Not all car owners are familiar with the cabin filtration mode, its beneficial properties, and application features. Let's look at what air recirculation in a car is and how to use it. In fact, recirculation is the intake of air from inside the cabin, filtration through the air conditioning system and subsequent distribution through the deflectors.

The main difference between recirculation and conventional intake is that the air flow comes from the cabin, and not from the outside. The recirculation mode allows you to quickly heat and cool the air, since the temperature in the cabin differs from the temperature outside the car. The climate control system consumes less time, power, and fuel consumption by the engine.

In practice, few people use this function. Most often, recirculation is used to prevent unpleasant odors from penetrating into the interior. For example: the car ahead is smoking heavily, there is a lot of smoke, there is a dusty section of the road. In order not to feel these odors, they activate the mechanical air recirculation button and block access from the outside.

Mechanism of operation

When the recirculation button is in the pressed (on) position, the electro-pneumatic valve opens, then a flap in the area of the intake pipe extends and blocks the access of outside air to the vehicle interior.

The circulation system starts only when the engine is running and functions due to the coordinated operation of the valve-flap complex. Circulation in the car will continue as long as the fan is turned on, in which case the air flow passes through the heater ducts.

To determine the presence of this device in the car, first of all, there must be chips and a button in the cabin. When the ignition and recirculation button are turned on, there should be voltage on the chips.

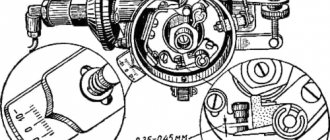

Air conditioning system diagram

Then, it is worth checking whether the damper control valve and the electro-pneumatic valve are present. If this system is absent, you can block exhaust gases and smoke using a fan, but the damper isolates the car from the outside air much more effectively.

To regulate the level of humidity in the car and solve the problem of glass fogging, it is recommended to have an air conditioner in the VAZ model 2110.

Ventilation system with recirculation mode

This mechanism works according to this scheme through a separate passage in the atmospheric air masses of the cabin. Which then enter the hood structure, partly outside the car and partly into the mixing chamber. The existing air is mixed with the new inputs, flows into the air conditioner, and then returns to the living room.

To ensure optimal indoor air quality, follow these guidelines:

Read also: Android set-top box for TV

- The amount of air from the atmosphere must correspond to at least 10% of the power of the supply system;

- The volume of harmful impurities in incoming air masses should not exceed 30% of their concentration corresponding to the standards.

Maintenance

Don't forget to regularly maintain your car by changing the cabin air filter. You should definitely change this cabin air filter at least once a year. We also advise you to treat the ventilation system with antibacterial sprays every year. To do this, having purchased antibacterial agents (preferably spray, etc.), turn on the engine and start the interior ventilation system, turning off air recirculation. Next, open the hood and spray with an antibacterial agent in the place where air is taken into the cabin. This substance, together with the air, will pass through the entire ventilation system and enter the cabin. This way you will protect yourself from the formation of harmful bacteria and microbes in the ventilation system.

Typical faults

Subject to moderate use and careful handling, the service life is unlimited. Failure is caused by exceeding the permissible current, a short circuit in the circuit, and the negative consequences of an accident or shock.

In practice, there are cases of poor contact between the block and the terminals, blown fuse, and mechanical damage.

Don't forget to periodically ventilate the interior. Every second technical inspection, replace the cabin filter and troubleshoot the external air supply channels.

Rarely used options for air recirculation in the car

A car, especially a modern one, is a rather technically complex device, the design of which contains a considerable amount of smart technologies and comfortable solutions.

For example, behind a not so noticeable air recirculation button in the car interior, three quite useful functions can be hidden at once. But not every driver has the necessary knowledge to use them.

Using the system. Both in hot summer weather and in winter cold, the use of a climate control system or air conditioner is indispensable. In cold weather, we try to make the air a little warmer, for which the temperature control knob is turned to the red zone. In hot weather, on the contrary, we set the minimum possible temperature in the cabin in order to cool down as quickly as possible. At first glance, everything is clear. But what is the purpose of having this mysterious “air recirculation” button?

Most drivers use this system to combat existing unpleasant odors. For example, if the road passes by a landfill, or a smoking truck passes nearby. In this case, pressing this button closes a special damper on the supply ventilation, which causes the absence of unpleasant odors. The only point is that all this must be done in advance so that all these substances do not have time to enter the system.

