- Design

- Tension

- Dismantling and replacement

The VAZ 2114 car has good performance, reliability and maintainability.

But this does not allow you to completely insure yourself against possible breakdowns. Considering the state of domestic roads, it is not surprising that most often car owners turn to service stations with problems in the braking system or suspension.

A striking example of a breakdown is problems with the handbrake. More precisely, with cables that are responsible for blocking the rear wheels and do not allow the car to move until the handbrake is returned to its original position.

Whether you use a handbrake or not, sooner or later you will need to use the system. And if the handbrake has to survive regularly, then there is no debate at all regarding the need to urgently solve the problem.

Design

Many people mistakenly believe that the handbrake is a simple lever located near the gearbox, on the right hand of the driver. In fact, it is a whole system of elements that are connected to each other.

When the hand brake fails, in 90% of cases the culprit is a cable or a pair of cables that go to the rear brake pads from the equalizer.

To determine the reasons for the failure of the handbrake, it is necessary to understand the circuit diagram of the device and its components.

The device includes a number of structural elements. Namely:

- Lever arm;

- Traction;

- Springs;

- Lever button;

- Main cable axis;

- Bolts;

- Washers;

- Drive unit;

- Equalizer;

- Case;

- Locknuts;

- Cotter pins;

- Right and left lever;

- Expansion left and right strip;

- Lock washer, etc.

System elements

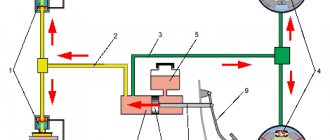

The hydraulic brake drive of the VAZ 2114, 2115 will include the following components:

- brake mechanism from the front right wheel;

- pipeline from the brake circuit, front left-rear right;

- a pair diagonal to them;

- hydraulic main cylinder;

- tank from it;

- vacuum booster;

- brake mechanism for rear wheels;

- elastic lever that regulates pressure;

- pressure regulator;

- a simple lever to drive the pressure regulator;

- pedal;

- hoses for front and rear brakes.

Tension

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.

To check the operation of the handbrake, it is enough to perform one simple action. Place the car on a level surface, apply the handbrake, get out of the car and try to push it hard. If movement begins, the cable is dead and needs urgent replacement.

Dismantling and replacement

It is difficult to confuse the cable from the handbrake with anything else under the bottom of your VAZ 2114, which greatly simplifies the repair and replacement procedure.

We provide detailed instructions for replacement, and additionally recommend watching the video.

- We advise you to get the car in order in terms of cleanliness in advance. This will make it easier for you to find all the nuts and fasteners.

- Additionally, treat the nuts with the almighty WD40. This will make it much easier for you to unscrew the sometimes sticking and rusting nuts.

- Place the handbrake lever all the way down.

- Start with the adjusting nut and locknut that you used recently to try to tighten a loose cable. In this situation, you should loosen the nuts and remove them from the handbrake rod.

- Remove the washers and cable equalizer. Although this can be done after you jack up the car. But be sure to do it before removing the wheels.

- Raise the rear of the car with a jack, unscrew the wheel bolts and remove them.

- Tap the brake drum locking pins. This will allow them to be removed from the brake pads.

- Remove the block.

- You now need to disconnect the ends of the two cables from the equalizer. The fasteners can be removed from their places with the simplest pliers, so don’t bother.

- The shifted spacer lever has hooks from which the cable loop can be removed.

- The cable sheath must be removed from the entire suspension of the rear of the car. To do this, the mounting bolts are first unscrewed.

- Pull the cable out of the holes through the brake flaps.

- We got rid of the old cable, so all that remains is to replace the old one with a new element. The procedure is performed exactly in reverse order.

- Thread the new cables through the washers and hook the loops. You can additionally make bosses - this is a special clamp that allows you to fix the cable even more tightly.

- Reassemble the entire disassembled wheel structure.

- Route the cable along the suspension through the sheath and secure the bolts.

- Pull the handbrake in the cabin.

- Check the correct tension and operation of the new hand brake, or rather the cable.

