Print this article Font size 16

The design of any internal combustion engine, including VAZ 2109 engines with 8 valves, requires the following components:

- The combustion chamber;

- Valve mechanism;

- Cast lines;

- Exhaust manifolds;

- Intake manifolds.

If you bore and correct the current state of the manifold and cylinder head channels, you can increase the cylinder filling ratio, which leads to increased efficiency and engine power. It is not uncommon for modifications to be performed as the final stage in increasing the volume of the internal combustion engine.

Object of improvement

Undeniable economic benefit

At the same time, the cost of boring makes it much more profitable than purchasing a new similar block. There is no great need to expand the cylinders only for the owner of a Soviet car made in the 1980s and 1990s, any spare parts for which can be found almost free of charge.

Which motors can be sharpened and which cannot?

As you know, the cylinder block can be made of cast iron or aluminum. The first option, despite some disadvantages, which include high mass and low heat dissipation, has good strength and is ideal for turning. An aluminum block, on the contrary, is much lighter and more efficient at removing heat.

However, the walls of its cylinders are coated with a special wear-resistant compound, which is why it is not recommended to grind them. This procedure will simply remove the coating from the walls, causing the cylinders to lose their strength and not last long.

What is better - buy a contract motor or have the block bored?

If a car enthusiast has acquired a Mercedes that is far from old, then a new BC will be very, very expensive for him.

The purchase of a contract unit proposed in such cases will not allow achieving significant savings.

- It is unlikely that it makes any sense at all, since it would be much simpler and more far-sighted to pay an additional approximately 150 thousand rubles for a completely new block, and even with “zero” pistons.

- But boring a worn-out imported block will cost significantly less and will not bring those surprises that usually upset seasoned contract blocks or those that have been in accidents.

Channels

Refinement of the cylinder head also involves the need to modify the channels, since they may have a deformed shape, metal under the bushings, etc. The channels are refined using a ball cutter. It’s better when you have not one cutter, but several with different parameters (sizes and shapes). By working with a milling cutter, you can remove any irregularities and also increase the cross-section.

It is extremely important to ensure that the channel bend is as smooth as possible and that the appropriate curvature dimensions are observed. The surface on the intake channels should be slightly rough - this promotes good evaporation of gasoline from its walls. The exhaust channel can be polished to a shine. The cross-section of the channel should not be circular, but slightly elliptical. When enlarging the channels, it is important not to overdo it; you need to know when to stop, since there is a possibility of hitting the cooling channel or oil channel. The cylinder head on classic engines allows you to enlarge and expand the channels, while on 8-valve VAZ engines problems are inevitable.

Before you start directly boring the channels, you should find out where to start this process - from the manifold or GB. If you need to significantly increase the diameter of the valves, then it is better to start from the area where their walls are thinner. This way you will reduce the risk of accidentally opening the channels the next time you combine them. The parts of the bushings that protrude into the channels also need to be modified so that they do not create interference.

As a rule, they need to be either shortened or sharpened. There are situations when the bushings grind off the valve wall. Some car enthusiasts consider this method the best in terms of benefits, although in practice rarely anyone does this, since it significantly reduces the service life of the guides. Correct modification of valves is possible only under two conditions: experience and following the instructions.

Real opportunity to increase power

Effectively boosting a motor requires lengthy engineering calculations and the most accurate implementation of the drawn up project. At the same time, it is important to be aware that not all types of engines allow any kind of pumping.

Noticeable changes in the dynamics of the car will appear even with an expansion of the cylinder diameter by only 2 mm. This will be quite enough to increase the pressure of the gases on the pistons.

Modification of the cylinder head on the VAZ 2109 (8 valves)

The design of any internal combustion engine, including VAZ 2109 engines with 8 valves, requires the following components:

- The combustion chamber;

- Valve mechanism;

- Cast lines;

- Exhaust manifolds;

- Intake manifolds.

