The most powerful electrical consumer is the VAZ 2114 starter on the car. The load on the rotor is very large - the electromotive force has to overcome the resistance caused by compression in the engine. And if the starter is in poor technical condition, there is a short circuit in it, the current consumption increases. And the maximum is approximately 600-800 A (when the rotor is jammed).

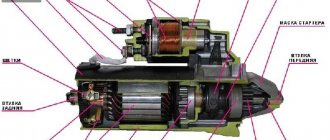

Starter device

- A housing with a winding and four magnets is a stator.

- The rotating part is the rotor.

- The transmitter from the moving part to the engine flywheel is Bendix.

- The operating switch that starts the rotor when the ignition key is turned is a relay.

- An axis with a pressed core and collector plates is an anchor.

Starter device

The device is a DC motor with a two-winding relay and a power of 1.55 kW.

Main malfunctions and their symptoms

The most common breakdowns that occur in the starter are as follows:

- The electric motor of the device does not rotate. A short circuit has occurred on the stator windings, the rotor has become soured in the support bushings, or the contacts have oxidized;

- The electric motor spins, but at insufficient speed and low power. Either the graphite brushes are worn out or a short circuit has occurred on one of the windings;

- The starter works as it should, but rotation is not transmitted to the crankshaft. Bendix wear or breakdown;

- The starter starts the engine, but does not turn itself off. The retractor relay mechanism has oxidized or the return spring has burst.

Disassembled starter

If you notice one of the above signs on the starter, you should dismantle it and carry out detailed diagnostics in the removed state.

Causes of malfunctions

- Does not turn: short circuit of the winding, jamming of the armature on the solenoid relay, oxidation of the battery contacts.

- Insufficient rotation speed of the bendix: break or short circuit of the armature (stator) winding, wear of the brushes.

- It turns, but does not transmit speed to the flywheel: the bendix is faulty.

- Operation after the engine speed has increased: the traction relay is stuck, the freewheel spring is broken.

Also, the causes of malfunction include wear of the unit, increased loads, violation of operating conditions and defects. Most often, the bendix, armature commutator and solenoid relay fail. Sometimes there is a loose fit of the brushes.

If one of the brushes has failed or the gearbox shaft has become skewed, this is usually a sign of impending destruction of the entire assembly, and it is easier to replace it entirely than to repair it.

In cold weather, the engine does not start well, the starter works at the limit and may fail. If the device is poorly secured or operates in conditions of constant strong vibrations, this also leads to its destruction. Sometimes a factory defect of the unit occurs - incorrect distribution of the lubricant composition in the housing, which leads to failure of the solenoid relay.

You can clean the shaft and add lubricant. The device is installed at an angle with the bendix down, white spirit is drawn into the syringe, and, turning the bendix as it extends, the white spirit is squeezed out onto the exposed section of the shaft, wiping it with a rag. Lubricant is added to the wedge-shaped teeth along which the bendix slides out.

For complete cleaning, the assembly is disassembled and washed in gasoline. Then they put new lubricant in the places from which the old one was removed, and assemble the device.

If the starter does not turn the flywheel, clean the terminals and start the car again.

Sometimes the problem with frequent bendix failure lies in the flywheel bushing. It is necessary to check the condition of the bushing and, if it is unsatisfactory, replace it with a new one.

Gear starter VAZ 2114

DESIGN FEATURES AND OPERATING PRINCIPLE

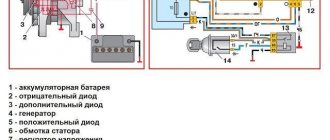

The starter on the VAZ 2114 (5712.3708) has an operation cycle, which can be divided into four main stages:

- After turning the ignition key, the fourteenth battery in the contact chain begins to supply power to the starter and traction relay;

- The Bendix gear drive (overrunning clutch) is connected to the flywheel;

- At the moment the gear drive is connected, power begins to be supplied to the electric motor of the unit;

- The electric motor begins to spin the drive, the revolutions of which are transmitted to the crankshaft of the car, as a result of which the engine starts. When the engine speed begins to exceed the starter speed, the drive and the crankshaft are disconnected.