Replacing the handbrake for Lada 21124 (VAZ 21124)

If the cable removed from the car is difficult to move in the casing, lubricate it, pour transmission or engine oil into the casing until it begins to flow out from the opposite end of the casing.

During the pouring process, periodically move the cable in the sheath. Install the cable with an assistant: the lever pull is short, therefore, to install the equalizer, you need to pull the cable tightly. Replace the cable if the following malfunctions occur: - the cable tips are loose; - the cable threads begin to tear; - the cable moves heavily in the sheath even after it has been lubricated.

When is cable drive repair needed?

While operating the vehicle, it is important to determine the moment when replacing the handbrake cable becomes absolutely necessary. When stopped by a traffic police inspector, the defect is equated to a technical malfunction and is punishable by a fine. A simple check of the functionality of the handbrake is to park the car on a slope with the brake applied. If the car rolls, it's time to start repairing it.

The main symptoms of problems with the cable mechanism are as follows:

- Excessive heating of brake drums.

- Lack of response when tensioning the cable transmission.

- Worn cable sheath.

- The tension adjustment of the mechanism is broken.

If the last point can be solved with a simple adjustment, then other manifestations of the malfunction require drastic methods. In this case, you need to understand the reasons for the situation:

- cable breakage or stretching;

- moisture entering the shell, especially in winter;

- souring of the cable inside the sheath due to insufficient lubricant.

Sometimes you can do without replacing the cable or other elements of the handbrake - just restore the lubrication. Practice shows that such a procedure, carried out once a year, significantly increases the service life of parts.

Preparatory activities

replacing the cable Novice VAZ 2114 drivers usually do not risk starting to repair the cable unit on their own, preferring the services of auto repair shops, and, it must be said, in vain. Finding the handbrake drive under the bottom of the car is not difficult, and with minimal skills and a small set of tools, the issue will be resolved within 3-4 hours. For repair you will need:

- Overpass or inspection hole.

- Open-end wrench set to "10".

- Two keys for "13".

- Pliers.

- Plastic clamps.

- Large flathead screwdriver.

- WD-40 lubricant.

To make your work more comfortable, you should clean the bottom of the car from dirt and lubricate all threaded units with WD-40.

The procedure for replacing a faulty handbrake cable on a VAZ 2114

Having placed the car on an overpass or inspection hole, you need to release the handbrake lever all the way and secure the wheels with shoes. It won't hurt to dismantle the muffler can - this will make the work much easier. The process then proceeds as follows:

- Unscrew the adjusting and locking nut using keys “13” and remove them from the rod.

- Loosen the wheel bolts with a wheel wrench, jack up the rear of the car and remove the rear wheels.

- Using a hammer and a wooden extension or long bolts, remove the brake drums and knock out the locking pins.

- Remove the brake pads.

- Disconnect the cable ends from the equalizer and remove the clamps using pliers.

- Before replacing faulty handbrake cables, the loops of both cables must be removed from the spacer lever.

- After unscrewing the fastening bolt, remove the cable sheath from the rear suspension.

- Pull the cable mechanism out of the holes in the brake flaps.

- Install the new element in the reverse order, first pulling it through the washers and loops on the hooks of the lever.

If the device shell is damaged, it must be replaced. Since the design of the parking brake on the VAZ 2114 involves the use of two cables, regardless of their condition, both need to be changed.

It happens that fastening parts become corroded and are no longer suitable for further use. In this case, the use of plastic clamps as clamps is justified. All that remains is to check the functionality of the system by setting the car on an incline and tightening the handbrake. If it rolls, then you need to adjust the tension of the cable mechanism.

Features of pedal settings

The driver controls this entire complex assembly using a single pedal. That is why it is very important to monitor the condition of these mechanisms and correct errors in a timely manner. It is necessary to pay attention to the following features:

- Each owner of this vehicle must remember that when the engine is not running, the pedal must have free play. The adjustment can be made with the vehicle turned off. This can be done by moving the brake light switch and lowering its nuts.

- When the switch at the brake light is very close to the pedal itself, this risks the fact that it will not return to its original state. But even here there is a possibility of only partial release of the wheels when the pedal is released.

