Even with a perfectly adjusted high and low beam light beam, you often have to adjust the angle of the headlight reflector. This is primarily due to the loading of the car. If, according to the rules for adjusting the headlights of the VAZ-2110, we start from the load of the driver + front passenger, then in real life, when the cabin is fully loaded, our adjustment will leave no stone unturned. The rear of the car will squat, the front will rise and the light beam will blind oncoming drivers. To quickly adjust the angle of the headlight reflector, a hydraulic corrector is installed in all VAZ-2110s.

The principle of operation of the VAZ-2110 headlight hydraulic corrector

Its purpose is clear - without leaving the cabin, the driver can change the angle of the light beam relative to the road. The device must work correctly with two headlights at once and have a sufficient range of adjustment - to maximize the angle of the reflector when the rear part of the body is fully loaded, and also reduce the adjustment to zero when the load is minimal.

The principle of operation of the headlight hydrocorrector.

The VAZ-2110 hydraulic corrector, installed as standard, consists of:

- main hydraulic cylinder and switch, both of them are assembled in a single block and installed to the left of the steering wheel on the front panel;

- hydraulic drive system, line - tubes that connect the elements of the system;

- working hydraulic cylinders, actuators that raise or lower the headlight reflector;

- working non-freezing liquid.

The low-pressure hydraulic system allows you to change the working pressure and move the rod of the working cylinders within 6–7.5 mm . In theory, this is enough to change the angle of installation of the reflector from minimum to maximum and, accordingly, change the direction of the angle of the light beam.

Removal and installation of headlight hydraulic corrector Niva 2121, Niva 2131

What to do if the Renault Logan stove does not work. A little about the air conditioning system of the Renault Logan car - watch the video

We disconnect the hydraulic corrector from the headlights and instrument panel when removing these components. We completely dismantle it for replacement. To disconnect the working cylinder of the Niva 2131 hydraulic corrector from the headlight...

...press the lock, turn it counterclockwise...

...and remove the hydraulic corrector working cylinder from the headlight.

Having removed the rubber plug from the mudguard (see Removing and disassembling a VAZ 2131 headlight, replacing the lamp),…

...we bring the working cylinder into the engine compartment.

Similarly, we remove and remove the working cylinder of the other headlight. To remove the hydraulic corrector master cylinder in the passenger compartment of a VAZ 2121,…

... by pulling it towards you, we remove the control handle.

Using a 21mm socket, unscrew the nut securing the master cylinder to the instrument panel.

We remove the main cylinder of the hydraulic corrector from under the instrument panel.

Having removed the plug from the front panel, we bring both working cylinders into the passenger compartment through the resulting hole. We install the headlight hydraulic corrector Niva 2121 in the reverse order.

Lighting VAZ 2121, Niva 2131

| Headlight diagram and lighting Niva 2121, Niva 2131 |

| Disassembly and assembly of headlights Niva 2121, Niva 2131 |

| Adjusting headlights Niva 2121, Niva 2131 |

| Removal and installation of headlight hydraulic corrector Niva 2121, Niva 2131 |

| Brake and reverse lamps, interior and trunk lighting Niva 2121, Niva 2131 |

| Removal and installation of the front lamp Niva 2121, Niva 2131 |

| Removal and installation of the side direction indicator Niva 2121, Niva 2131 |

| Removal and installation of the rear light Niva 2121, Niva 2131 |

| Replacing the reverse light switch Niva 2121, Niva 2131 |

| Removal and installation of license plate lamps Niva 2121, Niva 2131 |

| Removal and installation of lampshades and interior lighting switches Niva 2121, Niva 2131 |

Direction indicator diagram Niva 2121, Niva 2131 |

| Replacing the turn signal and hazard warning switch relay Niva 2121, Niva 2131 |

| Removing and installing the hazard warning switch Niva 2121, Niva 2131 |

Units and diagrams of electrical equipment VAZ 2121, VAZ 2131

Diagnostics of electrical circuits of the Niva 2121 car. Instructions for repairing electrical equipment: generator, starter. Niva 2131 car diagram.

Malfunctions and diagnostics of hydraulic corrector

Despite the simplest design, the hydraulic corrector is considered one of the most unreliable systems in cars of the tenth family. Design flaws, quality of materials and workmanship force us to return to the problem of adjusting headlights almost every year.

