Adjusting the engine idle speed

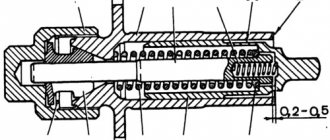

Adjustment is provided by adjusting screw 2 (Fig. 9-14) for the quality (composition) of the mixture and adjusting screw 1 for the quantity of the mixture. Adjusting screw 2 is closed by plug 4. To access the screw, you need to remove the plug with a corkscrew.

Rice. 9-14. Carburetor idle speed adjustment screws 21073-1107010:

1 — adjusting screw for the amount of mixture; 2 — adjusting screw for the quality (composition) of the mixture; 3 - sealing ring; 4—adjusting screw plug.

Idle speed adjustment must be performed on a warm engine (coolant temperature 90-95°C), with adjusted clearances in the gas distribution mechanism, with the ignition timing correctly set and with the air damper fully open.

Using adjusting screw 1 for the amount of mixture, set the engine crankshaft rotation speed in the range of 750-800 rpm using the stand tachometer.

Using adjusting screw 2 for the quality (composition) of the mixture, achieve a carbon monoxide (CO) content in the exhaust gases of no more than 3% at a given position of screw 1 (CO content is reduced to 20 ° C and 101.3 kPa (760 mm Hg).

Using screw 1, restore the crankshaft speed to 750-800 min -1.

If necessary, use adjusting screw 2 to restore the CO content to no more than 3%.

After completing the adjustment, sharply press the throttle pedal and release it; the engine should increase the crankshaft speed without interruption, and if it decreases, it should not stall. If the engine stops, use screw 1 to increase the crankshaft speed within 750-800 min -1.

Install a new plastic plug 4 into the hole for the mixture quality adjusting screw 2.

Adjusting the starting device of the Niva 2121-2131 carburetor

Carburetor repair, stages of assembly and disassembly of VAZ 2121 carburetor parts, instructions for repairing and replacing the valve. Operation and maintenance of the fuel injection, ignition, exhaust system Niva 2121. Injection and carburetor engine. Niva 2131 power supply system device.

When turning the Niva 2131 air damper control lever counterclockwise all the way, the air damper should close completely. If it does not close, eliminate the cause of the jam (or straighten the deformed valve). With the air damper completely closed, the VAZ 2131 throttle valve of the first chamber should be slightly open to a starting gap C equal to 1.1 mm. We measure the gap with a wire of suitable diameter.

Inserting a thin slotted screwdriver into the slot, unscrew (to increase the gap) or tighten (to decrease the gap) the screw, and then tighten the locknut. |

Engine 21213 (1.7l 79hp)

ENGINE VAZ 21213-1000260.

How to adjust the Solex carburetor

CHARACTERISTICS OF THE VAZ 21213 ENGINE.

The engine is carburetor, the camshaft is located on top.

Cylinder displacement:

Power at a crankshaft speed of 5200 rpm:

Minimum crankshaft rotation speed rpm:

Maximum torque at 3400 rpm:

Cylinder operating order:

Octane number of gasoline:

Fuel supply system:

Engine Features.

The VAZ-21213 engine is installed on Niva-2121, 21213, 21214, 2131 (long Niva) cars; VAZ -2120 Nadezhda

Designed specifically for Niva-21213.

Engine cylinder block 21213-1002011 with a center-to-center distance of 95 mm and a height of 214.58-0.1 mm (distance from the axis of rotation of the crankshaft to the upper surface of the block). The cylinder diameter is 82mm. (repair sizes of cylinders - 82.4 and 82.8) Cylinders come in five classes A, B, C, D. The size of each class differs from the previous one by 0.01 mm. The cylinder block markings are located on the bottom surface.

Crankshaft 21213-1005015 corresponds to the crankshaft of the VAZ-2103. The shaft has additional counterweights that reduce vibration. There are two oil supply holes on each connecting rod journal. The diameters of the shaft journals are increased by 0.02 mm. When using standard bearings, this reduction in clearances optimizes the thickness of the oil layer between the shaft journal and the bearing surface. Crankshaft 21213 is recommended for installation instead of shaft 2103.

New piston group. Piston 21213 has a special oval hole on the bottom. Hole for piston pin D=22mm. The hole in the piston for the pin is offset by 1.2 mm from the piston axis. Piston pin length 67mm Piston weight - 347g. Connecting rod 21213-1004045. Connecting rod length 136 mm. Hole sizes: for the crankpin - 47.8mm; under the piston pin – 22mm.

