator at, mm. Hg Art. | 85 |

| Maximum angle of the vacuum regulator, o | 6 |

| Operating temperature range, oС | -40 — +100 |

| Weight, kg | 1,05 |

Where is the distributor located in the VAZ 2107

The ignition distributor is mounted on the left side of the engine cylinder block. Its shaft is driven by the auxiliary drive gear. The number of revolutions of the distributor shaft directly depends on the speed of rotation of the crankshaft.

The distributor is located on the left side of the cylinder block

Malfunctions of the VAZ 2107 distributor and their symptoms

The most common breakdowns of the “seven” distributor include:

- burning of the fixed contacts of the cover;

- mechanical damage or electrical breakdown of the cover;

- burning of the runner.

As for the symptoms, for the listed problems they will be similar:

- unstable engine operation;

- reduction in power characteristics of the power plant;

- increased fuel consumption.

To diagnose major distributor failures, it does not need to be removed from the engine. It is enough to disconnect the high-voltage wires from the cover and unfasten the two latches that secure it to the body. By removing the cover and inspecting the contacts with the slider, you can visually assess their condition and draw a conclusion about how suitable they are for further work. If the contacts cannot be cleaned, the device cover must be replaced. Such a part costs about 200 rubles. The runner will cost half as much.

The distributor cover is attached to its body using two latches

How to set the ignition on a VAZ 2107

There is no need to adjust the ignition even in a garage. If you have the tools, you can set the lead angle literally on the street. The procedure is as follows:

- Allow the engine to cool (if it is hot). This will avoid burns during operation.

- Remove the high-voltage wires from the spark plugs.

- Unscrew the spark plugs (you can limit yourself to just the spark plug of the first cylinder, but with all the spark plugs unscrewed, there is no compression in the cylinders and it is much easier to rotate the crankshaft).

- Close the spark plug hole on the first cylinder with your finger (this will help determine the beginning of the compression stroke in the cylinder).

- Using a special key, rotate the crankshaft until the compression stroke begins (your finger should feel the air pressure).

- Continuing to rotate the crankshaft, align the mark on the pulley with the second mark on the front engine cover.

Adjusting the contact group

What is needed, now in detail about how to correctly configure the ignition system on the six. First, remove the cap from the distributor. Using a ratchet wrench, you need to turn the crankshaft until you notice that the distance between the breaker contacts is at its highest value. The contact group is fixed using two small bolts; to make adjustments, they need to be loosened slightly. If the VAZ 2107 has contactless ignition, then you will only need to set the advance angle.

How to install contactless ignition on a VAZ 2107.

Installation of BSZ, detailed video instructions. Installation of the BSZ kit on a car, advice during installation, any obstacles that arise. contact group.

It is best to do this with a wrench rather than a screwdriver. Typically, the tightening of these bolts is very strong, so you will damage their heads faster. For the correct option, you will need a stylus with a width of 0.44 mm. Install it between the contacts and fix the position of the breaker. For this purpose, you must tighten both bolts. Using this procedure it is possible to achieve the required angle value when the contact group is closed.

Checking the ignition timing

First of all, you need to start the engine. If it started before, but after adjustment it doesn’t, it’s worth checking again that the advance angle is set correctly. If the engine is running, it is necessary to check the advance angle while driving:

- Accelerate the car to 45 km/h.

- Turn on 4th speed.

- Squeeze the gas pedal sharply.

- Detonation should occur for 2-3 seconds, and then, after accelerating the car, it should disappear.

If the detonation does not disappear after accelerating, the ignition is “early”. If detonation does not occur at all, ignition is “later”. To reduce the advance, you should unscrew the distributor fixing nut and turn it clockwise a little less than a scale mark. You can increase the advance by turning the distributor counterclockwise.

Tip: when the ignition is perfectly set, you should paint a mark on the scale. This will make subsequent ignition adjustments easier.

Ignition module

The ignition module is a device designed to convert DC voltage from the on-board network into electronic high-voltage pulses with their subsequent distribution among the cylinders in a certain order.

In the injection VAZ 2107, the ignition module replaced the coil and switch

Design and operating principle

The design of the device includes two two-terminal ignition coils (transformers) and two high-voltage switches. The voltage supply to the primary windings of the transformer is controlled by the controller based on the information received from the sensors.

