When operating a diesel engine, especially one that is already thoroughly worn out, a situation may arise when increased engine oil consumption begins to annoy. These are normal consequences of changes in the geometry of the cylinder-piston group, but a significant contribution is made not only by the penetration of oil into the combustion chambers through problematic rings and increased clearances, but also by its entry along with the air entering through the intake valves.

Breather operating principle

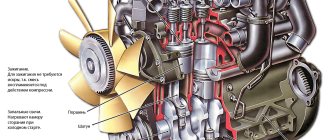

Even in a fully functional engine, the pressure in the crankcase will increase. This happens due to the penetration of part of the working gas through the gap between the piston and the cylinder, sealed by compression and oil scraper rings. This consumption is small and is compensated by the crankcase ventilation system.

The system includes:

- pipelines from the crankcase to the intake manifold;

- check valves that open at slight excess pressure;

- an oil separator that collects oil vapors present in the crankcase gases and sends the liquid back to the crankcase.

For gasoline engines, the system works efficiently due to the significant vacuum in the throttle space. A diesel engine does not have a throttle valve, so it is impossible to use an intake manifold.

Moreover, almost all diesel engines are equipped with a turbocharging unit, so in the intake manifold, instead of vacuum, there is increased pressure created by the turbine.

On the subject: Eliminating air leaks in the intake manifold and other places

There is some vacuum only in the air intake line into the cold part of the turbine. The role of the throttle here is played by the air filter. It is a microporous structure that creates an obstacle to air flow.

A pressure difference is formed; on the back side of the filter it is less than atmospheric pressure, so crankcase gases are relatively efficiently removed from the breather. The minimum consumption is obtained at idle speed, but the amount of gases produced is small, so the system has some balance.

Ventilation system

This is perhaps the most dangerous problem. If in all other cases this was a consequence of a malfunction, then here the problem can lead to serious damage.

A little higher we talked about the “shot” from the breather, this is the consequences of a clogged ventilation. A clogged vent does not relieve pressure

formed in the engine crankcase. At one not very wonderful moment, a sharp release of gases occurs through a blockage in the filter. The tube connecting the breather to the manifold flies out with a sharp bang. This is quite frightening for the driver and the people around him.

And this is the simplest option. There were cases when the gases ruptured the valve cover, broke engine parts, and tore out the pan.

Reasons why the engine is breathing

Malfunctions leading to an increase in crankcase pressure above the calculated value are associated with an increase in gas flow through the pistons and rings.

It could be:

- heavily worn surface of the cylinders, formation of geometry distortions such as “ellipse” and “barrel”;

- wear and breakage of piston rings;

- incorrect orientation of ring gaps;

- destruction, burnouts and cracks in the pistons.

In addition to normal wear and tear, such violations may be associated with malfunctions in the power supply, cooling or air filtration systems.

Oil injectors, which cool the pistons and supply additional oil to the cylinder walls, also often fail.

VKG system (crankcase ventilation)

Ventilation has a finite performance. Excess gases overload the channels, the VCG system cannot cope. The pressure in the crankcase increases. This may be due not only to external reasons, but also to problems in the VKG itself. Its channels can be clogged with deposits, the valve becomes clogged, and the tightness of the pipes is compromised.

An additional problem may be an increase in pressure so much that the normal oil supply to the turbocharging unit is disrupted.

The connection between ventilation performance and the turbine is not obvious, but the consequences can be costly. The turbine shaft rotates in bushings, which receive oil under pressure.

It flows freely back into the crankcase through the drain pipe. But if the pressure in the crankcase is high, it begins to interfere with oil circulation through the turbine bearings. The bushings overheat and the turbine fails.

Piston rings

The rings work normally only when they are not worn out, and there is a hone on the surface of the cylinder walls that holds the oil necessary to lubricate the rings.

After a significant mileage, operating conditions are violated, the rings no longer tightly block the path of gases, and the pressure in the crankcase begins to increase. The VKG system ceases to cope with all the consequences.

The process has a self-developing, avalanche character. Excess oil and temperature causes coking and loss of ring mobility. The compression seals stop sealing, and the oil scraper seals lie down and open the way for ever new portions of oil.

The situation is aggravated by intakes from the turbine. The engine may even go haywire by running on oil instead of diesel. even one defective cylinder is enough to trigger this destructive process.

KamAZ engine vibration

Engine vibration on KamAZ is caused by the following malfunctions:

- Crankshaft imbalance: Vibrations are usually observed after installing a new crankshaft. Rarely does vibration occur due to a broken crankshaft.

- Engine Trouble: Vibration is usually caused by a faulty cylinder or several of them. This often occurs due to an incorrectly secured motor.

- Unqualified repairs: unreliable installation of parts provokes their mobility, which causes vibration during engine operation.

How to troubleshoot

If the measurements show a significantly increased pressure, the permissible value of which is indicated in the diagnostic information for a given engine, as well as the method for measuring it, then the engine is subject to diagnostics and subsequent repair.

As a rule, this is a major intervention with the replacement of pistons, rings, boring the cylinders to repair size, checking and replacing all defective and worn parts. Sometimes cleaning the crankcase ventilation system and decarbonizing the rings temporarily helps.

The condition of the cylinder walls can be assessed using an endoscope inserted through the injector holes. You can examine the remains of the hone, the presence of burrs and scratches from broken rings, as well as the condition of the piston bottom.

