The inability of VAZ engineers to make a normal manual gearbox for the second decade now has forced management to look for other possible solutions to this problem.

Partners in the Renault-Nissan alliance came to the rescue with their Renault mechanics. This box is designed to relieve car owners from noise and howling while driving, which was caused by the old VAZ box.

At the moment, the French gearbox is paired with a 1.6 liter 106 hp engine. 21129 depending on the configuration. The possibility of installing it in tandem with a Nissan 110 hp engine cannot be ruled out. But whether the JH3 can withstand the high torque of the 21179 1.8L engine is a questionable question.

Manual transmission JH1, 5 speed

This market veteran is still in demand among renovators. The reason is the simple design and low cost of repairs and spare parts. Structurally, the JH1 is a single housing that combines the drive and driven shafts, differential and main gear; The clutch drive is a simple cable.

The JH1 transmission is considered reliable, although it cannot be called easy to use: gears are not always engaged clearly, and there are jerks and jolts when changing gears. But if you forgive this manual transmission for some laxity and the resulting oil seal leaks, in general, the unit is very worthy. It runs for 200 and 250 thousand kilometers, and if reviews from owners with the resources of the same box and up to 500 thousand km.

Everything, of course, depends on driving style and maintenance. If you regularly change the oil of this “maintenance-free” gearbox every 60 thousand, you can significantly extend its life.

Mechanics Renault Arcana 1.6 l TL8

This is a 6-speed gearbox for the French crossover, which is paired with a 1.6-liter engine and all-wheel drive. Manual transmission6 Renault Arkana TL8 was developed on the basis of the TL4 model and was initially aimed at all-wheel drive vehicles of the Renault-Nissan Alliance.

Design

This is a modern transmission that implements the following principles:

- 2-shaft arrangement;

- Control by 2 flexible cables;

- Synchronizers at all speeds, including reverse;

- Hydraulic clutch drive.

Torque is transmitted to the rear wheels through a driveshaft that is connected through a gearbox. To enable all-wheel drive, a special button is provided in the crossover interior, which closes the electromagnetic clutch.

Oil

As with the previous transmission, oil changes are not provided for by the factory. However, service stations recommend replacing them every 60,000 km.

Resource

As practice shows, the mechanical life of the Renault Arcana 1.6 TL8 is not impressive and is at the 150,000 km mark. However, if you don’t take your crossover off-road and don’t skimp on maintenance, its service life will increase significantly.

Problems

Like the JR5 model, the TL8 manual transmission has no obvious weak points. As for the most common malfunctions, there is an oil leak through the seals, as well as background noise.

In general, the mechanics of Renault Arcana 1.6 - both JR5 and TL8 - perform well. They are quite enough to work in tandem with the 114-horsepower crossover engine.

Options

According to the price lists with prices and configurations, the 5-speed manual Renault Arcana JR5 is combined only with the base 1.6 liter engine and front-wheel drive.

The all-wheel drive version of the 1.6 crossover is equipped with a 6-speed manual transmission TL8.

For the top 1.3 liter turbo, the CVT X-Tronic variator is exclusively designed. Some potential buyers see this as a drawback, believing that a version with a 150-horsepower engine and a stick would also be popular.

Description

The gearbox is new. The gearbox on LADA LARGUS and X-Ray is a 5-speed component of the car, installed in the back of a van with an internal combustion engine. Designed for cars with 16 valve engines. This transmission element integrates and transmits the rotational torque generated by the internal combustion engine to the drive wheels. Its functioning affects the speed and direction of movement of vehicles. Also, the JR5-517 gearbox on a VAZ is a part that provides idle speed.

Specifications

- What cars it is installed on: Renault 8V, VAZ, Lada Largus and their modifications.

- For which engines is it suitable - K4M and K7M, with 16 valves.

- Number of steps – 5.

- The gears are forward and 1 reverse.

- Subordinate numbers (1,2,3,4,5 degrees): 4.928, 3.727, 2.048, 1.321 0.971, 0.738, 3.545.

- Capacity – 2.5 liters.

- Switching the clutch on/off using a working hydraulic cylinder.

- The maximum speed of the 1st stage on an incline and on a straight road is 60-80 km/h.

Design features

VAZ automatic and manual transmissions offered in the catalog of our online store are housings made of rolled aluminum with built-in parts:

- transmission mechanism;

- friction clutch;

- main gear gear.