Now let's look at the design features of the fourteenth starter. In the diagram below you can see the main elements of the device.

Starter device

- Housing - made in the form of a cast steel cylinder at the ends, closed with lids, inside which the cores and the exciting winding (stator) are located;

- Solenoid relay - consists of a movable jumper and power contacts. The purpose of the solenoid relay is to close the contacts when the ignition is turned on, as a result of which power begins to be supplied to the electric motor. Upon completion of the operating cycle, the solenoid relay disconnects the power and the device turns off;

- Bendix of the VAZ 2114 starter (aka overrunning clutch) - at the beginning of the operation of the device, the bendix is connected to the crankshaft and transmits the electric drive speed to it through the engagement gear; at the end of the cycle it is disconnected. The serviceability of the entire device depends on the normal functioning of the bendix, since if disconnection does not occur at the moment when the engine speed exceeds the speed of the electric drive, the unit will be damaged;

- Anchor - is a cast axle made of alloy steel, onto which collector plates and a core are pressed;

- Brushes and brush holders are structural elements that are necessary to supply power to the armature. Properly functioning brushes increase the power of the device's electric drive;

- The starter bushing - there are three in total: the rear and front - are pressed into the body, the third is located at the junction of the armature and the bendix. The bushings are responsible for fixing the drive shaft.

The cost of a new device varies between 3.5-5 thousand rubles, depending on the manufacturer. Owners of fourteen speak positively about devices manufactured by Eldix, KATEK and PRAMO. If you buy Bendix separately, it will cost you 300-500 rubles.

Choosing a new starter

According to statistics, when answering the question “Which starter is better for a VAZ 2114?”, most car enthusiasts are advised to choose a geared version. It is smaller in size than the standard one, provides a quick start even with a weak battery, and spins the flywheel better in winter. It is easier and faster to install. The engine of such a device weighs less and experiences less mechanical stress.

Of the gearbox options, KZATE (KATEK) has the most positive reviews. Eldix and PRAMO brands are also popular.

The disadvantage of geared devices is that there may be problems with waterproofing, which cause short circuits and anchor breakages.

Starter KZATE

There are machines with the device fastened not with three, but with two bolts. In this case, a starter from ten is suitable, but you need to replace its Bendix with a gearbox from nine.

Causes and effects - why won't the car start?

The reluctance of a car to start is often due to a discharged battery. The problem is especially relevant in the winter, when the outside temperature is below zero. The lack of energy to start can be determined by the sound - if you hear a sharp, unpleasant noise of the starter trying to crank and start the engine, then it’s time to recharge. In this case, it is necessary to partially or fully charge the battery, but if time is pressing, you can “light it” from another car.

It is also worth checking if there is an open circuit in the ignition contact group. Partial disconnection of the contacts occurs when the key is turned in the ignition mechanism of the VAZ 2114, in this case the starter will not even try to turn over. To fix this breakdown, you need to remove the plastic from the steering column and reconnect the ignition contacts. In some cases, it is necessary to tighten these terminals with pliers.

The lack of contact mass on the starter of the VAZ 2114 is also a common problem for this series of cars. Due to the slightly unsuccessful design of the engine frame, the starter is very poorly protected from direct contact with water and therefore rust forms on its contacts. If you encounter this problem, you need to re-clean the contact wire and screw it onto the starter solenoid relay. Before carrying out this procedure, you need to remove the terminals from the battery.

Starter replacement

The work does not require a pit or a lift. When you don’t have time to travel to a car service center, you can replace the device yourself.

Sequencing:

- Open the hood.

- Remove the terminals from the battery.

- Remove the air filter pipe.

- Remove the air filter.

- Find the starter between the radiator and the manual transmission.