Cylinder head 21213-1002011 (1.7 l.) Cylinder head height 21213 - 111.0 mm (1.8 mm lower than head 21011) Combustion chamber size - 81x52 mm, volume 30 cm3.

- Camshaft 21213-1006010. The shape of the cams has been changed to increase the intake valve stroke.

- Valves and valve mechanism from the VAZ-2101 engine.

- Timing chain 2103. Extended tensioner shoe.

- Carburetor 21073 SOLEX.

- BSZ ignition system (non-contact ignition system): Ignition distributor (distributor) 3810.3706 (21213-3706010) or equivalent 2107.3706.010-21. Switch - 3620.3734 SOATE or 133.3774-01 (2108) Ignition coil - 27.3705 (2108)

Source

Why did it happen so?

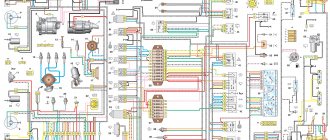

Wiring diagram for VAZ 21213 Niva carburetor with description

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

Which carburetor is better to put on the Niva

21213

The Russian auto industry, after more than fifty years, continues to firmly maintain its leading position in the car markets. The VAZ family has a completely reasonable price and is quite easy to maintain.

Great demand has appeared for the Russian jeep VAZ-21213, as well as its analogues. This type of VAZ car has achieved tremendous success in world motorsport, setting unattainable records. Working with vag-com, operating the Varta battery, taxi companies of the USSR, photos, how to sheathe a profile on the roof, what tires to put on a field in winter, Daewoo Winstorm Max, front hubs of a Chevrolet Niva. A similar model of car is very intensively exported to European countries and beyond.

Car enthusiasts who do not have much experience in servicing this type of car quite often encounter various problems associated with the operation and repair of the Niva. One of these common problems is carburetor repair and replacement.

Many drivers do not know which model is better

choose how they differ from each other and how to manage when choosing one or the other.

See:

Often the carburetors on different Niva models are very identical and are designed identically. They are located in the propulsion system and make the required combustible mixture from the fuel, combining the fuel with air, and feeding it into the engine. The carburetors are also designed identically. The main elements include:

- Float chamber (jet).

- Diffuser.

- Throttle valve.

Depending on the car model, the carburetor can have from one to 4 chambers; the dampers can open one by one or at once; the movement of the flammable consistency can be horizontal, downward or upward.

For less experienced car enthusiasts, you can use a carburetor diagram, on which all the parts will be indicated and their position and functions described. With its help, it will be much easier to find and change this or that part.

The Niva 21213 model replaced its previous version, the VAZ-2121, and became more advanced and improved. The updated model now includes:

- 1.7-liter engine, the founder of which was the engine from the Russian “six”;

- five-speed gearbox;

Solex carburetor- contactless ignition with microcontroller.

In order to always be confident in your car, you need to thoroughly know its entire “inner”, understand its features, and understand its details. Further in the article we will look at the structure of the Niva 21213 carburetor in order to have an idea about this part and know the intricacies of its operation.

Features of servicing DAAZ-21073 devices

Electrical diagram of VAZ 2121 Niva carburetor

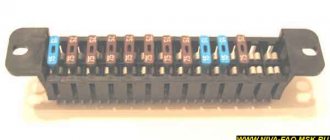

All possible disruptions in the operation of the device directly depend on the quality and frequency of service. Despite the design differences between the VAZ DAAZ-21073 and the DAAZ-4178 carburetor on the UAZ, their maintenance is not much different. The technically required work includes:

- external cleaning;

- washing the float chamber strainer;

- cleaning the float chamber;

- cleaning jets;

- adjustment of the float device;

- adjustment of the starting device;

- stabilization of the XX system.

Washing the external and internal parts of the carburetor unit is carried out using kerosene, white spirit or preparations in aerosol cans. The aerosol composition is injected into the chambers and jets while the engine is running. The cleaned apparatus is blown with compressed air.

Carburetor Features

When modernizing the Niva in 1994, it was decided to install a Solex carburetor on it. Before this, a unit called Ozone was used. Which one is better? This question interests many owners.