The operation of the ignition module is controlled by the controller

In the ignition system of an injection engine, voltage distribution is carried out according to the idle spark principle, which provides for the pairwise division of cylinders (1–4 and 2–3). A spark is formed simultaneously in two cylinders - in the cylinder in which the compression stroke is coming to an end (working spark), and in the cylinder where the exhaust stroke begins (idle spark). In the first cylinder, the fuel-air mixture ignites, but in the fourth, where the gases burn out, nothing happens. After turning the crankshaft half a turn (180), the second pair of cylinders enters the process. Since the controller receives information about the exact position of the crankshaft from a special sensor, problems with sparking and its order do not arise.

Location of the ignition module VAZ 2107

The ignition module is located on the front side of the cylinder block above the oil filter. It is secured to a specially designed metal bracket using four screws. It can be identified by the high-voltage wires coming out of the housing.

The ignition module is located on the front of the cylinder block above the oil filter

Factory designations and characteristics

VAZ 2107 ignition modules have catalog number 2111–3705010. As an alternative, consider products numbered 2112–3705010, 55.3705, 042.3705, 46.01. 3705, 21.12370–5010

They all have approximately the same characteristics, but when purchasing a module you should pay attention to the engine size for which it is intended

Table: technical characteristics of the ignition module 2111–3705010

| Name | Index |

| Length, mm | 110 |

| Width, mm | 117 |

| Height, mm | 70 |

| Weight, g | 1320 |

| Rated voltage, V | 12 |

| Primary winding current, A | 6,4 |

| Secondary winding voltage, V | 28000 |

| Duration of spark discharge, ms (not less) | 1,5 |

| Spark discharge energy, MJ (not less) | 50 |

| Operating temperature range, C | from -40 to + 130 |

| Approximate price, rub. (depending on manufacturer) | 600–1000 |

Adjusting the gap of the VAZ 2107 distributor breaker

The quality of the spark depends on the gap between the breaker contacts and the condition of the contacts themselves. To adjust the VAZ 2107 distributor, you must perform the following operations:

- unclip the fastening brackets and remove the distributor cover;

- unscrew the screws securing the slider;

- remove the slider;

- Clean the breaker contacts with sandpaper (to avoid damaging the contacts, you must use sandpaper with a grain size no larger than 600).

- loosen the screw securing the breaker contacts;

- turn the adjusting screw to set the gap to 0.4 mm, using the appropriate feeler gauge;

- tighten the fixing screw;

- install and secure the slider;

- fix the distributor cover.

In addition to adjustment, repair of the VAZ 2107 distributor may be required. This consists of cleaning the contacts on the distributor cover or replacing the cover itself, replacing the slider, resistor or contact group.

The ignition system is one of the components of any gasoline engine. Incorrect ignition adjustment of the VAZ 2107 becomes a problem: the spark plugs flood, and the engine completely loses power. Let's look at what the advance angle is, what it affects, and how the ignition of a VAZ 2107 carburetor is installed.

Adjusting the ignition of a VAZ 2107 carburetor

How to ensure that the installation and ignition setup procedure is completed correctly

Despite the fact that the procedure is not very complicated, not all people can carry it out on their own. That is why, if you are not confident in your own abilities, it is recommended to entrust the process of installing and adjusting the ignition of the VAZ-2107 (carburetor) to qualified specialists with experience. They know exactly how to perform this procedure in a short time and still achieve the desired result.

Typically, these services are provided at most gas stations. Therefore, there should be no problems contacting specialists. It is recommended to give preference to experienced professionals. They will not only be able to do the job efficiently, but will also answer all your questions with great pleasure. By approaching this problem responsibly, there will be no problems with the operation of your car.

Installing electronic ignition on a VAZ 2107 allows you to make the operation of the car engine smoother and smoother.

Installing the ignition on a VAZ 2107 is easier than it seems. This does not require special skills or tools. The article describes the complete procedure.

Installing the ignition on a VAZ 2107 is not so difficult. But in this matter you need to be extremely careful and precise, otherwise the whole procedure will have to be repeated.

How does the ignition system work?

The standard ignition system consists of the following components:

- High voltage coil;

- Cables;

- Candles;

- Breaker;

- Switch and Hall sensor (if it is contactless);

- Distributor;

During operation, a low voltage current is applied to the primary winding of the coil and creates a magnetic field, through which it creates a high voltage current on the secondary winding. By means of a distributor and a breaker, the impulse is distributed to the desired spark plug.