In this case, neither the working nor the main cylinders can be repaired and require replacement if they fail.

The signs of a malfunction are clear - the headlights do not respond to the corrector knob and are frozen in one position . The most common problem is depressurization of the hydraulic system. This trouble can be easily calculated by the leakage of liquid from the system, and it is also easy to eliminate. It is enough to seal the joints (on the cylinders) of the hydraulic system and check its operation again.

Another problem is fluid leakage through the cuffs of the working cylinders . No one is going to repair cheap plastic cylinders; they are replaced with new ones. By the way, the price of a new hydraulic corrector for the VAZ-2110 and all cars of the family (article 2110–3718010 and 2110-3718010-10 ) is 450–550 rubles, depending on the manufacturer. The difference between them is the stroke of the working cylinder rod. For tens in a station wagon, a larger load and a larger adjustment angle are provided. Accordingly, a larger stroke of the cylinder rod.

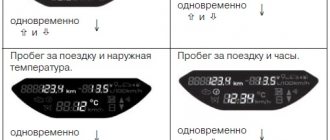

You can check the operation of the headlight hydraulic adjustment system by measuring the working stroke of each of the working cylinder rods:

- 2110–3718010 — working stroke 6–7.5 mm for sedan and hatch;

- 2110-3718010-10 — working stroke 6–8.5 mm for a station wagon.

If the hydraulic cylinders do not work or the working stroke does not correspond to the nominal values, we replace them and install a previously purchased new hydraulic corrector of the appropriate modification.

Instructions for installing headlight range control yourself

If the system breaks down, the device must be removed and repaired. If the mechanism cannot be repaired, it may need to be replaced.

Brief instructions on how to install an automatic corrector with dismantling the electromechanical device (using the Halla model as an example):

- First of all, the electromechanical corrector is removed and removed.

- Next, you will need to slightly enlarge the technological hole for installing an automatic device, if the dimensions do not match and this is necessary.

- The new socket for fixing the device should be secured with glue or sealant.

- After this, the device is installed in the mounting location.

- The connection diagram for the headlight range control involves the use of ground clearance controllers; we mount them on the rear of the underbody.

- Now all you have to do is install the wiring from the sensor; for this you can use existing tubes. The control module is mounted in any convenient place and connected to the battery.

Replacing hydraulic corrector VAZ-2110

There shouldn’t be any difficulties during replacement; we only need standard tools for the job, and we can change the hydraulic corrector even in the field.

The only thing that will make it easier to unscrew the hydraulic corrector switch mounting nut is ordinary tweezers.

Let's get started:

- Open the hood, loosen the clamps, and release the hydraulic drive line pipes.

- Remove the working cylinders by releasing the clamps using a flat-head screwdriver.

Open the hood and remove the actuator cylinders from the inside of the headlights.

As you can see, replacing the system is not at all difficult and it will not take much time. But the new hydraulic corrector will only work for a year or two , after which the operation will have to be repeated. By the way, there are electric headlight levelers on the market (from 3.6 thousand rubles) and electromechanical automatic ones (from 6–8 thousand). Their service life is much longer, and the adjustment accuracy is better than that of a hydraulic system.

Good luck with your choice and bright, accurate headlights on night roads!

Replacement

Many car enthusiasts struggle with replacing and installing a hydraulic corrector. But in reality this work is not difficult. And if everything is done correctly, then no problems should arise. Replacement consists of the following steps:

- First the preparation is done. All clamps securing the tube to the body are removed. It is also advisable to remove the radiator expansion tank. This will make access to the headlight easier. In the cabin, the control knob is removed; to do this, you simply pull it towards you;

- Next you need to get the cylinder. To do this, grab the switch on the panel and pull it off. In most cases it can be easily removed. After this, the cylinder is unscrewed from the switch. This is done using a 22mm head. Afterwards the cylinder is pulled out by the tube under the torpedo. As a result, he should hang on the hoses;

- The actuator cylinders are disconnected from the headlamp. They are dragged into the salon. This completes the dismantling of the corrector.