If you bore and correct the current state of the manifold and cylinder head channels, you can increase the cylinder filling ratio, which leads to increased efficiency and engine power. It is not uncommon for modifications to be performed as the final stage in increasing the volume of the internal combustion engine.

Object of improvement

Some difficulties of engine tuning

True, in order to ensure this result, it will be necessary to intervene in the arrangement of air and gas lines, and to alter the fuel and exhaust mechanisms.

In the easiest case of tuning, you can simply replace the connecting rods with longer ones and install repair sleeves, pre-bored to the required parameters.

Cutting off part of the guide

The intake and exhaust valve stem sits in the middle of the ports, creating significant resistance on the intake and exhaust.

The situation is aggravated by the presence of a protruding part of the valve guides and the tide flowing around them. In “hard” tuning, all protruding parts are cut off, and the valve stem is ground to a smaller diameter. It is not recommended to reduce the valve stem by less than 10%. It is better to process the protruding end of the guide from the outside to obtain a more streamlined shape, this is more difficult and less effective in terms of filling, but cutting off part of the guide reduces its length and greatly increases wear, especially when using a camshaft with increased valve lift. When the guide protrusion is completely cut off, you can somewhat compensate for its wear by replacing conventional bushings with bronze ones, which have much higher wear resistance than conventional ones. Tuning valve guides

Machined valve guides for less flow resistance.

Complete cutting of the valve guides to ensure even better cylinder filling. To the detriment of the durability of the valve mechanism.

Why bore the cylinder block?

Tuning is often done when the need for a thorough restoration of the cylinders is discovered. Most often, a pleasant increase in traction is combined with useful repairs if the BC diagnostics reveal:

- Severe distortion of the original configuration;

- Deviations in the diameter value;

- Critical accumulation of defects, including burrs and scratches.

Erasing the cylinder with piston rings

A typical reason for distortion of the factory geometry at a certain stage of the run is the friction of the rings on the glass. Under the influence of the pistons, it acquires an oval or conical shape.

This defect cannot be detected with your own eyes, but high-precision instrumental measurements can reveal it.

Pros and cons of boring

Among the advantages are the following:

- Power increase

- Increased service life

- Reduced oil consumption

- Increase compression

- Improving the dynamics of the unit

The disadvantages include:

- Reduced engine efficiency

- Reducing the size of the cylinder walls, which causes the engine to heat up faster

- Violation of the factory characteristics of the power unit, which may negatively affect the passage of maintenance

Indirect signs of the appearance of an ellipse

In a number of cases, the fact that the cylinder is no longer round can be guessed by the following deviations from the standard parameters:

- Reduced compression;

- Excessive consumption of engine oil;

- Oil clogging of spark plugs;

- Exhausts acquire a bluish tint.

16-valve engine for the "seven"

The VAZ 2107 is equipped with an 8-valve power unit from the factory. Of course, one of the easiest tuning methods is to replace it with a 16-valve engine. Traditionally, the engine from the VAZ 2112 is chosen, since it is almost identical in size to the engine from the VAZ 2107 and meets all the requirements for power and efficiency.

Installation of a 16-valve engine on a “seven” is carried out according to the following algorithm:

- Prepare the motor for installation. To do this, you need to remove the flywheel and grind the crown from the inside. Turning is necessary so that the starter parts are more easily connected to the flywheel clutch. In addition to turning, you will need to replace the input shaft bearing with a bearing from 2112, otherwise the new engine simply will not fit into the seat.

Video: installation procedure

A 16-valve engine instead of an 8-valve is the best option for those drivers who want to feel quick feedback from their actions while driving, optimize engine power and the resource of the entire car as a whole.

Thus, any type of tuning of the VAZ 2107 engine can turn the car into a faster and more durable model. However, when performing any type of work, you must adhere to regulations and safety precautions; otherwise, it is better to contact experienced specialists.

Source

Ways to eliminate deformations and defects

To correct this situation, use BC boring and installation of repair caliber rings on the pistons. These measures allow us to solve the problem of significant expansion of the glass. In some cases, the block is first bored to the required diameter, and then replacement sleeves are installed into it.

