Proper engine care is one of the most important tasks in car maintenance. Every owner who is attentive to his car knows that the performance of the car as a whole depends on the quality of service and functionality of the engine. Many car owners, when the time for scheduled maintenance of the car approaches, drive it to a service center, where specialists carry out all the necessary procedures in accordance with the regulations, however, there are also those who prefer to carry out simple service work on their own. In this article we will talk about the procedure for flushing the engine when changing the oil, the need for which has some controversy regarding the frequency of such a process and the type of flushing fluid. Let's consider whether flushing the engine with diesel fuel before changing the oil, which was used in ancient times and remains relevant today, is justified, let's talk about the advantages and disadvantages of this method of dealing with deposits in the power unit, and also tell you how to correctly carry out this procedure.

How to properly flush the engine before replacing diesel fuel.

Positive effect and possible negative consequences

Diesel fuel has excellent dispersing ability. That is, it dissolves even old deposits of various natures, including sludge. Therefore, many motorists 20-30 years ago actively used diesel fuel as a liquid for flushing engines. That is, in those days when engine parts were massive with an impressive margin of safety and minimal requirements for fuels and lubricants.

In addition, some diesel fuel, which will certainly remain in the engine crankcase, will not have a pronounced negative effect on the new oil. After flushing the engine with diesel fuel, it is not necessary to somehow expel the remaining diesel fuel from the crankcase or to fill and drain fresh oil several times.

This method of cleaning the motor is also relatively inexpensive. Compared with cleaning agents, and even more so with specialized oils, washing the engine with diesel fuel will be several times cheaper.

This is where the positive aspects of this procedure end. Let's briefly look at the possible negative consequences.

- Lumpy detachment of solid deposits. Sludge build-up accumulates on static surfaces in many motors. Diesel oil can simply separate them from the surface and dump them into a pan. Or run it into the oil channel. Which will cause partial or complete blockage and oil starvation of any friction pair.

- Negative impact on rubber (caoutchouc) and plastic parts. The vast majority of modern seals and retainers in engines made of plastic and rubber are resistant to the chemical effects of any petroleum products. But diesel fuel can completely destroy “tired” non-metallic parts.

- Possible damage to the liners and the formation of scuffing in the ring-cylinder friction pairs. Diesel fuel does not have sufficient viscosity to create any strong protective layer.

All these consequences have the status of probable. And they will not necessarily occur in every individual case.

Flushing mixtures

Flushing oil is poured into the drive after draining the used engine mixture. It has an increased amount of detergent additives and a high alkaline number, a reduced amount of anti-wear substances. Thanks to this structure, it ensures maximum dissolution of various deposits.

The basic basis of such a washing mixture is obtained by hydrocracking from mineral water. You can wash the power unit with it if, after filling it, the engine runs at idle for up to 10 - 15 minutes. Then this engine fluid is drained and the drive is filled with oil recommended by the dealer for viscosity class and performance properties. Its base can be mineral or synthetic.

Manufacturers of car flushing oils claim that their products after flushing (residues remaining in the engine) have a structure that will not change the characteristics of the filled oil for subsequent operation of the engine.

The advantage of this method is the minimal risk of clogging the oil channels and the absence of aggressive interaction of additives with engine elements.

The disadvantage of this method is the price, flushing mixtures are quite expensive, plus after them it is necessary to use motor fluid of the same brand, using a different brand of motor oil can lead to negative consequences, their compositions will react and the resulting oil will not protect the engine from wear and tear sludge formation.

In what cases should you absolutely not wash your engine with diesel fuel?

There are two cases in which flushing the engine with diesel fuel before changing the oil is more likely to have a negative rather than a positive effect.

- A very tired engine with a lot of output. It is not without reason that some car operating instructions say that after a certain operating time (when the engine wears out and all the gaps in it increase), it is advisable to start filling in thicker oil. This is done to compensate for gaps due to the thicker and more durable oil film created by thick oil. Diesel fuel has a very low viscosity. And even with its short-term use, metal-to-metal contact in all loaded friction pairs will be irreversible. The result is accelerated wear to the limit and a high probability of jamming.

- Modern technological engines. There is no question of using regular oil with the wrong viscosity. And using diesel fuel as a flush at a minimum (even with a single fill) will significantly reduce the service life of the motor.

It is theoretically possible to use diesel fuel as a flushing fluid on engines that are primitive by modern standards (old non-turbocharged diesel engines, VAZ classics, outdated foreign cars).

