The ZMZ 406 engine was being developed to replace the 402 engine simultaneously with the design of the GAZ-3105 car for the government. However, these new Volgas were equipped with them only for the last batch, which had to be urgently sold due to the removal of the cars from production.

ICE ZMZ 406

The basis was taken from the ZMZ 402 (equipment) and the H series engine from the manufacturer SAAB (design solutions). As a result, with the same volume of 2.3 liters, the power drive provided 177 Nm of torque instead of the prototype’s 210 Nm and 100 hp. With. power instead of the expected 150 hp, like the Swedish internal combustion engine. The injection system, which later replaced the carburetor, was able to improve the situation slightly - 201 Nm and 145 hp. s., respectively.

Carburetor version ZMZ 4061.10

For the first time, several advanced technical solutions for that time were used in the engine of the manufacturer ZMZ:

- two intake and two exhaust valves per cylinder;

- electronic ignition and injection systems;

- diagram of the DOCH gas distribution mechanism with two overhead camshafts;

- hydraulic pushers instead of adjusting the thermal clearance of valves with gaskets.

Valve tappets

After the changes made, the technical characteristics of ZMZ 406 correspond to the values given in the table:

| Manufacturer | ZMZ |

| Engine brand | 406 |

| Years of production | 1997 – 2008 |

| Volume | 2286 cm3 (2.3 l) |

| Power | 73.55 kW (100 hp) |

| Torque moment | 177/201 Nm (at 4200 rpm) |

| Weight | 192 kg |

| Compression ratio | 9,3 |

| Nutrition | injector/carburetor |

| Motor type | in-line petrol |

| Ignition | switchboard |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 2 pcs. DOCH scheme |

| Cylinder block material | cast iron |

| Cylinder diameter | 92 mm |

| Pistons | original |

| Crankshaft | lightweight |

| Piston stroke | 86 mm |

| Fuel | AI-92/A-76 |

| Environmental standards | Euro-3/Euro-0 |

| Fuel consumption | highway – 8.3 l/100 km combined cycle 11.5 l/100 km city – 13.5 l/100 km |

| Oil consumption | maximum 0.3 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 10W30, 10W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for ZMZ 406 by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 6.1 l |

| Operating temperature | 90° |

| ICE resource | declared 150,000 km actual 200,000 km |

| Adjustment of valves | hydraulic pushers |

| Cooling system | forced, antifreeze |

| Coolant volume | 10 l |

| water pump | with plastic impeller |

| Spark plugs for ZMZ 406 | domestic A14DVRM or A14DVR |

| Spark plug gap | 1.1 mm |

| Valve train chain | 70/90 with shoe or 72/92 with sprockets |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | 7 offset holes, 40mm inner diameter |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | Goetze, light intake, dark exhaust |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 38 Nm flywheel – 72 – 80 Nm clutch bolt – 19 – 30 Nm bearing cap – 98 – 108 Nm (main) and 67 – 74 (rod) cylinder head – three stages 40 Nm, 127 – 142 Nm + 90° |

The factory manual contains a more precise description of the parameters:

- ZMZ 4063.10 – carburetor, compression ratio 8 for operation on A-76 fuel, power 110 hp. s., torque 186 Nm, weight 185 kg;

- ZMZ 4061.10 – carburetor, compression ratio 8 for A-76 gasoline, power 100 hp. s., torque 177 Nm, weight 185 kg;

- ZMZ 4062.10 – injector, compression ratio 9.3 for AI-92 fuel, power 145 hp. s., torque 201 Nm, weight 187 kg.

ZMZ 4063.10

ZMZ 4062.10 injector

ZMZ 406 engines for Gazelle

The ZMZ 406 engine was first installed on the Volga car in 1994 as a prototype, and was developed even earlier.

Since that time, the engine has had a huge number of different modifications; it has established itself as a reliable unit with good technical features. The first Gazelles, which went into production in 1994, were first equipped with the well-tested ZMZ 402 engine. This is what the ZMZ 406 engine installed on a Gazelle looks like

But the carburetor internal combustion engine was still rather weak for a one and a half ton truck, and it had another setback - the 402 consumed a lot of fuel, especially under load. Therefore, since 1997, GAZ 3302 cars began to be equipped with a ZMZ 4063 carburetor engine with a volume of 2.3 liters and a power of 110 hp. With.

Fuel consumption – according to factory standards and real

According to technical passport data, fuel consumption at a speed of 60 km/h with the ZMZ 4063 and ZMZ 4061 engines is 10.5 liters, at a speed of 80 km/h – 13 liters. But during control measurements many factors are not taken into account:

- Car load;

- Weather;

- Road conditions;

- Technical condition of the car.

These standards can be met if the car is operated in the summer on a dry road, without a load and in fully working order. Much still depends on driving style. The harder the driver presses the gas, the more fuel is consumed. Gasoline consumption also depends on its quality. It has been noticed that fuel with a higher octane number is consumed less. Therefore, for the Gazelle it is preferable to fill with AI-95 fuel instead of AI-92.