- When it was not possible to correct errors using a brake light and eliminate incomplete release of the brakes, you can simply disconnect the master cylinder at the brake drive and double-check that the adjusting bolt is not too far from the plane to which the flange of this cylinder is attached (the difference can be from 0.2 to 0.25 mm). This size will be optimal for adjusting the pedal.

Adjusting the parking brake on a VAZ 2114

Incorrect adjustment is reflected not only in unsatisfactory vehicle holding. A characteristic creaking noise coming from the rear wheel area indicates that the cable is too tight. Setting up the handbrake is quite simple:

- Remove the muffler from the special mountings.

- Unscrew the locknut securing the cable mechanism.

- Depending on the situation, loosen or tighten the nut.

- After checking, tighten the locknut.

The optimal stroke of the handbrake drive lever after replacing the cable is considered to be 2-4 clicks until it is completely locked. If the result is not achieved, then you need to repeat the setup procedure.

Functionality check

After replacing the cable, check its operation.

- Place the car on a hill and turn on the handbrake. If the car starts to roll, the new cable needs adjustment.

- Loosen the parking brake lock nut in the handbrake, tighten the adjusting nut, and then pull the cable using the lever.

- The optimal lever stroke should include 2-4 strokes. If this happens, tighten the locknut and check it again.

- We drive up a hill and turn on the handbrake. Now the car should definitely stand still. Unless the cable turned out to be fake or an error was made during the assembly stage.

Disassembled handbrake

Before frost, it is recommended to lubricate the parking cable, which will significantly extend its service life. Under the influence of negative temperatures, the cable breaks down faster. The tips, axle and rod of the equalizer should be lubricated.

Tightening and replacing the handbrake cable is not a difficult task. Even if you don't have a lot of experience working on cars, you will be able to do this job.

But if you are not confident in your own abilities or simply do not have time to do such things on your own, contact a service station. A lift will cost about 500-700 rubles, but for a replacement they will ask for at least 1,500 rubles

Didn't find the information you are looking for? on our forum.

conclusions

High-quality repair of the brake system is possible not only in a car service center, but also in your own garage. This is not only financial savings, but also an understanding of one’s own importance, which novice car enthusiasts so lack.

The fact of taking preventive measures is important. In the pre-winter period, it is recommended to lubricate the cables, which extends their service life and optimizes the operation of the entire system. The axles, tips and rod of the equalizer are also treated with lubricant. Periodic inspection and adjustment will ensure the safety of not only the driver and passengers, but also other road users.

VAZ 2114 parking brake cable - it is with its help that we interact with the rear wheel brakes (brake drums). Another name for the handbrake is the parking brake. Many people think that they can live well without it, they say, who even puts the handbrake on their feet these days? But don’t forget that the fourteenth is a manual transmission, with our downhill traffic jams the handbrake is very useful, and also, in the parking lot, the chance of the car being stolen is sharply reduced, plus you can take turns in the winter effectively! Anyone who has ever jacked up a car themselves knows about the need to put the handbrake on. If you come up with a hand brake for your car, it should work properly. But it doesn't always work.

Hint of replacement

Elementary wear of a part - the handbrake cable may rust, break or become loose so that it cannot be tightened - this is the most common reason for replacement. The two rear wheels seem to hint that the parking brake is connected to the wheels in the form of two cables. Almost always one of the cables fails. This does not mean that one needs to be changed. Buy a set and change both. The price for a VAZ 2114 parking brake cable varies from 200 to 1000 rubles (depending on the manufacturer and place of purchase). Otherwise, the cable that turns out to be older will definitely fly in the near future, and you will simply pay double the price.

Symptoms of a cable failure are usually as follows:

- The handbrake does not hold the required traction

- brake drums get hot

- when pulling the handbrake, the cable may not respond to the action

- the cable sheath is worn out

It’s easy to check if something is wrong with the cable: put the car on the handbrake, get out of it and try to give it a good push – it will roll a little if the cable is dead.

How do they work?

The operation scheme is trivial and simple - there is a handle that connects to a cable, which, in turn, is in a special braid (that is, the cable flows through it).