The gearbox housing houses the primary drive gear assembly and the main gears. Also the secondary shaft with the main gears. For harmonious working interaction of both shafts, synchronization rings are installed on them. In the JR5-517 model, the pressure on the release bearing is transmitted using a hydraulic system, which includes two cylinders - the main and the working one. Speed control is standard - a pair of cables connected to the gear shift lever. Each cable has its own functionality. Let us add that this model has a synchronizer that ensures smooth gear shifting and reduces wear on elements and noise during operation. All speed synchronizers except the fifth one are located on the secondary shaft.

What's the result?

The design of the gearbox installed on the entire Lada Largus model range, regardless of modifications (JR5 or JH3, etc.), is quite modern and reliable. As a rule, these manual transmissions rarely fail.

If malfunctions and breakdowns of the manual transmission occur (gears fly out or do not shift, noise or crackling noise occurs, etc.), then comprehensive diagnostics should be carried out to identify malfunctions.

Repairs should also not be delayed, since the design of the box is complex; one malfunction can lead to another. It is recommended to immediately contact a service station, where experienced specialists will be able to quickly and efficiently eliminate existing problems.

Gearbox for Lada Vesta: types of manual transmission Lada Vesta, robotic gearbox Lada Vesta. Changing the oil in the Lada Vesta box.

Automatic transmission on the domestic GAZelle Next car: features of automatic transmission, advantages and disadvantages of automatic transmission.

Checking the oil in the Lada Granta gearbox: how to check the oil level in the Lada Granta automatic transmission, checking the oil in the Granta manual transmission. Adding oil, recommendations.

Russian cars with automatic transmission: automatic transmissions on models from the USSR, modern Russian cars with automatic transmission. Popular models, types and types of automatic transmissions.

Lada Vesta with an automatic transmission: what type of automatic transmission is on the Lada Vesta, pros and cons. Prospects for the appearance of an automatic transmission or a CVT on Vesta.

Automatic transmission for Renault Duster: Renault Duster automatic transmission and Duster with a robotic gearbox. Features of these types of automatic transmissions for Duster.

Transmission oil Suprotek Atomium - a universal soldier in manual transmission

As discussed above, half of the problems with gearbox noise and hum are associated with low-quality transmission oil or insufficient filling. For vehicles with a manual transmission, it is recommended to use Suprotek Atomium transmission oil on a fully synthetic basis. This allows you to achieve stable operating properties throughout the entire service life. The peculiarity of this transmission oil is that it practically does not break down when heated, does not oxidize, does not burn at all and does not evaporate. In addition, the mineral impurities included in the composition absolutely do not enter into chemical reactions with wear products, fuel or other additives.

Operation and service life of the JR5 gearbox

The manufacturer claims that the transmission oil is filled for its entire service life. However, owners prefer to change it every 60 thousand km. Fortunately, the crankcase has factory drain and fill holes. By the way, unlike the old boxes, you will need 2.3 liters of ELF Tranself NFJ 75W80, that is, about one liter less than before.

The transmission life is estimated at approximately 250,000 km, although in practice you can run at least twice as much without any problems, with gentle operation and proper maintenance, of course.

Inspection and subsequent repair of the synchronizer

Removing the synchronizer involves removing the gearbox itself. This is hard work and quite dirty, so be prepared with gloves and rags. Since you have to remove the unit, it is worth carrying out cleaning work. Here's how to remove the gearbox synchronizer:

- Remove the gearbox;

- Remove the clutch cable bracket (by unscrewing the bolts and removing the cover);

- Unscrew the fork mounting bolt;

- Move the synchronizer clutch down;

- Unscrew the nuts securing the primary and secondary shafts;

- Lift the gear from the transmission, the fork and remove the synchronizer.

Please note that the algorithm may differ slightly depending on which transmission model is installed in your vehicle. Here it is worth turning to the manuals and looking for information on thematic forums. This kind of work is easiest to do in pairs rather than alone. Once the gearbox has been removed and you have been able to remove the synchronizer, it is worth starting to inspect and service it. Here's what to do:

- Mark the position of the coupling with a marker or chalk relative to the hub, then carefully remove the coupling;

- Wash the removed parts in kerosene;

- Inspect the hub, coupling, splines. There should be no burrs or chips on the parts. Also pay attention to each of the crackers and springs;

- Replace defective parts with new ones. Individual synchronizer components are rarely on sale, but they can be found at disassemblers. Every part should be lubricated with engine oil;

- Assemble the synchronizer, taking into account the position of the mark. If everything matches, then the grooves on its coupling will immediately align with the grooves of the hub. It is better to insert crackers with balls using a screwdriver;

- Install the synchronizer and assemble the gearbox.