Comparison table for fuel consumption in various modifications of the Gazelle car

Disassembly and assembly of K151D

Main characteristics of the 1.6 engine on Lifan Solano

All repair work on the carburetor unit is carried out in a dry room, on a clean table, where there are no foreign objects (only the necessary tools and devices). When disassembling we remove:

- top cover (held on by seven screws)

- to completely dismantle it, it is also necessary to disconnect the telescopic suction rod;

- then we remove the top gasket, it can be replaced in any case, unscrew the side plug screw, remove the axle, remove the float from the chamber;

- the float must be without external damage and without gasoline inside (to determine this, you need to shake it);

- we remove the needle of the locking mechanism, it can be removed here freely;

- Next, we unscrew the GDS (main dosing system) jets; the fuel jets are located at the bottom, inside the chamber, the air jets are at the top;

- each jet has its own marking, and when replacing them, you need to install strictly in their places those parts that correspond to the parameters;

- Next, we remove the accelerator pump nozzle, the primary/secondary chamber diffusers (we pry them off very carefully, trying not to damage them anywhere, and there are also small gaskets installed there);

- unscrew the four screws of the accelerator pump diaphragm housing; if the diaphragm is not even torn, but has lost elasticity, it is better to replace it immediately;

- turn the case over, unscrew the two screws securing the lower part with the throttle valve, the screws are located almost in the middle;

- between the housings there are two thin and one thick gaskets, it is also advisable to change them immediately;

- All that remains is to unscrew the three screws securing the forced idle economizer housing (EFS), and at this point the main disassembly can be considered complete.

If you need to change the transition system jets, then you should also unscrew the side plugs.

When replacing parts using a repair kit, under no circumstances should the jets be mixed up; they have a certain calibration, and if they are installed incorrectly, the engine will operate unstably and fuel consumption will increase. Two screws in the main body (pictured below) are adjusting (one is the needle of the accelerator pump in the drainage channel, the second is the valve regulator of the same system, there is a ball inside the channel). The side screws located next to the diffusers are the XX air jets (main and additional (second)) and the transition system.

Engines of the ZMZ 406 family on the Gazelle

Design and characteristics of Binar engine preheaters

The ZMZ 406 engine had many advantages over the 402nd internal combustion engine:

- It had good dynamics and power;

- Didn't have any huge problems with oil consumption. At least, oil flowed through the rear main oil seal very rarely, unlike ZMZ 402;

Rear main oil seal on the ZMZ 406 engine

Rarely needed repairs. The main problem with the 406s was the timing chains, which had to be changed every 70-100 thousand km.

At the moment, many owners of old versions of Gazelles with the 402 engine have already replaced the internal combustion engine with a more modern power unit. Moreover, car owners install not only the carburetor version of ZMZ 4063.10. You can also install a more modern ZMZ 405 injector, but additional changes will be required to the electrical part of the car.

List of internal combustion engine modifications

Initially, the engine was designed to be fuel-injected, so version 4062.10 is considered the basic one. The need for carburetor modifications 4061.10 and 4063.10 arose later. They were installed on Gazelle, so while maintaining the volume of the combustion chambers, it was necessary to reduce the owner’s operating costs. To do this, ZMZ management lowered the compression ratio in order to switch the engines to cheaper A-76 fuel.

A reverse modernization was made with motors 4061 and 4063:

- reduced power and torque;

- XX speed became 750 min -1 instead of 800 min -1 ;

- Maximum torque is achieved at 3500 rpm, rather than 4000.

Everything else mounted is located in the same places without changes. Some parts are interchangeable, with the exception of the cylinder head and piston.

Installation of ZMZ 405 instead of UMZ 4216

Engine 1ZZ Engine characteristics

Many Gazelles are still equipped with a 123-horsepower UMZ 4216 internal combustion engine. It’s a shame, but the engine is not reliable, and there are many complaints about it. It often happens that car owners, having suffered with UMP, decide to rearrange the power unit.

First of all, the reliable and proven ZMZ 405 motor is considered as a replacement; various companies offer this replacement service.

It is not difficult to rearrange the motor with your own hands. The replacement scheme and principle are practically no different from the installation scheme of the ZMZ 406 engine instead of the ZMZ 402. Paradoxically, the vaunted Cummins turbodiesels are sometimes removed and the ZMZ 405 is installed instead. Do-it-yourself trimmer repair stihl fs 38. Cummins - in general It’s a good motor, but with Russian diesel fuel its service life before major repairs is significantly reduced.

MZ 405 engine ready for installation on Gazelle

Various commercial services are also offered for replacing Cummins with ZMZ 405. And this means that such work is in demand.