Ozone is equipped with an old style breaker. In addition, it does not have a vacuum corrector. Solex does not have a microswitch for the economizer. This negatively affects the purity of the exhaust, and also partly on fuel consumption. Both carburetors have both their advantages and disadvantages. However, VAZ engineers opt for Solex, as a more modern model. In turn, many owners of cars with this carburetor often complain about its incorrect operation. Experts explain that this is caused primarily by the use of low quality fuel. In addition, troubles can arise for those who rarely change the fuel or air filter, and also do not clean the carburetor of oil soot entering through the ventilation system. Some owners of old Niva cars equipped with Ozone decided to install Solex instead. And they don’t regret it.

Adjusting the carburetor VAZ 21213

This procedure may be necessary when jerks or dips appear during movement. In addition, adjustment is needed if the car has an unstable idle. It is advisable to know what fuel consumption accompanies these symptoms. If you have no desire to go to a car repair shop, you can adjust the carburetor of the VAZ 21213 and eliminate the causes of incorrect operation with your own hands. This is not much more difficult than adjusting the carburetor of a VAZ 2101.

First you need to remove the air filter. But before this, the engine must run for at least a few minutes. You can now disconnect the fuel supply hose. To remove the carburetor cover you will need to unscrew five bolts. After removing the lid, place it on a flat surface. Now we take a caliper and measure the distance from the edge of the body of the float chambers to the level of the fuel in them. Normally it should be 25.5 mm. In cases of non-compliance with the standard, the tongue of the float bracket should be bent. To achieve a positive result, this will most likely have to be done more than once. After each bending, we check the distance to the fuel and adjust our actions. Having achieved success, we put everything back together.

Now you need to adjust the engine idle speed. To do this, fully tighten the mixture quality screw. Then unscrew it 4 turns. We start the engine, turn on the high beam lamps and the fan. The choke handle must be recessed. Using the screw that regulates the amount of mixture, we bring the number of revolutions to 800 per minute. After this, we use the quality screw to achieve maximum speed. Now use the quantity screw to reduce the speed to 900 per minute. We go again to the quality screw, and with it we reduce the speed to 800. We turn the quality screw until the engine operation becomes unstable. As soon as this happens, unscrew the quality screw 1 turn. And finally, use the quantity screw to achieve the required speed level. Which one is needed? For summer from 800 to 900, for winter from 900 to 1000 rpm.

"Solex" and "Ozone"

The VAZ 2121 Niva model can be equipped with an “Ozone” carburetor with the serial designation 2107-110-7010-10 or 2107-110-7010-20. They differ from each other in that the first option has an old-style breaker and does not have a vacuum corrector. The second carburetor does not have a microswitch from the economizer, which affects the environmental friendliness of emissions and has some impact on fuel consumption.

This is the car part

The Niva 21213 is equipped with Solex type carburetors (model 21073-110-7010). They are considered quite “capricious”, which is primarily due to the negligence of the owners themselves. The incorrect operation of the device is primarily affected by low-quality fuel with a large amount of impurities, since in this model the fuel is taken through holes in the bottom of the float chambers (in other models these elements are raised above the bottom).

In addition, problems arise for those “nivovods” who do not promptly change the fuel or air filter, and also do not pay attention to proper cleaning of the carburetor from oil soot emissions through the ventilation system. Adjustment of the VAZ carburetor is usually carried out in the float mechanism or in the starting and idle systems

These are very important operations that are best left to the experts.

Adjustment of the VAZ carburetor is usually carried out in the float mechanism or in the starting and idle systems. These are very important operations that are best left to the experts.

The float mechanism on the Niva 2121 is adjusted in terms of the position of the floats relative to each other and relative to the walls of the float chamber. In addition, the mechanisms in the open and closed positions of the needle valve may need to be adjusted. In order not to disturb good adjustment, the car owner needs to carefully handle the carburetor cover when removing it, monitor the level of wear of the shut-off cone from the needle (its seat and tongue), as well as the axis of the mounting bracket.

Do-it-yourself VAZ 2121 carburetor repair

Repair of the carburetor unit on the Niva may be required in different cases. If a car enthusiast has practical skills in servicing his “four-wheeled friend,” then performing repair work independently will not be difficult for him. However, it should be noted that the design of carburetor mechanisms is highly complex, so high-quality work without preparation is unlikely.