- Due to the fact that the piston constantly moves in the cylinder, the smooth surface of the glass becomes covered over time with a wide range of various types of flaws. As a rule, they look like burrs and scratches.

- Similar damage is also typical for pistons and their components. To correct such deformations, the glass is not only bored, but also honed, that is, polished using abrasive substances.

Combustion chamber shape

Refinement of the cylinder head also involves changing the shape of the combustion chamber. In this case, three areas of work can be distinguished:

- Reduced detonation

- Improvement for cylinder filling

- Fulfillment of conditions for optimal distribution of the mixture in the combustion chamber.

Detonation places severe stress on the pistons and rings. It can be determined by the level of metallic sounds that spread throughout the car engine. The sources of this phenomenon can be the most remote areas of the combustion chamber from the spark plug. This can be solved this way: · It is necessary to reduce to a minimum the work in the combustion chamber, which increases the spread of combustion. · It is necessary to minimize the number of CS sections. These areas include camera corners and sharp edges. To do this, you need to smooth the surface as thoroughly as possible.

The last two steps to improve the shape of the combustion chamber are very difficult to do on your own, since you need to have excellent knowledge of physics.

Refinement of the cylinder head is quite simple at some stages and is a completely justifiable procedure. Proper modification will increase the power of your car's engine.

Finding a well-equipped workshop

It is better to entrust the boring of the cylinder block not to a simple person who likes to tinker with cars in the garage, or even not to a local famous Kulibin, but to a professional specializing in this field of car service. True, you will have to look hard for such a master.

Even after finding him, you should definitely ask what kind of equipment he intends to use.

It must not only be in good condition, but also new, meeting the current standards of processing accuracy, speed of the process, automation of cutter control and cooling.

How is cylinder head porting carried out?

Before porting the cylinder head, you need to check that you have several components:

- Inlet/outlet type channels;

- Guide bushings;

- Valves;

- Springs/plates for bushings;

- Combustion chambers.

Next we follow the instructions:

- Take the cylinder head and remove all the valves present on it.

- Inspect the channels, remember the places where defects are present.

- Remove the guides.

- Use the helper pins to install the intake manifold.

- Using bolts, screw the auxiliary studs into the separate channels intended for the cooling mixture. Small holes can be made in the studs to maintain normal heating.

- We combine the manifold with the cylinder head.

- File down the intake manifold.

- When work on the collector comes to completion, you will have to combine the channels. Docking can be done using plasticine.

- Use a chisel to remove any rough spots on the exhaust type valves.

- Subject the remaining channels to a thorough polish to remove all surface defects.

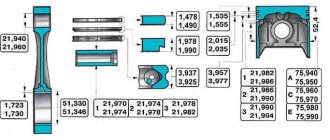

The result of all the above-described manipulations will be that the cylinder head will have more advanced characteristics:

- The diameter of the intake channels is 32 millimeters;

- The diameter of the exhaust channels is 29 millimeters;

- The diameter of the valve stems is 8 millimeters;

- Camshafts cylinder head, sports - standard - 13.5 millimeters;

- The guide type bushings are longer than standard.

Thus, by modifying the cylinder head, it is possible to maximize the potential of a car engine.

>

Types of honing machines

For service work of this kind, three types of machines are produced:

- Vertical boring, which are the most widely used;

- Jig boring machines, which allow you to set a particularly precise position of the cutter and accurately track the work process. Machines of this type are quite expensive and therefore can only be found in large car repair shops;

- Horizontal boring machines, which are modified milling machines. Such equipment is almost never used today, as it operates with large errors.

Enlarged inlet and outlet channels

Increasing the diameter of the inlet and outlet channels reduces the resistance to the movement of gases, but the speed of their movement also decreases. Which is good for high-speed engines and bad for a motor without calculating its operation at high speeds. Increasing the diameter of the channels is ineffective without increasing the diameter of the valves. In this regard, it is necessary to either bore and repress the seats for large valves, or bore existing seats by a small amount in order to increase the diameter in the valve area, and not just the channels themselves.

