Hi all! Today we will talk to you about such elements as anti-squeak plates of brake pads. From this material you can find out what they are, what they are needed for, and whether you should buy them or make them yourself for your own car.

When braking occurs important and quite accurate. The elements of the braking system come into contact, creating a large friction force, which helps slow down the vehicle.

There are several reasons why car brakes squeak, and the reason does not always lie in some serious malfunction.

Again, there is no point in dwelling on the reasons for the creaking. It’s better to talk about these plates.

Description and purpose

Anti-creaking plates are also called balancing plates. Their main role is to redistribute the force from the brake piston over the entire surface of the pad. If dust or dirt gets in and there are no such plates, a slight misalignment of the pad may occur. This almost always causes an unpleasant sound from the brakes. That is why the plates are called anti-squeak plates.

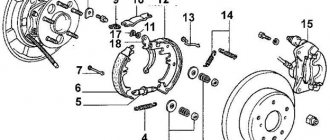

Externally, they consist of two parts and are made of thin metal (tin). The plates follow the contours of the brake pad, and they are located on its non-working side, closer to the piston. The part that comes into direct contact with the brake piston looks like a solid plate. The other one, which is adjacent to the block, is corrugated. This is just necessary to be able to evenly distribute the force in the presence of contamination.

Main function

They are also called “balancing” (absorbing vibrations). Their main purpose is to remove distortions, as well as to evenly transmit braking force from the caliper piston over the entire surface of the brake element.

After all, dust and dirt (sometimes moisture) often gets on the caliper guides, this contributes to the misalignment of the pad (even if not significant). This is one of the reasons for squeaking, and it is these linings that fight this disease.

However, if the piston and guides are clean, the brake pad and disc itself may resonate during braking. To change their frequency and prevent sound from passing further, these plates are used, often using a special lubricant.

Design Features

The appearance of anti-squeak plates is often misleading. Subtle and frivolous, they are often not taken into account and not installed. This attitude is also facilitated by the fact that non-original sets do not include records. And if the car owner has a car with pads that have already been replaced once with non-original ones, then even more so.

In fact, the pads may not creak without such plates. This is due to the good operating conditions of the car and timely maintenance. That is, with proper technical care, when all brake mechanisms are regularly carefully rebuilt and lubricated.

Anti-squeak plates for rear brake pads are originally available only on cars with rear disc brakes.

Which passenger trailer is better to choose: review of popular brands

As for the plates themselves, they are presented in the form of a thin piece of metal. The shape exactly follows the contours of the pad on a specific car. Basically, tin or stainless steel is used as raw material for the manufacture of such components. Installation is carried out from the reverse side, that is, not where the friction coating is located. It turns out that the sheet of metal rests on the piston or counter part. Many companies, as well as manufacturers of automotive brake system components, initially install such auxiliary plates on vehicles.

Or they come as additional components. Thus, the car owner can decide whether he needs to install them or not.

Some companies offer 2-3 plates at once, and also add high-quality lubricant to complete the set.

Squeak or anti-squeak plates?

Brake pad replacement kits for disc brakes sometimes contain so-called squealers. They should not be confused. The anti-squeak plates of the brake pads follow the shape of the lining, and the squeak is a small, intricately curved tin. It is usually installed perpendicular to the long axis of the block by riveting or snapping.

The purpose of such a plate is completely different - on the contrary, it creaks when the pad is close to abrasion, hence its name. Essentially, this is a cheap version of a brake pad wear sensor. It is made of soft metal and does not tolerate distortion and deformation of brake discs.

“Squeaks” are much more common in brake replacement kits. They are also produced by companies that supply non-original products.

Why does the creak appear?

All elements of the brake system wear unevenly. Everyone knows that pads, as a rule, wear out faster on one edge; brake discs also tend to wear out in fragments. In some cases, the caliper pistons become sour and they press the pad unevenly against the disc.