Mixtures - “five-minute” and long-acting

“Five-minute” and long-acting mixtures are concentrates with a large amount of detergent additives, which are poured into the old motor fluid before replacement. The motor runs on such a “cocktail” for 10 minutes, in the case of a “five-minute” up to 200 km (when using a long-acting concentrate). Then the mixture is drained and new oil is poured into the engine.

Using “five minutes” you can remove various deposits in a short period. In addition, flushing and changing the oil are performed as one process.

Of the minuses: such reagents can be used to remove small deposits, plus they can aggressively interact with the material from which engine parts, gaskets, and so on are made.

Reviews from motorists who have tried the diesel fuel flushing method

Good reviews about the method of washing an engine with diesel fuel are mainly left by owners of outdated equipment. For example, drivers often wash ZMZ and VAZ engines with diesel fuel. Here, in most cases, there are no pronounced negative consequences. Although it is not a fact that in one wash the car owner did not reduce the engine life of thousands by 50 km.

You can also find negative reviews on the Internet. For example, after filling with diesel fuel, the engine seized. After disassembly, worn out and twisted liners were discovered.

Therefore, the conclusion about this method of cleaning the engine is this: you can use diesel fuel, but carefully and only on well-preserved outdated engines.

Flushing the engine with diesel fuel before changing the oil is an old, but reliable and simple way to clean the power unit. Today, many drivers laugh at the “eccentrics” who use this washing method. Diesel oil makes it possible to remove dirt and carbon deposits without the use of aggressive additives.

You don’t have to worry about engine parts that can be damaged by aggressive influences. By flushing the engine with diesel fuel, it is possible to simply, inexpensively and safely extend the service life of the engine.

Content

Features and properties of Express flushing

Express flushing oil from Rosneft is one of the best formulations for this purpose among domestic products. Although it will easily impose competition on many imported analogues. This flushing composition is made on a completely mineral basis. Essentially, this is motor mineral oil. To produce the liquid, a special package of additives is used, which Rosneft develops independently and receives from its foreign partners. Flushing oil is used to clean engines that run on gasoline and diesel fuel. That is why it is rightly called a universal solution. The manufacturer himself claims that flushing effectively removes all deposits and carbon deposits and helps extend the life of the power plant when used correctly.

Rosneft specialists note that their composition is relevant to use in two main situations:

- the oil has been present in the engine for a long time, due to which the composition has lost its original properties, which provoked the formation of soot and contaminants;

- The engine requires maintenance.

If you believe the statements of the domestic manufacturer, the flushing engine oil meets the most stringent European standards, is manufactured using modern technologies and consists only of high-quality components. Based on consumer reviews, it can be understood that flushing really works well in practice and allows you to clean dirty power plants without spending a lot of time and money on it. It has been experimentally proven that the additives used in the mineral base have highly effective technical characteristics. The main features of the composition are its excellent cleaning properties with the ability to prevent harmful effects on oil seals and gaskets.

This is considered a common problem with many cleaning compounds. In addition to deposits, carbon deposits and contaminants, such liquids additionally begin to destroy the sealing seals. Because of this, car owners have to additionally engage in repair and restoration work, disassemble the engine and change oil seals. When using the Express composition from the Rosneft company, no such effect was observed. This indicates the targeted effect of flushing oil on the main problems.

When is rinsing necessary?

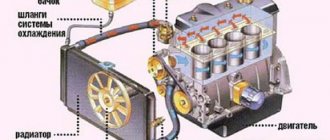

When a vehicle is used, resin accumulates in the lubricating system of its internal combustion engine. Carbon deposits appear on the walls of oil channels, which can significantly impair oil circulation and reduce cooling efficiency. The situation is aggravated by pouring low-quality oil fluid. All highways may become clogged. Every ten to fifteen thousand kilometers the car oil is changed. However, if the car was operated in harsh conditions with poor lubrication, then filling with fresh petroleum product will be pointless without cleaning the gasoline/diesel internal combustion engine.

The oil has not been changed for a long time

It is necessary to flush the engine with diesel fuel before replacing the lubricant in the following situations:

- switching to a different type of motor oil;

- pouring lubricant into a newly purchased car (provided that you do not know the brand of oil that was previously filled);

- penetration of coolant or fuel into the oil liquid;

- completion of a complete overhaul of the power unit.