Repairing a diesel engine costs a pretty penny; a 405 engine is much cheaper. Do-it-yourself engine repair ZMZ 406, ZMZ 405, ZMZ 409 in the garage, grind the block, valve seats, chipped valve seats. In addition, many spare parts for the Zavolzhsky motor can be bought used - they sell any spare parts through advertisements on Avito, and there are more than enough offers.

Electronic ignition system

The completely Russian development of electronic filling is now practically unified and different versions of this electronic unit can be installed. It should be noted that the software must be installed taking into account the technical characteristics of a particular engine.

The Gazelle with the 4061.10 engine was designed to operate on 76 gasoline and the 406 engine had a reduced compression ratio; accordingly, firmware was required to ensure stable operation of the engine on this fuel.

Electronic ignition units for power units are not interchangeable with other series of engines. Those. The block for 405 is not suitable for installation on a gazelle equipped with a 406 engine.

The procedure for connecting pipes to the K151D carburetor

The carburetor unit (CU) in the K151D modification is identical in appearance, design and many components to the K151S model, which was installed on ZMZ-402 engines. The device itself is not very complicated, moreover, it is easy to install, but some drivers (car owners) have difficulties connecting the hoses, since there are quite a lot of them.

Let's dwell on this issue in more detail, consider with the help of diagrams (photos) where the pipes are connected, and what each of the fittings is needed for:

- in the first picture: No. 1 – for the main fuel supply hose, No. 2 – for the “return” hose, No. 3 – for the crankcase ventilation pipe, No. 4 – for connecting the solenoid valve (EMV) of the idle speed economizer;

- in the second picture: No. 5 – for connecting to the economizer EMC (second outlet), No. 6 – for connecting to the exhaust gas recirculation valve (exhaust gas).

The first two fittings are the most important, designed to connect the hoses for supplying and discharging excess fuel; they cannot be confused with each other, since the “return” is equipped with a valve, and fuel will not flow through it into the CU from the gas tank, and the engine will not start. Number three connects the pipe for the forced removal of crankcase gases from the engine, which fall under the influence of vacuum into the intake manifold. Since this outlet is located in the lower part of the housing, crankcase gases do not enter the carburetor assembly itself.

Numbers 4 and 5 (they are in different pictures) are outlets with hoses with which the EMC is connected to control the XX (idle) economizer; this valve often breaks (although the fuse may also fail). In addition, it is believed that it does not play a big role, has practically no effect on fuel economy, and it is often turned off by looping the bends together with a tube. You cannot leave the fittings unconnected or turn them off - the engine will stall, operate with significant interruptions, and lose power.

Number 6 is the most “optional” of all the taps, since the recirculation valve only affects the environmental friendliness of the exhaust gases, moreover, this device is not always installed on the car. If desired, fitting No. 6 can be plugged, but it is not at all necessary; if it is left open, nothing will change and will not affect the operation of the internal combustion engine in any way.

VolgaGazelle ZMZ-406 engine tuning

Forcing ZMZ 406

The first option for increasing engine power, according to tradition, is atmospheric, which means we will install shafts. Let's start with the intake, install a cool air intake, a larger volume receiver, saw the cylinder head, modify the combustion chambers, increase the diameter of the channels, grind, install the proper, lightweight T-shaped valves, springs 21083 (for evil variants from BMW), shafts (for example OKB Engine 38/38). There is no point in turning a standard tractor piston, so we buy forged pistons, light connecting rods, a lightweight crankshaft, and balance it. The exhaust is on a 63 mm pipe, direct-flow, and we set it all up online. Output power up to approximately 200 hp. and the character of the engine will receive a pronounced sporty color.

ZMZ-406 Turbo. Compressor

If 200 hp. you want childish fun and want real fire, then supercharging is your way. In order for the motor to withstand high pressure normally, we will install a reinforced forged piston group under low coolant

8, otherwise the configuration is similar to the atmospheric version. Garrett 28 turbine, manifold for it, piping, intercooler, 630cc injectors, 76mm exhaust, DADDTV, tuned in January. At the output we have about 300-350 hp. You can change the injectors to more efficient ones (from 800cc), install a Garrett 35 and blow until the engine falls apart, this way you can blow out 400 or more hp. As for the compressor, everything is similar to turbocharging, but instead of a turbine, manifolds, pipes, intercooler, we install a compressor (for example, an Eaton M90), tune up and go. The power of the compressor options is lower, but the engine is trouble-free and pulls from the bottom.

Motor RATING: 3

Gazelle

Model ZMZ 40524.10 is a gazelle carburetor known to everyone. The car brand “Gazelle” is one of the most popular and affordable trucks in Russia, which were originally intended for transporting not very large loads. Due to the huge number of such machines, we will consider several nuances of different gazelle systems. For example, a microprocessor ignition system, which is installed on the 406 model.

If the driver claims that his car makes some popping noises, jerking noises and loses its power. In this case, the power system, engine and ignition system should be checked. We checked the carburetor with a gas analyzer not during the operation of the 1st and 2nd chambers, cutoff, enrichment and during idling and did not find any violations. Next they check the engine. When checking the compression, no problems were identified, but the next time deviations from the norm were detected. It was concluded that the jerks and pops that the driver did not like were due to the jumping of the teeth of the upper chain.