As you can see, the work is quite complicated - you need to remember the location of each element of the synchronizer, and to be sure, even mark it with chalk or a marker. Be extremely careful. Since restoring a worn synchronizer requires skill and special tools, we do not recommend trying to troubleshoot it yourself. As for the mechanism that is not too worn out, it only needs to replace individual components, clean and apply lubricant. Otherwise, it does not require specific maintenance. Many craftsmen classify this mechanism as conditionally unrepairable, advising immediate replacement if problems arise with the gearbox.

Purpose and device

The gearbox is designed for several tasks:

- torque changes,

- speed changes,

- correcting the direction of movement of the car,

- disconnecting the internal combustion engine and transmission and, on the contrary, connecting them (this need is relevant when changing gears, the need to obtain low “creeping” speeds, and short-term stopping of the vehicle),

- locking the torque converter (the function is valuable for reducing the loss of useful energy of the “automatic” when transmitting torque in a situation where the speed of the driven and driving turbines is equalized).

At the same time, some gearboxes are capable of solving all these problems, while others, such as a mechanical one, only do the basics - changing torque and speed. The design of the device depends on the type of gearbox.

The housing of the gearbox with “mechanics” combines shafts (2, 3 or more), a synchronizer, gears, a gear shift lever, wire rings, bearings, and oil seals.

The automatic transmission device (gearbox with “automatic”) is a unit that includes a torque converter, planetary gear, clutches, brake band, control unit (pump + oil sump + valve box).

Robotic gearboxes can be based on either mechanical solutions with an electric or hydraulic clutch and gear control system, or automatic gearboxes equipped with an electro-hydraulic clutch drive.

Let's look at the clutch, gears, shafts and synchronizers in more detail.

Clutch

Designed to transmit torque from the flywheel of the internal combustion engine crankshaft to the input shaft of the gearbox.

It is thanks to the presence of the clutch that the engine can be carefully disconnected from the transmission for a short period of time, and the transmission can be protected from overloads.

The standard clutch on most manual transmission vehicles includes the flywheel, pressure plate, driven plate, throwout bearing, drive, fork, and clutch switch.

One engine is connected to the wheels, the other to the internal combustion engine. The moment the driver releases the pedal, the discs are pressed against each other and begin to rotate together.

It is the classic clutch as such that is most often talked about when using a manual transmission, and when driving with an internal combustion engine on an automatic transmission they talk about a combined solution of the clutch and torque converter. Its immediate function is similar to that of a clutch. But the driver does not need to perform any routine actions and press the clutch manually. The checkpoint itself will do everything for him.

As for robotic solutions such as DSG (with mechatronics), they have two clutches. The presence of two clutches is valuable for increasing the power of the vehicle, while minimizing slippage and optimizing fuel consumption.

Indeed, physically, at the moment of switching, the engine speed when using two clutches can remain at the same level.

In the picture below you see the “behavior” of the clutch in the DSG robotic gearbox at the moment after switching to second gear.

Gears and shafts

Gears and shafts are the main “controllers” of torque. It is the gears and shafts that help change the gear ratio. Integral elements of all manual transmissions and some automatic transmissions (for example, Honda).

The design of a manual transmission is most often designed so that the shaft axes are in a parallel plane. Gears are mounted on top.

The primary or drive shaft (pedal shaft) is connected to the flywheel through the clutch basket. The lugs help advance the second clutch disc and direct torque to the intermediate shaft through the gear.

The end of the secondary shaft is adjacent to the bearing on the drive shaft. Since there is no fixed connection, the shafts are independent and there is no obstacle to them rotating in different directions. There are no obstacles to varying speeds.

The design of an automatic transmission involves a planetary gearbox instead of gears and shafts. Gears and shafts always rotate as a single unit. But structurally it can be either different parts or a non-separable unit.

Synchronizers

Synchronizers are an integral element of a gearbox with gears - except for solutions with sliding gears. Physically, the work of synchronizers is due to the force of friction.

The function of synchronizers is to equalize the rotation speed of gears and shafts, thereby creating all the conditions for smooth gear shifting. Thanks to synchronizers, the gearbox wears out less and makes less noise.

Synchronizers are actively present in manual transmissions and robotic gearboxes. For cars with planetary automatic transmissions, an alternative to synchronizers is friction control elements. Synchronizers consist of a clutch, locking rings, a retaining ring, a spring, and gears.

How does a standard synchronizer work?

- The clutch is fed towards the gear.

- The clutch locking ring absorbs the force.

- The tooth surfaces begin to interact.

- The locking one acquires the position “on the stop”.

- The teeth of the coupling are opposite the teeth of the locking ring.