- Unscrew the three nuts securing the device. To do this, use a key of 13.

- Remove wiring.

- Moving to the right and removing from the engine guides, remove the device.

- After dismantling, the condition of the flywheel shaft (bushing) is usually checked.

- The mechanism is installed in the reverse order.

Starter Eldix

When installing, apply lubricant to the surface in contact with the flywheel bushing.

Bendix replacement

- The plug at the point of its attachment to the body is bent with a flat screwdriver.

- The ring is removed. You may have to knock it down with a hammer.

- The retaining ring is removed. It is enough to pry it off with a flat screwdriver.

- The part is pulled out from the body.

If there is no visible damage on the bendix, this does not mean that it is working. If indirect signs of malfunction appear, it must be changed.

Starter PRAMO

The new part is installed in the reverse order.

By installing a VAZ 2114 gear starter, car enthusiasts solve most problems with starting the engine and constantly replacing Bendix and other spare parts.

Starter repair procedure:

1. First, you need to remove the starter from the car. Now let's start disassembling the part.

2. You need to unscrew the nut.

3. Disconnect the busbar from the contact bolt of the traction relay.

4. Carefully remove the two bolts that hold the traction relay.

5. The traction relay must be removed from the starter.

6. Set aside the starter itself and remove the armature from the traction relay. To do this, lift it up and the armature loop is released from the lever.

7. Now we return to the starter itself. Unscrew the tie rod nuts.

8. The next step is to remove the cover from the drive side with the gearbox and the same part assembled.

9. The cover must also be removed from the side of the commutator with brushes and brush holders.

10. Then remove the gear from the anchor shaft.

11. Pull the armature itself out of the starter.

12. There is a washer installed on the anchor shaft on the drive side (pay special attention to this).

13. Using a screwdriver or other thin object, remove the anchor shaft support.

14. Then use a small screwdriver to remove the two tie rods from the starter cover. In general, it is not necessary to remove them; if you are in a hurry, you can leave them, but it is more convenient to remove the drive and gearbox without these pins.

15. After this, remove the three gears of the gearbox. A starter breakdown may be due to the fact that these gears have damaged, broken teeth or needle bearings embedded in the gears. If this deficiency is present, then replace the parts and the starter will work again.

16. But, if the gears are in order, then continue to disassemble and check the starter for damage further. You need to remove the gearbox with the drive from the cover by first pressing the starter drive gear.

17. The support with the seal must be removed from the lever.

19. Using a hammer, knock the restrictor ring off the retaining ring using a suitable mandrel.

20. Carefully remove the retaining ring first and then the restrictor ring.

21. Remove the drive assembly from the drive shaft.

22. Unscrew the lock ring of the lever.

23. Then remove the lever with the washer and driver.

24. Use a screwdriver to unscrew the lever spring.

25. Now you can remove the lever from the connection and separate the halves of the lever.

26. Remove the internal gear retaining ring.

27. Next, disassemble the internal gear and remove the drive shaft support from the shaft.

28. Carefully remove the O-ring from the pore. Examine it carefully. A damaged, deformed, hardened ring has a bad effect on the operation of the entire starter. It definitely needs to be replaced.

29. The next step is to remove the liner from the support.

30. On the commutator side, remove the two screws and remove the brush holder.

31. Using a screwdriver, pry up the brush clamps.

32. Then remove these retainers and their retainer springs. Again, replace deformed or damaged parts, heavily compressed or bent, or torn springs.

33. Remove the brushes themselves from the brush holder guides.

34. Non-insulated brushes must be removed.

35. Then remove the cardboard insulation pad. If it is damaged, compressed, torn, replace it with a new one.

Article number and approximate price for the original VAZ 2114 starter

There are two main types of starters used on VAZ 2114 cars. With a carburetor engine, a unit with the factory index 29.3708 is used. Its cost is from 3600 rubles.