Carburetor ZMZ 406 series

What to do if a gazelle loses power?

From the very beginning, you need to check how the diagnostic circuit and the on-board diagnostic system function, because when the travel image mode is activated, a malfunction code of 12 should be obtained. To read the code, the 10th and 12th contacts of the diagnostic block must be closed. Using a diagnostic toaster, engine sensor parameters are measured and then compared with typical values for average engines. The most common reason for a decrease in car power is contamination of the tube that connects the intake manifold and the pressure sensor.

Gazelle ignition system

The microprocessor ignition system ignites the working fluid in the cylinders and sets the required vehicle ignition timing for all engine modes. The ignition system performs the function of regulating the operation of the forced idle economizer. Thanks to the ignition system, engine operation becomes more economical, compliance with all exhaust gas toxicity standards is monitored, detonation is eliminated and the vehicle's power is increased. If we compare the classic system with this one, then this ignition system is much more reliable and durable. Here only the spark plugs can wear out.

How does diagnostic mode work?

When the ignition system is turned on, the indicator light begins to light. At that very moment, the diagnostic system begins to work. If the system is working properly, the light stops lighting, but otherwise it continues to light. That is, an extinguished warning light indicates that the ignition system is absolutely working.

Carburetor ZMZ 406 series

Why does the 406 engine sometimes not start during a freeze?

The most common reasons why the 406 engine does not start:

- Poor quality oil;

- The battery is not powerful enough, which prevents the engine from starting;

- Faulty starter;

- Misregulated ignition system;

- Poor quality gasoline;

- Failure to supply gasoline.

How to adjust the carburetor?

- Disconnect the choke actuator cord;

- Remove the air filter and carburetor cap;

- Check the level of the float chamber, it should be below 3 centimeters from the edges;

- Remove the plug from the float rod;

- Make sure the valve seal ring is tight;

- Install the carburetor top;

- Install the choke cable and air filter;

- Screw in the idle speed adjustment screw all the way, unscrewing it five turns. Carry out the same actions with the quality screw, but unscrew it three turns;

- Start the power unit;

- Let it heat up to 90⁰;

- By rotating the operational adjustment screw, select the crankshaft speed, about 700 rpm;

- Press the accelerator pedal and release quickly. If the engine stalls, increase the frequency;

- Stop by a car dealership and adjust the CO and CH of the engine.

Adjustment

Fuel consumption directly depends on the adjustment, even if the carburetor is absolutely working.

There is only one external adjustment in the device - idle speed. How to do it correctly:

- We start the engine and warm it up to a hot state, then perform adjustments at idle speed;

- We unscrew the quantity screw (a large screw with a spring) and the quality screw until the engine reaches maximum speed;

- By evenly tightening both screws, we find the position when the engine starts to work with minimal interruptions;

- Using the quantity screw we set the speed to a slightly higher speed, at this point using the quality screw we achieve stable operation of the motor, but at the same time we need to try to keep the quality screw unscrewed to a minimum (as far as possible);

- Having adjusted the quality, turn the quantity screw until the optimal idle speed is obtained (700-750 rpm).

If there are malfunctions in the carburetor or engine that affect the stability of idle speed, there is no point in adjusting the idle speed - you must first fix the problem.

There are many reasons for unstable operation of the internal combustion engine - from a simply non-functioning spark plug or a piercing high-voltage wire, to a burnt-out exhaust valve or piston.

If you remove the carburetor housing cover, you can adjust the gasoline level in the float chamber. Adjustment is made by bending the tongue on the float.

UMZ engines era 92x92

Of all the engines currently installed on the Gazelle, the Ulyanovsk UMZ421 has the longest life. It is based on the Volga GAZ M-21 engine, which was put on the assembly line back in 1956. Of course, during this time it was modernized several times, but the inter-cylinder distances of the block, the diameters of the main and connecting rod journals still remained unchanged. But by and large: connecting rods, camshaft and crankshaft, oil pan, and the external appearance of the block cannot be confused with any other engine. And it all started in the late 60s and early 70s with the production of “loaves” and “tadpoles” UAZ-451 and UAZ-452, as well as all-terrain vehicles UAZ-469, initially they were equipped with a pure Volgov engine. Due to the loads associated with off-road driving, as well as the considerable mass of the gearbox and transfer case assembled together, the flywheel housing cracked and shattered in half. Several ventilation holes served as stress concentrators, and we learned how to modernize the crankcase on the ZMZ-24 engine. At the same time, instead of coarse and fine oil filters (a “pan” with a cardboard replaceable element connected to the block by frequently torn hoses), a full-flow oil filter from a Zhiguli was installed. This immediately increased the service life of the engine, and this solution turned out to be more successful than even on the ZMZ-24, although further modernization was carried out with an eye on the Zavolzhsky Motor Plant. They weren't competitors then. The crankshaft was changed - the main liners became the same width, and their covers became cast iron, the temperature compensation slot was removed from the piston skirts, a closed crankcase ventilation system was introduced, and the collectors were made “round” in cross-section. The next modernization took place in the late 80s; in the early 90s, the engine received the designation UMZ-417. By this time, in the Volga region they switched to the production of ZMZ-402 engines, and the ZMZ-24 block head went to the Ulyanovsk residents, it became possible to install two-chamber carburetors, and the power increased. We installed an oil pump with increased performance, with a larger gear diameter - the oil pressure became more stable in all modes. Thanks to this, “advanced” repairmen stopped putting a nut under the pressure reducing valve spring, and the motor turned out to be less sensitive to wear in the shaft joints.