However, a fairly small number of drivers use this button when they get into a traffic jam, in which the difference between the surrounding air and the mountain air is most clearly felt. For example, scientists were able to prove that using this button while driving along sections of roads with the highest level of traffic or traffic jams will make it possible to reduce the level of harmful emissions entering the cabin by about 20%.

Of course, driving through a traffic jam completely in this mode of operation of the air conditioning system will be quite difficult, since after some time the windows may begin to fog up. And the air in the cabin also needs updating. But still, the use of recirculation in conjunction with cabin filters becomes a good option for protection against the harmful effects of exhaust gases.

Other functions. In addition, there is another functional side of this button. It is also necessary to ensure that the air inside the car warms up as quickly as possible. The scheme of its operation is approximately as follows: when the recirculation button is pressed, the valve of the air duct supplying air from the street will be closed. The consequence of this is that only the air inside the car begins to circulate through the stove.

Despite the fact that the air temperature outside is firmly below zero, inside the car it should be a little higher. This parameter is also supplemented by air coming from the stove, which is starting to heat up, or from a special electric heater, which is equipped with some car models even as standard. This means that the climate control system will require much less energy to maintain the required temperature in the cabin. This will make it possible to save both time and fuel. The main thing is not to forget to turn off this installation after the air has completely warmed up. This is necessary in order to prevent moisture condensation on cold glasses.

Bottom line. This system can also work in the opposite direction. That is, to heat the car in a short time in the winter season. If you study the car in detail, you can find a sufficient number of useful functions in it.

The American Dream remains a reality. Cadillac introduced new crossovers

See all photo news >>

How to do it yourself?

The piping of the boiler of a private house is done in each case according to its own scheme. The reason for this is the large number of projects, different configurations and layouts of houses. In addition, the choice depends on the design of the boiler, its features and volume.

Before starting work, you should draw up a wiring diagram and mark on it the installation points of all consumer devices, pumping equipment and other elements.

Typically two options are used:

- through an indirect heating boiler;

- through a storage boiler.

Let's consider both options in detail.

Through an indirect heating boiler

An indirect heating boiler is a container with a coil installed inside it. It is connected to the heating boiler, and the coolant circulates in a closed loop without mixing with hot domestic water.

Read also: Grechka, Anastasia Ivanova, singer

This boiler is equipped with five pipes:

- a straight pipe running from the boiler to the coil;

- return pipe through which the return from the coil enters the boiler;

- cold water make-up pipeline;

- straight pipe (supply) of hot water to water collection points;

- return pipe leading to the boiler.

The circulation pump is installed in the return pipeline . This is done to create normal operation of the device and prevent overheating of parts.

The diagram shows a heated towel rail that always remains hot thanks to recirculation. This allows you to ensure a dry and warm microclimate in the bath, eliminating the appearance of dampness or mold.

Through a storage boiler

A storage boiler is a regular container with thermally insulated walls into which hot water flows from the boiler.

The reservoir contains a working volume of hot water sufficient for the household needs of the family. Typically its capacity ranges from 100 to 1000 liters , depending on the number of residents of the house and their needs.

The recirculation connection diagram to the storage boiler is a loop, where T3 is the supply, T4 is the return line.

It enters the make-up pipeline B1, and the entry point is located after the shut-off valve assembly with a check valve. A circular pump is also installed on the return line, along with shut-off and control elements.

The peculiarity of this scheme is that the temperature of H2O in the boiler and the make-up line are different. This is achieved by setting up a mixing unit that connects hot water from the make-up pipe to the cooled return pipe.

In this case, it is necessary to take into account the possibility of mixing layers of water in the container. If the water is made up with water that is not too hot, the temperature in the boiler will be noticeably lower than the standard value.

The specificity of the operation of storage boilers is such that water is heated only by replenishing it during disassembly.

Over a long period of time, a simple drop in temperature is inevitable, and recirculation becomes useless. Therefore, the use of storage tanks is recommended for houses with high and constant consumption of hot water.