In any of these cases, a small gap appears between the disc and the pad. But this is not the main reason. The fact is that when moving, the wheel deviates slightly from the axis. Moreover, this happens with a certain frequency, as soon as there is a loose fit between the pad and the disc, a resonance occurs, which leads to the appearance of sound. To remove sound, resonance must be eliminated.

Plate Lubricant

The original brake pad replacement kit always contains a small bag of lubricant. Often they simply lubricate the guides. It turns out that this special lubricant is for the anti-squeak plates to work. After all, without this, they will simply behave like a couple of tins and cause terrible noise. It is thanks to the lubricant that is applied to the corrugated plate that the remarkable effect of uniform, silent pressing of the pad occurs.

What to do if there is no lubricant, how to lubricate the anti-squeak plates of the brake pads? This can happen when replacing a non-original set when the records remain unworn. Lubricant for adjusting plates has special properties. Firstly, it must be high-temperature, since when the brakes are used intensively, one disc can heat up over 500°C. Secondly, the synthetic base and the lack of impact on rubber products - guide anthers - are important. Among well-known companies producing lubricants, Liqui Moly is widely known.

The main thing is not to use lithium and graphite lubricants, which are not suitable for temperature and burn out quickly. In addition, they cause deformation of the rubber boots. Copper grease is also not suitable. When it burns out, it also leads to corrosion.

Determining the wear of the pads

If you hear a squealing sound when braking, something in the brakes probably needs replacing, usually the pads. Discs are expected to wear at half the rate of pads, so discs usually need to be replaced every other time the pads are replaced. A caliper is the best solution for measuring wear on both components. After removing the wheel, you can check how many pads and discs can still be worn.

Another alarming symptom is vibration when braking. Here, however, you need to make allowances for the fact that the suspension geometry could also be “worn out” - but it’s worth checking the brakes first, because their condition can be assessed faster, easier and at no additional cost.

After installing new pads, it is important to handle them very carefully for the first 100-200 km to allow them to adapt to the discs. Immediately pinching them under heavy braking can cause warping, cracking, caking and destruction of the discs. In theory, the pads and discs fit together perfectly. In practice, discs have microscopic curves and irregularities, just like pads. This cannot be seen with the naked eye and cannot be measured without the use of specialized, very precise instruments.

Dirt on the rims is a visible phenomenon indicating excessive pad wear. When driving, dust from the lugs accumulates on the wheel rims - this is normal. But when there is too much of it, a problem arises. Either the pads are too worn and wear out quickly, or their quality is poor, or the driver drives too roughly. In any case, their condition is worth checking.

The pads can be broken. This is rare, but possible. If a person presses the brake pedal all the way down while driving very fast, or keeps their foot on the brake pedal the whole time when going down a hill, they can damage the pads. If the friction is very strong and the temperature exceeds the limit value, the surface of the pads may be baked. A special glass-like layer is then created to prevent braking as it slides over the disc. Then both the pads and discs are usually replaced.

Or maybe with your own hands?

It happens that it is not possible to order an original set of brake pads. At the same time, the original plates also became unusable due to creaking. In this case, there are only three options to get out of the situation:

- Leave everything as is and do not drive the car so that the brake discs do not wear out.

- Change the set without plates and just carefully monitor the condition of the brakes.

- Be smart and make anti-squeak brake pad plates with your own hands.

What might this require? Yes, just a sheet of tin of the same thickness. Having attached the old anti-squeak plate to it, we carefully trace its outline with a pencil. Then, using metal scissors, we cut out the plate as accurately as possible. After this, combining the old and new part and pressing them together using clamps or a vice, we bring it with a file until it matches completely.

Both anti-squeak plates are made in a similar way. The corrugated inner plate will require more time and patience, but it will also give in to perseverance and work. All that remains is to choose the right lubricant - that’s all. Now the skew of the pad or its central deformation in the place where the piston presses is not dangerous.

Materials used

Speaking of lubrication. It is highly recommended to purchase not only the plates themselves, but also the appropriate lubricant.