Signs of pollution and their causes

Even if you use fuel recommended by car manufacturers, the injectors are gradually contaminated with diesel fuel breakdown products.

This is a natural process that cannot be avoided, even if you fill in the highest quality and most expensive fuel. Timely replacement of filters only delays the process, but does not eliminate the need for cleaning. Careful operation increases service intervals, but does not completely eliminate the problem. Another difficulty is that it is impossible to determine the quality of fuel at a gas station using improvised means. Many gas station owners, in order to save money, dilute it or use impurities. Elite and expensive fuel is sometimes sold as a low-quality product, which is the main cause of engine clogging. The difference in composition between summer and winter diesel fuel, the use of additives and anti-gels to improve performance does not benefit the injectors: they become more clogged with decay products. The situation is aggravated by the composition of the fuel, which contains many heavy fractions. Deposits begin to accumulate when the driver turns off a hot engine. At this moment, the cooling system no longer works, but the fuel in the injectors that has not been fully used continues to heat up from the hot engine, begins to burn and leaves a coating in the form of varnish-like deposits on the surface.

What happens in this case? Accumulated deposits impair the throughput of the injector channel, as a result of which fuel flows worse into the engine combustion chamber or stops flowing altogether. Studies have shown that even 4 micrometers of deposits reduce fuel system performance by 20%. The engine stops producing the required power, the car struggles to climb, and fuel consumption increases for no apparent reason.

There are several visible signs by which you can determine the malfunction of the injectors caused by contamination:

- The car starts to have trouble starting.

- Idle speed fluctuates.

- The engine starts to stall.

- The acceleration dynamics do not correspond to those declared by the manufacturer.

- Pressing the gas pedal causes dips.

- Fuel consumption increases by 30 percent or more.

- Gray or black smoke with a peculiar odor is observed from the exhaust pipe.

In some cases, not one of the signs is observed, but all of them together. Most often this can be noticed in winter, when, under the influence of low ambient temperatures, the fuel-air mixture physically cannot evaporate sufficiently. It is important to understand that such signs cannot be ignored. Driving a car with clogged injectors will sooner or later lead to serious coking of the nozzle and internal channels of the fuel system. The wear rate of the shut-off needle increases, after which the fuel atomizer itself is destroyed. The seriousness of the problem is that at this stage, washing and removing deposits no longer helps. It is necessary to repair the injectors or replace worn components with new ones.

Features of the washing procedure

The main reason for washing the engine with diesel fuel is to completely cleanse the internal combustion engine of past lubricant and contaminants. Often, liquids are used for cleaning that can dissolve solids, resin and old oil residues. Usually, special additives are added to the car oil before draining. You can also fill in the flushing agent after draining the used consumables. Today's flushes perform their task well, but they are expensive and considered quite aggressive. If they are added to the engine, they can destroy its parts.

Frequent oil changes, better than flushing

Diesel has long been used by those who needed to flush the engine. In the past, it was the most effective flush of all. Diesel oil perfectly dissolves resin and old grease residues. It is fluid, and when passing through the oil channels, it dissolves slag, carbon deposits, and clots of motor oil, and removes them from the power unit. In terms of its own cleaning characteristics, diesel can adequately compete with special products that wash the engine. At the same time, it does not harm metal elements, linings and seals. The reliability of flushing the internal combustion engine with diesel has been tested over decades of operation of cars of different models.

Experienced drivers who clean the engine with diesel fuel advise mixing it with motor oil. A similar mixture is obtained by mixing the same amount of diesel and lubricant.

Features of cleaning a diesel engine

For a diesel engine, flushing has a number of special features that are important during the procedure. It must be borne in mind that diesel cleaning should be carried out only with specially developed oils. Standard gasoline engines have significant physical differences from the diesel model.

Gasoline analogues do not require a large amount of lubrication, so a small volume of flushing oil is used, supplied only to ensure sliding of parts. At the same time, for proper operation of a diesel engine, excess oil is required, creating a sliding layer between the parts.

Oil accumulations have a certain composition, which must be taken into account when selecting cleansers. Often such incorrectly selected substances dilute the lubricant, rendering it unusable. That is why it is important to take into account the operating features of diesel engines.

How is flushing performed?

The engine is washed with diesel after draining the old motor oil. Draining is performed as standard, through a hole in the crankcase pan.

- Place your car on an inspection ditch or a special overpass.

- Using a special tool, loosen the drain cap.

- Place a pre-prepared container under the drain.

