In the official technical manuals of most cars, there is usually not a word about warming up the car before starting at sub-zero temperatures. This is because manufacturers are not interested in ensuring that the car operates for as long as possible; it is quite enough to ensure that the engine operates perfectly within the warranty period.

But with the arrival of winter, the question increasingly arises of whether it is necessary to heat the oil in the crankcase before starting

. Let's try to figure it out.

Oil thickens in the cold, and the lower the temperature, the thicker the oil will be. A cold start means that the frozen oil is not pumped through the pump and it remains in the sump. In this case, the engine runs partially without lubrication, because what has been pumped is not enough. Warming up the oil in the crankcase in winter will eliminate startup loads and will facilitate rapid pumping of fluid through the lines.

Mechanical heating of the oil in the crankcase

Mechanical oil heating in the crankcase

To heat the oil using this method, external heat sources are used. These include a hair dryer, a gasoline burner, or even just a lighted fire. The main thing is to quickly heat the engine and avoid damage to the wiring and pipes.

Advantages of the mechanical method of heating oil

Low cost

Easy to use

The temperature rises very quickly

Flaws

Open fire is dangerous, especially near fuel lines

Exceeding the maximum permissible temperature may cause the machine to catch fire and damage wiring or pipes.

Consequences of inept heating with open fire

Mechanical methods of heating the oil in the crankcase also include the old method of heating it with a heating pad. This is not as dangerous as an open fire, but you also need to monitor the heating temperature so as not to bring the oil to a boil, because this will lead to a change in the working formula.

Briefly about the main thing

An electric probe, a heated drain plug, a heating element and a heating plate - with these simple means you can safely heat the oil inside the engine in winter before starting. In fact, you don’t need to invent anything - each of the four options is available for purchase on many trading platforms.

In terms of power supply, there are no difficulties: a wire and a plug or a simple electrical circuit based on a relay and a toggle switch. Another question is whether it is necessary. The answer is short and advisory in nature: it is necessary, especially in cold weather worse than -10°C.

Many motorists are forced to think about how to heat the engine sump with their own hands due to the weather conditions in winter, which affect the normal starting of the engine. Some drivers mistakenly believe that in winter it is difficult to start the power unit due to weak battery power. In fact, the problem is caused by a change in the lubricant, which becomes very viscous, making it difficult to start the engine and the functionality of the crankshaft.

Ineffective lubrication in the initial minutes of engine start leads to excessive wear of the piston unit. These troubles can be avoided by heating the crankcase and eliminating excessive oil viscosity.

Aggregate method of heating oil in the crankcase

These methods are more modern and safer. The aggregate method involves connecting a heating element, which is immersed in the oil pan, often directly into the liquid. The heating element can be placed in a special hole, if there is one in the car’s design. If there is no such hole, you can use the hole for the drain plug or add a new special hole where to mount the heater.

Various crankcase heaters

The principle of heating with a heating element involves applying voltage to the heating element right before starting the engine. The power source for the heater can be the home electrical network if the car is in the garage, or independently from the battery.

There are several types of electric heaters for heating crankcase oil:

- Silicone heater

. The flexible silicone heating element has an adhesive side and easily attaches to the outside of the engine cover. It can be powered by 12, 24 or 220 V.

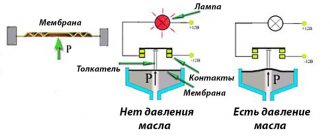

- Flexible probe

. Warming up with an electric probe is carried out through the hole for the oil dipstick. A flexible heating element is immersed in the crankcase and heats the oil when a 12 V electric current passes through it.

- Heater built into the drain plug

. Instead of a standard plug, a part with a built-in heating element is used.

- Electric heating element

. The heater is built into the pan and produces heating in a direct (for standard metal heating elements) or indirect (for ceramic dry heating elements) method.

When choosing a heating method, you need to be guided by factors such as heating speed and type of power supply. It is believed that the electric probe heats best, and the heating element heats as quickly as possible.

When heating with a heating element, you need to either accurately detect the heating time, but it is better to use a thermostat

, which will control the temperature and prevent overheating.

Another important note when heating the oil with heating elements. If you use a standard metal heating element, make sure that it is completely immersed in liquid, otherwise the heater will quickly burn out. A dry ceramic heating element is free from these shortcomings - it will quickly and efficiently heat the oil while in a special protective flask, which is welded into the pan (see photo below). However, the cost of a dry heating element is higher than a regular one, although this is compensated by its durability and efficiency.