Next, this wire hooks onto a special adjusting screw (it can be tightened and unscrewed), which connects to a rail, along the edges of which there are two wires going to the two rear wheels. These cables (going to the wheels) are in a mesh with a special bracket; it is he who unfastens the blocks and blocks the drums. Simply put, when we move the lever up (raise the handbrake), the cable stretches and pulls two separate cables towards the wheels. Inside the drums, brackets push apart the rear blocks, which block the wheels.

How to remove the handbrake cable on the fourteenth?

Before changing the handbrake cable on a VAZ 2114, it must be removed. Fortunately, it is clearly visible and cannot be confused with anything. You need to work in a hole or on an overpass under the bottom of the car. It’s good if the car is clean, because all the nuts and fasteners need to be found and unscrewed (you can also spray them with WD for a smooth fastening movement); dirty ones will take longer to work with. Before replacing, move the handbrake all the way down.

- We start with the locknut and the adjusting nut, loosen them and remove them from the handbrake rod (now you can remove the washers and cable leveler, or you can do this after jacking up the car, before removing the wheels).

- Jack up the rear of the car, unscrew the wheel bolts and remove the wheels.

- To remove the brake drums, tap the locking pins to dislodge them from the shoes.

- Remove the brake pad.

- We disconnect the tip of the first and second cables from the equalizer (the clamps can be removed with simple pliers).

- Remove the cable loop from the hook of the shifted spacer lever of each wheel.

- We remove the cable sheath from the entire rear suspension, having first unscrewed the fastening bolt.

- Pull the cable out of the holes in the brake flaps.

Replacing the VAZ 2114 parking brake cable is the same as removing it, only in reverse order. We start by threading the new cables into the washers, attaching the loops (many people make special clamps at the end of the loop - bosses - so that the cable sits even more tightly in place), and assembling the entire wheel hub. They laid each cable along the suspension and secured it. In the end, you will need to tighten the handbrake in the cabin itself.

By the way, the parking brake is the cause of the unpleasant squeaking sound in the rear of the cabin. Replacing the VAZ 2114 parking brake cable is a good reason to get rid of it for one thing: you should come up with a rubber seal for attaching the cable to the body frames.

After replacing the old cable with a new one, we check how it works. Just put your fourteenth on the hill on the handbrake, if it moves, you need to adjust it:

- We loosen the lock nut of the tension device in the handbrake, and tighten the adjusting nut, then pull the cable with a lever.

- The lever should move 2-4 strokes (this is the working stroke of the handbrake), if it works, tighten the lock nut.

- We drive up the hill again, put the handbrake on, check how it holds.

Before frost, you should always remove and lubricate the handbrake cable; you will increase its service life, protecting it from the adverse effects of low temperatures. Thus, you will ensure stable operation of the entire brake system of the car. It is worth lubricating the axle itself, the tips and the equalizer rod.

One more point: the handbrake cable does not always need to be changed, excluding, of course, an obvious rupture or wear of the mechanism. Most often it just needs to be tightened. And your handbrake will be back to normal. Tightening also means that the cable gradually becomes unusable, and it will soon have to be replaced with a new one. Also, the brake pads may be acting up. Very often, especially after tightening, drivers sin on the handbrake cable, buy a new one, change it, but there is zero effect. Look at the pads, they also tend to run out.

To remove the handbrake lever (handbrake handle), we need an inspection hole or overpass. You can also get by with a jack, or put the car on the curb.

Cable faults

- Over time, the cable stretches. Doesn't hold the car even after being pulled up.

- The cable threads begin to break.

- The cable itself broke.

- Even after lubrication, the cable has difficulty moving in the sheath.

- The cable becomes sour.

The parking brake can often be restored to normal function by lubricating the cable. If you carry out this procedure regularly once a year (usually this is done before frost), then you can forget about situations when the handbrake fails.

The cable will last longer as it will be well protected from freezing. The brake system will work stably. You need to lubricate the axle, equalizer rod and tips.

Please note that there are two cables going to the wheels; it is recommended to replace them at the same time. Otherwise, the old one will fail earlier and you will have to do double work, which we will discuss below.

Why change

- If you notice problems with the handbrake but continue to use it, you may be in for an unpleasant surprise when the car suddenly rolls downhill.

