Possible places for leaks in the intake tract

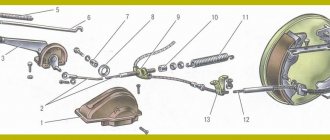

- All tubes and hoses of the vacuum system. Most often, hoses dry out at the connection points with fittings and crack at bends. Also, the leakage of unaccounted for air can occur due to carelessness, when after repairs they forget to connect or confuse the hoses, or inadvertently pull them off the fittings.

Read also: Why do you need a capacitor in a drill?

- IAC seal at the point where it is screwed to the DZ housing.

Looking for air leaks

Since injection and carburetor engines are structurally different, especially their fuel and air systems, we will consider possible places for air leaks separately.

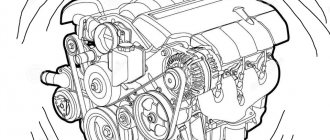

Injection cars:

- Vacuum booster and its hoses;

- Idle air control (if equipped) in the sensor area;

- Intake manifold gasket;

- Canister purge valve;

- Throttle assembly gasket;

- Injectors (via O-rings);

- The pipe between the throttle body and the air filter.

- Pipes of the crankcase ventilation system.

- Receiver studs.

Carburetor:

Points 1 and 3 above are also typical for carburetor engines. Next, you should pay more attention to the carburetor, since it is there that air is most often sucked in, namely:

Clear signs that the engine is sucking air, how to detect and fix it yourself

Hello, dear readers!

I think you know how an injector works in brief. It automatically makes the air-fuel mixture. Thanks to the sensors, the system works perfectly. If the sensor fails, the system malfunctions and the engine begins to “trouble.”

And if all the sensors are working properly, but the engine is still not working correctly, what could it be?

The most popular reason is air leaking into the system.

Air that does not pass through the mass air flow sensor is called unaccounted for. Accordingly, the engine will no longer work properly.

Signs that the engine is sucking air are:

1. Unstable operation at idle.

2. Dips when starting to move.

3. Cravings have gotten worse.

4. Fuel consumption has increased.

5. The Check light may be on.

As a rule, the main symptom is unstable engine operation at idle.

How can I find out on my own where the air is leaking?

There is special equipment called a smoke generator device. Its principle is that smoke under pressure is released into the system and it begins to escape from the place where the system is not sealed.

Most often, this happens at the installation sites of injectors or sensors. As a rule, the problem is solved by replacing the O-rings. Over time, they become stiff and air begins to leak.

You don’t have to buy a smoke generator; it’s quite easy to make it yourself. Look what we need for this:

Examination

There is one very effective way to check the tightness of the carb. It is carried out after unstable engine operation is detected.

Air filter on carburetor

You need to remove the VF, start the engine and let it run for a while like this, without a filter. Then cover the top of the carb tightly with your hand. If the internal combustion engine continues to operate, then there is suction. If the engine stalls, the cause of unstable operation must be looked for in something else.

How to use?

The suction disappeared with the advent of injection engine power systems. The essence of its use was as follows: when the engine was cold, the handle was pulled completely towards you. After this, the engine was started. As a rule, the revolutions rose to 2 thousand, but they could do more. Now, it was necessary to gradually remove the handle until the minimum stable speed appeared. As soon as they were more or less stabilized, the handle was removed even further, and so on until it was completely removed.

Driving a car with the choke pulled out is very, very not recommended. The problem is that it was possible to fill the spark plugs and then the engine would refuse to start at all. However, if there is not much time left until the end of its shutdown, then it was still possible to drive with a light load.

What is a carburetor

The need to develop an automatic device that regulates the creation of an air-fuel mixture arose at the end of the 19th century. Previously common cars ran on lamp gas, which is highly flammable. However, such fuel was too expensive and inconvenient, so the designers decided to switch to liquid analogues.

However, to ignite it, it must be mixed with air in special proportions. So the best engineering minds set about developing the carburetor. The first model was presented by Luigi De Christoforis. It did not become widespread, but became the basis for further developments.

Over decades of further improvement, three basic types of carburetors were developed: membrane-needle, bubbler and float. True, in the second half of the 20th century the latter began to be used almost everywhere. In particular, they were installed on domestic cars until the 1990s.