Signs and causes of malfunctions of Ozone carburetors

External manifestations of the operation of the engine unit and the driver’s own sensations, as a rule, may indicate the occurrence of any malfunctions in the operation of the carburetor. The most common signs of malfunctions on Ozone are:

unstable operation of the power unit at idle;

the car loses its dynamics;

after reaching a speed of 90 km/h, engine productivity drops sharply;

difficulty starting;

increase in fuel consumption.

Thus, if Ozone shows one or more of these signs of malfunction, this means that repair work is necessary.

The engine receives too much gasoline - the carburetor is flooded / the needle is stuck

If a car owner notices that the carburetor is constantly being filled with excess gasoline, we can conclude that the needle valve is faulty. Over time, it can lose its throughput, which is why at first there are difficulties in starting the engine, fuel drips appear on the carburetor, and then it will be impossible to start the engine at all.

The way out of the situation is to replace the needle valve yourself. To do this you will need:

Remove the cap from the carburetor.

Align the float along its original axis.

Disconnect the needle valve.

Screw a new valve into the vacant space.

Screw the lid into place.

The car cannot maintain idle speed and immediately stalls

In this case, the economizer will need to be replaced. Most likely, the reason lies in this component, since it ensures the supply of fuel to the engine at idle. In rare cases, the idle speed control unit on Niva carburetors may fail.

To determine the cause of the malfunction, it is recommended to disassemble the carburetor and inspect the economizer and idle devices. Their condition will be visually noticeable (adhesion of a large amount of soot and dirt, deformation). If devices fail, the procedure for replacing them is as simple as possible: a new one is installed in place of the old component.

How to adjust Ozone

Self-adjustment of the Ozone carburetor on a VAZ 2121 car allows you to achieve stable operation of the power unit and reduce gasoline consumption.

Typically, adjustment work includes adjusting the starting unit, the idle speed unit and the fuel level in the float chamber tank. To quickly carry out the work, it is recommended to immediately prepare the following set of tools:

multimeter (or tachometer);

flat narrow screwdriver.

The procedure for performing adjustment work:

It is necessary to warm up the engine to its operating temperature.

With the engine running, you will need to fully open the air damper of the carburetor mechanism - fully press the damper drive handle (that is, the choke).

Connect the tachometer (multimeter) to the engine: the minus wire to the vehicle ground, the plus wire to the ignition coil to terminal K.

After connecting, you need to start the engine again, immediately turn on the lighting and the fan to supply heat.

Use a screwdriver to start adjusting the air-fuel mixture supply screw - you need to turn the screw until the power unit begins to idle smoothly. The optimal tachometer indicator is 750–800 rpm.

If it is not possible to achieve the desired performance by normal adjustment, you will need to remove the carburetor and thoroughly rinse it from dirt deposits. Apparently, the mechanism is so clogged with sediment coming from the fuel that its adjustment is impossible.

Video: do-it-yourself carburetor adjustment on a Niva

By adjusting or repairing the carburetor with your own hands, the car owner can be confident in the high quality of the work. In addition, a visual inspection of the internal components of the unit will allow you to draw a conclusion about its resource and thus calculate the frequency of maintenance or routine cleaning. Ozone carburetors have been an invariable attribute of Niva cars for many years, ensuring reliable engine operation and excellent operating characteristics.

Step-by-step adjustment of the Solex carburetor on the VAZ 21213

Adjusting the Solex carburetor comes down to part of the adjustment processes in the float chamber and adjusting the idle system. This is quite painstaking work that requires certain knowledge. Correctly setting up Solex in the future will allow you to enjoy an economical, hassle-free and comfortable ride in a VAZ 21213 Niva.

All work should begin with establishing the optimal amount of fuel in the chamber:

- Start the engine for a few minutes; while the engine is running, you must also periodically press the gas pedal;

- After running the engine for five minutes, it must be turned off;

- The fuel supply hose is disconnected;

- The screws securing the carburetor cover are unscrewed;

- In a horizontal position, the upper part of the power system mechanism rises;

- A ruler measures the distance from the surface of the carburetor cover to the fuel level.

The level should be within 25 mm in the chambers, but this may vary since the collector is not horizontal, so you should measure the value in the chambers and average it. If the level exceeds the norm, then use the float tongue to remove some of the gasoline and reassemble the mechanism in the reverse order. Then start the engine again and make observations. Gasoline should not leak from small diffusers, otherwise the appearance of fuel will indicate an overflow. There is no need to press the gas during the adjustment!