All this time, somewhat outdated design solutions and technologies from ZMZ were transferred to the Ulyanovsk motor plant, and it lagged behind in modernization. But on the UMZ-417 engine, Ulyanovsk designers still overtook their mentor colleagues, given the low quality of our rubber products, they moved the front crankshaft oil seal to the outside of the cover.

Carburetor repair K151D

Repair of the K151 carburetor includes disassembly and reassembly, washing and purging, replacement of parts, subsequent adjustment, mainly during repair work the following are replaced:

- jets (both air and fuel);

- sprayer (“spout” or “elephant”) of the accelerator pump;

- gaskets;

- float chamber locking mechanism (needle and seat included);

- quality screw;

- diaphragm.

If there is no need to overhaul the unit, repairs can be made without removing it; for the convenience of buyers, parts are often sold in repair kits.

The fine mesh filter is also replaced; it is located in the housing of the fuel supply and return fittings.

If a carburetor is being overhauled, the entire unit is disassembled to the ground, all channels are washed and blown, including the removal of large and small diffusers.

Fuel system

The engine had two versions, which made it possible to use 76 and 92 gasoline. Due to the transition to international environmental requirements, gasoline with an octane rating of 76 is no longer produced. For normal operation of the engine with index 4061.10, it is necessary to modify it.

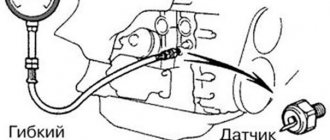

Fuel is supplied by a diaphragm fuel pump driven by the intake camshaft.

Engine 406 - description

The ZMZ 406 internal combustion engine is produced at the Zavolzhsky Motor Plant, which is the main supplier of components for the Gorky Automobile Plant (GAZ). The ZMZ enterprise is also engaged in the manufacture of the 405 model engine. These two engines have become the real pride of the Zavolzhsky plant. In their design and technical data, they differ somewhat from each other. But still, almost every car enthusiast knows their operating principle.

What cars is this engine model installed on?

Most often, the engine of the 406th model was installed on the Volga model 31105, as well as on the well-known Gazelkas. Moreover, since 2003, the Gorky plant has completely updated the technical characteristics of all models of these trucks. From that moment on, the 402 engines completely went out of production and were no longer installed on any modern truck. They were replaced by two new units - ZMZ 406 and ZMZ 405.

406 engine - characteristics and description

This engine model went into mass production back in 1997. But, despite this, GAZ 3302 GAZelle cars until 2003 were equipped with only 402 engines. The new product ran on 92 gasoline. The main detail that distinguishes it from other models is fuel injection, which was first developed by engineers at the Zavolzhsky plant. Over its long period of existence, the engine of the 406th model has gained enormous popularity and has become one of the most common in Russia. It gained such popularity due to its reliable design and economical fuel consumption.

History of creation

When operating the 405 engine, significant shortcomings were noticeable: on hot summer days, the Volga and Gazelle simply overheated and boiled (probably everyone has seen such a phenomenon when there was an empty plastic bottle under the hood of a Gazelle). This indicated flaws in the cooling system. Many drivers installed a three-section radiator in place of the serial two-section one, but still the engine sometimes made itself felt. The engineers of the Zavolzhsky Motor Plant understood that they could not go on like this, and began to develop a new injection engine, the ZMZ 406. It was not developed from scratch - its entire design was reminiscent of the 405 engine. But now all the shortcomings have been taken into account and are not included in the new 406 engine (injector).

What are the changes in these two models?

So, the very first difference of the 406 engine is the presence of an injector. The carburetor had its drawbacks and was unreliable. The power of the new product was 145 horsepower. Working volume – 2.4 liters. The unit has significantly lower fuel consumption and is very easy to start in winter. This engine is also distinguished by its high reliability, which cannot be said about the 405 model. Actually, these are the main advantages because of which many motorists choose the 406 model engine.

Major renovation

Approximately every 200-300 thousand kilometers this engine requires major repairs. This procedure costs much more than repairing ZMZ 402 and 405 (approximately 30-40 thousand rubles). And all because of the complex design of the unit. Therefore, when operating the GAZelle, you should remember that in about 3-4 years it will require significant repair costs.