- It is also possible that the pads will not return to their original position. This already threatens to heat up the brake discs and wear out the pads. As a result, the wheel may jam. The effect will be the same as driving with a handbrake.

Rope price

The cable itself costs from 200 to 1000 rubles. The price depends on the manufacturer and place of purchase. Replacement at a car service center will cost on average from 400 to 1000 rubles, depending on the region.

Replacement

It is not difficult to independently replace the VAZ-2114 parking brake cable.

To replace you need the following tool:

- key to “10”;

- two keys to “13”;

- a large screwdriver and WD-40 for smooth fastening.

Replacement is carried out on an inspection hole or overpass.

- The handbrake must be lowered all the way down.

- All parking brake nuts need to be cleaned. Don't forget about the leveling bar.

- The locknut must be loosened and removed from the rod. The same is done with the adjusting nut.

- Now they begin to remove the wheels. First loosen the wheel bolts. The rear part is lifted with a jack. Don't forget about the supports! Once they are aligned, you can remove the rear wheels.

- Remove the brake drums using a hammer and a wooden spacer. You need to knock the locking pins off the pads.

- The end of the parking brake cable of a VAZ-2114 car is attached to the rear brake shoe lever. First you need to remove the block, and then the cable end.

- Unscrew the fastening bolt and disconnect the cable sheath.

- A cable is pulled out from the holes in the brake flaps on each side.

- Then they take out the cable sheath from the fastenings on the body.

Bottom line

The cable has been removed. You can replace or lubricate the parking brake cable. Installing a new one is done in reverse order. Afterwards the tension of the handbrake is adjusted.

How to remove the handbrake handle?

- Before you start removing the parking brake handle, be sure to put the car in gear.

- We remove the cable equalizer from the adjusting rod (How to remove the equalizer, see here: How to replace the parking brake cable?

- Remove the rubber protective cover from the adjusting rod. A slotted screwdriver will help us with this.

- Then remove the decorative trim of the floor tunnel.

- Take a Phillips screwdriver and unscrew the self-tapping screw of the front mounting of the parking brake switch bracket.

- Using a 10mm socket wrench, unscrew the last 2 bolts securing the bracket.

- We take out the lever along with the bracket and the adjusting rod.

Operating principle

The brake in the VAZ 2114 will work on the hydraulic principle: when pressed, the liquid pressure will increase and the brake mechanisms will operate. As a result, the wheels begin to rotate more slowly and force appears at the point of contact of the tire with the road surface. And the harder the pedal is pressed, the faster the process will go. The forced-up pressure in this case will reach from 10 to 15 MPa. It will also increase in the drive itself: this will move the pads to the wheel rims.

How to install the handbrake lever?

We install the lever step by step, reverse the disassembly process. Do not forget to apply grease to the threads of the adjusting rod. Litol will do. After this, install the equalizer, the adjusting nut and the control nut. Adjusting the handbrake: How to tighten the handbrake?

The VAZ 2114 car has good performance, reliability and maintainability. But this does not allow you to completely insure yourself against possible breakdowns.

Considering the state of domestic roads, it is not surprising that most often car owners turn to service stations with problems in the braking system or suspension.

A striking example of a breakdown is problems with the handbrake. More precisely, with cables that are responsible for blocking the rear wheels and do not allow the car to move until the handbrake is returned to its original position.

Whether you use a handbrake or not, sooner or later you will need to use the system. And if the handbrake has to survive regularly, then there is no debate at all regarding the need to urgently solve the problem.

Handbrake cable

Features of work

Both the VAZ 2114 and the AZ 2115 models use a braking system that has diagonal separation of circuits. Each of them is responsible for their own area of work: one is responsible for the activities of diagonal systems.

In the event that one of the circuits fails, the other is designed to ensure effective stopping of the vehicle. It should also be noted here that the parking brake system of the VAZ 2113, 2114, 2115 will be driven by mechanisms for the rear wheels.

Design

Many people mistakenly believe that the handbrake is a simple lever located near the gearbox, on the right hand of the driver. In fact, it is a whole system of elements that are connected to each other.