Adjusting the starting system

You can adjust the Solex starting system both on an installed carburetor and on a dismantled one. In the first case, the adjustment comes down to determining the number of crankshaft revolutions, but with the carburetor removed, it is possible to adjust the starting system due to the gaps at the edge of the dampers. On the engine power system device removed from the vehicle, adjust the gap between the damper and the chamber wall - the gap should be 1.1 mm. Adjustment work is carried out using a wrench or screwdriver.

More experienced and advanced car owners prefer to adjust the Solex by determining and setting the crankshaft speed. This method is faster, but also requires certain specific knowledge. This technique consists of the following:

- Air filters are dismantled;

- The choke is disconnected, the engine starts;

- Using available tools, the air damper is opened by a third;

- The lever sets 3200 rpm of the crankshaft;

- The air damper should be closed, loosen the lock nut, and use the adjusting screw to reduce the rotation speed to 3000 rpm;

- Tighten the locknut.

Using a gas analyzer, you can also configure the starting system. The device measures the amount of carbon monoxide in gases. If the value is 8%, then there is no need to configure the launch system. If the value is below 8%, then the screw on the diaphragm mechanism cover should be tightened, and if the value is higher than normal, the screw should be loosened and the measurement taken again.

Adjusting idle speed

This procedure is necessary to ensure that the power unit operates stably and that the exhaust gases contain as few harmful substances as possible. In the garage, using your own efforts, all the work can be done using a tachometer. The motor is first brought to operating temperature, after which the adjustment itself is carried out directly. Using the mixture quantity screw, the crankshaft rotation speed is set at 850-900 rpm, after which the quality screw is tightened with a screwdriver until the speed is set at around 800 rpm. A similar procedure must be carried out several times until the engine begins to operate stably, and a minimum amount of vacuum in the tube is observed.

Correct tuning of Solex will allow the car owner to enjoy high-quality, and most importantly, trouble-free engine operation. Experts recommend adjusting the idle speed twice a year. Thus, it is possible to achieve significant fuel savings and the emission of a minimum amount of harmful substances into the atmosphere, plus, a properly adjusted mechanism of the engine power system will significantly save personal funds on the services of service stations.

- https://expertvaz.ru/niva/karbyurator-21213.html

- https://prokarbyrator.ru/zamena-karbyuratora/karbyurator-soleks-21073-na-nivu.html

- https://avtooverview.ru/remont/regulirovka-karbyuratora-soleks-na-vaz-21213-niva/

We carry out the adjustment ourselves

Niva 21213 can be subject to adjustment of the starting system by the gap at the edges of the valves, if the carburetor is removed, or by the crankshaft speed directly on the car. In the first case, the gap at the location of the lower edge (in the direction of air movement) from the throttle valve is set to a width of 1.1 mm. It is adjusted with a screw that has a 0.7 cm hexagon on the head and a slot from the shank. This operation is carried out with the cam lever turned counterclockwise from the starting system control (all the way). In the same position, the gap at the lower edge of the air damper is set to 3 mm using a screw in the cover from the diaphragm mechanism in the starting system (you need to loosen the lock nut). At the same time, the rod from the diaphragm must be forcibly recessed completely into the adjusting screw. After adjustment, the screw is fixed with a locknut.

The principle of powering a carburetor engine

Adjusting the Niva starting system directly in the car saves time:

- You need to remove the air filter from the engine, pull the control lever away from the air damper, and start the engine.

- When the air damper is forcibly opened (by touching a flat screwdriver to a third of its full angle of rotation) using a screw (next to the lever on the axis from the throttle valve from the first chamber), the initial rotation speed is set to 2.08.mar.0 thousand rpm (on a warm engine).

- Remove the screwdriver, lower the air damper and, using the screw stop (next to the diaphragm), set the frequency to be 100 rpm lower than the original one (you need to select the appropriate position of the air damper).

- The screw can then be secured using a locknut.

If you have a gas analyzer, then the carburetor adjustment in the starting system part can be done based on the amount of CO (carbon monoxide) in the exhaust gases. If, with the choke control lever fully extended, the gas rate is 8%, then everything is in order. If there is less gas than this value, then the screw on the cover of the diaphragm mechanism is tightened; if there is more, it is unscrewed and repeated measurements are taken.