Using silicone heaters and ceramic dry heating elements to heat the oil in the crankcase

In the video you can see a review from a client who purchased a dry ceramic heating element from the manufacturer Polimernagrev and installed it on his car.

Install the heating element to heat the engine crankcase quickly enough,

but installation should be carried out only by specialists, because everything must be done with special care and accuracy. Improper installation of the heating element can damage wiring or fragile elements in the car.

Why is it necessary to heat the lubricant in the engine in winter?

How often in frosty weather we fail to start the engine of our car, or it starts after several attempts at the starter, which is accompanied by a strong discharge of the battery. It’s especially hard for those drivers whose cars sleep in the open air, in courtyards, and in parking lots. Diesel engines are subjected to the most difficult tests, since diesel fuel has the properties of thickening more than traditional gasoline.

At the same time, the oil pump is not able to immediately supply thickened lubricant to all parts of the power unit. It reaches the most distant of them only after 2–3 minutes, and at this time their accelerated wear occurs, subsequently leading to repairs. Therefore, the most optimal task would be to ensure that the oil is warmed up in the engine crankcase, and this can be done using any device powered by 12 Volts.

Effective pre-heating is designed to be provided by special heaters, which are presented in a variety of ways on the automotive market. These are heating devices that are installed in the same place where the drain plug is usually located, which we use when draining used oil. Their task is to heat the lubricant to the required temperature and ensure its supply to various engine components. This makes it easier to start the engine and, at the same time, reduces its wear.

Another useful function is the fact that the battery is recharged with a weak current, which makes it possible not only to warm it up, but also to restore capacity. Such devices are quite simple and unpretentious to use and maintain. They are durable and suitable for almost any brand of vehicle. If you periodically have problems starting from a battery in winter, I recommend purchasing one of these devices.

Tags: pre-start, oil heater, 12v.

Comments 93

The thing is controversial, the efficiency is not great, but the battery life may not be enough to start. But you can definitely use it after the start, speeding up the warm-up. And another very important point, the maximum transmitted power density for oil is 2.4 W/cm2. Oil conducts heat poorly and can create local overheating. For myself, I heat the oil at 220V. For antifreeze it’s already worth it, and it’s difficult to fit into these 2.4 W, I’m thinking about putting on spring rings. I also installed a heat exchanger under the oil-antifreeze oil filter, which speeds up the heating of the oil after starting (in reality, the oil takes three times as long as the antifreeze to heat up in winter) and cools it under heavy loads.

I also want an oil heater. I installed the Gulf Stream Heat Accumulator pre-heater. It warms up the engine cooling jacket well in 5 minutes. But the main thing is the oil, if it doesn’t flow well, scuffs will form. It would be a good idea to connect the oil heater to the same timer as the Gulf Stream. But I see it takes you 40 minutes to warm up. Is it possible to heat up in 5 minutes? And why not make a more powerful heating element so that 5 minutes is enough?

It’s better to make such a thing from 220 and if it works together with an electric boiler, the effect will be greater

Videos don't work.

Well, how are the results for 2 years? How many batteries died? Does the gene have time to charge them? But if you heat the oil from -45, will it be enough to heat the oil?

I want something like this too)))) can I order from you?

Hello, tell me how it heats up?

My diesel engine starts at -24 with one turn of the starter (if the battery can turn normally), although it takes a minute. The oil is Lukoil luxury, semi-synthetic.

A competent report, everything is beautiful and neat! Enjoyed reading it. My opinion is that the engine will die faster, but it will add life to the engine, good luck...

...the idea is not new, in the 80s I did a similar one on a humpback, it’s useful (even for the battery, it’s not just that they recommend turning on the headlights for a while before starting in cold weather), and the oil was AC8 and that’s all (in the summer they poured waste from the cornfields) ...but fortunately there is progress in this direction too, it’s synthetic and as a completely budget option - an electric probe (from 12V, hooked up with a crocodile), although there is a drawback - the whole thing gets hot, but you need the part that’s in the oil... think about it, it can do it smart probe... (if you like the idea, take it as a co-author)

A little more work and it will be useful.

Heat the oil? As soon as oil with a temperature of -5 enters an engine with a temperature of -24, it will immediately cool down.

You cannot thermally insulate the crankcase - you will overheat the oil and it will lose its characteristics.

The motor needs to be warmed up, that is, such a heater needs to be put into the cooling jacket.

And also, I would recommend lubricating the contact between the insulator and the pin itself with thermal paste, otherwise the work is 5+

Regarding the heater in a shirt, the idea has been around for a long time, the project is in the process of development.

even a deeply seated battery will show 12 volts