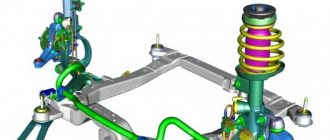

The design of the front suspension of the VAZ 2110 is identical to most Lada models and consists of the following elements:

- Oil type shock absorber;

- Spring;

- Support bearing;

- Stabilizer's pole;

- Stretcher;

- Silent blocks, rubber bushings.

During the operation of the car, parts wear out, become unusable, and operating efficiency decreases. The technical equipment needs preventive maintenance and repair.

The process of replacing suspension elements yourself is not complicated, and the operating principle is intuitive. We carry out restoration work on our own; there is no need to contact a workshop.

Originals, analogues, article number, price of stabilizer strut for VAZ 2110

Technical data: length 110 x width 32 mm.

Stand structure: base, metal tip, rubber boot, lock ring. Nuts and washers are not supplied, the owner must purchase them separately. Thread pitch 1.25, diameter 8.0, length 60.0 mm.

| vendor code | Price, rub.) | vendor code | Price, rub.) |

| Original front | |||

| VAZ-2110 assembled kit 2110-2906050 | From 320 | VAZ-2110 2110-2906050SS | From 320 |

| 2110-2906050 | —/— | 2110-2906055 | —/— |

| Front analogues | |||

| SIDEM 19169 | From 300 – 350 | MOOG LALS10573 | From 300 – 350 |

| SS40106 | —/— | SS40102 | —/— |

| SLST-104 | —/— | SS20-10-29060 | —/— |

Before purchasing consumables, be sure to check the compatibility of the catalog items specified in the operating instructions.

Stabilizer struts with polyurethane bushings SS20.21.00.000-02 for VAZ 2110 (2 pcs.) * [SS40106]

Stabilizer struts SS20 for VAZ

The SS20 stabilizer struts are distinguished by a reinforced design with argon welding around the perimeter of the jumper.

Applicability

- VAZ 2108-21099

- VAZ 2110-2112

- VAZ 2113-2115

- VAZ 1117-1119 (LADA Kalina)

- VAZ 2170-2172 (LADA Priora)

- VAZ 2190, 2191 (LADA Granta)

- VAZ 2192, 2194 (LADA Kalina 2)

- Datsun mi-DO, Datsun on-DO

Advantages of SS20 stabilizer struts

- reinforced stabilizer link housing with a box-section jumper has increased strength and rigidity;

- high service life of rubber and polyurethane bushings

- argon welding along the perimeter of the jumper provides a tensile force 2.5 times greater than that of a standard part and eliminates rupture of the stabilizer link;

- the ability to choose stabilizer struts with softer rubber or more durable and wear-resistant polyurethane bushings;

- silent blocks retain elasticity down to -40°C and are resistant to gasoline, oils and reagents;

- on the Grant and Kalina 2 stabilizer struts, the size of the upper bushings has been increased;

- 2 year unlimited mileage warranty.

Warranty 2 years Description

Instead of the standard design, we offer an SS20 stabilizer link of increased reliability (according to test results, the breaking force is 2.5 times higher than the standard one).

Spot welding cannot be checked visually since it is a closed weld, so it is recommended for use in non-critical connections.

Argon arc welding provides high quality and stability of the weld, which is easy to check visually.

Under critical loads, the SS20 stabilizer strut may be deformed (crushed, twisted, bent), but rupture and integrity will not occur. The car will not lose lateral stability, which significantly increases safety, especially at high speeds. Equipment options

With silent blocks made of black rubber (Shore hardness 65-70 units), with high dynamic endurance to repeated deformations and loads, with good resistance to air and ozone exposure.

With silent blocks made of imported polyurethane in yellow (Shore hardness - 65-70 units) and red (Shore hardness - 80 units) colors with high resistance to abrasion and abrasive, gasoline, oils and saline solutions, destruction under high dynamic loads and deformations, exposure to ultraviolet and ozone (very slow aging). Environmentally friendly material - does not have harmful chemical emissions. Maintains elasticity at low temperatures down to -40°C.