When the hand brake fails, in 90% of cases the culprit is a cable or a pair of cables that go to the rear brake pads from the equalizer.

To determine the reasons for the failure of the handbrake, it is necessary to understand the circuit diagram of the device and its components.

Handbrake diagram

The device includes a number of structural elements. Namely:

- Lever arm;

- Traction;

- Springs;

- Lever button;

- Main cable axis;

- Bolts;

- Washers;

- Drive unit;

- Equalizer;

- Case;

- Locknuts;

- Cotter pins;

- Right and left lever;

- Expansion left and right strip;

- Lock washer, etc.

BRAKE SYSTEM DEVICE

Like any other mechanism in your car, the brake system consists of several elements that work together. The VAZ brake system is no exception. It is much simpler both in structure and functionality than in popular foreign cars, but it also deserves attention.

Its main elements are:

- Front wheel brake structures;

- Pipelines (both sides);

- Hydraulic drive main cylinder;

- Tank;

- An amplifier that has a vacuum structure;

- Braking mechanisms located on the rear wheels;

- Two pressure control levers;

- The hydraulic system also has a regulator that controls the pressure;

- Pedal;

- Hoses made of flexible material.

The system is designed so that if one of the circuits fails, the second will provide safe braking. This is done in order to make driving as safe as possible. The brake system of the VAZ 2115 works on the same principle.

The hand brake consists of:

- Lever with locking button;

- Cable in a protective sheath;

- Adjustment nuts;

- Equalizer;

- Locknuts;

- Protective cover.

The weak point of the handbrake is the cable . It requires constant attention. Its stretching or rupture can lead to disastrous consequences. It is also worth remembering that the pads are constantly worn out (especially with active use). It is important to pay attention to the brake force regulator of the VAZ 2113.

Diagram of the brake system of a front-wheel drive VAZ car (device)

These are the elements that make up the brake system of the VAZ 2114. Everything is quite simple, both in repair and in preventive maintenance. Any adjustments are also made without much effort. For example, you can adjust the handbrake in half an hour yourself, and adjusting the brake pressure regulator of the VAZ 2114 will not cause stupor even for a beginner. These are the key features of the domestic automobile industry - everything is easy and simple.

Tension

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

Stage

Explanation

Spin the wheels after tensioning is completed

The wheels are lifted one by one on a jack. When the handbrake lever is turned off, they should rotate freely without obstacles. By squeezing the brake, the wheels should lock.

Drive up a slight slope, stop and engage the handbrake

The fact that the wheels do not spin when suspended is good. But you need to make sure that the handbrake holds the car even when exposed to gravity.

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.

The handbrake doesn't hold

The article and the presented videos are devoted to adjusting the handbrake, but in some cases the handbrake does not hold due to worn brake pads or the absence of a cable. If the handbrake has not worked since you purchased the vehicle, before making adjustments, make sure that the cable has not been broken due to normal wear or loose fitting.

Drum brakes

The easiest way to adjust the handbrake is on a drum brake system. Schematic representation of the VAZ 2113-15 hand brake device.

Raising the handbrake lever moves the rod (5), from which cable contours go to each of the wheels under the bottom of the car. Passing through the brake shield, the cables are connected to the levers of the manual drive of the pads. When the handbrake is raised, the cable acts on the lever (13), the upper part of which is fixed to the axis (12). As a result, the force created by the lever is uniformly transmitted through the expansion bar to the brake pads, pressing them against the drums.

In some types of construction, a combination of rods is used instead of cables, but it is the device described above that can be found on all modern cars with rear drum brakes.

How to tighten the cable

The essence of the adjustment is to move the cable equalizer along the rod towards the front of the car. Depending on the design of the car, the adjustment mechanism can be located in the cabin or under the bottom, as is the case with VAZ 2115,2114,2113,2199,2109,2108, Opel Astra F and many other cars.

To access the adjustment mechanism located in the cabin, there is often a special hatch in the central tunnel. In our case, the process is described and shown in the video using the example of a car, where the adjustment is carried out under the bottom, so the car must first be driven onto an overpass or inspection hole. Instructions that will allow you to tighten the cable if the handbrake does not hold.