It is necessary to adjust the idle speed of the Niva 2121 so that there is less carbon monoxide in the exhaust gases and so that the engine runs stably. At service stations, such work is carried out with gas analyzers on the MV. In the garage, adjustments can be made using the tachometer.

For these purposes, on a warm engine, a plastic plug is pierced with a screwdriver, then the quality screw is rotated in different directions until the maximum idle speed is reached. Then, using the quantity screw (has a ribbed plastic handle), you need to set an increased speed (50-70 rpm more than at standard idle speed). Operations with screws must be repeated two more times. Then, on models 2121 or 21213, at idle speed, at speeds increased by 50-70 rpm, the quality screw is tightened, and the speed should drop to normal (i.e., decrease by 50-70 revolutions).

Lada Niva 4x4

How to decide on a carburetor for Lada Niva 4x4?

Niva-2121, also known as VAZ-2121, is a popular small-class SUV with continuous all-wheel drive and a monocoque body. It is noteworthy that even the very first configuration of this car had the same markings on the engine - VAZ-2121. The car was also equipped with a DAAZ 2107-20 carburetor device, otherwise called “7-20”. If this unit fails, you will now have to choose a carburetor for the Niva from those that are produced today.

Main characteristics of the carburetor VAZ 2121, 21213

The carburetor got its name directly from the functions it performs - carburetion and mixing. In this unit, gasoline is mixed with air. The supply of the mixture that will end up in the engine cylinders is also regulated.

The carburetion process is also influenced by the design of the unit itself. The “native” carburetor for Lada Niva 4x4 includes:

- Float chamber (the volume of fuel contained in it affects the functioning of the optimal idle mode and a number of other systems);

- Jet (this element is responsible for dosing the volume of air-fuel mixture entering the VAZ 2121, 21213 carburetor);

- Diffusers (are narrowings of the carburetor pipes of both chambers, their function is to accelerate the air passing through the mixing chambers);

- The throttle valve (“manages” the cross-section of the channel, changing the volume of fuel or gas that passes through this channel).

Fuel is supplied through the carburetor VAZ 2121, 21213 of the old model as follows:

In the required volume, fuel flows from the tank directly into the float chamber. Filling with this liquid, the chamber goes down. When the fuel starts to move, it moves up. After passing through this chamber, the fuel ends up in the nozzle. From there it goes to the atomizer, which is located in the narrow passage of the diffuser. In the carburetor, air enters through the outer pipe. The required volume of fuel, passing through the intake manifold and throttle bodies, ends up in the engine.

When the carburetor on a Niva 2121 fails, craftsmen usually replace it with one of the options produced today.

Which carburetor for Lada Niva 4x4 should you install?

Experienced auto mechanics say that it is optimal to install one of two types of carburetors on the Niva: Ozone or Solex. In principle, these models are largely identical to each other, but there are certain differences. In particular, Solex does not need an economizer to function, and Ozone does not have a vacuum corrector.

These devices are important to a certain extent, and their absence may have some impact on the functioning of the machine. Thus, the vacuum corrector rotates the table located in the tumbler to change the ignition timing. And the economizer, in essence, is a mechanism for heat exchange that preheats the water supplied to the steam boiler.

Theoretically, you can choose any of these carburetors for the Lada Niva 4x4, but the vast majority of experts believe that Solex is less picky than Ozone. And this is influenced by the difference in the design of the devices themselves.

Carburetor adjustment screws 21073 Solex

The carburetor 21073 Solex of the Niva 21213 with a 1.7 liter engine has five adjusting screws. With their help, the operation of most of its systems is configured.

Fuel mixture quantity screw

Screwed into the casting with a threaded hole in the middle part of the carburetor body. Its tip touches the edge of the throttle control lever of the first chamber. Designed to increase the volume of the fuel mixture entering the engine cylinders at idle. When turning, it moves the control lever with its tip, slightly opening the throttle valve of the first chamber - the XX speed increases. When turning it out, the idle speed drops. The tip of the “quantity” screw also acts as a negative contact in the EPH system. It signals the start of opening the throttle valve to the EPHH control unit. This signal stops the fuel supply to the XX system.

Fuel mixture quality screw

The “quality” screw is located in the lower part of the carburetor body and, with its cone, blocks the outlet of the fuel mixture from the idle system.

It is designed to control the exact dosage of the fuel mixture entering the engine cylinders through the idle system by changing the cross-section of this hole. Simply put, the “quality” screw introduces additional gasoline into the fuel mixture at idle, thereby enriching it.