Silent blocks can be replaced as they wear out. Marking

Modifications SS40101 Stabilizer link with rubber bushings VAZ 2108, VAZ 2109, VAZ 21099, VAZ 2113, VAZ 2114, VAZ 2115, 2108-2906050, 21080-2906050-00 2-year warranty 2 pieces included

SS40102 Stabilizer link with rubber bushings VAZ 2110, VAZ 2111, VAZ 2112, 2110-2906050, 21100-2906050-00 2 year warranty Includes 2 pieces

SS40103 Stabilizer link with rubber bushings VAZ 2170, VAZ 2171, VAZ 2172, VAZ 1117, VAZ 1118, VAZ 1119, 1118-2906050, 11180-2906050-00 2 year warranty 2 pieces included

SS40104 Stabilizer link with polyurethane bushings VAZ 2170, VAZ 2171, VAZ 2172, VAZ 1117, VAZ 1118, VAZ 1119, 1118-2906050, 11180-2906050-00 2-year warranty 2 pieces included

SS40105 Stabilizer link with polyurethane bushings VAZ 2108, VAZ 2109, VAZ 21099, VAZ 2113, VAZ 2114, VAZ 2115, 2108-2906050, 21080-2906050-00 2-year warranty 2 pieces included

SS40106 Stabilizer link with polyurethane bushings VAZ 2110, VAZ 2111, VAZ 2112, 2110-2906050, 21100-2906050-00 2 year warranty 2 pieces included

SS40111 Stabilizer link with rubber bushings VAZ 2190, 2190-2906050, 21900-2906050-00 Warranty 2 years Includes 2 pieces

SS40112 Stabilizer link with polyurethane bushings VAZ 2190, 2190-2906050, 21900-2906050-00 Warranty 2 years Includes 2 pieces

SS40113 Stabilizer link with rubber bushings VAZ 2191 Lux, VAZ 2192, VAZ 2194, Datsun mi-DO, Datsun on-DO, 21928-2906050, 21928-2906050-00 2 year warranty Includes 2 pieces

SS40114 Stabilizer link with polyurethane bushings VAZ 2191 Lux, VAZ 2192, VAZ 2194, Datsun mi-DO, Datsun on-DO, 21928-2906050, 21928-2906050-00 2-year warranty Includes 2 pieces

Signs of a faulty VAZ 2110 suspension

- Minor vibrations, beating in the steering wheel while driving;

- Moving by car is accompanied by creaking;

- Body tilt to one side;

- Insufficient vehicle stability at speeds above 90 km/h;

- Knocking, impacts in the front axle area;

- Reduced acceleration dynamics, increased fuel consumption.

Sequence of actions when carrying out diagnostics

Diagnostics is essential before starting work on replacing parts. A visual inspection will help identify the source of the breakdown, assess the general condition of the vehicle, and correctly calculate spare parts and consumables.

- We drive the car into the inspection hole, ensure priority safety measures, squeeze the handbrake, install wheel chocks;

- Jack up the side, unscrew the bolts, remove the wheel;

- We use a metal pry bar to facilitate the diagnostic process. We press at the junctions of metal structures. If the rod is in good condition, there should be no squeaks or knocking. Otherwise, this will indicate defects and wear of elements.

We summarize the data obtained based on the diagnostic results and make a decision on the need to replace spare parts.

At the same time, we check the technical condition of silent blocks and the brake system. If there are signs of wear or deformation, we replace the elements with new ones.

Replacing stabilizer struts on a VAZ 2110

Service center technicians recommend replacing suspension elements in pairs. It is highly undesirable to leave worn parts in their original places without attention, since repair work will soon be repeated.

- We install the car on the inspection hole, install the shoes to avoid any arbitrary rollback, squeeze the hand brake;

- Jack up the side, unscrew the bolts, remove the wheel;

- Using a “17” wrench, we unscrew the rack mount from under the hole, use a metal spacer to knock out the bolt, and knock down the rack;

- Lubricate the bolt with graphite grease, having previously cleaned it of rust and deposits;

- We carry out troubleshooting of adjacent mechanisms, parts, levers. If there is no damage, install a new rack, fix it with a bolt, and tighten the nut.

By analogy, we carry out work on the opposite side.

Replacing suspension arm silent blocks

Sometimes the knocking noise is caused by a worn out silent block of the lever. To replace it with a new one, perform the following steps:

- Jack up the side and remove the front wheel;

- Unscrew the ball joint fixing nut, the key is set to “14”. We knock out the finger from the seat;

- The fastening of one silent block is located vertically, the other horizontally. Unscrew the nuts one by one, head to “19”;

- We remove the lever from under the car;

- We fix it in a vice, press out the rubber bushings one by one;

- We inspect the seat and, if there are no defects, press in new bushings. We reassemble the structure.

After installation is complete, we visit a service station to check the wheel alignment angle. Despite the fact that the tie rod ends have not moved, the wheel angle may not be set correctly initially.

What is Bendix for?

This part is part of the starter.

Bendix wears out due to the significant loads it experiences when starting the car engine.

To change it, you need to completely remove the starter from the car. The starter rotates the crankshaft, which creates pressure in the combustion chamber . If the starter power is insufficient, the engine will not start. Therefore, periodically it is necessary to replace the starter with a new one or repair it. Before the event, you should read the safety instructions for working on a car.

