September 16, 2020 Lada.Online 113 801 24

Why do LADA owners care about the frequency of replacing the timing belt (gas distribution mechanism) on their cars? Mainly due to the consequences of a broken belt, in some cases the valve bends, which ends in expensive repairs. Let's figure out at what mileage the manufacturer recommends changing the timing belt and rollers, as well as what its actual service life is.

Factory replacement schedule

According to the service book issued by AvtoVAZ, the timing belt should be changed every 50,000 km. In this case, adjustments should be made every 0 km.

But since the Largus is equipped with a Renault engine, these data do not coincide with those written in the Renault service manual.

So, who to believe in this case? It is worth referring to the factory manual, which is published in French for the K4M engine that is installed on Largus.

A similar K4m engine is found in Renault Megane and Renault Logan

According to this document, the timing belt must be changed every 60 thousand km, regardless of condition. The adjustment is carried out, it is worth paying attention - no later than 15,000 km. That is, it can be carried out earlier.

When is it better to change according to the experience of the owners

The valve rockers came off because the timing belt broke.

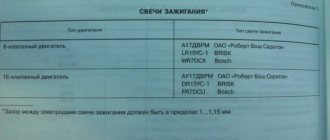

Having considered the information and experience of many owners of this car, we can say that there are quite a lot of cases when the belt fails ahead of schedule. This is due, first of all, to the quality of the spare part. So, a Bosch timing belt will last as long as the original one, or maybe even better.

Of course, it is worth noting that, although we do not always expect that we are buying a high-quality spare part, it lives up to expectations.

8 exhaust and 2 intake valves “bye-bye” as a result of a broken timing belt

So, a timing belt can fail at 30,000 km, and it’s good if this is discovered during adjustment, and not on the road, because then the owner will incur a large sum of money for repairs. Therefore, it is recommended to monitor the condition of the part regularly, or better yet, every 5,000 km. If cracks occur, replace the belt.

Possibilities for improvement

The only real modification, according to the experience of many motorists, is the installation of a sports-type timing belt and pulley. They have increased strength and resource. They are produced mainly by analogues from France, such as “FRW” and “FranceSport”.

On the domestic spare parts market, these parts are very difficult to obtain, but possible. So, having installed a sports timing belt, you can forget about it for the next 80-90 thousand km. But this does not cancel the adjustments.

Features of service provision

Before talking about the services we offer and their relevance, you should pay attention to the design features of the engines installed on this station wagon, its pseudo-off-road version and van. There are four in total

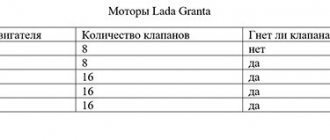

Initially, the model, which is essentially a modernized version of the Dacia/Renault Logan MCV of the first generation, was equipped with engines installed on Renault Largus cars. It received K4M and K7M gasoline engines, both in-line “fours”, the first has 16 valves, the second has 8 valves. A further development of the model was the installation of motors of our own production, adapted for French gearboxes. The K7M engine was replaced by the VAZ 11189 (a slightly modified version of the VAZ 11186); this power unit is not found anywhere else on other Togliatti-assembled models. The K4M was replaced in 2022 by the VAZ 21129 (a modernized version of the VAZ 21127 brought into compliance with Euro5 environmental standards), this engine is also installed on the Lada Vesta and Lada X-Ray

There are four of them in total. Initially, the model, which is essentially a modernized version of the Dacia/Renault Logan MCV of the first generation, was equipped with engines installed on Renault Largus cars. It received K4M and K7M gasoline engines, both in-line “fours”, the first has 16 valves, the second has 8 valves. A further development of the model was the installation of motors of our own production, adapted for French gearboxes. The K7M engine was replaced by the VAZ 11189 (a slightly modified version of the VAZ 11186); this power unit is not found anywhere else on other Togliatti-assembled models. The K4M was replaced in 2022 by the VAZ 21129 (a modernized version of the VAZ 21127 brought into compliance with Euro5 environmental standards), this engine is also installed on the Lada Vesta and Lada X-Ray.