On VAZ 2114 cars that have an injector, a starter 5712.3708 is used. It is distinguished by the presence of a planetary gearbox. The presence of a gear in the design made it possible to increase engine speed. Therefore, planetary starters have gained great popularity compared to those previously discussed. At the same time, carburetor VAZ 2114 car owners, when replacing a starter, give preference to units with a planetary gearbox. The price of a new such product starts from 2200 rubles.

In retail sales, original starters are found with article numbers 2108370801006 and 21130370801000. They are interchangeable, but it is recommended to choose a unit with a planetary gear, regardless of the type of vehicle power unit.

What causes the starter to fail?

Understanding the reasons for the failure of a part, we can say that there are not so many of them:

- Manufacturing defects. Due to the design features of the body, the manufacturer had to reduce the size of the mechanism, so it has insufficient power and often fails;

- Operation of the device with unacceptable overloads. If you have to turn the engine for a long time, the element can overheat;

- Violation of operating rules. For example, a car enthusiast has run out of gas, and in order to move the car to the side of the road, he puts the car in gear and turns the starter, which allows him to move the car. The mechanism is not designed for such a load;

- Natural wear and tear of parts.

The mechanism is a defect of the manufacturer and is considered a “sore” of the VAZ 2114 car, as it often fails.

Catalog number and cost of analogues

Finding a branded VAZ 2114 starter is not always easy. At the same time, the quality of the original components is very poor, which is further complemented by a high level of defects among the products sold. Therefore, experienced car owners recommend purchasing analogues from third-party manufacturers. The best alternative options for the original VAZ 2114 starter are presented in the table below.

Table - Good analogues of the original VAZ 2114 starter

| Manufacturer | vendor code | Approximate cost, ruble |

| As-pl | S9008 | 1750-2300 |

| HC Parts | CS332 | 2650-3500 |

| Startvolt | LST0115 | 3400-3800 |

| Bosch | 986014950 | 7300-8900 |

| WPS | 30714N | 2880-3500 |

Required Tools

In order to carry out repairs yourself and replace a faulty starter, you need the tools that are listed in the table below. Table - Tools required to replace the front strut

| Name | Note |

| open-end wrench | "at 8", "at 13" |

| Spanner | "at 13", "at 14", "at 15" |

| Ratchet | With extension |

| Head | "at 13", "at 14", "at 15" |

| Pliers | Can be replaced with pliers |

| Penetrating lubricant | For example, WD-40 |

| Screwdriver | With flat cross blade |

| Wire brush and rags | For cleaning contaminated surfaces |

Useful tips

- Before removing the starter, you need to make sure it is faulty. First of all, you need to check the reliability of the terminals on the battery. Oxidized terminals should be cleaned of deposits and re-secured. The reason for the failure may also be poor weight of the engine and the body. You should also check whether the solenoid relay wire has come loose from the connector and whether the positive terminal nut on the starter is tightly tightened;

- When removing a part, you can disconnect the positive wire of the terminal last. In this version, it is more convenient to unscrew the nut of the positive wire. By pulling the starter closer to you, it will be easier to get to the desired nut;

- You need to install the solenoid relay wire in place until it stops. The connector must be fixed, and in this case the wire will not fly off during movement due to shaking;

- Do not forget to first remove the terminals from the battery and turn off the ignition - this will save you from additional problems.

That’s basically all that can be said about how to change the starter on a VAZ 2114.

Differences between starter and relay failure

In order not to confuse what exactly has failed - the starter or the solenoid relay, there is an excellent method for recognizing the “culprit”.

- Remove the starter, connect the negative terminal of the battery to ground;

- The design of the device has copper bolts and a tongue-shaped element;

- The positive wire from the battery is connected to this “tongue”;

- If there is contact, the solenoid relay clicks and starts working;

- If not, then you will have to go to the store for a new relay.

But there is one more very important point. Even if all the facts indicate that the starter or retractor relay is not working, another unit - the ignition switch - may still be the cause of ignition problems. Take the time to check its serviceability before buying new parts.