Maintenance of rear suspension on VAZ 2110

The rear suspension circuit consists of:

- Shock absorbers;

- Springs;

- Cross beam;

- Pressed silent blocks;

- Stabilizer struts.

The process of replacing elements of the stabilization system is similar to the front ones. After jacking up the rear of the car, remove the wheel, unscrew the upper mount of the stabilizer bar, key to “17”.

- To unscrew the lower mounting nut, slightly pry the suspension arm with a metal pry bar. We clean the lugs, carry out troubleshooting, inspect the levers for integrity and absence of deformation.

- We install new rods and screw the structure.

- The source of the knock is also a sagging spring. To eliminate the defect, dismantle the rear shock absorber assembly. We remove the spring, support bearing, support bowl.

- We install a new spring, troubleshoot the shock absorber, and check the tightness of the cylinder. We reassemble the structure and check the proper operation of the rear shock absorber strut. We replace the rubber bushings of the shock absorber eye.

Do-it-yourself repair of VAZ 2110 suspension elements is completed.

Purpose and principle of operation of the stabilizer

The stabilizer is a U-shaped rod made of spring steel. The stabilizer connects the left and right sides of the car in the transverse direction. It works like a torsion bar, that is, the centrifugal force is counteracted by the twisting force. The VAZ 2110 and almost all modern cars have a front stabilizer in their design.

Let's consider the principle of operation of the stabilizer. When the car rolls, the stabilizer unscrews. One end of the stabilizer goes up, the other goes down. As a result, one wheel is unloaded, and the second, on the contrary, receives additional load. When rolling, the stabilizer tries to level the car.

The effectiveness of the stabilizer directly depends on the rigidity. Hardness depends:

- on the material from which the stabilizer is made;

- on the shape of the stabilizer;

- on the method and geometry of attaching the stabilizer to the body.

The stabilizer bar is attached in the middle to the body of the VAZ 2110 car using two brackets. The stabilizer is isolated from the brackets by rubber gaskets - stabilizer bushings. On the left and right sides, the stabilizer is attached to the lower arm through the stabilizer links. The VAZ 2110 is not equipped with a rear stabilizer. But some car enthusiasts install it.

Recommendations for servicing the VAZ 2110 suspension

- Strictly follow the recommendations of the operating manual regarding the timing of technical inspection. For VAZ 2110 it is 15,000 km.

- The average service life of the suspension does not exceed 50 – 60 thousand km. Mandatory maintenance every 15,000 km.

- Buy consumables mainly from certified points of sale and dealerships;

- When purchasing, always ask for quality certificates.

- Check that the catalog numbers correspond to the data in the operating instructions.

- If you do not have personal skills in servicing technical equipment, use the services of certified service stations, where they provide a quality guarantee for the work performed.

A moderate driving style and professional installation of parts will increase the service life of vehicle mechanisms by 7–10%.

Many motorists ask: which racks are better - obviously those whose catalog numbers are indicated in the instruction manual.

Replacing the anti-roll bar for a VAZ 2114

Replacing stabilizer struts for a VAZ 2114 - subtleties and features

The VAZ 2114 model is one of the most popular on the Russian automobile market. The machine has a relatively low cost, as well as optimal operational capabilities. It is thanks to the price-quality ratio that the car is in great demand among our car enthusiasts. Like any other car, the VAZ 2114 eventually needs to replace struts. If the driver is doing this for the first time, we will tell you what replacing stabilizer struts on a VAZ 2114 is and how to do it.

Why do you need to change

Important: before making a replacement, the driver must clearly understand why to change the struts, how this may affect the movement, so that in the future the car owner can identify the malfunction at the initial stage. Racks need to be changed for several reasons

Since the anti-roll bar is one of the most important parts of the vehicle's suspension, it must be directly connected to it. Since the stabilizer and suspension are in parallel planes, a perpendicular part is needed that will allow them to interact with each other. This is exactly the part that the stabilizer strut acts as.

Racks need to be changed for several reasons. Since the anti-roll bar is one of the most important parts of the vehicle's suspension, it must be directly connected to it. Since the stabilizer and suspension are in parallel planes, a perpendicular part is needed that will allow them to interact with each other. The stabilizer strut is just such a part.

Car suspension

When driving a VAZ 2114, the car can skid when turning. At this moment, a roll is created and the anti-roll bar signals the suspension to overcome this roll by raising and lowering the car in the right places. The fact is that this process goes through the racks, which is why they wear out. In fact, this is quite convenient, since a separate part is subject to wear, and not the stabilizer, suspension and other participating elements, which suffer much less from roll.

Anti-roll bar