GC Rosprom - They are also Transport Technologies

Negative sides

IN THIS COMPANY YOU WILL ALWAYS BE GUILTY. If you started doing it without a command, you are guilty of arbitrariness; if you didn’t start, you are guilty of lack of initiative. I got any result - why so few. And you will always PAY - there are fines for everything, they are invented on the fly. If you deviate from the instructions, pay a fine; if the instructions are on your side, they will immediately change them. They can blame you for absolutely everything: a non-working printer (did it work? But now it doesn’t? So you broke it - pay), and leaking antifreeze from the car (did you leave it? And now it’s gone? So you missed it - pay) . You will work 70 hours a week in the office, or drive the steering wheel for six months “while standing” with a constant nervous breakdown and receive 25-30 thousand of your gray salary. The department is pitted against the neighboring department, and within the department - everyone against everyone. The state of a cornered rat is the most highly productive. Dig a hole for someone else, faster than he can dig a hole for you. People here have dirt under their fingernails. The Labor Code is an empty phrase. On Instagram and Vkontakte, of course, they post photos with pranks and team building, but the reality here is spiders in a jar. For more than a year, only scoundrels and opportunists have stayed here, they become heads of departments like Skarzhinsky and Evseev (they are still assholes, they hate each other, despise their subordinates and grovel before HIS Majesty the Fedchenko) At first I thought that Fedchenko was just a tyrant. But no, he calculatedly and deliberately robs his subordinates - this is the competitive advantage of this office. He cold-bloodedly takes your money, creating all the conditions for this. For example: low fuel consumption standards, no standards for autonomous operation at all. At the same time, drivers easily work for 6 months between Perm and Tyumen at a temperature of -25 outside. These pennies of yours make up Fedchenko’s billions. And at this time, Fedchenka, for your money, is vacationing in a distant, warm country in the best hotel. And you freeze your kidneys off on the highway. The main question in this company is who will pay for it? And the only answer is definitely not the owner. If your car breaks down, then the driver, mechanic and logistician pay for downtime and lost profits. The owner of the car still gets his money, whether the car drives or not. Or you came to the office, turned on the computer 1 minute later and get -500 rubles. Tomorrow you turn on a minute later, the fine is no longer 500, but 1000 rubles. Failure to respond to a message on time will result in a fine. and there are a lot of such fines for everything. Needless to say that any fines are illegal from the point of view of the Labor Code? But a “gray” salary allows you to take them off without any questions asked. They pay salaries of 50-60t. , with hand holds you will receive 25-30 tr. + an eye twitching from nerves or frostbitten kidneys (officially you will generally have 6 thousand, i.e. forget about your pension altogether) You can even work at zero or minus - in the summer of 2022 a young guy got a job as a driver, for two months he drove a car with a faulty fuel .. And he complained to everyone, both mechanics and logisticians, but as long as the car didn’t stop. As a result, he worked for two months without days off or downtime, he was deducted for overwork and he still owed the company. This is despite the fact that the car transported cargo for two months and earned money. The driver was left a fool with his bare bottom. And the Fedchenka is in double fat. You can only come here to work if you are 18 years old and you don’t know how to do anything and have no experience at all. After a couple of months, you will develop chronic diseases, understand what the “animal grin of capitalism” is and begin to look for a normal job. And Mr. Fedchenko will earn you extra hundreds of thousands to add to his fortune, repeating Yura Dudya’s phrase “Capitalism! Happiness! ZBS!”

Positive sides

There is none of them

Complain

!

information for company representatives

?

step-by-step instructions for self-checking a company

Clutch gas 3221

The clutch on the car is single-plate, dry, friction, the drive is hydraulic.

Figure 4. Clutch

1 – master cylinder of the clutch release drive; 2 – clutch housing; 3 – flywheel; 4 – friction linings of the driven disk; 5 – pressure disk;

6 – support rings; 7 – pedal spring; 8 – diaphragm spring;

9 – clutch release bearing; 10 – master cylinder rod;

11 – pedal; 12 – gearbox input shaft; 13 – foam rings;

14 – release clutch; 15 – fork ball joint; 16 – casing; 17 – fork;

18 – working cylinder rod; 19 – connecting plate; 20 – working cylinder; 21 – bleeder fitting; 22 – damper spring; 23 – driven disk.

The clutch consists of an aluminum housing, a release clutch with a bearing and a fork, a drive disc assembly (basket), a driven disc, a master and slave cylinders, connected to each other by a hose and tube.

The drive disk (basket) consists of a casing in which a diaphragm spring, support rings and a pressure disk are installed. A spring attached to the casing presses on the pressure disk with its edges.

The driven disk consists of a hub with a splined hole and two disks, one of which has leaf springs riveted to it. Friction linings are attached to them on both sides.