BSZ uses the operation of a commutator and a Hall sensor, which transmit energy taking into account the number of revolutions of the distributor. The electronic ignition switch distributes currents more efficiently. Its advantages are that there is no need to clean the contacts and it makes it easier to start the engine in the cold season.

Unlike a carburetor, an injection system uses an ignition module to distribute energy, the operation of which is adjusted by the ECU, which fixes the position of the crankshaft at top dead center. This is why there is no need for adjustment.

Design and principle of operation of the BZ

Contactless or electronic ignition on the VAZ 2107 is installed on models with injection engines. Carburetor sevens were supplied from the factory with contact ignition systems, which have many disadvantages. If you plan to install a contactless ignition module, then before starting it won’t hurt to understand the issue of its design.

The ignition system is the mechanism by which a pulsed voltage is created to supply the spark plugs in order to promptly ignite the fuel-air mixture in the cylinders. The main disadvantage of contact SZ is that the contact groups require regular cleaning, replacement and adjustment. As soon as difficulties arose with igniting the combustible mixture, the car owner immediately knew where to look for the reasons.

With the advent of the BSZ, these difficulties automatically disappeared. To understand why, let’s look at the components of the mechanism:

- Electronic type switch with transistors.

- Double winding coil.

- A distributor or distributor equipped with a Hall sensor, a slider and a contact cover.

- Spark plugs with armored wires.

The BSZ diagram for the VAZ 2107 is shown in the photo below.

Ignition circuit for VAZ 2107

Based on this diagram, let's consider the principle of its operation:

- When you turn the ignition key, current is supplied to the primary winding of the coil, thereby creating a magnetic field.

- When the engine starts, power is supplied to the starter coil and the rotor begins to turn the crankshaft.

- In this case, the crankshaft rotates the distributor shaft, which is connected to the runner.

- As soon as the shaft with the slider rotates, this phenomenon is detected by the Hall sensor (along the protrusion on the shaft) and transmits the corresponding signal to the switch.

- When a signal arrives at the switch, the primary winding of the coil is de-energized (on the low-voltage side).

- A powerful discharge of about 25-30 kV is induced in the secondary (high-voltage) winding, transmitted to a moving contact located at the end of the distributor shaft.

- When the slider moves in a circle, it practically touches the contacts in the cover, a spark occurs between them, and a high voltage discharge is transmitted to each of the contacts in turn.

- This discharge flows through armored cables to the spark plug electrodes.

The mechanism in question received the name “contactless” due to the connection and disconnection of the circuit of the primary winding of the coil with a commutator due to the output transistor (without using contacts).

Operating principle of BSZ

Electronically controlled spark generation operates according to a fairly simple algorithm, which determines the reliability of such a circuit. When the driver turns the key in the ignition switch, a constant voltage from the on-board network is applied to the primary winding of the coil, causing a magnetic field to form around it. Then the system works like this:

- The starter turns the crankshaft and drives the distributor shaft along with the slider.

- The Hall sensor, which reacts to the passage of a metal mass nearby, registers the rotation of the shaft along the protrusion on it and sends a signal to the switch.

- The electronic unit, based on a signal from the sensor, turns off the voltage supply to the primary winding of the coil.

- At the moment the circuit breaks, a high voltage pulse (up to 24 kV) is formed in the secondary winding of the coil. It is directed along a thick wire to the moving contact of the distributor.

- The slider redirects the impulse to one of the fixed contacts built into the cover. From there, the voltage goes to the spark plug of the cylinder where the piston is at top dead center.

- At this moment, the fuel is already in a compressed state in the combustion chamber. When a spark jumps across the electrodes of the spark plug, it ignites.

- The runner rotates and transmits a spark to all cylinders according to the 1-3-4-2 scheme, after which the car engine starts and starts working.

Note. In old VAZ 2107 cars there was no switch, and the electrical circuit was broken mechanically - the shaft cam opened the contact group.

Outdated circuit with contact breaker

This is interesting: Detailed instructions on how to check the crankshaft sensor with your own hands: methods

Pros and cons of the system

If you decide to install a carburetor-type BSZ on a VAZ 2107, then it is recommended that you first understand all the advantages and disadvantages of the device. The advantages of the mechanism under consideration include:

- The absence of contacts automatically eliminates the need for their maintenance. As a result, we have a more reliable system that does not require frequent maintenance.