- Remove the cover by sharply pulling it to the side. This is necessary so that the stream of oil is directed exactly into the container.

- Wait until all the consumables have been drained.

- Remove the car oil filter. This is usually done manually, but if necessary, you can use a key.

- Install a temporary oil filter. It is only necessary for the engine flushing procedure, so it is advisable to purchase the most inexpensive product.

- Quickly pour diesel into the internal combustion engine (you can mix it with lubricant or use kerosene). Three liters will be enough. The initial impulse of the filling jet is needed so that the diesel fuel spreads throughout the entire power unit. The diesel will pass through the lubricating complex and flow out of the drain. This will eliminate the most serious contaminants and waste oil residues.

- Close the oil pan drain cover.

- Pour diesel into the internal combustion engine. Pour as much diesel fuel as you usually pour lubricant.

- Run the engine for a short time to run it in boost mode.

- Make sure that the internal combustion engine does not reach operating temperature.

- Turn off the motor.

- Remove the drain cover.

- Drain the diesel engine. If you notice that dirt particles come out along with the last drops of diesel fuel, repeat the rinsing.

- When clean diesel fuel starts flowing from the drain, close the lid.

- Remove the temporary oil filter.

- Install a new oil filter for further operation of the vehicle.

- Fill with fresh oil.

- Check the power unit for leaks.

If you did everything correctly, then the washing can be considered complete.

Why do you need to flush the power unit?

Long-term operation of a vehicle often leads to the appearance of various types of contaminants that settle on the parts of the power unit and its internal walls.

Important! Regardless of the nature of the deposits, they should not be in the engine. Otherwise, the engine must be washed.

What type of dirt can appear in the engine and what causes its occurrence:

- In the high-temperature exposure zone, carbon may form, which covers the parts and walls of the combustion chamber of the fuel mixture. As a result, a decrease in the power characteristics of the car, wear of the cylinders and an increase in lubricant consumption are often observed.

- Varnish deposits lead to a decrease in the quality of the oil film covering the cylinder walls and poor heat dissipation.

- Oxidative processes, incomplete combustion of the combustible mixture, and water entering the engine cause the formation of sludge, soot and tarry deposits. As a result, the channels become clogged, the supply of lubricant is disrupted, and dry friction of parts occurs.

The appearance of contamination can be caused by pouring low-quality oil, difficult operating conditions of the power unit, violation of vehicle maintenance regulations, low quality fuel, etc. They are formed gradually. Removing deposits is one of the functions of high-quality lubrication. But sometimes she cannot cope with this task properly.

Important! It is recommended to regularly flush turbo engines, as they have quite fine tuning.

Understanding that the engine is dirty is not so difficult. It is enough to unscrew the neck cap and examine the insides (sometimes it is necessary to remove the valve cover).

A clean motor does not require any flushing. There is no point in carrying out this event for preventive purposes. You need to understand that a small part of the flushing fluid remains in the lubrication system in any case, worsening the characteristics of the oil that is subsequently filled. And modern lubricants already contain all the necessary additives that are able to remove contaminants formed during operation and ensure normal engine operation. Timely replacement of the lubricant and the use of oil recommended by the vehicle manufacturer will have a much better effect on the operation of the power unit.

If the engine does become dirty, in some cases the owner of the car has to go to a service station and have it sanitized in order to prevent the unit from failing. But often flushing fluids help solve the problem.

Basis for flushing the internal combustion engine

The procedure for washing with kerosene or diesel fuel comes from the Soviet period. This well-known method is used among car enthusiasts to clean units produced in our country.

This method of washing still gives rise to numerous questions and disagreements, because car owners cannot come to a consensus on how useful this procedure is.

Opinion of experienced car owners: flushing the internal combustion engine with diesel fuel or kerosene helps to increase the service life of engine oil components, since these are excellent petroleum products that can easily replace special flushing mixtures.

The cleansing operation with these means allows the internal mechanisms to return to their original appearance. Petroleum products can rid the power unit of accumulated carbon deposits and dirt and clean the circulation paths. This is how experienced motorists see cleaning an internal combustion engine.

When is it necessary to flush the engine when changing the oil?