Leaf springs with bends contribute to a better fit of the disc and additionally smooth out jerks in the transmission when the clutch is engaged.

For a smoother transmission of torque when starting the car or changing gears, damper springs are installed in the disk windows.

The driven disk is pressed against the engine flywheel by the pressure plate of the basket. Through friction linings that increase friction, torque is transmitted to the driven disk and then to the input shaft of the gearbox, to which the driven disk is connected by a splined connection.

The clutch release drive is used to temporarily disconnect the engine from the transmission. When you press the clutch pedal, the clutch master cylinder piston moves forward.

The displaced liquid enters the working cylinder through a tube and hose, pushing out a piston with a rod.

The rod acts on the shank of the fork, which rotates on a ball joint, with the other end moving the clutch release clutch along the gearbox bearing cover. The clutch bearing presses on the ends of the diaphragm spring petals. When deformed, the spring ceases to act on the pressure disk, which in turn “releases” the driven one, and the transmission of torque stops.

On the outside, the clutch mechanism is covered with an aluminum housing. The crankcase is attached to the engine cylinder block with six bolts and two reinforcements. On the other side, four studs are screwed into the crankcase to secure the gearbox.

The crankcase has a seat for the clutch slave cylinder and a window for installing the fork. To increase rigidity, a reinforcement is installed on the lower part of the clutch housing.

Replacing a carburetor with an injector on a ZMZ-4063 engine

In order to improve technical characteristics, quite often Gazelle owners replace the carburetor system with an injector, although this pleasure is not cheap. For such a modification it will be necessary to purchase additionally:

- air flow sensor;

- electric fuel pump;

- other wiring for the engine;

- intake manifold (receiver) assembled with dampers;

- air pipes;

- DTOV (ambient temperature) and TPS (throttle position) sensors;

- fuel rail with injectors and fuel pressure regulator;

- the engine control unit;

- front small engine cover;

- both camshafts (differ in cam profile);

- fuel filter;

- air filter housing (“can”) assembled with a filter element;

- idle speed controller.

You may also need various small things, such as gasoline hoses, clamps, fuses, gaskets, fuel filter bracket, etc. The work here is labor-intensive, but the end justifies the means. The advantages of an injector over a carburetor are significant:

- the engine receives a significant increase in power;

- no need to constantly struggle with adjusting and cleaning the carburetor;

- You can install HBO of almost any generation, except the first.

Some injector spare parts are expensive, but it is not necessary to purchase them at the store. Excellent quality used parts can be found at car dismantling yards or through advertisements from private traders, especially since you can almost always bargain. Sometimes, when a brother and sister grow up, they become interested in everything about sex and there are times when they fuck while their parents are not at home. Not every sister can arrange incest with her brother, but there are a lot of such cool videos on our site, so just follow the link and watch how a young bitch sucks her brother and jerks off, and then gives herself to her pussy and ass. Definitely, it is better to buy a used collector (receiver), since it almost never wears out, and there is no point in overpaying here.

Video on repairing the Gazelle ZMZ 406 engine:

Technical differences

Electrical wiring Gazelle 406 under Mikas 7.1

A power unit that has exhausted its service life is replaced, often giving preference to more modern versions.

Structurally, everything fits into the factory seats, and the differences, for example from the Gazelle Business, appear only in the electrical wiring diagram at the location of the equipment:

- Another form of connecting blocks;

- A different diagram for connecting devices;

- Different voltage.

Supply system

Leaving the carburetor in the past, replacing the power unit inevitably entails replacing the power system:

- A new gas tank is installed, since the injector must dump excess fuel back, and the old tank design is not suitable for this;

- The gas line is replaced (the return line is laid + the supply connection is modified);

- The operation of the injectors is regulated using connecting wiring.

Cooling system

The new injection engine ZMZ-406 is more demanding on the cooling system, therefore, during the installation of a new power unit:

- An electric fan is installed on the cooling radiator;

- The engine compartment wiring harness is being replaced.

Fuel injection control system

Mikas control unit, connected in the engine compartment

Do not forget that the power supply system of an injection engine is controlled by an electronic unit, which also needs to be connected to the vehicle’s standard electrical network. Accordingly, the electrical wiring on the Gazelle 406 is different than on older versions of the car with 402 series engines, and must be replaced.

Ways to reduce the amount of fuel consumed

Having considered all the points that in one way or another affect the fuel consumption of the Gazelle 406 carburetor, we should highlight some methods by using which you can reduce the amount of fuel consumed. Necessary:

- adhere to the maximum permissible driving speed;

- in addition to the gasoline engine, install an LPG, which will allow you to alternately use two types of fuel;

- always maintain the car in technically sound condition;

- avoid malfunctions, check all components and parts of the fuel supply system for cracks and breaks;

- check the fuel tank for integrity, prevent leakage of fuel and lubricants;

- carry out tuning of the Gazelle after a certain number of kilometers stated in the technical passport.