- Stability of spark propagation through the cylinders, which is due to the absence of the breaking effect of the contacts using the cam method.

- A large discharge in the spark plug, the value of which reaches 25-30 kV, while in contact modules it does not exceed 12 kV. High voltage promotes a stronger spark and improved ignition of the fuel assembly, as well as its complete combustion.

- Simplified engine starting at low temperatures.

This system has much fewer disadvantages, and they consist in the impossibility of repairing the Hall sensor, which has a relatively short service life of up to 50 thousand km. In addition, such a system is more expensive, due to its design features.

What is included in the electronic (contactless) ignition kit for VAZ 2107

The contactless ignition system for VAZ includes:

- distributor;

- ignition coil;

- switch;

- set of wires

What is ignition timing?

For the ignition to work correctly, the following condition must be met: sparking must occur at the moment when the piston is at TDC. This should be a compression stroke. This moment should be the flash point.

| Options | Units | Classical | Contactless |

| Spark energy | mJ | 20 | 60 |

| Secondary voltage rise time from 2 to 15 kV | mks | 30 | 20 |

| Secondary voltage max | kV | 26 | 29,5 |

| Spark duration | ms | 1,5 | 2 |

However, that's not all. The time it takes for the fuel mixture to completely burn must also be taken into account. Therefore, the spark plugs must create an impulse with some advance, which is called the advance angle. As a result, the mixture reaches the peak of combustion, and the cylinder begins to move downward.

If sparking occurs earlier, then such ignition is called earlier, and if late, then later. Early leads to detonation. This is why the engine quickly overheats and becomes inefficient, although fuel consumption can sometimes be greatly reduced. This can be determined by the spark plug electrodes, which are covered with a white coating. With late ignition, power is noticeably lost, and black smoke comes out of the exhaust pipe, which indicates that gasoline, without having time to burn in the cylinder, burns out in the exhaust system.

Ignition coil

The ignition coil acts as a step-up transformer, increasing the voltage from 12 volts to 24 kilovolts or more. In VAZ 2107 cars with contactless ignition, a coil of type 27.3705 is used. All carburetor Samaras were equipped with the same transformers.

The ignition coil increases the on-board voltage to several kilovolts to form a spark that ignites the fuel mixture in the combustion chamber

Table: technical characteristics of transformer coil type 27.3705

| Characteristics | Indicators |

| Operating voltage, V | 12 |

| Output voltage, kV | 22 |

| Resistance value of the primary winding, Ohm | 0,45–0,5 |

| Resistance value of the high-voltage winding, kOhm | 5–5,5 |

| Inductance, mH | 3,9 |

| Secondary voltage rise time to 15 kV, µs | no more than 21 |

| Discharge energy, mJ | 60 |

| Discharge duration, ms | 2 |

| Weight, g | 860 |

| Temperature range, 0С | -40 — +85 |

Coil location

In the "sevens" the ignition coil is installed in the engine compartment on the left. Usually it is mounted on a special bracket under the expansion tank. Sometimes car owners move the coil to a safer place, for example, on the engine shield, to protect it from moisture and process fluids. You can find the coil by the central high-voltage wire that connects it to the distributor cover.

Four high-voltage wires from the distributor cover go to the spark plugs, and the central one goes to the ignition coil

Coil malfunctions and their symptoms

Of all the components of the ignition system, the coil is considered the most reliable component. Its resource is unlimited, but it happens that it also fails. The main causes of transformer malfunction are burnout or short circuit in the windings. If this happens, the spark disappears altogether, because voltage is no longer supplied to the distributor.

Methods for checking the ignition coil of a VAZ 2107

There are two methods to check the coil for performance: rough and fine. In the first case it is necessary:

- Disconnect the end of the center wire from the distributor cap and insert a known good spark plug into the end.

- Place the wire with the spark plug so that the skirt of the spark plug touches the ground of the car.

- Have an assistant sit behind the wheel and turn the starter.

If a spark appears between the spark plug electrodes when starting the engine, it means the ignition coil is working properly.

If the coil is working properly, sparking will be observed between the electrodes of the spark plug.