Careful control measurements

Before starting work, the boring mill mechanic measures the parameters of the glass with his hands or on a special stand. This moment is the most critical in the entire boring procedure and therefore must be carried out with special care.

If the master correctly fixes the cylinder block on the frame, then the measurements will be made flawlessly.

If inaccuracies are made, the principle of alignment will be violated, a right angle will not be ensured during measurement, and the subsequent tuning will lead to accelerated wear of the car engine.

Instructions for tuning the cylinder head

The most effective method of increasing the power of a piston engine is considered to be cylinder head tuning.

First of all, you need to understand how, by modifying the cylinder head, you can influence the engine power parameter. The torque and power characteristics that are determined by engine operation are based on the NCDC coefficient. Therefore, with increasing filling, the power characteristics of the engine system improve.

To perform cylinder head tuning with your own hands, you will need the following set of tools:

- A ball cutter that will fully match the diameter of the boring itself;

- Sandpaper;

- Construction drill;

- Special rollers;

- Calipers;

- Small diameter working hose.

By shifting the shelf of the rotational element to the highest return channels, you can obtain a normal increase in power, which will be proportional to the increase in full speed. The rotating element operates on the basis of 2 basic factors - the volume of work, as well as the cylinder filling factor. If the volume of labor has already been increased to the maximum level, then you will have to deal with the peculiarities of filling. Here you will have to use sports camshafts, which have increased valve lifts, as well as expanded entry and exit stages.

The next stage of cylinder head tuning is the joining of the main manifolds. First of all, it is necessary to eliminate the “ladders” that form various turbulences in the channel opening, which ultimately causes incorrect connections and inhibition of the main flow. In the process of removing defects, it is also necessary to modify the gaskets activated by the manifold. Before removing areas of inconsistency, it is recommended to dock the manifold and pins. This needs to be done because the manifold mount on many engines can cause a certain displacement of the cylinder head and planes. Two pins will need to be placed on both edges of the manifold. Next, we find an area where you can drill a hole and insert a pin. The collector is placed on it, and the work takes on a finished form.

Then ball cutters come into play. They process the channels. It is necessary to ensure that the channel bend acquires the smoothest shape. The surface must have some roughness, because this has a positive effect on how quickly gasoline evaporates from the surface of the channel walls. Elements of guide bushings must also be tuned to reduce the frequency of interference they create. Bushings are usually ground down to reduce service life on forced-type motors. For seats and valves, weight is reduced and flow capacity is increased. For normal operation of the combustion compartment, the filling of the main cylinder is improved and the possibility of detonation is prevented.

Boring, polishing, honing

Then the master himself or in the process of negotiations with the client decides what kind of repair actions should be carried out. The most important task of a car mechanic at this stage is to accurately adhere to the dimensions of the bore.

It itself does not take much time, especially if it is carried out automatically under the full control of a computer.

Next, grinding to a mirror smoothness or honing is carried out. Given that there will not be even the slightest deviation from the ideal cylinder on the mirror surface of the cup, practice shows that standard honing creates the prerequisites for more successful grinding of piston rings to cups.

Valves

Refinement of valves consists of reducing weight and increasing throughput. To make the valve lighter, it needs to be reground or reground. In this case, excess metal will be removed from both sides. The valve stem is also subject to modification - it needs to be narrowed. You can also choose the option without replacing the bushings; in this case, you need to make the leg thinner along the entire area from the guide bushing to the plate. Particular results can be achieved by reducing the diameter of the stem. For example, reducing the stem from eight mm to seven helps reduce the mass of the rod itself by 20% and increases throughput (this is in 8-valve engines).

In reality, the valves are made from an alloy of titanium and aluminum and therefore have amazing lightness, which is combined with some unpleasant aspects: high cost and fragility. Given this fragility, strict recommendations are made for springs and valve seats. The springs may remain factory or may be slightly weakened. It is advisable to change the saddles to others made of bronze.