Source

General characteristics

The ZMZ 406 engine is carburetor, four-cylinder, and also in-line with a microprocessor ignition system. ZMZ 406 equipped with a carburetor has a power of 110 hp. s., and with an injector - 145 liters. With. In addition, injection modifications have different environmental standards. ZMZ, For example, 4062.10 is class 0, and ZMZ class.10 is 40621 Euro - 2. The 406 oil cooler is considered an extra part in ZMZ, because the 6-engine does not heat up. In the ZMZ 405, the oil radiator does not perform its functions, and the engine naturally overheats in hot weather and does not start.

The cost of gasoline ZMZ carburetor 406 directly depends on the conditions and driving style, as well as the time of year. The ZMZ 406 carburetor ignition system is considered a sufficient engine. Reliably, it will be able to reach speeds of up to 500 thousand kilometers using high-quality oil and also gasoline with careful handling of the pedal.

Project evaluation

Advantages:

simplicity, reliability (with timely maintenance) and high maintainability. Based on it, more powerful ZMZ-405 and ZMZ-409, as well as the ZMZ-514 diesel engine and its modifications were developed.

Flaws:

Problems often arise due to the low quality, complexity and bulkiness of the timing drive and its individual parts (primarily chain tensioners). Unstable quality of casting, processing, as well as the use in the design of obviously unsuccessful solutions in critical components (chain tensioners on the bearing, dismountable block star of the oil pump drive), powder metallurgy technologies, as well as the archaic design of piston rings are the cause of large mechanical losses , high fuel and oil consumption, premature engine failure.

Malfunctions and repairs of the VolgaGazelle ZMZ-406 engine

The ZMZ-406 engine is the successor to the traditional ZMZ-402. a completely new engine (albeit made with an eye on the Saab B-234), in a brand new metal block, with an overhead camshaft, of which there are now two and, accordingly, a 16-valve engine. On the 406th, hydraulic compensators appeared and fussing with constant valve adjustment is no threat to you. The timing drive uses a chain that requires replacement every 100,000 km, but in fact, it lasts more than 200 thousand. and from time to time it doesn’t even reach 100, so every 50 thousand km it is necessary to keep under control the condition of the chain, dampers and hydraulic tensioners; tensioners are usually of very low quality. Despite the fact that the engine is ordinary, without variable valve timing and other modern technologies, for GAZ, this is a big progress in relation to the 402 engine.

Modifications of the ZMZ 406 motor:

1. ZMZ 4061.10 - carburetor engine, SZh 8 for 76 gasoline. Do-it-yourself power steering repair Volkswagen Passat V5 power steering pump repair. Used on Gazelles. 2. ZMZ 4062.10 - injection engine. The main modification is used on Volgas and Gazelles. 3. ZMZ 4063.10 - carburetor engine, SZh 9.3 for 92nd gasoline. Used on Gazelles.

Malfunctions of ZMZ 406 engines

1. DIY Nissan Almera n16 steering rack repair video. Hydraulic timing chain tensioners. It tends to jam, as a result of which the absence of oscillations is not ensured, chain noise appears, followed by the destruction of the boot, the chain jumping, and maybe even its destruction. In this case, ZMZ-406 has an advantage; it does not bend the valve. 2. Overheating of ZMZ-406. A frequent problem, usually the thermostat and a clogged radiator are to blame, check the amount of cooling water again, if everything is in order, then look for air pockets in the cooling system. 3. Highest oil consumption. Usually it's the oil rings and valve seals. The second reason is a labyrinth oil deflector with rubber tubes for oil drainage; if there is a gap between the valve cover and the labyrinth plate, then this is where the oil leaves. The cover is removed, coated with sealant and there are no problems. 4. Thrust failures, uneven idle speed, all these are dying ignition coils. This is not uncommon on the ZMZ-406, change it and the engine will fly. 5. Knock in the engine. Usually in the 406th the hydraulic compensators are knocking and asking for a change; they walk for approximately 50,000 km. If not, then there are a lot of options, from piston pins, to pistons, connecting rod bearings, etc. an autopsy will show. 6. The engine is shaking. Look at spark plugs, coils, measure compression. 7. ZMZ 406 stalls. The problem, in most cases, is in the explosive wires, crankshaft sensor or IAC, inspect.

In addition, the sensors are constantly glitching, the electronics are of poor quality, problems occur with the fuel pump, and in general, the low build quality, characteristic of Russian engines, did not escape the 406 engine. Replace the ignition switch with your own hands, repair the sensor on the Opel Zafira grenade. Despite this, the ZMZ 406 is a huge step forward compared to the ZMZ-402, a mid-50s design, the engine has become more modern, the service life has not gone away and, as before, with adequate maintenance, timely oil changes and a measured driving style, it can exceed 300 thousand km. In 2000, based on the ZMZ-406, the ZMZ-405 engine was developed. and later a 2.7 liter ZMZ-409 appeared, a separate article about it.