Typically, refractory compounds that can withstand elevated temperatures are used. When the lubricant hardens, its consistency resembles a layer of rubber, which protects against extraneous vibrations and sounds.

How hard is it to find anti-squeak plates?

How rare are kits that include anti-squeak brake pads? Where do questions about making plates with your own hands come from? In fact, there is no hype. The plates are always included in the original brake pad replacement kits for disc brakes. Almost all Japanese foreign cars are equipped with such kits. At the same time, the price of the sets in the original packaging is significantly higher than any analogue. Separately, anti-squeak plates are sometimes more difficult to find.

Again, as for Japanese cars, the original catalogs have all the information. There it is easy to find separately the number of the part being described. Anti-squeak plates for Toyota brake pads, for example, are sold and ordered separately.

Among companies producing non-original products, TRW stands out well. This company's range of pad sets includes complete copies of the originals, which necessarily contain anti-squeak plates.

Purchase

Now you can find ready-made versions of such plates on sale, and the manufacturers of this part may be different. For example, Honda offers both universal plates that are suitable for any model, and original ones that are suitable for a specific modification. Some other brands have repairs. sets of records that are designed for several models that are created on the same base.

If you find plates in a store, be sure to check what cars they are intended for. It is better to buy cars created for your model, but you can also purchase universal options. Always use these parts on all wheels at once.

Pay attention to the material from which this part is made; it is best to buy stainless steel plates, they will last much longer. You should not buy Chinese parts; these spare parts are often of very low quality, which will lead to the need to quickly replace them. As a rule, you won’t find such components in regular stores, so the best way is to order anti-squeak plates online.

Nissan anti-squeak plates

Japanese cars are a high-tech product. Anti-squeak plates have long been installed on many cars of Japanese origin. In order not to be unfounded, consider as an example the Nissan Teana, produced in 2006.

By entering all the necessary data, which is the Vin number or body number for a right-hand drive car, we get full access to the car’s spare parts.

Having followed the “brake system” branch, we find the front pads without much difficulty. There is also a catalog number for the pads themselves - AY040NS106, which by entering it into any online store, we will get the price and delivery time for spare parts, as well as the price and delivery time for non-originals.

Anti-squeak plates for Nissan Teana brake pads also have their own separate catalog number - 41080AU025. This kit includes all plates for replacing pads: two anti-squeak plates and one squeak plate for each wheel.

What are they made of?

Let's see what anti-squeak plates are made of. When choosing a material, you look at several things. First of all, they must be durable, because the pressure from the caliper is quite high. Also, these elements should not have any problems with corrosion, because water and reagents constantly get on the wheels, so the risk of rust is quite high. As a result, not all materials are suitable for this purpose.

The best options for creating these plates are stainless steel and galvanized steel. But the last option is much worse. Galvanized steel is just not that strong. She also has a problem with peeling off the protective layer. Therefore, stainless steel is the best option. In some cases, non-ferrous metals, such as bronze, are used. But, it has a number of disadvantages. In particular, it is less dense, which negatively affects the efficiency of the part. In addition, bronze is a fairly expensive material, and it is not always rational to use it for consumable components.

User reviews

Anti-squeak brake pads are still a very controversial issue on automotive forums. Among the arguments for and against, the main criteria remain observations after the installation of plates and without them. So, some forum users notice the lack of changes. That is, the pads creaked and continue to creak. And opponents argue that in this case there are installation inaccuracies and defects not related to the plates.

Some Internet users note the possibility of using non-original brake pads without anti-squeak plates. At the same time, no noise occurs during operation. Based on the above, only the manufacturer can recommend something, and you will have to resolve the installation issue yourself.

Is it worth using

The main task of the metal elements in question is to eliminate the unpleasant sound that occurs when braking.

The plates have virtually no effect on the effectiveness of the braking itself.

Therefore, we draw a logical conclusion. If the car brakes quietly and without squeaks, there is no point in installing such plates. Although it is important to understand that it can arise over time.

Practice shows that owners of a wide variety of cars install anti-squeaks. It could be: