3.9/5 — (60 votes)

This material will be somewhat philosophical, as we will try to understand why the VAZ 2107 tachometer jumps and its needle behaves inappropriately. Even if the quality of the engine does not change, there is still a feeling that something is wrong, the car is broken. The sight of an arrow jumping from side to side is somehow very annoying. What to do, how to get rid of this? Of course, there will be some features if you have an injector installed. However, even if there is a carburetor in the power system, the design of the tachometer turns out to be similar.

Tuning VAZ → how is the speedometer cable noisy?

When driving, the car makes sounds something like “shork-shork-shork” or “shur shur shur.” starting from about 10 km/h until I stop hearing this sound because of the wind. one might even say it makes a loud shuffling or rustling sound. About a year ago the speedometer started ticking, the needle starting from 40 goes “poke-poke-poke”. Could the speedometer drive now start shuffling? or is it something else.

- Lexandr_amp

- 25 July 2014, 19:43

- Lexandr_amp

- 25 July 2014, 19:48

- v

- Dmitriy_Ponomarev

- July 26, 2014, 00:24

- v

- Artur_Komlev

- July 26, 2014, 02:17

- v

- Ivanesko_Mihaylov

- 26 July 2014, 08:57

- v

- Lexandr_amp

- July 26, 2014, 11:30

- v

- Orsik_Aleksandrovich

- 26 July 2014, 13:02

- v

- Orsik_Aleksandrovich

- 26 July 2014, 13:44

- v

- Rim_Shaybakov

- 26 July 2014, 15:35

- v

- Lexandr_amp

- 26 July 2014, 15:36

- v

- Orsik_Aleksandrovich

- 26 July 2014, 18:35

- v

- Lexandr_amp

- 26 July 2014, 21:26

- v

I can’t define O_o I’m just panicking.. it feels like people in the car are going crazy. To those who are traveling with me, I say: “Can you hear something making noise??” passenger(s) - “No, everything is quiet.” after about 30 minutes. Me: “Can you hear me now?” Passenger: “By the way, I can hear it now.” Me: “Well, where is the noise?” "Passenger:"mmmmmm. God knows, it’s unclear” Me: “Well, here’s another one”

I don’t really know where the noise is, when it seems in front, when in the back... my head is fucking spinning. Well, in the middle there’s definitely nothing to make noise. collapse branch

Description of DS

As we have already said, the main purpose of the speedometer drive sensor is to accurately determine the speed of the vehicle. Thanks to this device, the model can always know at what speed his car is moving. As for the varieties, DS can be of the contact or non-contact type. Today, most of our compatriots prefer contactless options. Contact DS, despite all the advantages, have one significant drawback - they are prone to contamination, which in turn will lead to inaccuracy of the displayed readings.

Design and principle of operation

Structurally, according to the diagram, this part consists of:

- speedometer drive;

- housings;

- as well as the controller itself with a connector for connecting to the on-board network.

As for the principle of operation, it is based on measuring the frequency level of signals from the controller, which is located on the gearbox housing or transfer case. At the output of the device, while driving, rectangular pulses are formed, the minimum value of which should be at least 1 volt, and the maximum value should be at least 5 volts.

According to international standards, the controller must generate about 6 thousand such pulses over one kilometer. The pulses themselves are subsequently converted into current, which is measured by a magnetoelectric device. It should be noted that the current value directly depends on the number of signals supplied per certain unit of time. That is, this value will be directly proportional to the speed of the vehicle.

In addition, thanks to the electronic circuit installed in the dashboard, the operation of the stepper motor is ensured by counting incoming signals. The latter is designed to rotate the counter reels, after which it displays the relevant information on a small screen, where the total and daily mileage of the car is shown. If we are talking about daily mileage, then this value can be reset to zero if necessary.

Symptoms of a problem

If the DS for some reason fails, this will lead to the control unit being unable to determine the speed of movement. However, this is not the only problem, since malfunctions in the performance of the power unit may also occur.

We suggest that you familiarize yourself in more detail with the signs of a malfunction, by which you can determine the failure of the DS:

- the speedometer on the dashboard has either stopped working altogether or displays incorrect readings;

- malfunctions appear in engine operation, in particular at idle speed;

- fuel consumption increased;

- engine performance has deteriorated, the power unit cannot reach the required speed;

- the engine may stop spontaneously while idling, in particular when the driver tries to press the clutch to change gear;

- if the car is equipped with an on-board computer, a Check indicator may appear on the dashboard;

- if the car is equipped with an electric power steering, this unit may also fail;

- in some cars, for example, Lada Kalina, failure of the diesel engine can also lead to increased sensitivity of the fuel level controller in the gas tank (the author of the video is the Autoelectrics HF channel).

https://youtube.com/watch?v=qiDmZLUuTMI

As for the reasons, as a rule, they are caused by damage to the car's electrical wiring, so checking the functionality should begin with diagnosing the condition of the contacts and electrical circuits. Perhaps the problem lies in oxidized or dirty contacts, so they will need to be cleaned and treated with a lubricant, for example, Lithol. A broken wiring should be looked for first of all near the connection connector, since in this place the wires are bent and usually frayed.

Also, the cause of the malfunction may be a violation of the integrity of the wiring insulation in the area where the exhaust manifold is installed. At elevated temperatures, the insulation may melt, causing the device to short out. Also, the DS may transmit incorrect readings due to a worn speedometer cable. Over time, cracks and tears form on it, which contributes to the failure of the controller.

Why the VAZ-2107 speedometer drive does not work and how it can be replaced

The reason for the malfunction of the device often lies in the fact that the VAZ-2107 speedometer drive has failed.

Speedometer characteristics of this car model:

- display scale 0-180 km/h;

- speed coverage 20-160 km/h;

- gear ratio 1 to 1000.

The speedometer drive of the VAZ-2107 car model looks like a braided cable, which ensures the transmission of torque from the gearbox to the device. One end of it is connected to the speedometer mechanism, and the other to the gearbox on the gearbox.

Main speedometer malfunctions:

- the device does not determine the current speed;

- the drive is noisy.

The speedometer does not work for the following reasons:

- the mechanism is broken and needs to be replaced;

- The locknuts securing the ends of the flexible shaft have been unscrewed. They need to be screwed in;

- the flexible shaft is broken. A new part needs to be installed;

- The drive tip or mating socket is damaged. In this case, the device itself or the speedometer cable is changed.

The drive can make noise for the following reasons:

- the cable has a small bending radius. Here it is necessary to re-route the drive;

- The cable sheath is damaged. In such a situation, it is necessary to replace the speedometer drive assembly.

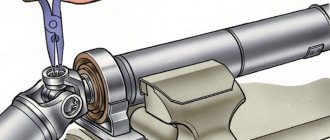

As practice shows, the largest number of breakdowns of the VAZ-2107 speedometer are associated with its drive and can be eliminated by replacing the flexible cable. To do this you will need pliers and a screwdriver. To facilitate installation, you can use steel wire with a length of about 2 m and a cross-section of 0.5 mm. The drive is fixed in the lower part of the crankcase to the gearbox, so repairs require a lift or inspection hole.

Dismantling the VAZ-2107 speedometer drive

The actions are performed in the following sequence:

- the car is installed on an inspection hole;

- the ground wire is disconnected from the battery;

- the instrument panel is removed;

- the nut securing the drive to the speedometer is unscrewed and it is disconnected;

- a wire is tied to the eye of the nut;

- the nut securing the flexible shaft to the gearbox is unscrewed;

- the speedometer cable is disconnected from the gearbox;

- the drive is pulled out so that the guide wire remains in it;

- the wire comes untied from the nut.

Installation of the VAZ-2107 speedometer drive

Before installation, you must remove the cable from the braid and treat it with Litol lubricant, and then insert it back. Then you need to fix the guide wire to the drive fastening nut and pull it from below the car into the interior.

The following steps are carried out in the reverse order of removing the speedometer cable.

Typical faults

There is no need to talk about the reliability or unreliability of this sensor. On some cars it works throughout its entire service life, while on others it often fails. However, there are a number of typical problems that motorists face:

- Failure due to old age. Each electronic device, regardless of quality, has its own resource. Therefore, it can fail at any time.

Mechanical impact. Simply put, damage to the sensor housing or wiring. If any work has been done to remove and install the sensor, it is likely to be damaged.

Oxidized, dried out or broken wires. Also, the wiring simply wears out its own life if it has not been changed for a long time. The sensor does not fit this car model. In this case, you should not count on correct speedometer readings.

The speedometer cable of the VAZ 2107 is noisy

VAZ 2107 speedometer malfunctions

A speedometer malfunction is a non-critical, but quite unpleasant problem. Data on mileage and, most importantly, current speed should not be neglected. The cause of the problem lies in a breakdown of the speedometer or its drive. To repair a VAZ 2107 speedometer, it is enough to have minimal repair skills.

Speedometer VAZ 2107

The device serves to indicate the current speed of the vehicle and record its total and daily mileage. The characteristics of the VAZ 2107 speedometer do not differ from other “classic” VAZ speedometers:

- indication range: 0-180 km/h;

- measured speed range: 20-160 km/h;

- gear ratio: 1 to 1000.

The VAZ 2107 speedometer, unlike the VAZ 2106, is manufactured without a housing.

Speedometer drive VAZ 2107

The speedometer cable (drive) is a flexible braided cable and serves to transmit torque from the gearbox to the speedometer. One end of the drive is connected to the gearbox on the gearbox, the other to the speedometer mechanism.

Basic speedometer faults

Malfunctions can be divided into two types:

- the speedometer does not show the current speed;

- The speedometer drive is noisy.

The VAZ 2107 speedometer may not work for the following reasons:

- The speedometer is faulty. In this case, the device must be replaced.

- The nuts securing the ends of the flexible shaft have come loose. To fix the problem, they need to be screwed on.

- The flexible shaft is broken. It must be replaced to restore the speedometer's functionality.

- The tip of the flexible shaft or the mating socket on the speedometer is damaged. In this case, you should change the VAZ 2107 speedometer cable or the speedometer itself

- The flexible shaft drive is faulty or the speedometer drive socket in the gearbox is damaged. This is a rare breakdown, the elimination of which involves repairing the gearbox and is worthy of description in a separate article.

The VAZ 2107 speedometer drive can make noise for two reasons:

- The drive is laid with small bending radii. To fix the problem, you need to re-route the speedometer cable, having previously lubricated it.

- The braiding of the VAZ 2107 speedometer cable is damaged. In this case, the flexible speedometer drive assembly needs to be replaced.

Tachometer malfunctions

Why the tachometer does not work on the VAZ 2106

Despite the fact that the TX-193 tachometer is considered quite reliable, it also has malfunctions. Their signs are:

- lack of response of the needle to changes in engine speed;

- chaotic movement of the arrow up and down, regardless of the engine operating mode;

- obvious underestimation or overestimation of readings.

What kind of breakdowns do the listed signs indicate?

The arrow does not respond to measuring the number of revolutions

Usually, the lack of response from the arrow is due to a broken contact in the connectors of the main wires of its connection, or damage to the wiring of the circuit. The first step is:

- Inspect the fastening of the conductor in brown insulation to terminal “K” on the ignition coil. If you detect poor contact, traces of oxidation, burning of a wire or terminal, fix the problem by cleaning the problem areas, treating them with anti-corrosion liquid, and tightening the fastening nut.

- Check the reliability of the connection of the black and white wire to the vehicle ground. If contact is broken, clean the wire and the surface to which it is attached.

- Using a tester, determine whether voltage is supplied to the red wire when the ignition is on. If there is no voltage, check the serviceability of fuse F-9, which is responsible for the integrity of the instrument panel circuit, as well as the condition of the ignition switch contacts.

- Disassemble the instrument panel and check the connections of the contacts in the tachometer wiring harness block. “Ring” all the wires going to the device with a tester.

Video: tachometer needle does not respond to engine speed

The tachometer needle jumps chaotically

Jumps in the TX-193 needle in most cases are also a symptom of malfunctions associated with its electrical circuit. The reasons for this behavior of the device may be:

- lack of good contact at the negative terminal of the battery;

- oxidation or burning of the brown wire on the ignition coil;

- burning or wear of the contacts of the ignition distributor cap or slider;

- wear of the distributor shaft bearing;

- shorting the red wire powering the device to vehicle ground;

- malfunction of the crankshaft position sensor (for injection engines).

A similar problem is solved by stripping the contacts, replacing the ignition distributor cap, slider, support bearing, restoring the integrity of the insulation of the device’s supply wire, and replacing the crankshaft sensor.

Video: tachometer needle jumps

The tachometer underestimates or overestimates the readings

If the device is outright lying, then the problem most likely lies in the ignition system. In other words, it shows correctly, but the number of pulses created by the chopper per revolution of the distributor shaft is more or less than four. If the tachometer readings are incorrect, there is usually a deterioration in engine performance. In this case, the speed may fluctuate, misfires periodically appear, which is accompanied by engine vibration and white or bluish exhaust.

In this case, the fault should be looked for in the breaker, or rather, in its contact group or capacitor. To fix this problem you need to:

- Disassemble the ignition distributor.

- Check the condition of the breaker contacts.

- Clean contacts.

- Adjust the gaps between the contacts.

- Check the serviceability of the capacitor installed in the breaker.

- Check the serviceability of the crankshaft position sensor. In case of malfunction, replace it.

However, the reason may be in the tachometer itself. Malfunctions occur related to the parts of the electronic board, as well as to the milliammeter winding. You can't do without knowledge of electronics here.

Older models of TX-193 devices are designed exclusively for contact ignition systems. All owners of “sixes” who independently converted their cars to a contactless system subsequently encountered problems with the tachometer. It's all about the different forms of electrical impulses arriving at the device from the breaker (in a contact system) and the switch (in a contactless system). The simplest way to solve this problem is to install a capacitor in the cut of the same brown wire coming from the breaker. But here it is necessary to experimentally select the desired container. Otherwise, the tachometer will lie. So, if you have no desire to engage in such experiments, just buy a device for a contactless ignition system.

The speedometer cable of the VAZ 2107 is noisy

Moderator: Rustem

Speedometer cable whistle

Unread message by sadizd666 » Tue Jan 12, 2010 06:32:58 PM

Get the hell out of it.

then see what condition it is in, if it is worn out then replace it, if it is in good condition then dig deeper

Added after 1 minute 2 seconds:

or the lubricant in the jacket has dried out, if the cable is dry, then pour oil there..

Unread message sadizd666 » Tue Jan 12, 2010 21:20:14

Unread message Alex » Tue Jan 12, 2010 21:22:54

Added after 33 seconds:

Unread message sadizd666 » Tue Jan 12, 2010 21:34:42

But won't the oil leak out from below? where is it attached to the box?

Added after 49 seconds:

Unread message by Inoy84 » Sat Jan 16, 2010 8:33:20 AM

Re: Speedometer cable whistling

Unread message byran » Sat Apr 03, 2010 10:17:25

Re: Speedometer cable whistling

Unread message ella » Sat Apr 03, 2010 12:50:18

Re: Speedometer cable whistling

Unread message Serega73 » Sun Apr 04, 2010 9:19:13

Re: Speedometer cable whistling

Unread message Violent » Sun Apr 04, 2010 11:08:54

Re: Speedometer cable whistling

Unread message ella » Sun Apr 04, 2010 13:00:46

Re: Speedometer cable whistling

Unread message Serega73 » Sun Apr 04, 2010 15:04:10

Re: Speedometer cable whistling

Unread message Buiny » Sun Apr 04, 2010 18:29:31

Re: Speedometer cable whistling

Unread message ella » Tue Apr 06, 2010 11:40:15

Re: Speedometer cable whistling

Unread message Susanin » Tue Apr 06, 2010 21:42:33

Re: Speedometer cable whistling

Unread message byran » Wed Apr 07, 2010 10:51:06

Re: Speedometer cable whistling

Unread message Stalkerun » Wed Apr 07, 2010 14:15:38

Re: Speedometer cable whistling

Unread message ella » Wed Apr 07, 2010 16:07:25

oil is leaking from the drive. It’s just that your drive is already worn out. It can only be eliminated by replacing it. It was leaking on my old box too. I thought it wasn’t from him, but the leak stopped as soon as I changed the drive code!

about the cable. Again today the convulsions at the speedometer needle started. They either appear, THEN DISAPPEAR! In short, you need to try changing the cable anyway

Replacing the speed sensor

If the speedometer needle of a VAZ-2107 twitches, then it is necessary to replace the cable or worn-out gears, the edges of which have already worn out during the operation of the car. This rule applies to practically all cars that are equipped with a manual transmission. A speed sensor is installed in the automatic transmission. Let's look at the replacement process using Accent as an example.

To carry out the work, we will need to buy original speed sensors costing 800-900 rubles apiece. From the tool you need a wrench for 10 and 12, as well as the corresponding heads. There are two sensors in total. The first is located on top of the box, the second on the bottom. To get to the top one, you need to dismantle the air filter box and remove the battery from the platform. After that, use a 10mm key to unscrew the old one and install the new one. The lower sensor is located behind the left wheel. To get to it, you need to remove the box protection and the front part of the fender liner.

The speedometer cable of the VAZ 2107 is noisy

Messages: 1428 Registered: Sep 27, 2007, 00:00 From: Tyumen, microdistricts Experience: 2003 :

Awards: 1

| Rating: 1 428 |

| Reputation: 0 |

VAZ 2107. The speedometer has gone crazy!

- Quote

Post 880 » 02 May 2009, 22:02

The problem is a strange twitching of the speedometer needle. It all started after I switched to summer tires in mid-April. Since then, the speedometer needle jerks strongly when driving, i.e. shows the speed correctly, but at the same time they crack. What’s most interesting is that at speeds above 80 km/h the speedometer works clearly. And one more strange thing: when leaving in the morning there are no problems either, but after driving 2-3 kilometers the needle begins to shake. I was at the service station, but apparently frightened of the mechanic, the needle stood rooted to the spot, clearly showing the speed.

Maybe someone can tell me where to look for the problem.

Messages: 9858 Registered: August 21, 2007, 00:00 From: Tyumen, 1st Zarechny Experience: since 09/11/2004 Car: Skoda Octavia :

Awards: 3

| Rating: 22 020 |

| Reputation: +29 |

Thanked: 82 times Thanked: 185 times

- Quote

Posted by Denver » 02 May 2009, 22:11

Messages: 141 Registered: Dec 18, 2007, 00:00 From: Belgorod Experience: 1997 Car: Grand Cherokee (WJ) :

Awards: 1

| Rating: 291 |

| Reputation: +1 |

Thanked: 3 times Thanked: 1 time

- Quote

Post by Andrey_72 » 02 May 2009, 22:16

Messages: 540 Registered: 05 Oct 2008, 00:00 :

Awards: 1

| Rating: 690 |

| Reputation: +1 |

Thanked: 5 times Thanked: 1 time

- Quote

Post by taha074 » 02 May 2009, 22:16

Messages: 696 Registered: June 12, 2008, 00:00 From: Tyumen Experience: since 2002 Car: Shkoda Octavia 1.4 TSI

| Rating: 846 |

| Reputation: +1 |

Thanked: 1 time

- Quote

Post by Wofftai » May 02, 2009, 10:18 pm

Messages: 1428 Registered: Sep 27, 2007, 00:00 From: Tyumen, microdistricts Experience: 2003 :

Awards: 1

| Rating: 1 428 |

| Reputation: 0 |

- Quote

Post 880 » 02 May 2009, 22:20

| Rating: 2 592 |

| Reputation: +2 |

Thanked: 2 times Thanked: 7 times

- Quote

Message 172RUS » 02 May 2009, 22:24

Atypical breakdowns

If the speedometer needle twitches (2109 is a VAZ or another model - it doesn’t matter, this type of breakdown is common to many cars), and the above method did not help, then there are several more options. One of them is wedging the arrow in a certain position. Therefore, when picking up speed, the instruments may show normally, but at some point there will be a jump. The problem can be solved by disassembling the dashboard and repairing the speedometer. It is likely that you will need to remove the arrow and lubricate it or replace it with a new one.

Another atypical failure is the failure of gears after turning off the mileage on a mechanical speedometer. It is quite rare and suggests that the technicians who corrected the mileage did not take too much pride in the car. But on the electronic speedometer, when the mileage is increased, the system may be blocked, and the “Check Engine” error will appear on the dashboard. The last thing you should look at is the on-board computer, but this only applies to electronic systems.

Replacing the speedometer cable for a VAZ 2107 injector. How to change the speedometer cable on a VAZ 2107

The drive can make noise for the following reasons:

- the cable has a small bending radius. Here it is necessary to re-route the drive;

- The cable sheath is damaged. In such a situation, it is necessary to replace the speedometer drive assembly.

As practice shows, the largest number of breakdowns of the VAZ-2107 speedometer are associated with its drive and can be eliminated by replacing the flexible cable. To do this you will need pliers and a screwdriver. To facilitate installation, you can use steel wire with a length of about 2 m and a cross-section of 0.5 mm. The drive is fixed in the lower part of the crankcase to the gearbox, so repairs require a lift or inspection hole.

Checking and replacing the VAZ 2107 speed sensor

While the vehicle is moving, the VAZ 2107 speed sensor (injector) generates speed data sent to the electronic engine control unit. Its breakdown causes injection control errors and leads to a drop in engine power and an increase in fuel consumption. You can check and replace the sensor yourself. To do this, you will need a garage with an inspection hole, a slotted screwdriver, a 22 mm wrench and a multimeter or test lamp.

Speed sensor problem

In order to understand the question of why the speedometer needle twitches, it is necessary to become more familiar with the design of the car. For example, domestic classics did not have a speed sensor. The system worked approximately as follows. The gearbox contained a motor (drive), which, while the car was moving, turned a cable going to the speedometer.

If the motor failed, then the arrow on the instrument panel completely “died” and always showed “0”. But most modern cars are equipped with a speed sensor that is installed in the gearbox. It determines the speed limit practically without error and transmits data to the speedometer via wires. From the same wire and sensor, data also comes from the distance traveled, that is, to the odometer.

Gearbox device

In general, the concept of “remaking” the box is not entirely correct, since the design of the VAZ-2105 gearbox with 4 speeds was practically no different from the same gearbox 2101. The 2105 gearbox has a three-shaft layout, with constant gear meshing and manual control. Externally, the Kopeika and Pyaterki checkpoints can be distinguished almost only by the markings on the body of the box.

The VAZ-2105 gearbox diagram with 4 stages is presented below, and structurally it does not differ from modifications 2101 and 2106:

| 1 | Bottom cover; | 40 | Needle bearing of the front end of the secondary shaft; |

| 2 | Filler and inspection plug; | 41 | Synchronizer spring thrust washer; |

| 3 | Intermediate shaft second gear gear; | 42 | Fourth gear synchronizer ring gear; |

| 4 | Intermediate shaft third gear gear; | 43 | Sliding clutch for synchronizer of third and fourth gears; |

| 5 | Intermediate shaft; | 44 | Third and fourth gear synchronizer sliding clutch hub; |

| 6 | Front intermediate shaft bearing; | 45 | Synchronizer retaining ring; |

| 7 | Clamp washer bolt; | 46 | Synchronizer locking ring; |

| 8 | Intermediate shaft front bearing clamp washer; | 47 | Synchronizer spring; |

| 9 | Intermediate shaft constant mesh gear; | 48 | Third gear synchronizer gear and ring gear; |

| 10 | Constant mesh gear of the input shaft; | 49 | Second gear synchronizer gear and ring gear; |

| 11 | Spring washer; | 50 | Secondary shaft; |

| 12 | Retaining ring; | 51 | First gear synchronizer gear and ring gear; |

| 13 | Rear input shaft bearing; | 52 | First gear gear bushing; |

| 14 | Input shaft oil seal; | 53 | Secondary shaft intermediate bearing; |

| 15 | Transmission front cover; | 54 | Intermediate bearing lock plate; |

| 16 | Bearing mounting ring; | 55 | Secondary shaft reverse gear; |

| 17 | Clutch housing; | 56 | Elastic cushion for gear shift lever damper; |

| 18 | Gearbox input shaft; | 57 | Damper rubber bushing; |

| 19 | Reversing light switch; | 58 | Damper spacer; |

| 20 | Intermediate shaft reverse gear; | 59 | Damper locking sleeve; |

| 21 | Reverse intermediate gear; | 60 | Inner gear shift lever cover; |

| 22 | Reverse fork; | 61 | Secondary shaft rear bearing oil seal; |

| 23 | Gear shift lever release spring; | 62 | Flange of the elastic coupling of the propeller shaft; |

| 24 | Tension spring bolt; | 63 | Screw; |

| 25 | Gear shift lever guide cup; | 64 | Centering ring seal; |

| 26 | Ball joint of the lever; | 65 | Centering ring retaining ring; |

| 27 | Spherical washer; | 66 | Centering ring; |

| 28 | Spring; | 67 | Rear secondary shaft bearing; |

| 29 | Gear shift lever; | 68 | Drain plug; |

| 30 | First and second gear shift fork; | 69 | Mud deflector; |

| 31 | Third and fourth gear shift fork; | 70 | Speedometer drive gear; |

| 32 | Fork rod for first and second gears; | 71 | Speedometer drive; |

| 33 | 3rd and 4th gear fork rod; | 72 | Rear gearbox cover; |

| 34 | Locking blocks; | 73 | Reverse idler gear axis; |

| 35 | Reverse fork rod; | 74 | Rear intermediate shaft bearing; |

| 36 | Rod lock ball; | 75 | Intermediate shaft first gear; |

| 37 | Retainer spring; | 76 | Gearbox housing; |

| 38 | Retainer cover; | 77 | Sliding clutch for synchronizer of first and second gears. |

| 39 | Breather; |

Since the box from the VAZ-2105 is structurally similar to the 2101, the kinematic diagram of the gearbox is the same. But the gear ratios are different; on 2105 gearboxes they are:

- 1st – 3.67;

- 2nd – 2.10;

- 3rd – 1.36;

- 4th – 1.00;

- Rear – 3.53;

As for the differences in the design between gearboxes 2105 and 2101, they mainly come down to different numbers of teeth on different gears. So, on the intermediate shaft of the gearbox, a 1st speed gear with 14 teeth is used (15 for 2101), and their inclination angle is greater. The constant mesh gear of this shaft has 28 teeth (29 for 2101). The input shaft uses an 18-tooth gear (19 for 2101). Because of these features, the shafts with gear blocks of these two gearboxes are not interchangeable if you try to install them separately. But in the case of a complex replacement - the input shaft along with the intermediate shaft and all gear blocks, then installation is quite possible. As for the secondary shaft, modification 2105 differs from shaft 2101 in the first gear gear (its teeth have a different angle, although their number is the same, and its diameter is also slightly larger).