Pay attention to the spark itself. It should be stable and have a light blue tint.

If there is no spark, it is necessary to make a more accurate diagnosis, since not only the coil, but also the switch, the Hall sensor, and the ignition switch may be to blame.

To accurately check the coil, you will need an ohmmeter or multimeter with a resistance measurement function. The verification procedure is as follows:

- Using a 13 mm wrench, unscrew the nuts securing the coil to the bracket. We disconnect all the wires from it and remove it from the car.

- We clean the body from dirt and dust.

- We turn on the ohmmeter in the measurement range of 0–20 Ohms.

- We connect the probes of the device to the side terminals of the coil (low voltage winding terminals), look at the readings.

They should be in the range of 0.45–0.5 ohms. When connecting the probes to the outer terminals of the coil, the multimeter should show a resistance of 0.45–0.5 Ohm - To check the integrity of the secondary winding, connect one ohmmeter probe to the central terminal, and the second to the terminal marked “+B”.

We switch the device to the range of 0–20 kOhm and look at the readings. The working coil's secondary winding resistance should be in the range of 5–5.5 kOhm. The resistance between the central terminal and the “+B” terminal of a working coil should be in the range from 5 to 5.5 kOhm

If the device readings differ from those indicated, the coil must be replaced.

How to set the ignition on a VAZ 2107 carburetor with your own hands?

There are many ways to set up the ignition on a VAZ 2107, so let's start with the simplest one, which will not require any costs. The posting process doesn't change much. To do this, the car is placed on level ground, wheel chocks are placed under the front wheels, and neutral gear is installed at the gearbox. Prepare your instrument. If you don't have a ratchet wrench, lift the rear wheel and engage 4th gear. The car must be insured to avoid injury.

First of all, it is necessary to install the piston in the 4th cylinder at TDC and this must be a compression stroke. To make it easier to set up contactless ignition, remove the spark plugs and install a paper plug in the 4th cylinder in place of the spark plug holes. Rotate the crankshaft using a ratchet or spin the wheel as it rotates. As soon as the plug flies out, this will be TDC. It is exhibited there. After this, loosen the nut 13 holding the distributor and pull it out. It must be installed so that the slider faces the contact of the fourth cable. To do this, you need to look at the distributor cover, where all the cables are marked with numbers. The housing is located next to the engine.

Now tighten the distributor nut slightly so that the breaker can move. Ask an assistant to start the engine after installing the spark plugs. While the starter is rotating, you need to position the distributor so as to catch the starting moment and tighten the nut. You need to adjust slowly. When the engine starts, you also need to install the distributor so that the speed becomes stable. This ignition setting for the VAZ 2107 carburetor is optimal.

If you have any questions, I recommend watching this video on installing the ignition on a classic VAZ:

Tuning the ignition of a carburetor VAZ-2107 - comparing Sonar IR and BSZ

If you are not satisfied with the operation of the standard contact ignition system of the carburetor VAZ-2107, then you can improve its operation in various ways. This article will help you choose one of them and implement it on your own.

Pros and cons of a contact ignition system

Most carburetor “Sevens” have a contact ignition system. It is simple in design, easy to maintain and operates reliably. The contact system has been known for a long time and, in case of failure, any craftsman can fix it.

Unfortunately, this simple and ingenious design also has a lot of shortcomings. The main problem is the contacts themselves. By closing and opening the electrical circuit, they gradually burn out and change their size. This leads to a change in the ignition timing, and as a result, to a loss of power and efficiency of the engine.

The slightest contamination on the surface of the contacts leads to a decrease in spark energy, and this causes difficulties when starting. And yet, the contacts are sensitive to the amount of wear on the distributor shaft bushings. Shaft play leads to uneven engine operation, especially noticeable at idle.

Because of all these “charms”, the contacts need to be constantly looked after: kept clean and the gap monitored. On a car with a significant mileage, these shortcomings are especially pronounced.

Sonar IR - budget option

It is for such machines that a good solution is to replace the contact group with a contactless device, well known as Sonar IR. It works by interrupting the infrared beam with the cams of the breaker.

Installing Sonar IR is quite simple. Anyone who is used to repairing their car themselves can do this.

In order not to repeat the same thing ten times, I’m putting a link to a video where everything is shown in detail.