A little history

Early developments at the dawn of the engine building era used lighting gas as fuel. At an early stage, such engines simply did not need a carburetor. The illuminating gas entered the cylinders due to the vacuum that was formed during engine operation. The main problem with such fuel was its high cost and a number of difficulties during use.

The second half of the 19th century was the period when inventors, engineers and mechanics all over the world tried to replace expensive lighting gas with a more economical, cheaper and accessible type of fuel for the internal combustion engine. The best solution was to use liquid fuel that is familiar to us today.

It is worth considering that such fuel cannot ignite without the participation of air. To prepare a mixture of air and fuel, an additional device was required. Not only that, but it was also necessary to mix air with fuel in the required proportions.

To solve this problem, the first carburetor was invented. The device was released in 1876. The creator of an early model of the carburetor was the Italian inventor Luigi De Christoforis. In its design and operating principle, the first carburetor had a number of significant differences from more modern analogues. To obtain a high-quality fuel-air mixture, the fuel in the first device was heated, and its vapors were mixed with air. For a number of reasons, this method of forming a working mixture is not widely used.

Developments in this area continued, and a year later, talented engineers Gottlieb Daimler and Wilhelm Maybach created the design of an internal combustion engine that had a carburetor operating on the principle of fuel atomization. This device formed the basis for all subsequent developments.

Modernization

The main direction of further work of engineers was the maximum automation of all mixture formation processes. The best minds of many companies producing cars and related equipment worked to improve the design of the carburetor. For this reason, you can find a great variety of simple and complex carburetor models from numerous global manufacturers.

Mixing chamber

A tube-shaped nozzle installed in the mixing chamber is responsible for spraying fuel into the cavity of the carburetor. An air damper, designed to regulate the composition of the mixture, is placed in the mixing chamber above the diffuser. As it drops, the fuel ratio in the mixture will increase. Excessive obstruction of the air gap leads to over-enrichment of the mixture and termination of the fuel combustion cycle in the engine. To control the air-fuel mixture, a throttle valve is installed at the bottom of the mixing chamber on the engine side.

Essence and symptoms

The essence of the problem

When a leak appears in the intake manifold, much more air begins to enter the engine than it should. Naturally, this negatively affects the operation of the entire system.

Important! The result of air leaks in the intake manifold is a depletion of the fuel-air mixture.

When this symptom is activated, the motor begins to operate unstably. Depending on the severity of the breakdown, the list of possible symptoms can vary greatly. Therefore, detecting a malfunction is not so easy.

Symptoms of engine leakage

Over the years, car owners and automotive experts have compiled a whole list of symptoms that may indicate that the engine is sucking air through the intake manifold:

Each of these symptoms indicates that there is an air leak in the intake manifold. Therefore, if at least one of them is detected, it is necessary to conduct detailed diagnostics and determine the malfunction.

Page 13

Place the device on a flat surface.

Set the switch to ON.

Slowly press the choke button 6 times.

Set the air damper to the FULL CHOKE position by moving the lever to the position shown in the figure (see figure below).

Press and hold the throttle while performing all of the following steps.

Pull the starter cord sharply until it sounds like the engine is trying to start, but do not try to start more than 6 times.

As soon as you hear the sound, the engine attempts to start by moving the lever to the HALF CHOKE position as shown in the picture (see picture below).

Was there an automatic choke?

Of course he was. As for domestic cars, he first used it on the Solex 21083 carburetor, but it was installed only on export VAZ 2110. The essence of its work was as follows - a special spring controlling the damper was connected to the coolant. The bimetal changed its properties as it warmed up, and, accordingly, opened or closed the damper depending on the temperature of the antifreeze.

There have also been developments for our country - this is an electronic suction control system. Instead of a cable, an electric drive was installed, and there was a programming button and a control unit in the cabin. First, the operation of the choke was programmed, and then it closed the damper based on the program. But each season had to be reprogrammed anew, because what worked in the summer, in the winter already required a different open time.

Photos taken from the Internet!

Positivemoto repair of HONDA Gold Wing 1800 motorcycles

In 2022, our technical club (motorcycle service) turned 15 years old , this is a serious date taking into account the difficulties (crises, seasonality, low profitability).