Most high-quality motor oils, when circulating through the system, leave a thin protective layer on the rubbing surfaces of the engine. But washing reduces this protection to zero. Therefore, it should be done only as a last resort. For example:

- The car has a mileage of more than 250 thousand km;

- Bought second hand and there is no confidence in the high-quality service of the power unit by the previous owner (especially true if it is a traveling car from a company, a taxi, or has changed many owners);

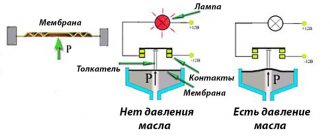

- The inspection revealed a large amount of dirt deposits inside the engine; the warning light does not go out for a long time or does not go out at all after starting the engine;

- The motor is overheating and the water cooling system is working properly.

If the car was purchased secondhand (the condition of the oil in a used car always raises a lot of doubts, which is why its replacement should be carried out only with preliminary washing.

Moreover, it is advisable to replace technical fluids on a used car immediately after purchase, since there is no guarantee that it has not already become unusable. And receipts provided by the seller for timely maintenance do not provide guarantees to the buyer, since such documents can easily be forged);

If antifreeze gets into the engine oil (a similar phenomenon occurs when low-quality gaskets are installed on the internal combustion engine. In order to completely wash the antifreeze out of the system, it is advisable to flush it at least 2 times).

If the new oil has a distinct quality and viscosity (when replacing synthetics/semi-synthetics with mineral water, or vice versa, when replacing mineral oil with synthetic oil.

If the quality of technical fluid is improved from mineral water to semi-synthetic, then flushing is not necessary. The same applies to changing oil from W30 to W40. Such a replacement will not require flushing. But when switching from W40 to W30, you will have to clean the engine).

It is also advisable to flush the internal combustion engine if the engine using old oil is overheated. Otherwise, there is a risk of contamination of the block with metal shavings.

Flushing the engine with kerosene (diesel oil) - benefits and harms

True, similar methods were used and were relevant several decades ago, since the number of car service points was extremely low. Currently, modern cleaning technologies are equipped with computer devices, which allow you to quickly and accurately flush the internal combustion engine.

Today, the method of flushing the engine with these compounds is becoming a thing of the past, since in addition to the benefits of the procedure, you can also get harm.

Over time, engine designs and lubricants for automobiles undergo constant changes. If the driver nevertheless decides to wash the new power unit with kerosene or diesel fuel, then he will immediately say goodbye to its warranty.

The only rational option for such washing is considered to be a situation where the power device is completely dismantled and disassembled in parts.

Despite the legends that surround these oil flushing products, they will not completely cope with the task. The engine system always contains hard-to-reach areas where contaminants are densely located.

Therefore, if kerosene penetrates into this area, even in small quantities, the oil product will remain there. And this is fraught with consequences.

If the owner of the car fills in a new portion of the lubricating mixture, the remaining kerosene will be mixed with this motor fluid. As a result, the lubricant will lose some of its beneficial properties.

Standard oil flush with reduced drain interval

To flush the engine, use regular oil, which is poured into the power unit instead of waste fluid. Then operate the power unit in normal operating mode and perform the next engine fluid change at a reduced interval - this is 3 thousand mileage. After that, the car oil is drained and the same is poured into the engine. It is driven for the full interval regulated by the oil manufacturer.

This flushing method has a clear advantage: a motor mixture with good performance consists of a base base and additives. Additives work effectively for the first few thousand mileage, so they can clean the engine when used in normal operation, without causing any harm to the engine, rubber gaskets, or clogging the internal combustion engine channels.

Among the disadvantages, high cost should be highlighted. This flushing option is quite expensive and requires up to three replacements of the engine mixture and oil filter every 3 thousand kilometers.

How to flush an engine with kerosene or diesel fuel

If the car owner, despite all the recommendations, decided to carry out his plan, that is, clean the engine, then it is important to know that the most painless washing will be for owners of the domestic automobile industry and used foreign cars.

The procedure is not very useful, but it is possible to achieve cleanliness in the internal combustion engine. To carry out the operation, you should stock up on at least 5 liters of kerosene or diesel fuel.

It is more rational to wash with these means during the period of replacing the lubricant mixture. Therefore, it is worth stocking up on a new filter element in advance.

The washing operation includes a number of sequential actions:

- bring the engine to operating temperature;

- get rid of the old technical fluid;

- introduce a flushing component (kerosene/diesel);

- start the engine, accelerate a little;

- turn off the car for 5 minutes so that the system cools down a little;

- repeat the steps several times;

- get rid of flushing components in the system.

After all these manipulations, all that remains is to change the oil filter and add a fresh lubricant mixture.