Measuring compression with a pressure gauge is usually useless due to the large amount of oil in the gap between the piston and cylinder (oil compression).

What it is?

Why is the engine breathing? The causes and consequences of the problem can be varied. First you need to determine the symptoms of this malfunction.

Sometimes you can see smoke similar to exhaust escaping from all the open openings of the engine. This can happen through the air filter, through the oil filler neck, and so on. Usually at the same time there is an increase in oil consumption. This is what is called - the engine is breathing. These are the main symptoms. Sometimes it shoots out of the hole so that the hood lid opens. This occurs when there is a sudden disruption of crankcase ventilation.

What not to do

There are “folk” methods of dealing with high pressure in the crankcase. In one way or another, the breather hose is vented into the atmosphere, thereby reducing the pressure. Such methods are ineffective and dangerous.

If the engine is already running unevenly across the cylinders, then its further operation will lead not only to oil losses comparable to fuel consumption, but also to major breakdowns, overheating and even fires.

Also, decarbonization does not always help. More often it will simply lead to a loss of time and money. Rings that are worn out and have lost mobility are unlikely to be returned to normal operation; they will become stuck again soon after the procedure.

And chemically active substances, once in the engine, will disrupt the operation of the seals and lubrication system, which will lead to wear of the sliding bearings, overheating and scuffing.

Symptoms

The first, main symptoms that a diesel engine has begun to breathe are lubricant leaks and a decrease in the oil level in the crankcase. Having noticed such characteristic phenomena, it is necessary to make sure that the suspicions are correct. To do this, you need to warm up the engine to operating temperature, unscrew the oil filler cap and check for bluish smoke.

If suspicions are confirmed and smoke is present, the diagnosis is obvious. Let's try to figure out why the diesel engine is breathing and how to fix it.

Signs of wear on valve stem seals

The engines of modern cars have many very small parts in their design, but very important for its proper functioning. If it is not discovered in time that they have become unusable and appropriate measures are not taken, then the consequences of this for the power unit, and, accordingly, the budget and nerves of the car enthusiast can be the saddest. These “little things” include valve stem seals.

They are part of the design of the gas distribution mechanism (GRM) of the internal combustion engine of a car. Their dimensions are quite small and they are not located in plain sight, but inside the engine.

As you can understand, this article will be devoted to valve stem seals. Here you will learn why valve stem seals are needed and what are the signs of their wear.

What are valve stem seals?

Valve and oil seals.

Oil seals are required in engines to prevent oil and small debris from entering the combustion chambers. They are often called valve seals, and this name fully reflects the role they perform.

The valve stem seals are located directly on the valve stems and consist of three main parts:

- Base;

- The actual cap;

- Spring.

The base is a sleeve made of steel. It plays the role of the frame of this part and gives it the necessary strength. The cap itself is the main element of the part. It is made of special rubber that is resistant to high temperatures and friction. The cap is installed inside the sleeve, and when mounted on the valve, it fits tightly around the stem and removes oil. And the spring is mounted in a special annular recess of the cap and ensures its tightest fit to the stem.

As for the oil that these caps must remove, it is supplied to the gas distribution mechanism by an oil pump. It is designed to lubricate timing parts that experience friction and increase their service life. At the same time, its penetration into the cylinders through the valve groups is extremely undesirable, since, when burned, it forms carbon deposits that accumulate on their walls.

It should be noted that in modern internal combustion engines, valve stem seals have to function under rather harsh conditions of high temperatures and increased mechanical loads. In addition, they are negatively affected by substances contained in the lubricant being removed. Therefore, manufacturers of valve stem seals use the most durable materials that are resistant to friction, thermal and chemical influences for their manufacture.

Wear of valve stem seals

Like any other part of an internal combustion engine, which regularly experiences a combination of negative influences of various kinds, valve stem seals gradually but steadily wear out. Their most loaded rubber part loses elasticity over time and cracks appear in it. In addition, over time and under the influence of high temperatures, the clamping force of the spring inevitably weakens. As a result, wear of the valve stem seals leads to the fact that oil is not removed from the valve stems and it enters the combustion chamber of the internal combustion engine.

As practice shows, the service life of valve stem seals installed in modern internal combustion engines is approximately 100,000 kilometers. After the car has traveled this distance, they must be replaced. Experts also recommend changing valve stem seals in car engines that have been out of service for a long time.

In addition, it often happens that valve stem seals wear out prematurely for one reason or another. In such cases, they, of course, also require replacement with new ones. Several characteristic signs indicate that the time for this kind of engine repair has come.

Signs of wear

The following signs may indicate wear of the valve stem seals:

- Significantly increased oil consumption;

- The appearance of carbon deposits on the electrodes of the spark plugs;

- The appearance of blue exhaust gases when the engine warms up.

The increase in the engine’s “oil appetite” when the valve stem seals wear out is quite logical and understandable. The fact is that the lubricant that is not removed from the valve stems gets into the cylinders and burns. Accordingly, it is irretrievably lost from the lubrication system of the power unit, and oil has to be added more often than usual.

As the oil burns, the blue-colored combustion products come out, coloring the exhaust gases the corresponding color. When the engine warms up, the oil burns almost completely, so the blue smoke disappears.