Personal experience and studying numerous reviews on the Internet showed the following. After installing Sonar IR, there are no other noticeable improvements in engine performance. Only the stability and uniformity of engine operation has noticeably increased, and the “twitching” at idle has disappeared. What I liked was that I then forgot about the device for 2 years. The distributor did not require any work.

This device is installed instead of contacts

After about 50,000 km and two years, the car began to jerk when accelerating. The search for the cause led to Sonar IR. I had to put the contacts back on the road. I did not buy a new device to replace the burnt one, since I decided to replace the entire ignition system with a contactless one.

From reviews on the Internet I learned that there were cases of Sonar IR overheating in a traffic jam in the summer, but this did not happen to me. If it weren’t for the brand new Nivovsky distributor I got for cheap, I would have installed Sonar IR again. The cost of the device is now about 850 rubles.

He earns his money honestly.

Read, it may be useful: Cooling radiator malfunction

Contactless ignition system - expensive, but annoying

This option already gives a very tangible result. A set of an ignition coil, distributor, switch and wiring harness with blocks costs approximately 2,500 rubles. Plus, it is also advisable to replace the spark plugs and high-voltage wires.

This is what the BSZ kit looks like for a VAZ classic

But for this money you get easy starting in cold weather, smooth and stable engine operation in all modes and forget about problems with the distributor. After installing the BSZ, remember firmly - you cannot remove the wires from the spark plugs while the engine is running! The sensor located in the distributor will immediately fail.

But don’t be alarmed by the presence of electronic components that can “burn out” on the road - they are quite reliable. You can, just in case, buy and carry with you a spare switch and an emergency vibrator. The latter is connected instead of the burned-out Hall sensor in order to get to the repair site.

If you decide to buy a kit, or assemble everything separately, keep in mind that the “3810.3706” brand distributor is designed for the Niva. It may have a shortened shaft and completely different settings. With it, the car pulls “like a tractor” at low speeds, but “sours” during acceleration.

The distributor “38.3706” is designed specifically for the “Seven”; it will fit without any problems.

It is better to entrust the installation of the kit to specialists.

Source: https://21074.ru/dvigatel/tjuning-zazhiganija-vaz-2107-karbjurator-sravnivaem-sonar-ik-i-bsz/

How to set up contactless ignition using tags?

This method is not much different from the previous one, but this time the first cylinder is used. There are marks on the large crankshaft oil seal cover, and on the pulley itself there are marks. You need to turn the mechanism so that the mark on the crankshaft coincides with the middle mark and does not move to the side.

The further procedure is similar to the previous one: install the distributor and collect the elements.

After complete assembly, it is necessary to check the operation of the system. Otherwise, the installation will not work properly.

A few words about the BZS (Contactless ignition system) VAZ 2106

The coil operating as part of a contactless circuit differs in the number of turns of the primary and secondary windings. Simply put, it is more powerful than the old version, since it is designed to create pulses of 22-24 thousand volts. The predecessor supplied a maximum of 18 kV to the spark plug electrodes.

The cable with connectors is used for reliable connection of the terminals of the ignition distributor and the switch. The structure of these two elements should be considered separately.

In terms of reliability, the BSZ is significantly superior to the outdated contact ignition of the “six”; problems arise much less frequently and are easier to diagnose.

All elements of the system are connected to each other and to the engine as follows:

- The distributor shaft rotates from the motor drive gear;

- The Hall sensor installed inside the distributor is connected to the switch;

- the coil is connected by a low voltage line to the controller, a high voltage line to the central electrode of the distributor cover;

- high-voltage wires from the spark plugs are connected to the side contacts of the main distributor cap.

The threaded clamp “K” on the coil is connected to the positive contact of the ignition switch relay and terminal “4” of the switch. The second clamp marked “K” is connected to contact “1” of the controller, and the tachometer wire also comes here. Terminals “3”, “5” and “6” of the switch are used to connect a Hall sensor.

One of the effective options is to replace the standard ignition system with a non-contact ignition system (abbreviated as BSZ), where electronics are in charge of sparking

How to check early/late ignition?

To check the correct setting of early or late ignition, you need to do this while driving. To do this, you need to accelerate at 4th speed to 60 kilometers per hour and reset it to 40. Now sharply press the gas pedal and listen to the engine. If the angles are set correctly, a chirping sound will appear and disappear after a few seconds. The car should begin to pick up speed. With early ignition, detonation will not disappear for a long time, and with late ignition, it will not appear at all.