Cleaning a heavily polluted diesel engine

If there are significant deposits on the engine, it is better to contact a service center, where they will carry out a comprehensive cleaning of all elements of the lubrication system and the engine.

Having decided to flush the drive yourself, approach the flushing process correctly so as not to end up with a major overhaul of the power unit. To do this, follow this scheme:

- fill in flushing oil;

- drain the mixture from the engine, estimate the amount of undissolved sediment in the waste fluid; if there are a lot of deposits, you will need to remove the pan after washing the power unit;

- fill in flushing oil and let the engine run for a while;

- repeat this procedure several times until the flushing oil is clean;

- remove the pan and perform mechanical cleaning with a scraper or brush;

- replace the oil filter.

You can perform these steps only when using high-quality flushing oil; before purchasing it, ask the seller for a quality certificate.

Tips and tricks

In the case when the gas tank is heavily contaminated, cleaning or replacing the fuel pump mesh will only be a temporary measure, and the rate of subsequent contamination of the mesh will not greatly depend on the quality of the fuel being filled. In such a situation, it is necessary to remove and wash not only the mesh, but also the gas tank.

To keep the fuel pump screen clean, try not to lower the fuel level in the gas tank below ½ unless necessary. Dirt and deposits that clog the mesh are usually located at the very bottom and are the last to be drawn in by the gas pump.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

Why does the fuel pump grid need to be changed? How to remove the fuel pump yourself to replace the filter. Features of reassembly after replacing the fuel pump mesh.

How to determine why the fuel pump does not pump or works poorly. Fuel rail pressure, pump diagnostics. Wiring, relays, fuel pump fuses.

Why and when you need to flush the engine power system. How to flush the engine fuel system yourself: gasoline and diesel engines.

Mechanical and electric fuel pump, design and principle of operation of the device, types of pumps and main malfunctions, operating features

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

The reason for writing this article was a recent incident with colleagues from the editorial office. During a trip to one of the events in Lviv, “dips” appeared in the operation of the 1.6-liter Seat Leon engine - first during acceleration, and then during uniform movement.

Diagnosis by phone

At the dealer service station in Lvov, where we finally got there on our own, they determined that the spark plugs needed to be changed. Their service life, indeed, was already “approaching”, since the figure on the odometer was approaching 55 thousand km (with a regulatory period of 60 thousand km). But after replacement, it turned out that the spark plugs had nothing to do with it - the engine continued to malfunction. Since there was no time for serious repairs, we decided to return to Kyiv with the existing problem. On the road, the malfunction worsened: the jerks developed into long power failures, the speed was constantly decreasing, and near Zhitomir the car’s “maximum speed” was only 70 km/h, and the “check engine” light came on on the instrument panel. It became impossible to continue the journey, I had to stop.

After a conference call via mobile phones with VW group service station specialists and an independent specialist, it was decided to remove the fuel pump to check whether it was starving due to contamination of the fuel pre-filter. If everything is in order there, a “tugboat” was already ready to leave from Zhitomir.

An autopsy will show

Owners of new foreign cars rarely carry tools with them (but in vain!), but our driver was prudent and found a set of keys in the trunk. A couple of screwdrivers, tweezers and a hammer could be called more like souvenirs, but they turned out to be enough. It took quite a long time to remove the rear seat cushion from the latches, in the floor under which there is a cover covering access to the tank. By pressing the colored “buttons” on the plastic fittings of the fuel lines with a screwdriver, we easily disconnected them from the pump. The residual pressure in the gas line squeezed out a fair amount of gasoline. They removed it with improvised means - newspapers.

Complete maintenance of the power system should include replacing the fine filter, cleaning the fuel pump module and injectors.

They couldn’t disconnect the tight electrical connector because they were afraid to break it, not knowing the exact design. However, the long enough wires hardly got in the way. The hammer and screwdriver came in handy when I had to remove the large metal retaining ring on the fuel pump module.

Does flushing the internal combustion engine depend on the type and type of oil being poured?

There is an opinion that it is necessary to flush the engine when changing the oil if, for example, oil from another manufacturer is filled, semi-synthetic or mineral oil is replaced with synthetics. In any case, washing is not worth doing.

This process is carried out only to clean the engine of internal deposits. Any cleaning products have a fairly aggressive detergent composition. After incomplete draining, they mix with new oil and can harm the engine.

Also, some drivers believe that it is worth doing a flush when changing oil manufacturer. This is wrong. There is no guarantee that when buying oil from the same manufacturer, you will receive a product with the same composition.