- The clutch engages with the ring gear.

- The clutch and gear are blocked.

It would seem that there are quite a lot of steps, but all this happens in a fraction of seconds - at the moment the driver engages the gear.

Operating principle of manual gearboxes

Transmissions with “mechanics” use various combinations of gears during operation.

The operating principle of a manual transmission is based on creating connections between the primary and secondary shafts. Thanks to the use of gears with different numbers of teeth, the transmission adapts to the conditions on the road and the driver's goals.

As the speed of rotation of the output shaft of a manual transmission increases relative to the speed of rotation of the input shaft, the amount of torque from the internal combustion engine to the wheelbase decreases.

When the speed of rotation of the output shaft of the manual transmission decreases in relation to the speed of rotation of the input shaft, the amount of torque from the engine to the drive wheels, on the contrary, increases.

Gearboxes vary in the number of stages. Each stage has its own gear ratio. It represents the ratio of the number of teeth of the driven gear to the number of teeth of the drive gear.

A low gear has the highest gear ratio, and a high gear, on the contrary, has the smallest gear ratio. The lower the gear ratios, the faster the vehicle can accelerate.

When gear ratios and vehicle speed change, the clutch is used to momentarily disengage the transmission.

Depending on the design of the gearbox, it can be two-shaft or three-shaft. Both the device and the operating process of the units are somewhat different.

2-shaft gearbox: device and principle of operation

Twin-shaft solutions are very popular on front-wheel drive cars. The design includes the following elements:

- crankcase – load-bearing element, housing. All other parts of the device are attached to it. It also protects the unit from external influences, and a person from rotating parts, and also serves as a storage facility for oil.

- shafts – primary and secondary,

- gears (in blocks), part is attached to the drive shaft, part to the driven shaft,

- spline (connects PV and clutch),

- synchronizers.

Important!

The main gear and differential are also located inside the crankcase, but the gear shift mechanism is located outside it.

The shift lever is in the neutral position: the gears rotate, the torque from the internal combustion engine is not transmitted to the wheels.

The lever is moved - the synchronizer clutch also changes position. The angular velocities of the corresponding shaft and gear are equalized. Torque is transmitted from the primary shaft to the secondary shaft. Torque is transmitted from the internal combustion engine to the drive wheels with a given gear ratio.

The picture shows the reverse gear separately. For him, the gearbox has a reverse gear. The idler gear is used to correct the direction. It is mounted on a separate axle.

Gearbox JH3, JR5, 21809

Depending on the configuration, the car is equipped with five-speed Renault JH3 and JR5 gearboxes, as well as VAZ-21809 (from 2022), made according to a two-shaft design with synchronizers for all forward gears and combined with a differential and final drive. Transmission fluid is poured into the gearbox at the factory, which is designed for the entire service life of the vehicle. Therefore, there is no need to change the gearbox oil according to maintenance schedules.

Gearbox JH3

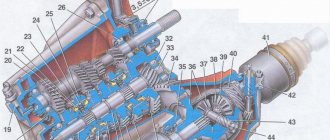

Gearbox JH3: 1 — rear gearbox cover; 2 — clutch cable bracket; 3 — clutch fork; 4 — gearbox housing; 5 — breather fitting; 6 — gear shift mechanism; 7 — cavity for the speed sensor; 8 — shaft of the right side differential gear; 9 — clutch housing; 10 - input shaft; 11 — boot; 12 — holder for electrical wires; 13 — oil filler cap; 14 — housing of the internal hinge of the drive mechanism of the left wheel; 15 - reverse light switch

The car engine, like all internal combustion engines, develops power and torque in a relatively narrow speed range. As engine speed decreases, power decreases

The power transmission allows you to reduce the number of revolutions of the drive axle in relation to the number of revolutions of the engine crankshaft, increasing traction force. The higher the traction force, the lower the speed.

When driving a car, it becomes necessary to use different speeds and different traction forces. For example, when driving through deep sand, the speed is insignificant, and a fairly large traction force is required to overcome the resistance of the road. Great traction force is also required when starting the car and overcoming steep inclines. On the contrary, when driving on a paved road, little traction is required, but the speed of movement can be high.

To increase or decrease the traction force on the drive axle while maintaining a constant torque on the engine shaft, a gearbox is used in the vehicle's power transmission.

Due to the fact that the engines of different car models have different power, then, of course, the gear ratios of individual gears, and, consequently, the number of teeth of the gears are different. However, the operating principle of the gearboxes is the same, and the disassembly, assembly and repair operations are generally similar.