Features of the use of recirculation and recovery

The main difference between recovery and recirculation is the absence of mixing air from indoors to outdoors. Heat recovery is applicable in most cases, while recirculation has a number of limitations that are specified in regulatory documents. SNiP 41-01-2003 does not allow re-supply of air (recirculation) in the following situations:

- In rooms where the air flow is determined based on the harmful substances emitted;

- In rooms where there are pathogenic bacteria and fungi in high concentrations;

- In rooms with the presence of harmful substances that sublime upon contact with heated surfaces;

- In premises of categories B and A;

- In premises where work is carried out with harmful or flammable gases and vapors;

- In premises of category B1-B2, in which flammable dust and aerosols may be released;

- From systems with local suction of harmful substances and explosive mixtures with air;

- From airlock vestibules.

Recirculation:

Recirculation in supply and exhaust units is actively used more often with high system productivity, when air exchange can be from 1000-1500 m3/h to 10000-15000 m3/h. The removed air carries a large supply of thermal energy; mixing it with the external flow allows you to increase the temperature of the supply air, thereby reducing the required power of the heating element. But in such cases, before being re-entered into the room, the air must pass through a filtration system. Ventilation with recirculation allows you to increase energy efficiency and solve the problem of energy saving in the case when 70-80% of the removed air is re-entered into the ventilation system.

Recovery:

Air handling units with recovery can be installed at almost any air flow rate (from 200 m3/h to several thousand m3/h), both small and large. Recovery also allows heat to be transferred from the exhaust air to the supply air, thereby reducing the energy demand on the heating element. Relatively small installations are used in ventilation systems of apartments and cottages. In practice, air handling units are installed under the ceiling (for example, between the ceiling and the suspended ceiling). This solution requires some specific installation requirements, namely: small overall dimensions, low noise level, simple maintenance. A supply and exhaust unit with recovery requires maintenance, which requires making a hatch in the ceiling for servicing the recuperator, filters, and blowers (fans).

Additional recirculation ventilation schemes

Recirculate indoor air using a ceiling fan

Recirculation using a single ceiling fan and indoor ductwork is not intended to introduce or change the volume of outside air. Such schemes, devoid of a fan coil and connection to the street air intake, are used in a number of types of premises (cafes, shops, administrative buildings) solely to increase air mobility in the work area.

Attention! This option cannot be called full recirculation, because with it air is taken from one part of the room to another so that it does not stagnate.

Indoor air recirculation using a fan coil unit

Recycling according to this scheme is quite common. The fan coil unit contains a heat exchanger for cooling or heating the air, and an industrial fan that moves it. In fact, this is a duct air conditioner, or rather its analogue. Such a system is mounted separately from the main supply and exhaust ventilation and works as follows: air is taken from some areas of the room, supplied through air ducts to a heat exchanger, where it is heated or cooled, after which it is sent through another network of air ducts to other areas of the room.

The use of this system can be considered rational in small and medium-sized rooms, where supply and exhaust ventilation is represented, for example, only by wall fans mounted in ventilation shafts. Here, the implementation of full-fledged combined recirculation ventilation is difficult and impractical, and this approach will create an acceptable microclimate at minimal cost without the need to completely redo all ventilation.

Recirculation using a fan coil with the addition of outside air

The basis here is the same system with a fan coil as in the previous case, with the only difference - it has the ability to take air from the street. The street fence is regulated manually or by an automatically controlled gate. Its use is justified mainly when effective supply and exhaust ventilation is already installed in the room, which there is no desire or opportunity to modernize.

Such a system can be used to heat or cool indoor air, as well as as an auxiliary air handling unit.

The essence and purpose of recycling

The recirculation system works on the principle of air purification through a carbon filter

The removed air is already heated to a certain temperature; mixing it with the flow coming from outside allows you to reduce the power of the heater. The mass is passed through a carbon filter before being reused for cleaning. Energy efficiency increases, up to 80% of internal air is allowed to be used.

Purpose of the hood in recirculation mode:

- formation and maintenance of a comfortable climate for humans and animals within the building, as well as plants and material objects (valuable artificial works, technological equipment);

- saving material resources to ensure the functioning of organized ventilation.

In a well-functioning recirculation system, engineering devices operate sequentially, cooling or heating the flows. The operating modes are different, for example, the system operates in the presence of people or the night schedule is selected. The cleaning and conditioning procedure is established separately for weekends and working hours, and is set for a certain period.

Operating principles of recirculation ventilation

The general scheme of operation of a supply and ventilation system with recirculation is as follows: street air is supplied into the room through the supply air, which after some time is drawn into the exhaust system. Some of it is irretrievably thrown out into the street, and some goes into the mixing chamber. There, the air is mixed with the fresh influx, cooling or heating it (depending on the type and settings of the system), then it enters the heater or air conditioner, from which it again enters the room through the ventilation pipes. The main purpose of recirculation is to reduce the load on air treatment systems (heaters, air conditioners, etc.).

What is it for?

There are several reasons:

- As I wrote above to remove odors from the road (remember the smoking KAMAZ), if the external air intake is turned off, then there will be much less smell in the cabin

- For efficient interior cooling. ON many cars, recirculation in the cabin is turned on together with the air conditioning (both keys light up at once). This is done in order to increase efficiency. After all, there is no intake of external hot air (and it can be +35, +39 degrees Celsius), in fact, it races in a circle, each time passing through the air conditioner evaporator - additionally cooling. As practice shows, interior cooling improves by 10 - 20%

- Fuel economy. If cooling efficiency increases, it turns out that the air conditioning compressor may turn off more often (especially on systems with climate control). I adjusted the temperature and turned off. This hypothetically saves fuel, although not globally. According to my observations, about 0.2 liters per 100 km

Improved heating. Recirculation can also be used in cold periods, with the stove, this also helps to quickly heat the interior. There is no intake of cold air from outside, it again races in a circle, only it passes through the heater, warming up more. BUT! According to my personal feelings, the glass sweats much more, because there is a large temperature difference.

These are the main reasons and one can say the advantages of the system, but there are also negative aspects.

Turning on the air conditioner

When turning on the air conditioning system, you must first turn it on to the minimum mode (Low). After all, every system in a car needs a little work before it begins to function more efficiently. You won’t like your friends waking you up in the middle of the night and forcing you to run quickly across some terrain..(?) Likewise, the air conditioning system will not work effectively if it is immediately initially turned on at 100% power. If your car is equipped with an automatic air conditioning mode, then when you turn it on, the system itself will first operate at the minimum mode, and then gradually increase the blowing power.

Advantages and disadvantages

DIY car seat ventilation

Note that the recirculation mode is useful only in certain cases. It has a number of disadvantages, due to which blocking access to outside air is allowed for a short time:

- rapid fogging of windows, especially when there are several passengers in the cabin;

- lack of air exchange, leading to a decrease in the amount of oxygen in the cabin;

- installation of an air conditioning system is required if it is not available;

- you will have to incur additional costs for maintenance/repair of the system (valve, damper drive mechanism).

At the same time, air recirculation in a VAZ-2110 car allows you to reduce the temperature inside the car much faster, since the air circulation circuit is limited by climate control ducts, where the temperature is obviously lower than outside. From an economical point of view, using this mode at the initial stage of movement is more profitable, since the energy costs for driving the damper are significantly lower than when the compressor operates with the damper open.

Negative factors

- complete absence of clean air from outside. Despite partial filtration during cyclic exchange, the air becomes polluted and absorbs more harmful substances, and humidity increases;

- prolonged inhalation contributes to the development of allergenic diseases;

- Prolonged air recirculation in the cabin leads to fogging of the windows. The problem is eliminated by combining the operation of air conditioning and filtration.

Health officials and car manufacturers recommend using the recirculation mode for 15 to 20 minutes. Afterwards, be sure to open the windows, let in fresh air and ventilate the interior.

Button location and mode activation

Each car has a mechanical button located differently. The practice has developed of installing it on the front torpedo in the central part in the area of the climate unit. To simplify the search, manufacturers use typical markings - a car with a ring arrow inside the cabin. In the image above, this button is indicated by the number 3. When you see it, feel free to activate it and use it. Deactivating the filtration mode occurs in a similar way, only for this purpose a mechanical button with a different design is used - an arrow “out of the cabin” or pressed again.

Some domestically produced technical equipment is not equipped with automation, and drivers use levers. For example: VAZ models discontinued from production have three adjustment levers: supply of cold, hot (warm) flow, closing the damper with a mechanical drive.