That is why you need to adjust the position of the distributor by loosening the nut to 13. If you cannot achieve the desired adjustment, proceed to the next step.

Instructions for setting the ignition

If you strictly followed the instructions, connected all the wires according to the diagram and did not misalign the marks, then the motor will start without problems. To adjust the ignition, you need to ensure stable engine operation, so first warm it up for a few minutes, without letting it stall by pressing the gas pedal.

Adjustments can be made on a warm engine using two methods:

- without the use of special devices - “by ear”;

- fine adjustment using a strobe light.

A strobe is a device with a light bulb that flashes simultaneously with the transmission of a pulse by the Hall sensor. When the switched on strobe is brought to the crankshaft flywheel with the engine running, the position of the notch becomes visible. Hence the possibility of precise adjustment.

This is what a strobe looks like for fine-tuning the ignition

To set up, connect the strobe power supply to the battery, and the thick wire to the high-voltage wire of the spark plug of the 1st cylinder. Loosen the distributor fastening nut and bring the flashing lamp to the pulley. Slowly turn the distributor body until the notch on the pulley aligns with the short notch, then tighten the nut.

Tuning in the traditional way “by ear” is done like this:

- Start the engine and loosen the nut holding the ignition distributor.

- Rotate the distributor smoothly and slowly within 15°. Find the position at which the motor operates most stably.

- Tighten the fastening nut.

When adjusting, turn the distributor by the membrane body

It is quite natural that after installing a contactless ignition system, the engine idle speed will increase to 1100-1200 rpm due to the increased spark power. Set the rate to 850-900 rpm by tightening the idle screw on the carburetor and using the tachometer as a guide. On VAZ 2105-2107 carburetors of the “Ozone” type, this screw is located in the lower section of the unit on the right side and is large in size. The VAZ 2108 carburetors of the Solex type (these were also installed on the “seven”) have a long plastic handle protruding from the right (in the direction of travel). The second screw, which regulates the composition of the air-fuel mixture, cannot be turned.

The arrow shows the idle speed adjustment screw.

How to adjust the contactless ignition of a VAZ 2107 using a light bulb

All previous methods are primitive and allow you to set the desired angle only approximately. To achieve the most accurate adjustment, you must continue the adjustment using a regular 12-volt test light. This will allow you to set the most optimal lead angle.

Adjusting contactless ignition

One of the wires of the light bulb needs to be connected to the positive contact of the ignition coil, and the second one should simply be shorted to ground. Loosen the nut by 13 and, holding the octane corrector, slowly turn the distributor until the light goes out. Next, rotate the breaker clockwise until the light comes on. The moment when this happens and there will be the most optimal ignition timing angle on the VAZ 2107. Now the nut can be tightened. If the spark plugs are still flooded, then you need to check the engine power supply system - the carburetor. It needs to be adjusted. There may be reasons in other systems.

Ignition coil design

Almost all ignition coils on VAZ cars are conventional step-up transformers equipped with two windings - primary and secondary. Between them is a massive steel core. All this is placed in a metal case with insulation. The primary winding is made of copper wire coated with varnish insulation. The number of turns in it can vary from 130 to 150. It is this winding that is supplied with an initial voltage of 12 volts.

The secondary winding is located on top of the primary. The number of turns in it can reach 25 thousand. The wire in the secondary winding is also copper, but its diameter is only 0.2 mm. The output voltage supplied to the spark plugs from the secondary winding reaches 35 thousand volts.

Location and connection diagram

The ignition coil on VAZ 2107 cars is located under the hood, near the left mudguard. Attached with two long studs. A rubber cap with a high-voltage wire is connected to it.

The coil is connected according to the diagram below.

Is there a difference between contact and electronic ignition?

On carburetor VAZ 2107, both an electronic and a contact device were installed. The adjustment process is no different. The only difference may be that before setting the marks, it is necessary to clean the contacts on the contact breaker and check the gap so that the system can be adjusted more accurately.

By the way, many people mistakenly call the switch the ignition relay. This relay is only a way to reduce the inrush current and is designed to preserve the life of the contacts. This relay is located in the engine compartment. The ignition setting does not apply to it.

This is how you can adjust the ignition on a carburetor VAZ 2107. Good luck on the roads!