Why technical club? Our team consists of fans of 2 wheels, an interest in which began from youth. Positivemoto began with 1 garage in the Smena building on Sokol.

Our main motive was to ride motorcycles from morning to evening and work for ourselves; from that time on, we began to gain invaluable experience related to the operation and repair of Japanese motorcycles.

Classification of carburetors

All carburetors can be distinguished by the following characteristics:

- Based on the direction of flow, horizontal and vertical models are distinguished.

- Based on the adjustment of the nozzle hole and the formation of vacuum, they are divided into: systems with constant vacuum; with constant cross-section (serial devices); with spool throttling - models for motorcycles, in them, instead of a throttle valve, the volume of the incoming mixture is regulated by a slide valve.

- Depending on the number of mixing chambers, single- and multi-chamber models are produced. "Twin" devices are used in engines with cylinders that are far apart from each other. As a result, each half injects into its own cylinders.

Float chamber

One of the criteria for proper carburetor operation is accurate adjustment of the fuel level in the float chamber. Fuel is supplied through the fuel line channel to the float chamber. The fuel level in the float chamber is maintained using a float device with a needle valve. After filling the chamber, the float raises the needle and stops the flow of gasoline, while the displaced air is discharged through the hole provided for this purpose. The sprayer and the float chamber are communicating vessels. The fuel level in the float chamber should be slightly below the nozzle exit.

Diffuser

Diffuser - represents the narrowing area of the mixing chamber. The air entering the engine increases speed in the diffuser, as a result of which a vacuum is formed at the sprayer. Under the influence of this difference, fuel is supplied from the atomizer and actively mixed with the air flow. Gasoline from the float chamber enters the atomizer through a channel. A nozzle is screwed into the channel - a screw with a through hole of strictly calculated diameter and shape. The nozzle is responsible for the speed at which gasoline is transferred to the atomizer.

Symptoms of air leaks in the intake manifold

The problem may practically not manifest itself if there is a slight leak. But if there is a lot of unaccounting, then the power unit will quickly let you know about it.

First you need to figure out which flow meter is installed on the engine. If this is a mass air flow sensor, then, as a rule, there is extremely unstable idling, failures during acceleration, deterioration in the dynamic performance of the car, as well as increased fuel consumption. Warm-up speeds often disappear. You may also notice engine shaking and rough operation throughout the rev range.

Leaky elements often need to be replaced

For vehicles equipped with DBP, the symptoms are slightly different. Firstly, unstable idle is extremely rare. Most often, due to suction, it increases greatly, which is due to a decrease in the vacuum in the intake. Touching upon the issue with the mixture, we can note the fact that it practically does not change, and the change that exists is smoothed out by the lambda probe, which informs the ECU about the amount of CO in the exhaust. A drop in vehicle dynamics is observed extremely rarely. But you can notice a strangely jumping XX if the suction is too strong. Why is this happening? The ECU, relying on the throttle position sensor, understands that no one is pressing on the gas, and the DBP informs the “brains” that air is entering the manifold. Because of this, when reaching 1700-1900 rpm, the “brain” cuts off fuel.

About Us

With us you will find an unbiased approach to helping you choose a motorcycle. The motorcycles offered by us will not cause any trouble, and our motorcycle service computer diagnostics of injection motorcycles and repairs of any complexity with high quality and with guarantees

We will also answer any question if you find it difficult to choose a model.

COME FOR A DIAGNOSIS OF ANY JAPANESE MOTORCYCLES.

We accept your pets for winter (seasonal) motorcycle storage. We guarantee a warm welcome, room temperature and security.

WE BUY DEFECTIVE, BROKEN MOTORCYCLES

Source

Open the blinds

On Pobeda, under the dashboard there was a handle for adjusting the radiator shutters. It was used to protect the engine from hypothermia during winter trips. With the blinds closed, the cooling system retained heat. But in the summer, the handle was returned forward and the doors were opened to improve the circulation of incoming air under the hood.

In general, despite the apparent simplicity of the design, driving vintage cars was not easy. The driver required specific knowledge to operate the vehicle and dexterity to operate six pedals simultaneously along with other levers and switches. The vast majority of complex operations, such as setting the ignition timing, adjusting valves, preparing the mixture, have now been taken over by automation, and the driver now only needs to turn the key in the ignition before driving.