Cars equipped with climate control automatically regulate the temperature and take care of the cleanliness of the air flow. All processes are controlled by an air recirculation sensor. It is installed under the center console of the car. When activated, the controller analyzes the temperature and air content. Household climate control equipment operates on a similar principle.

Why you can’t keep recycling on a constant basis

Constant use of this function can harm the general condition of all passengers in the car, since the same air masses constantly passing through the car become wet. This may cause occupants of the vehicle to become short of breath.

In addition, there is a problem with glass fogging; many drivers spend a long time looking for the cause of such fogging and forget about closed shock absorbers. And the cause of this problem often lies in air recirculation. Therefore, you can keep this mode active for no more than 15 minutes.

If you can't do it, fake it!

A functional air intake is expensive and creates certain disadvantages in the operation of the vehicle. Moreover, the modest increase in performance that a work bucket can provide is of more interest to racers than to the average car enthusiast. Therefore, it is not surprising that a significant number of cars with sports shapes are equipped with... imitation racing buckets! Fake buckets often have the most tangential relationship to the real thing and are usually installed where stylists thought they would look cool rather than where they would make functional sense. (This is especially obvious in vehicles that offer function buckets as an option; work buckets are often in different locations and have very different shapes.)

After all, sometimes it's more important to look fast than to go fast.

Source

What happens when recirculation is turned on

In order to understand correctly, it is necessary to understand two concepts: circulation and recirculation.

The first means that the air inside the car is constantly renewed, that is, it flows in and out.

In the second case, there is no air renewal. When the recirculation function is turned on, a special flap blocks the access of fresh air flow inside the car. As a result of this, a circular movement of the air flow in the cabin occurs inside the car.

Drivers do not use this function very often, but it has several significant advantages.

Where is it located and how is it removed?

VAZ designers placed the DTVS module in a very original way. It is located in the plastic housing of the interior lighting unit. Directly under the rearview mirror. Under two backlights for the driver and passenger, you can see the air intake holes for supply to the combustion engine.

The module is dismantled quite simply. First, the rearview mirror is removed.

After this, two bolts are opened that secure the light module to the body and upholstery. They are simply unscrewed with a screwdriver or hexagon, depending on the type of bolts. When this unit begins to separate, it becomes possible to disconnect the wire connectors from the Priora interior air temperature sensor and directly from the backlight unit.

The DFA itself is a plastic box secured to the module body with two screws. And a wiring harness with a connector coming out of it. By unscrewing these bolts, you can freely separate the diesel fuel assembly.

And when the node is removed, various actions can be carried out with it. But most often, this is simply cleaning and lubricating the fan. Or replacing one of the nodes.

Although practice shows that most often drivers prefer, without bothering too much, to simply replace the complete combustion engine assembly. It’s really simpler, since its cost is not so high. Around 400-500 rubles.

And installing a new one according to the description above, proceeding in the reverse order, is generally not difficult.

And you can watch a short video on this issue:

There is no need to explain why you need air conditioning in a car - the heat sometimes reaches about 0 and above, and even more in the car interior. This is very uncomfortable and even dangerous for the driver and passengers - you can get heatstroke. Open windows are not an option. The noise of the street will accompany you all the way. And this is of little use if the air is very hot.

Car air conditioning is no longer a new product - it can be ordered when purchasing any new car, even a domestic one. For most of them, air conditioning is already offered as standard.

And if there is no air conditioning, if desired, you can even install it on a VAZ “classic” - there are now enough specialists and equipment. However, in recent years, instead of air conditioning, more and more car buyers are ordering climate control in Priora.

How does the Priora climate control differ from a conventional air conditioner? If you have a simple air conditioner in your car, then you have to do everything manually - turn the air cooling on and off, adjust the temperature, strength and direction of the air flow.

This is certainly better than frying in a frying pan, but still not very convenient. You have to constantly be distracted from the controls in order to adjust the climate in the cabin so that everyone is comfortable - or ask passengers to adjust something.

If your Lada Priora car has climate control installed instead of an air conditioner, then, of course, you can be envied. The driver only sets the air temperature with the regulator - the climate control system does the rest. It monitors the current thermometer readings in the cabin and, in accordance with this, changes the ratio of hot and cold air flows, as well as the strength of the flows supplied to the cabin.

Climate control on Priora can be two-, three-, or even four-zone. In this case, the driver and passengers can each set the temperature in their own part of the cabin, independently of each other (or with a certain maximum difference).