On the timing belt of all Lada Largus engines there is a belt, or rather a timing belt of the Lada Largus, there are toothed pulleys for the crankshaft, camshaft (if there are 16 valves, then there are two pulleys, according to the number of camshafts, that is, one pulley for the intake camshaft, the second for the exhaust), water pump . A Largus timing tension roller is also used (if there are 16 valves, then the tension roller tensions the belt, and a second Largus timing support roller is also used).

Our specialists carry out both replacement of the timing belt for 16 Largus valves and replacement of the timing belt for Largus 8 valves.

In addition to the timing belt, the Lada Largus uses a belt that drives auxiliary units. This is the so-called Lada Largus generator belt or the second name is the Largus drive belt. We replace the Largus drive belt. The specifics depend directly on the design of the drive that ensures the operation of the auxiliary units, or more precisely, the configuration of the car. A number of configurations are “empty”. This is the simplest diagram, there are two pulleys, one for the generator, the other for the crankshaft, between them is the Lada Largus generator belt. In this case, we offer such type of work as replacing the Lada Largus belt.

The second scheme is a little more complicated. A number of trim levels include the installation of power steering (power steering). Then a power steering pump pulley and a belt tensioning roller (it’s called a tensioner) are additionally installed. This Largus drive belt differs from the generator belt, it is longer. In other words, a diagram with three pulleys and one roller.

Our craftsmen are replacing the Largus drive belt.

The richest trim levels come with not only power steering, but also air conditioning. In this case, an additional drive pulley for the air conditioning compressor and a bypass pulley for the belt, that is, four pulleys, two rollers and a Lada Largus air conditioning belt.

We replace the Largus air conditioner belt, and also offer to purchase the Lada Largus spare parts necessary to provide this type of service.

Owner reviews

How long does a timing belt last in practice? Belt breakage does happen, but rarely. Here are a few examples when the timing belt broke at low mileage:

The Za Rulem magazine, which has LADA models in its editorial fleet, encountered the problem twice:

Recommendations

. The reasons for a broken timing belt can be different. For example, due to the low quality of the rubber product itself or due to the pump jamming. To avoid costly repairs, it is recommended to regularly (every maintenance) check the condition of the timing belt, especially if the mileage is more than 60,000 km.

How often do you recommend changing the timing belt and rollers? Take part in the survey and leave your feedback in the comments.

Where can I buy

: Timing belt kits at low prices are available in our online store (Timing belt category).

Source

Preparatory work

If you forgot when you changed the timing belt on the Largus (16 valves), it’s better to carry out the repair. If you do not want to make the replacement yourself, contact a service station. To repair on your own, you will need to do the following preparatory work:

- Disconnect the negative wire from the battery. This will ensure that your vehicle is fully powered.

- Disconnect the inlet pipe, and then remove the drive belt of the generator and other auxiliary mechanisms.

- The support on the right side of the engine will interfere with you, so it must be removed.

- The protection cover consists of lower and upper halves. They must be removed by unscrewing the mounting bolts.

That's all, the preparatory work is finished. You can begin replacing the timing belt on the Largus (16 valves).

Timing belt, when to change?

We often come across the following comments from Largus owners: “I changed the belt at 60t.km, but it’s still completely new, it could have lasted just as long!” “I will be at 100t.km. change” “I change it every 60 thousand km and don’t worry” “I changed it at 120 thousand, the belt was not very worn”, etc.

Let's take a look at the service book:

But there is a nuance, we have a warranty of 3 years or 100,000 km, whichever comes first, that is, the last 20 thousand km before replacement will have to be driven at your own peril and risk.

Conclusion: If the car is under warranty, it is quite possible to delay replacing the timing belt for up to 100 thousand km, if not, then this is completely the choice of the car owner.

PS: Everything stated above is purely IMHO, and not as a recommendation for action. It would be interesting to see your opinions and who has already changed it - at what mileage. I myself plan to change it at 100 t.km., this will no longer be during the warranty period, since in 17 I’m unlikely to travel 75 t.km.

Replacing the timing belt and attachment belt, 105 t.km.