- Use a wire brush to clean the threads of the adjusting rod.

- Loosen the locknut. In order to stiffen the structure when unscrewing and tightening it back after adjustment, you will need 2 keys - with one you need to hold the adjusting nut while unscrewing, and with the second you need to unscrew the lock nut.

- Move the position of the adjusting nut by tightening it the required number of turns.

- Once adjustment is complete, tighten the lock nut until it is pressed firmly against the adjusting nut.

What degree of tension is considered correct?

In the case of technical inspection, which is not carried out on civilian vehicles in the Russian Federation, the effectiveness of the hand brake is checked in two ways:

- a vehicle with a full curb weight must be securely secured with a handbrake on a slope of 16º or 25º, depending on current requirements;

- The effect of the handbrake is checked on special drums. In this case, not only the braking force is measured, but also the uniformity of its distribution between the rear wheels.

Traditional methods

When adjusting the parking brake yourself, you can estimate the tension of the handbrake cable in two ways:

- by the number of clicks. In this case, it is worth looking for information on a specific car model, since, for example, for a Daewoo Matiz the norm will be 7 clicks, and for a VAZ 2106 – 2-4 clicks. The only drawback of the adjustment is that sometimes after replacing the brake drums, pads, and observing the average value for the number of clicks, even with the handbrake lowered, the brake pads can be pressed too hard against the drums. Therefore, after servicing the rear drum brakes, the degree of tension should differ from the average requirements, but after grinding in, the handbrake will need to be tightened;

- according to the degree of pressing of the friction linings. To adjust the handbrake, the rear wheels will need to be lifted. The cable must be tightened to such a state that when the parking brake lever is lowered, the shoes barely touch the brake drums. When rotated by hand, the wheel should rotate quite freely, but at the same time a barely noticeable sound will be felt from the friction linings pressed against the drums (if the pads are worn unevenly, then a characteristic sound during rotation will be in a certain position of the wheel). With this adjustment, after covering 100-200 km, the friction linings will wear off a little, and the gap will become close to ideal.

Dismantling and replacement

It is difficult to confuse the cable from the handbrake with anything else under the bottom of your VAZ 2114, which greatly simplifies the repair and replacement procedure.

Dismantling works

We provide detailed instructions for replacement, and additionally recommend watching the video.

- We advise you to get the car in order in terms of cleanliness in advance. This will make it easier for you to find all the nuts and fasteners.

- Additionally, treat the nuts with the almighty WD40. This will make it much easier for you to unscrew the sometimes sticking and rusting nuts.

- Place the handbrake lever all the way down.

- Start with the adjusting nut and locknut that you used recently to try to tighten a loose cable. In this situation, you should loosen the nuts and remove them from the handbrake rod.

- Remove the washers and cable equalizer. Although this can be done after you jack up the car. But be sure to do it before removing the wheels.

- Raise the rear of the car with a jack, unscrew the wheel bolts and remove them.

- Tap the brake drum locking pins. This will allow them to be removed from the brake pads.

- Remove the block.

- You now need to disconnect the ends of the two cables from the equalizer. The fasteners can be removed from their places with the simplest pliers, so don’t bother.

- The shifted spacer lever has hooks from which the cable loop can be removed.

- The cable sheath must be removed from the entire suspension of the rear of the car. To do this, the mounting bolts are first unscrewed.

- Pull the cable out of the holes through the brake flaps.

- We got rid of the old cable, so all that remains is to replace the old one with a new element. The procedure is performed exactly in reverse order.

- Thread the new cables through the washers and hook the loops. You can additionally make bosses - this is a special clamp that allows you to fix the cable even more tightly.

- Reassemble the entire disassembled wheel structure.

- Route the cable along the suspension through the sheath and secure the bolts.

- Pull the handbrake in the cabin.

- Check the correct tension and operation of the new hand brake, or rather the cable.

It is not uncommon for the parking brake to cause an unpleasant squeaking noise from the rear. By changing the cable, you can get rid of this problem at the same time. To do this, rubber seals are installed under the cable fasteners on the body frames.