Such systems, however, are not always effective - it depends, first of all, on whether the manufacturer has saved on the number of fans, air tunnels and other parts of the climate system.

As for the main malfunctions, everything is quite interesting. An ordinary air conditioner is a fairly simple thing; repair and maintenance are not particularly difficult (among the main faults are rupture of tubes, breakdown of the compressor and evaporator, insufficient level of freon in the system).

Climate control on the Lada Priora is a much more complex device, and therefore mechanics have to rack their brains over its malfunctions much more.

On a Lada Priora car, the climate control is single-zone, but still, it includes, in addition to the usual components of the air conditioner, many control modules (especially an expensive part), sensors, sensors, cables, electric motors, resistors, printed circuit boards and other things. When replaced, these parts can cost a pretty penny!

Installation process

Installation of a recirculation piping is one of the stages of assembling a hot water supply and heating line. Usually, it is carried out simultaneously with the installation of the boiler, assembly of the heating circuit and other work.

It is recommended that assembly be entrusted to experienced personnel who have the necessary skills and training. However, sometimes home owners assemble the system themselves.

Tools and materials

To assemble the recirculation loop you will need:

- a welding machine of one design or another (depending on the type of water pipes);

- device for cutting pipes (grinder, electric saw, jigsaw);

- a set of plumbing windings, Unipack type thread paste;

- set of fittings, adapters, fasteners.

In addition, you will need tools to install load-bearing elements:

- hammer drill with drills;

- impact electric drill, etc.

Necessary equipment

To install the line you will need the following devices:

- pipes and fittings (different types are used, from copper to metal-plastic);

- circulation pump;

- shut-off valves (valves or ball valves, three-way valves, check valves, etc.).

The circulation pump should be low-power. It is only needed to create a slight pressure to move the flow. Models that are installed in a heating system cannot be used.

The choice of pipelines is dictated by operating conditions and personal preferences of the owner. For example, to install copper (brass) pipes you will need to solder connections, which requires a torch, solder and an experienced craftsman.

You can use compression fittings in combination with polyethylene or metal-plastic pipes. This does not require the use of complex equipment, but is only suitable for DHW systems with low operating pressure.

Algorithm of installation actions

The circulation loop is assembled in stages:

- marking walls or other load-bearing surfaces in accordance with the developed scheme;

- installation of load-bearing elements (brackets, clips, clamps);

- cutting pipes along the length of routing sections;

- serial line connection, connection of fittings and adapters;

- connection of mixing units, circulation pump, shut-off valves;

- connecting the return line to the boiler.

When assembling complex lines, some deviations from the given scheme of work are possible. As a rule, additional elements are added or control devices are connected.

Six types

Science begins where classification begins. Well, let's get down to classification. Air purification systems are divided, firstly, by the number of cleaning stages (one-, two- and three-stage); secondly, by the method of collecting dust. In the latter case, six types of systems are distinguished.

1. Dry inertial with collection of separated dust into a hopper.

2. Dry inertial with dust suction from an external source.

3. Dry inertial with the release of dust into the atmosphere.

4. Inertia-oil.

5. Using filter elements with oil-moistened packing.

6. Using dry filter elements.

The first three types are mainly used in two- or three-stage cleaners on trucks and tractors. The fourth type was described in the previous section - this is already part of history. As for elements with wetted padding (type five), they are used mainly on expensive or sports cars. But the sixth type is the most popular, most in demand

Let's focus on him

Air supply system on diesel engines

The standard equipment of diesel engines is a turbocharger. Here the following components take part in organizing air circulation:

- filtration air purifier;

- air intake;

- turbocharger;

- air heat exchanger;

- inlet pipeline.

The air masses are launched into the turbocharger and then pass through the heat exchanger. The air enters the intake manifold, and then into the engine cylinders. The turbocharger uses the energy of recycled gases.

The air is released into the atmosphere using an exhaust structure. Modern diesel cars have begun to incorporate a throttle valve, which was not included in the design previously.

DIY seat ventilation

The above description of how the seat ventilation system works allows you to make a similar system with your own hands, based on the information received. In this case, seat ventilation can be installed in at least three different ways.