Reassembly is done in reverse order

In this case, pay attention to the seals. They must stand straight

Otherwise, you will have a noisy interior, and in winter it will blow from there. Don't forget to check the operation of the new hydraulic corrector. If it turns out that it does not work, you will have to repeat the procedure.

Repair of hydraulic corrector for VAZ 2110 headlights

Adjusting the light beam happens quite often, especially when the trunk of the car is heavily loaded; the light shines directly into the eyes of drivers of cars moving towards you. If the reflector has dropped and the adjustment does not work, our instructions will help you repair the headlight hydraulic corrector of the VAZ 2110; the repair will take very little time.

VAZ 2110 headlights Kirzhach - hydrocorrector repair

- Unscrew the headlight fasteners and remove them;

- We disassemble the headlights: carefully remove the glass, then the metal clips (6 pieces);

- Using a knife, clean the glass from the sealant;

- We cut off the convex profile (in the shape of the letter P) on the glass;

- Unscrew the screws (there are 3 of them) from the reverse side;

- Take out the paper reflector;

- Next to the hydraulic corrector hole inside the light housing there is a spring that must be removed;

- We perform the same actions with two plastic rosettes from two “turntables” securing the reflector.

Note: The hydraulic corrector ball snaps into a plastic groove, and the metal bobbin snaps into the second groove. It stops the adjustment, preventing it from being unscrewed further than itself. If you press the hydraulic corrector when adjusting the headlights, the metal latch will break. The ball will pop out of the plastic and then the headlight will “fall”;

- The repair will consist of replacing the broken latch with a gasket , which will not make it clear that the adjustment has reached the extreme position;

Broken iron latch of hydraulic corrector

Rubber gasket to replace a broken latch

- As a result, there is a high probability that the corrector will be compressed again;

- The correct solution is to improve the fastening by inserting a cotter pin made of solid wire between the petals of the plastic thing.

For the VAZ 2110, the repair of the headlight hydrocorrector has been completed. We assemble the headlights in the reverse order of disassembly. We first clean the old sealant, then apply a new one.

Second repair method

- We cut threads on the adjustment screws (metric 3);

- We screw them into the illuminator itself, then put on the washers;

- We take out the plastic fasteners;

- We put on the bar with the high beam and low beam modules located on it;

- We put a washer on top, a spring washer, and another washer on top of the spring. The use of a lock nut is recommended;

- We twist everything;

- We fix the structure using anaerobic sealant.

We repair the light fixture without disassembling it

You can snap the ball into place without removing the glass, through the holes of the light bulbs on the back side of the illuminator:

- We drill a hole exactly opposite the latch at the top of the headlight;

- Insert a screwdriver into the hole;

- Attach the collet to the corrector ball;

- We seal the hole we drilled;

- We attach a hinged loop from a furniture cabinet (hinges 5-6 centimeters long, with mounting holes and a cutout on top on which it is attached) to each broken corrector unit;

- We insert the canopy into the slot of the adjustment screw;

- We move the screw so that the slot is in a narrow place of the canopy;

- Holding the canopy, unscrew the screw until it stops with force. This is how the canopy is fixed, which needs to be placed in a horizontal position;

- Using an electric drill, using a 3 mm drill, we make a hole in the base of the light where there is a hole on the canopy;

- We screw a shortened screw into the hole so that it does not reach the high beam reflector. This slot secures the adjustment screw securely; it can be broken again.

Eliminating headlight shake

Many owners of the VAZ 2110 find that the light flickers when the car is moving. Such a breakdown most often occurs in Kirzhach headlights, but in Bosch parts such a breakdown rarely occurs. There is only one reason: reflector rattling. To eliminate light flicker, check:

- Is the reflector in place in the latch;

- The presence of an adjusting bolt rod;

- The emphasis is on the seating recess of the hydraulic corrector rod;

- We check the sagging of the thread (swap the high beam and low beam bulbs);

- Integrity of the tube in the hydraulic corrector (it may fray).