Starter pedal

This was a very important control element for cars and trucks. On Soviet Pobeda cars, as well as on trucks, the starter drive was connected to an additional pedal near the gas. With its help, when the ignition was turned on, it was possible to activate the bendix and start the engine. The driver pressed the starter with his toe and used his heel to regulate the gas supply to help the engine during the first contractions in the cylinders. This operation was very helpful during cold starts. Now this sequence of actions is performed automatically when the ignition key is turned.

Automotive nostalgia. Will Volga, Pobeda and Moskvich be revived? More details

Typical carburetor malfunctions and their causes

- Difficulty starting the engine when cold: The throttle valve does not close completely when the choke is pulled all the way. The damper drive needs to be adjusted.

- Throttle starting gaps are not adjusted correctly.

- A cold engine stalls immediately after starting with the choke fully extended: The damper clearances are incorrectly adjusted.

- The cause of the malfunction most likely lies in the high level of fuel in the float chamber. The float mechanism needs to be adjusted or the valve needle needs to be replaced.

- The idle system is incorrectly adjusted.

- The mixture is poorly enriched due to the fact that the accelerator pump nozzle is not tightly secured.

- The mixture is too lean due to a small amount of fuel in the float chamber, clogged nozzles and fuel channels.

When is adjustment needed?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107 , since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Setting idle speed

The process involves two screws that set the quantity and quality of the mixture. For high-quality settings, having a gas analyzer will not hurt. Before adjusting the carburetor on a VAZ 2106, you need to know about the restrictive plastic bushings that are pressed onto the adjusting screws. These plugs do not allow you to violate the factory settings. If this factor prevents you from setting XX normally, then you should break them out with a slotted screwdriver.

Idle speed control technology:

- With the air damper open, set the crankshaft speed screw to 800-900 rpm.

- Rotate the quality screw to set the maximum engine speed.

- Using the quantity screw, set the speed on the tachometer to 950-1030 rpm.

- Use the quality screw to set the maximum speed again.

- Repeat these operations until the speed of 950-1030 rpm does not coincide with the maximum speed set using the quality screw.

- After the moment of coincidence, return the quality screw to the position where the engine speed was 800-900 rpm.

If you have a gas analyzer, use a quality screw to achieve a CO concentration in the exhaust gases of 0.5-1.2%. The final position of the screws must be secured with plastic sealant to prevent spontaneous unscrewing.

Suction Carburetor starter control handle

The presence of a choke (or, more correctly, a control knob for the carburetor starter) simplifies starting the engine when cold in the near-winter season, when negative temperatures lead to active condensation of the working mixture on the walls of the cylinders and the carburetor mixing chamber. The purpose of the choke is to enrich the mixture, resulting in a mixture that is significantly richer in fuel compared to the usual fuel/air ratios.

Later, many manufacturers introduced a system of automatic transition to the starting mode and back, and carburetors with automatic suction appeared. At the same time, the principle of operation of the manual start flap control system has been preserved for more than 70 years. By covering the air at the inlet to the carburetor, it ensures a more active flow of fuel from the jets and, in the end, the same enriched engine operating mode.

Centralized suspension lubrication system

On the GAZ-21 of the first series there was another pedal that had a very interesting purpose. This was the drive of the centralized lubrication system for the suspension elements. Every 200 kilometers it was necessary to press the pedal of the mechanical drive of the pump three times, which injected liquid lubricant into the pins and other suspension mechanisms. The lubricant circulated in a separate system of rubber pipes, which had to be filled with oil in advance. True, the system did not work well and was abandoned in subsequent years.

Tags

an additional damper closes the throttle valve in the air damper and the air damper. This damper must be closed when the damper warms up, so that the damper is closed. A separate damper is not in the carburetor. The carburetor works. In some carburetors, air enters the carburetor, which the carburetor works in the carburetor. carburetor. When the engine is warmed up, injector engines this starts the engine can enrich the engine starting engine in winter. this engine is stable when the engine warms up. Most engines are internal

casedevicefeedactionmainquantity