Installation of a ready-made kit (kit)

To do this, use a ready-made set of parts and assemblies that are commercially available, for example, as shown in the photo below:

Do-it-yourself installation of such a kit involves removing the seat trim, perforating it, as well as positioning and connecting the fans in the right places. As a rule, such a system has several speeds for regulating fan performance, which allows you to select the best option based on the current climatic conditions.

Article on the topic: Rating of the best MTPL insurance companies

DIY installation using individual elements

To perform ventilation yourself using individual elements, you need to buy:

- computer fans;

- plastic mesh instead of a spacer;

- buttons, wires.

Their installation begins with the seats being dismantled and the places where the fans will be attached are determined, then holes are cut out in the foam rubber for them.

In these places, excess foam rubber is cut off and instead of it, a cut mesh fifteen millimeters thick is laid.

After the mesh has been installed, previously cut foam rubber must be laid on top of it, in which holes with a diameter of one centimeter must be made.

The fans are connected by wires, the button for turning on the ventilation in the seat is located on the panel, or in any other convenient place.

Seat ventilation system using a car heater

You can do the blowing with your own hands without using fans. How this is done should be clear from the given figure and photo. With this approach, air from the stove is supplied to the seat using a corrugation. Such an air supply system will allow not only cooling, but also heating of the seats. It is best if the corrugation is installed inside the channel.

Minuses

One very important point worth mentioning among the negative factors of air recirculation is the absence of any air exchange. In simple words, you will have to breathe the same air.

That is why it is not recommended to use this mode for a long time; usually auto experts allocate a time interval of within 15 minutes, then you should either open the windows or turn on the air supply from outside.

With prolonged use, glass fogging is inevitable due to increased humidity in the car interior. Many people solve this problem by using the air conditioner and recirculation mode together.

Air recirculation in Priora main faults

Many drivers never use the recirculation button simply because, having once tried this mode in unsuitable conditions, they did not see any advantages in it. Others use the button regularly, well aware of all the local advantages of this mode. Despite the simplicity of the design (the recirculation system consists of a damper that blocks the access of air from outside, and an electromagnetic valve that drives the damper), there are often cases when this mode turns out to be inoperative on a Priora. The reasons for the system’s inoperability may therefore be either problems with the valve or a violation of the integrity of the damper. The Priora recirculation button may also be faulty.

Jamming of the damper occurs in cases where, for example, it is covered with rust due to the presence of moisture in the air. Note that corrosion processes occur only with the damper on new-style air conditioning systems, since in this case it is made of metal, and a rubber seal is used as a gasket. On older models, the damper is made of plastic and protected by sealing foam.

To find out whether the damper is to blame for the inoperability of the recirculation mode, you should manually try to move it. True, for this you will have to disassemble the deflector of the main (central) panel. If the damper is metal and you can turn it by hand, but with difficulty (or if you can’t turn it), the reason really lies in the presence of rust. There are two options to solve the problem:

- try to treat the area exposed to corrosion with VD-40;

- if the result turns out to be negative or the damper’s functionality returns for a short time, you should simply replace this part with a new one.

Plastic dampers, although not susceptible to corrosion, can also jam due to deformation caused by exposure to heated air. In this case, it will not be possible to restore the damper geometry, and therefore the only solution is to replace the part.

pros

When using this mode, the air temperature in the cabin decreases in a faster manner than the mode of taking air masses from the environment. This mainly happens due to the repeated passage of air into the car, the temperature of which is already below the ambient temperature, through the air conditioning system.

With the reverse procedure - heating, everything is even simpler, since the temperature in the cabin is much higher than outside the car.

Another positive point is the fact that the power consumption for operating the compressor is significantly lower than when taken from the outside.

Recirculation is also an indispensable mode for people sensitive to road dust, pollen, unpleasant odors and other allergenic factors.

As an example, it is worth mentioning a situation that is probably familiar to any driver - this is a KAMAZ driving in front of you or any other vehicle that emits strong specific odors; recirculation in this case is an excellent way out of the situation.

Heating system

In some models, the air heating system works when the air mass passes through pipelines that contain hot liquid. This design is complemented by fans that move air when the machine stops or moves slowly.

Thermal control options in cars.

Heating design with water valves.

In a heating system where water valves are present, air flows through the pipes. The temperature of the pipelines is regulated by the volume of hot liquid that moves through them.