Replacing a VAZ 2110 headlight

Sometimes the entire headlight needs to be replaced. The work is done without any problems:

- Disconnect the negative terminal from the battery;

- We take out the radiator trim;

- Remove the block along with the wires;

- Press the latch of the hydraulic corrector cylinder and turn it clockwise 90 degrees until it stops;

- We take it out of the recess without disconnecting it from the hoses;

We take out the block with the wires, take out the hydraulic corrector

- We unscrew the bolts securing the headlight (shown in the photo with white arrows) and push the headlight itself back;

Unscrew the bolts securing the headlight

- We move the trim about four centimeters to the center of the car so that its hook comes out of the mount with the wing;

- To move the pad, loosen the tension of the bolts securing the buffer from above, push the buffer forward;

Loosen the screws securing the buffer

- We press on half of the lining so that the flange comes out of the mount, and take out the lining;

- Unscrew the nut securing the illuminator from the bottom;

Unscrew the nut from the bottom

- Disconnect the block from the turn signal lamp, pull the illuminator towards you and take it out;

- Unscrew the fastening screws to disassemble the illuminator;

- Separate the headlight from the turn signal;

Separate the headlight from the turn signal

- On the body of this pointer, unhook two hooks from the body of the optics part;

- We assemble in the reverse order to this and install the headlight assembly.

Congratulations! Do-it-yourself headlight replacement is complete, if anything remains unclear to you, I recommend watching the video on request VAZ 2110 headlight repair.

Installation of headlight range control for VAZ 2114, VAZ 2115, VAZ 2113, Lada Samara 2

To change the angle of the headlight beam depending on the load on the car, a headlight hydraulic corrector is used, consisting of a master cylinder mounted on the instrument panel and working cylinders installed on the headlight housings and connected to the main connecting tubes. The cylinders and tubes are filled with a special liquid with a low freezing point and do not communicate with the atmosphere. The hydraulic corrector is non-separable and cannot be repaired. When operating the vehicle, pistons in the cylinders may jam or fluid may leak from the cylinders or pipes.

If a hydraulic corrector fails, it is advisable to replace it with a more high-tech electromechanical headlight corrector (electric headlight corrector).

The installation kit for the electric corrector consists of a headlight leveler, two actuators with O-rings and a connecting wire harness.

We carry out the work on a car with a VAZ-2114 dashboard.

Inside the car...

...remove the instrument panel light switch handle.

...and the hydraulic corrector handle.

...remove the lining with the corrector scale.

Using a Phillips screwdriver, unscrew the self-tapping screw securing the light guide for the scale illumination of the VAZ 2113 corrector...

...and remove the light guide.

Using the “21” socket, unscrew the nut securing the main cylinder of the hydraulic corrector.

By pressing on the cylinder rod, we recess it into the hole in the instrument panel...

and remove the master cylinder from under the panel.

In the engine compartment, we disconnect the working cylinders of the VAZ 2114 hydraulic corrector from the headlight housings (shown on the right headlight).

By pressing the latch, we turn the hydraulic corrector working cylinder counterclockwise...

...and remove it from the headlight housing.

We cut the tubes with side cutters...

...and remove the right cylinder.

Similarly, we disconnect the working cylinder of the hydraulic corrector from the left headlight (for convenience, you can remove the battery).

...we remove the rubber seal of the hydraulic corrector tubes from the hole in the front panel.

We thread the wiring harness blocks of the VAZ 2115 headlight electric corrector into the seal. We lay the headlight electric corrector wiring harnesses along the factory wiring harnesses.

We insert the electric corrector into the hole in the headlight housing.

We connect the wiring harness block to the right electric corrector.

Similarly, we connect the electric corrector to the left headlight.

In the cabin, we connect the negative wire of the electric corrector to ground, and the power wire to the wire that supplies voltage to the low beam filament of the headlight lamp (after the fuse).

We connect the electrical corrector wiring harness block to the regulator. We install the regulator in the reverse order of removing the main cylinder of the hydraulic corrector.

Changing the type of optics (tuning)

Car enthusiasts often tune their car headlights to improve their appearance. High-quality tuning gives the car a fashionable look and beauty. If you choose the right accessory, the appearance of dozens will change completely . The most popular among car enthusiasts is tuning headlights in the form of tinting. It is carried out in a variety of ways that have virtually no effect on the brightness and quality of road lighting. Types of headlight tinting:

- Painting of the headlight mask;

- Glass painting;

- Glass tinting film.