The purpose of the gearbox is to ensure further conversion of torque in magnitude and direction in accordance with the load on the vehicle, as well as to enable the engine to idle.

The basic principle of operation of the gearbox is the same everywhere, the essence of which is the pairwise connection of gears that have a different number of teeth. In this case, the torque transmitted by the gears changes in proportion to the gear ratio, i.e. The ratio of the number of teeth on the driven gear to the number of teeth on the drive gear.

A gearbox is, in principle, a very simple device.

Gearbox control mechanism: 1 – bushing (the gearbox control rod is connected to it); 2 – gearbox lever retainer; 3 – gear shift lever (has a ball bearing that is inserted into the body); 4 – lever handle; 5 – plastic body

Gearbox control rod: 1 – coupling bolt; 2 – clamp; 3 – nut; 4 – traction; 5 – traction finger

The rod is attached at one end to the bushing of the gearbox control mechanism, and at the other end to the shift mechanism installed on the gearbox.

Gearbox JR5

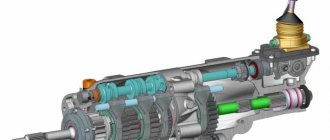

Gearbox JR5: 1 — input shaft; 2 — right wheel drive oil seal; 3 — clutch housing; 4 — gearbox housing; 5 — back cover; 6 — breather fitting; 7 — eye-bracket; 8 — gear lever; 9 — gear selection lever; 10 — speed sensor or plug; 11 — bracket for fastening transmission control cables; 12 — left wheel drive oil seal; 13 — reverse light switch; 14 — oil filler cap; 15 — tube for supplying fluid to the working cylinder of the hydraulic clutch; 16 — clutch release bearing

Gearbox control mechanism: 1 — gear selection cable; 2 — gear shift cable; 3 - control mechanism; 4 — gear shift lever; 5 — gear shift lever cover; 6 — gear shift knob

Gearbox VAZ-21809

Redesigned VAZ gearbox with cable-driven shifting. Installed on Lada Largus instead of the JR5 gearbox from 2022, paired with a 16-valve VAZ-21129 engine. Together with foreign engineers, a number of modifications were made to the box in order to reduce vibration noise, incl. The tooth profile of the gears was changed. Improved clarity and balance of gear shifting.

Tables of gear ratios of the LADA Largus gearbox

Note: gear ratios on cars with AvtoVAZ engines differ from those presented.

Gear ratios of the VAZ-21809 gearbox

| l | 3,636 |

| II | 1,952 |

| III | 1,357 |

| IV | 0,941 |

| V | 0,784 |

| Reverse | 3,500 |

| main gear | 3,944 |

Factory designations and parameters of fifth gear

| Gear ratio | Input shaft gear | Secondary shaft gear | ||

| Number of teeth | Part designation | Number of teeth | Part designation | |

| 0,892 | 37 | 8200611295 | 33 | 8200608035 |

| 0,820 | 39 | 8200611299 | 32 | 8200607980 |

| 0,795 | 39 | 8200611297 | 31 | 8200607978 |

| 0,756 | 41 | 8200611301 | 31 | 8200607981 |

| 0,738 | 42 | 8200611303 | 31 | 8200607983 |

Weight of gearboxes (gearbox weight in kilograms)

JH3 - 33.0 kg JR5 - 34.0 kg 21809 - 31.8 kg

Checkpoint identification

Determining the installed gearbox by configuration and engine (only for Renault engines)

| Body and engine | Station wagon 5 seats with K7M | Station wagon 7 seats with K7M | Station wagon 5 and 7 seats with K4M | Van with K7M and K4M |

| Installed gearbox | JH3 540 | JR5 551 | JR5 549 | JR5 517 |

The ratio of engines and gearboxes is indicated in more detail here

Note: To accurately identify the installed gearbox, see its markings (see below).

Plate 1, Figure 2-1, hammer-stamped onto the gearbox housing, provides information about the gearbox, Figure 2-2.

Figure 2-1 — Location of the identification plate on the gearbox:

1 - identification plate

Figure 2-2 — Location of information fields on the gearbox plate:

1 — gearbox type; 2 — gearbox index; 3—manufacturer; 4 - serial number

Markings on gearboxes are located below, on the crankcase.

The gearbox code is located on a sticker located on the rear, black gearbox cover (on the left in the direction of travel). Although it is difficult to see it by car, you can:

Differences in CP designation

| Production AVTOVAZ Marking of assemblies JH3 and JR5 of the AVTOVAZ assembly with the letter “P” | External supply Marking of units JH3 and JR5 external supply (e.g. “A”) |

Video