Replacing the device

If the indicators do not correspond to the above values, the ignition coil is considered faulty. Such a device must be replaced with a working one, which can be purchased at almost any spare parts store. When purchasing the device, you must inspect it and check the availability of documents: technical passport and certificate.

Removing the ignition coil on a VAZ2107 car is carried out with the battery disconnected. Use a wrench to unscrew the nuts on the contact and mounting studs. The faulty device is removed. A spare part is installed in its place and secured and connected. Now you can connect the battery and start the engine.

Prerequisites for failure

In situations where there is a malfunction, VAZ 2107 owners replace the spark plugs. Old factory spark plugs are usually replaced with iridium spark plugs from NGK or Denzo. Do not forget that only those spark plugs that are designed for the appropriate type of injection are suitable here.

The type of ignition system is no less important in determining the parameters of the spark plug. Often such manipulation does not provide much improvement (plugs have a fairly long service life), so the non-contact ignition system undergoes a full diagnosis.

Diagnostics of how the ignition module and each individual coil operates is carried out using a special device called a multimeter or ohmmeter. Its functional task is to show the voltage value supplied by the ignition module. As a result of diagnostics, it is possible to identify the source of current loss in the circuit and, accordingly, the nature of the malfunction. To facilitate painstaking work, it is recommended to dismantle the module outward before starting the process.

Non-contact ignition system checks for short circuits

First, pay attention to the coil winding. To get started, connect a multimeter, which determines the resistance value

There is a recommendation regarding the lubrication of the tip of a high-voltage wire: a special product for the VAZ 2107 or technical petroleum jelly is used here.

- the module is disconnected from the tips;

- one terminal of the device is connected to the central contact, which has a coil;

- the other terminal of the device is connected to ground.

The process of checking the secondary windings of the module includes:

Here we focus on an indicator whose value will be no less than 7 ohms. Recommendation: if at least one coil does not meet the specified indicator, the module as a whole must be replaced, otherwise it will not be possible to avoid a malfunction of the system with a VAZ 2107, where an injector is used.

The ignition coil of the VAZ 2107 is located in the engine compartment on the left side of the engine and is secured to the body with two nuts. The ignition coil is an independent element of the vehicle's electrical equipment that converts low voltage current into high voltage current up to 10-20 kV, which should be sufficient to break the gap on the spark plugs and sufficient to ignite the combustible mass. The coil is non-separable, which means that if it fails, it cannot be repaired and must be replaced with a new one.

The ignition coil is a transformer consisting of an internal magnetic circuit, primary and secondary windings, as well as an external magnetic circuit connected to the ignition distributor.

To remove the coil you will need a ten and eight wrench, also disconnect the battery.

- Disconnect the central magnetic circuit from the coil.

- Unscrew the two nuts securing the power wires with a wrench.

- Using a ten-socket wrench, unscrew the two nuts securing the coil to the car body, remove the ground wire and remove the coil from the studs.

At this point, work on removing the ignition coil of the VAZ 2107 is completed. Before replacing it with a new one, you need to make sure that it is not working; for this you will need a multimeter. Before checking, thoroughly clean the primary winding leads on the coil body (two studs to which the power wires are attached) from dirt and oxides.

- First, let's check the resistance of the primary winding. To do this, connect the ohmmeter terminals to the terminals of the primary winding (two pins on the body) and take measurements. Depending on the type of coil being tested, the resistance should be: B-117A = 3-3.5 Ohm; 27.3705 = 0.45-0.5 Ohm.

- Now we check the resistance in the secondary winding circuit. To do this, we connect one ohmmeter probe to the terminal of the high-voltage wire, and leave the second at the terminal of the primary winding. The resistance should be equal: B-117A = 7.4-9.2 kOhm; 27.3705 = 5-0.5 kOhm.

At this point, the repair work on removing and checking the ignition coil of the VAZ 2107 is completed. If, after checking, deviations from the norm are found, it is recommended to replace the coil with a new one.

Sources

- https://semerkavaz.ru/ehlektrooborudovanie/zamena-i-regulirovka-modulya-zazhiganiya-na-vaz-2107/

- https://autodont.ru/system-of-ignition/rabota-s-modulem-zazhiganiya

- https://remont-vaz2106.ru/katushka-zazhiganiya-vaz-2107