The process of such tinting is best shown in a video. For those who don't want to paint or tint their headlights themselves, there are ProSport headlights. They are already sold in black or chrome. You just need to install them instead of the standard headlights. Only they cannot boast of high quality or bright light.

Depending on how loaded the vehicle is, the headlights can be directed higher or lower. To adjust the light flux, special devices are used - hydrocorrectors. If the car is loaded, the headlights should be turned down so that the flow of light is directed not upward, but onto the road. This ensures the necessary illumination of the road surface and prevents the driver of an oncoming car from being dazzled. In the case of a minimal vehicle load, when the rear part of the frame is raised, the headlights should be turned upward.

Design of headlight hydraulic correctors

As a rule, the following components are included in the design of a hydraulic corrector:

- master cylinder mounted on the dashboard;

- actuator cylinders mounted on the headlights;

- connecting pipelines that are fixed with clamps;

- working fluid with increased frost resistance.

Typically, hydraulic correctors are made in the form of a non-removable structure that cannot be repaired. Therefore, if, for example, the hydraulic corrector of the VAZ-2114 headlights fails, it is repaired by replacing it with a new set.

The manufacturer provides a maximum operating pressure in the normal state of the corrector. To direct the luminous flux of the headlight downwards, the pressure in the system is reduced, as a result of which the actuator cylinder rod is retracted and the optics are rotated downwards. Thus, most of the time the device is under increased pressure.

Quite often, when temperature changes occur, especially in winter, the structure of the seals is damaged due to the poor quality of the rubber, which leads to leakage of the working fluid. In turn, this leads to jamming of the cylinder pistons in one of the positions.

Structurally, all hydraulic correctors that are installed on VAZ vehicles are made according to a similar design, with the exception of some differences in size, layout of cylinder fastenings and pipelines. Today the following modifications of hydraulic correctors are supplied to the market:

- “2105-3718010” - for VAZ 2105-2107;

- “2108-3718010” - for VAZ 2108-21099;

- “2110-3718010” and “2110-3718010-10” - for VAZ 2110-2112;

- “2114-3718010” - for VAZ 2113-2115;

- “21213-3718010” - for 21213 “Niva”.

Hydrocorrector malfunctions

Among the most likely causes of a non-working headlight hydrocorrector is depressurization of the joints of tubes and sealing cuffs. The consequence of loose connections is loss of working fluid and air being sucked into the system. For the working pistons to move properly, the system must be completely filled with liquid. The manufacturer does not suggest repairing the hydraulic corrector, so if the system fails, the assembly is replaced. Nevertheless, the article “Repairing a hydraulic corrector” shows that the system can be troubleshooted and restored.

This is interesting: Ways to check a car battery: how to determine the health of the battery using a multimeter

Where is the lamp hydraulic corrector located? Each headlight unit has an actuator that acts on a reflector, from which 2 tubes go into the cabin. Through a technological hole in the engine shield, the tubes go to the master cylinder and the switch on the dashboard.

Reasons for failure of the hydraulic regulator

If, when turning the headlight adjustment knob, the light beam does not change direction, this indicates a failure of the hydraulic corrector. There are several reasons for the malfunction:

- One of the working cylinders is jammed. In this case, the corresponding reflector will not rotate.

- The connecting tubes were damaged and the system depressurized.

- Failure of sealing due to damage or wear of seals.

If the system is depressurized, it is impossible to regulate both lamps. Most often, they lower and take a lower position, as a result, the headlights only illuminate the road next to the car. At night, this increases the risk of an emergency. You can try adjusting the hydraulic device rod.

Manufacturers of hydraulic correctors did not provide for the repair of the closed system as a whole and individual elements. Therefore, if the device fails, it is necessary to either install a new hydraulic regulator or replace the hydraulic device with an electric one.

Some car enthusiasts try to repair the regulator, but this does not bring long-term results. For example, they replace the working rod with a self-tapping screw of a suitable diameter with the sharp end removed. This makes it possible to fix the reflectors in a certain position. It will be impossible to make adjustments from the interior.

If, during a visual inspection of the hydraulic regulator, cracks are found in the connecting tubes, the repair will consist of eliminating them. The cause of cracks is temperature changes in the engine compartment of the car. If the crack is close to the main or working cylinder, cut off the cracked end. The tube damaged in the middle is completely replaced by pumping with antifreeze.

How to repair a hydraulic corrector on a VAZ 2110 – 2115

Repair of the VAZ-2110 headlight hydraulic corrector is not provided by the manufacturer. Therefore, if it fails, the entire device, complete with pipelines and cylinders, is replaced.

If the angle of inclination of the optics is not adjustable when the vehicle load changes and it is not possible to achieve the optimal luminous flux using the adjusting screws on the headlights, you should check the functionality of the corrector as follows:

- First of all, it is necessary to inspect the device for the integrity of the pipelines and the absence of liquid leakage.

- If after these measures no malfunction is detected, we proceed to checking the performance of the actuator cylinders. To do this, remove them from the headlight unit and measure the stroke of the rods. Normal operation of the cylinders is ensured when the rod stroke is within the range of 6.5-7.5 mm.

- Since repair of the VAZ-2110 headlight range control is not structurally provided for, we replace the non-working device with a new device included in the kit.

How does a hydraulic corrector work?

From the name of the device you can understand that its action is based on hydraulic principles. That is, the changing pressure of the working fluid in the system leads to mechanical movements of the desired part. This is true in reality. The entire system for adjusting the direction of light flow consists of the following main components:

- master cylinder;

- connecting tubes;

- working cylinders (on each headlight);

- force transmitting levers.

When the hydraulic corrector is working normally, the reflectors should respond to turns of the handle. This can be easily checked in the dark by pointing the headlights at a vertical plane (some wall, for example). If the reflectors remain motionless, this indicates a possible breakdown of the adjustment system.

Adjusting the headlight range control rod

Sometimes a malfunction of the headlight adjustment system can be caused by a misalignment of the adjustment lever with the lampshade rod. Therefore, if, for example, the hydrocorrector of the VAZ-2112 headlights does not work, do not rush to repair it by replacing it. First, make sure that the connection between the lever and the rod matches the operating position.

The rod of the corrector actuator cylinder rests on the lever, which, in turn, acts on a similar rod rigidly fixed to the headlight dome. The lever passes through the adjusting bolt, which is its fulcrum. The adjustment mechanism works on the principle of a swing. The corrector swings the lampshade, and the adjusting bolt allows you to raise or lower the support point of this swing. If the bolt is turned to the maximum position, the reverse end of the lever in the form of a ball may slip out of engagement with the lampshade rod.

In order for the VAZ-2115 headlight hydraulic corrector to work again, the device must be repaired by returning the lever to a special recess on the rod. To do this, first tighten the adjusting bolt until it stops, then press the lampshade down and insert the lever ball into the desired position.

Adjusting contactless ignition

On VAZ-2108 and newer cars that have electronic ignition installed, setting the timing is very simple. The most important thing is to install the camshaft and crankshaft according to the marks

Please note that it is impossible to install the distributor incorrectly (you already know what it is). The fact is that it is installed on the camshaft in one position; it is simply impossible to rotate it 90 or 180 degrees.

So, when you have set the marks on the shafts and installed the timing belt, you can begin fine adjustment. The distributor should be positioned on the axle so that the mark on the cylinder head cover is opposite the middle line. In this case, the ignition timing will be 0 degrees. By rotating the distributor body clockwise or counterclockwise, you can change the advance angle to a smaller or larger direction. It is necessary to perform these actions provided that you have at least a strobe light.

Replacing the hydraulic corrector for VAZ 2110, 2111, 2112 headlights

Replacing a faulty corrector yourself is not difficult. The replacement sequence is as follows:

- unscrew the screws securing the pipeline clamps to the mounting brackets;

- remove the handle from the master cylinder;

- Unscrew the nut securing the master cylinder to the dashboard;

- We disconnect the actuator cylinders from the headlamp;

- we push the actuator cylinders together with the seals inside the cabin;

- install the new unit in reverse order.

Many car enthusiasts, instead of the standard hydraulic corrector provided by the manufacturer, install a more practical and efficient electric headlight corrector. Its difference from a hydraulic device is that electric motors are used as a drive. For VAZ cars, a standard electrical corrector of the Silich-Zenit series is provided. It is easily mounted in the same places as a conventional hydraulic corrector. The installation procedure for the electrical corrector is as follows:

- disconnect the negative terminal from the AC;

- turn the master cylinder counterclockwise and remove it;

- replace the o-ring;

- install the electric corrector in place of the main cylinder;

- dismantle the master cylinder lever in the cabin;

- We connect the positive terminal of the corrector to the socket of block No. 20;

- We attach the negative terminal to one of the body studs under the dashboard;

- we lay the corrector wiring instead of pipelines or along the power supply harness;

- connect the corrector's electrical wiring to the actuators;

- connect the negative terminal to the battery;

- We check the functionality of the corrector.

After installing the corrector yourself, you will have an idea of how this device works. If necessary, repairing the electrical corrector will not be difficult.

Installation of electromechanical autocorrector

The electromechanical autocorrector is installed with your own hands in the places provided by the manufacturer for the standard hydraulic corrector. Therefore, before installing the EMKF, it is necessary to dismantle the failed device. To do this, you should first cut through the pipelines in the battery area and drain the liquid from them. Then remove the main slave cylinder. Using a screwdriver, press the latch that holds the cylinder body, turn it all the way counterclockwise and pull it up.

After this, in the car interior we remove the control handle from the hydraulic corrector unit. It is fixed with a nut, which is unscrewed using a spark plug wrench. We take out the control unit and pipelines. Remove the rubber plug installed in the engine shield.

We begin to prepare the electrical wiring that will connect the gearmotors and the control unit. We will need:

- Ten stranded wires with a cross-section of 0.35 m2. Half of them should be 1.65 m long, and the second - 2.55 m.

- Two polyvinyl chloride tubes 1.6 and 2.5 m.

- Twenty female terminals.

- Two 11-pin blocks.

- One 5-pin block.

- Two thick wires for power. Their length depends on the specific car model.

First, cut pieces of wire to the required length. We put polyvinyl chloride protection on them using talc. If you don't have it, you can use powder. On one side of the wire we solder the terminals, which we then insert into the control unit connection block. In order not to make a mistake with the length of the wires, we first try on the prepared harnesses at the place of attachment. After this, we insert the wiring through a rubber plug into the hole in the engine shield, which previously contained the hydraulic corrector pipelines.

At the second end of the wiring, we solder the terminals and place them in the sockets of the gearmotor connection block. As a rule, gearmotor pads are sold in ready-made kits in rubber protective covers. If they are not there, then you can insulate the pads with heat shrink tubing and sealant.

The power is connected using two thick wires and four female terminals (one wide and three narrow). For normal operation of the corrector, power to the control unit must be supplied when the low beam is turned on. The easiest way to do this is by connecting the rear fog light power supply to terminal No. 10 of switch No. 64. The ground wire can be connected through the free wire terminal that goes to the ignition relay.

After this, we install the gearmotors in their original place with the gaskets that come with the kit. All harnesses should be secured to the stock wiring with nylon ties.

Features of restoration of hydraulic correctors for VAZ 2107—2109

As a rule, on cars of the VAZ 2107-2108 series, a manual hydraulic headlight leveler is installed. With it, the driver can manually change the direction of the light flux depending on the load of the car, moving the headlights up or down within small limits.

The design does not provide for repair of the VAZ-2107 headlight hydraulic corrector, therefore, if it fails, it is replaced with a new device. The only thing you can try to do if it is impossible to adjust the angle of the headlights is to adjust the operation of the corrector in the order indicated above.

There are no fundamental differences in the optics adjustment device in the “nine” compared to other models. Therefore, the VAZ-2109 headlight hydraulic corrector is repaired using the replacement method.

>

How to find a breakdown

Many people, when headlight adjustment fails, immediately blame the hydraulic corrector for everything and rush to replace it as quickly as possible. But don't rush to conclusions. There may be other causes of the malfunction.

- Pay attention to any leaks of working fluid. If they are not there, check the stroke of the rod.

- To check the stroke of the rod, the actuator cylinders are dismantled. The normal value is between 6.5 and 7.5 millimeters.

- It is impossible to repair the hydraulic type corrector provided by the factory for the VAZ 2110, since the design of the device is not dismountable.

- If malfunctions occur, the entire assembly must be replaced, including cylinders and pipes.