Adjustment features: the initial position of the “quantity” and “quality” screws is 1 – 1.5 turns from the fully tightened state.

Necessary for installing the throttle valves of both chambers of the carburetor in the desired position for starting and normal operation of the engine.

Throttle position adjustment screw for the second carburetor chamber

Located on the ebb of the lower part of the carburetor body. Secured with a spring clip. A protective cap is placed on top of it. The throttle control lever of the second chamber of the carburetor rests on the screw head.

The screw is designed to adjust the gap between the walls of the carburetor mixing chamber and the edges of the throttle valve (0.1±0.05 mm) in order to prevent fuel accumulation when the accelerator pump is operating. The required position of the screw is set at the factory and does not change.

How to remove a carburetor from a Niva

To do the job you will need a simple set of tools. Typically, every car enthusiast has all these auxiliary devices:

- head at 8;

- head at 10;

- extension;

- combination key 13;

- flat screwdriver.

The mechanism is located as conveniently as possible for any work

When starting to remove the carburetor from the Niva, you need to make sure that the engine has already cooled down, otherwise you can get burned on overheated metal parts. The withdrawal procedure is as follows:

- Remove the air filter box. It will interfere with access to the motor, so it is recommended to immediately unscrew the three nuts securing the box with a screwdriver.

- Next, you will need to use a 8-mm head to disconnect the four bolts that secure the air filter box to the surface of the carburetor.

- After this, the box is moved to the side, and all hoses and lines going to it are disconnected from the carburetor

- The choke cable is disconnected (the clamp is unscrewed with a screwdriver).

- Using a thin blade of a screwdriver, you need to pry the throttle control rod to unhook it from the latch.

- The next step is to dismantle the carburetor itself. The four nuts that secure it to the manifold are unscrewed. After which the knot itself is pulled out from the pins.

It is recommended to place the carburetor on a flat, clean surface.

Cleaning procedure for removing carbon deposits and dirt

Removing the carburetor involves cleaning its components or replacing it in case of severe wear of the rubbing elements. However, most often it is removed in order to rinse and clean it inside and out from carbon deposits and adhering dirt:

- jets require a special approach to maintenance, as they have a fragile structure. To clean them, it is recommended to use toothpicks or thin copper wire. You cannot use any chemical cleaners, as liquid may remain in the nozzle holes and then get into the carburetor. After cleaning manually, it is allowed to blow out the nozzle with a can of compressed air;

- The float chamber is cleaned of carbon deposits with a special cleaner. The use of solvents of the 645–652 series is also allowed. The washing liquid must be poured into the chamber, stirred several times over two hours and drained. After which the internal cavity of the float chamber should be thoroughly dried with a soft, lint-free cloth;

- All throttle valve elements are cleaned of carbon deposits with a standard cleaner or kerosene. The damper, along with other metal parts of the carburetor, can be placed in a container with kerosene and kept there for two hours. After the accumulations of soot and dirt have dissolved, it is recommended to blow out the damper and wipe it dry.

Photo gallery: jets, float chamber and throttle valve

Gasket replacement procedure

The carburetor mechanism is in contact with the intake manifold. The absence of vibration, excess noise, and rapid wear of elements is ensured by the gasket located between this mechanism and the collector.

The gasket has a specific shape, thanks to which the carburetor and manifold successfully “get along” with each other. Replacing the gasket is necessary if additional vibration and extraneous noise are felt while driving. In addition, usually when removing the carburetor for washing, the gasket is also changed so that you do not have to later remove the entire device just to replace it.

The replacement procedure is quite simple: it includes all the steps that were described above (see p. How to remove a carburetor from a Niva). However, immediately after removing and removing the old gasket, a new product is put on the studs. Next you will need to install the carburetor in the reverse order.

The first gasket is new, the second is after a year of use, the third is with the maximum permissible degree of wear.

What is a carburetor

If we compare the carburetor Niva and the injection one, we can conclude that the first is more archaic and old. The carburetor is the main component in this system. That is, it is this mechanism that, during operation, mixes air with a portion of gasoline, thereby creating a flammable mixture. The system itself is a simple device. But, despite this, many car owners are not entirely happy with this engine, since quite often it let them down.

A carburetor engine contains: a float, jets, and needles. It is worth noting that all these mechanisms require regular cleaning and regulation.