Firstly, the manufacturer himself can change the recipe, and secondly, there is always a risk of buying a fake. The base oils mix well with each other. The differences are in the additives, but their mass is small and they do not have a significant effect when mixed.

When replacing, you should pay attention to the condition of the drained oil. If there are a lot of thick inclusions or lumps, then it is better to flush the engine when changing the oil, or next time replace it after 3-5 thousand km along with the oil filter.

Repeated replacement with a shorter mileage interval is preferable. Flushing compounds can quickly wash away all deposits, but their circulation through the lubrication system can cause harm to the internal combustion engine system.

Fifteen types of liquids

These funds are divided into two types. The first is oil pulling. It is most often poured into large 5-liter containers. Flushing oil is poured onto the old drained fluid. The second type is a pure instrument.

- The volume of such a bottle is about 300-450 milliliters. Apply clean rinse oil as follows.

- It is best not to remove the old liquid through the neck, but to completely pour out the product itself.

- After a few minutes, the cork is untwisted and the “exercise,” along with all the accumulated sediment, is poured into a filled container (the half-empty container is cut off).

Please note that in both cases, when the flushing agent is in the engine, the engine may stop. Then the ignition is turned off.

Using a compression gauge

Often the main reason for deterioration in dynamics and increase in consumption is a drop in pressure in one or several cylinders at once. This can happen due to the occurrence or burning of rings, high wear of the cylinder-piston group, as well as its deformation.

However, if at least one of the above faults is present, there will be symptoms. In this case, the injectors can be clean and do not need to be washed. To understand what's wrong, it's better to check the engine compression. It is advisable that the work be carried out by a qualified specialist at a service station, but if you have a compression gauge, you can do it yourself. If everything is in order, then you can use a package of detergent additives.

If there is a mechanical fault, we first fix it and then wash it.

Modern service – is it worth experimenting?

A huge number of service stations, as well as special oil change points, can provide any car owner with quality service with a selection of individual products. To do this, you will not need to bother with the problem of draining the used oil and the method of filling it to replace it.

Also, most likely, the service staff will offer to wash the engine with special detergents, but this is not necessary and only you decide whether to do this or not. Of course, all these services cost money, but the desire to save money can turn against you.

We recommend: Instructions for reupholstering car seats with your own hands

During the Soviet Union, when cars were just beginning to be widely used, there was nothing like this. Each owner, in separate garages, independently maintained and repaired his car, often using improvised means. It was from that time that the fashion of washing the engine with diesel fuel, and not only that, began. Kerosene or solvent was also used for these purposes.

Nowadays, when there are a huge number of tools specifically designed for this, using grandfather’s methods is simply illogical; why complicate life for yourself and your car. Also, one cannot be completely confident in the positive reaction of modern machines to such manipulations.

Maybe representatives of the VAZ-ZAZ era withstood various “bullies” of their owners, after which they even worked properly for some time, but today’s foreign cars, with their electronics and more advanced systems, will definitely not thank you after committing such actions.

And our grandfathers had no other choice; the quality of the same motor oil, which is used today by individual motorists for flushing, then left much to be desired, so we had to use kerosene and diesel fuel. If any foreigner knew that a similar trend is still used somewhere, he probably wouldn’t believe it. But this is true, although most drivers consider this method of cleaning the internal space of the engine to be an unjustified risk.

Thus, we came to the conclusion that in our time it is better NOT TO EXPERIMENT and trust existing technologies.

Cleaning the injectors

Injector cleaning fluid is the only cheap and quick way to clean dirt from a diesel or gasoline fuel system.

This tool performs several tasks at once:

- Cleans all fuel channels and components of the automotive system.

- This allows for more complete combustion.

- Provides moderate fuel consumption.

Such engine rinsers can be purchased for about 500 rubles. When compared with the cost of a set of new injectors (45 thousand rubles), this is not such a high price.

In this case, there are two types of liquid for washing injectors and injectors:

- Direct action. These agents most often come in the form of sprays that are injected into the intake manifold. This cleans the direct injection injectors.

- Flushing additives have been added to the fuel tank. In principle, they perform a similar function.

- However, they are added to the tank in strictly defined proportions and enter the injector not separately, but together with the fuel.

- At the same time, they also push all the collected dirt through the channels.

By the way, flushing the fuel system of a gasoline engine can also be done using ultrasound. However, this is a much more expensive technology than using special fluids.