The time has come to change, according to the regulations 120t.km or 6 years, I haven’t reached 120 yet, but 6 years have just passed. In addition to this, the timing belt rollers began to whistle when cold. To begin with, I ordered this set from a turner.

New timing kit Dayco KTB 460. Almost the same price as Gets. The belt is a reinforced type, with a fluoroplastic layer on the teeth. The tension bearing is again Pshek's.

The plugs did not want to come out, they were only able to be removed with the help of a mounting tool, and the new ones went in quite easily.

This is the view that opens when removing the timing cover.

The belt is in excellent condition in appearance, no cracks or other defects are observed, at first glance it could easily go up to the regulated 120t.km, but in fact it is overextended, as evidenced by a slight deviation from one plane of the grooves in the camshafts, and the indicator the tension went strongly counterclockwise.

Plus, there is a large amount of belt wear product in the form of soot on the walls of the compartment.

The tension roller has a lot of play, the tensioner mechanism creaks, the remaining lubricant has become like paraffin. The deflection roller plays, but less severely, it is double-row, there is severe wear on the outer row, because of this the cage of balls easily came out. If it had been a single-row roller, it would definitely not have survived. The lubricant in it is black, but not dry like in a tensioner.

The iron covers for additional protection of the cuffs from the standard bypass do not fit on the Dayco bypass, but although their installation is not essential.

The drive gear did not want to come off, so I had to make an improvised reverse hammer. And the reason for this was that rust had formed on it and it had become stuck to the crankshaft.

Pump without any comments. I checked the crankshaft stop against the stop again, put on the belt and adjusted the tension.

By the way, the rubber wear dust sticks so strongly to the walls of the compartment that it is not blown off by the compressor; I had to wipe it with a cloth with clean gasoline wherever I could get to it. The pulley was unscrewed and tightened simply by locking the crankshaft with a screwdriver inserted into the brake disc in 5th gear.

The poly V-belt is also in excellent condition, it could still run if it weren’t heavily clogged with grains of sand, they eat deep into the grooves and wear out the pulley ridges, the photo shows shiny inclusions in the belt grooves and you can see that the edge of the drive pulley ridge seems to be in small hiccups.

I also took a Dayco as a replacement, but not 1822, but 1820, since they write that this size is suitable for k4m, but it didn’t work out for me. I don’t know how it should fit, if the standard 1822 is difficult to tension with the tension roller fully retracted. But no matter how hard I tried, I couldn’t put it on, and ended up ruining it.

I installed it, a cheap Chinese one from stock, now I’ll have to constantly monitor it, I hope it will last until spring. The standard rollers are still loose, last year I took them off and they were dry, I added grease and a poultice for the dead ones, but it lasted for a year.

What’s good about standard rollers is that they are made of iron, but the price of such ones is high, in fact there is no point in changing them completely, only the bearing wears out, I’ll try to re-press them. In the meantime, I installed cheap Chinese ones, although probably now there are also expensive Chinese ones only under the brand.

I assembled it, started it up, the difference in performance before and after changing the timing belt is felt, the sweetness is gone, maybe it’s a placebo, but it seems that now the traction has become better. After a year, you will need to remove the cover and check the tension and condition. On replacement belts, such intervals for changing the timing belt can no longer be done. Maximum 50 thousand, or five years and constant monitoring.

20.05.2020:

a month after the replacement, the Chinese belt of additional equipment came to an end, I certainly didn’t count on its quality, but I didn’t expect that the kerdyk would come so quickly, in the end I had to clean the original belt from inclusions in the grooves and return it back, and it still stands and the mileage on it is currently 110,050t.km.

Brake system

Checking the fluid level in the reservoir++++++++++Checking the condition of the brake discs and pads of the front wheels++++++++++Checking the condition and cleaning of dust from the brake mechanisms of the rear wheels———+——— +——Replacing brake fluid*** (instructions)—————+————Lada Largus timing belt replacement

Content:

A broken timing belt on a Lada Largus can cause costly engine repairs due to bending of the valves, which rest against the pistons. Of course, it is under no circumstances worth bringing the equipment to such a state; to do this, you need to regularly service the engine and replace components that have exhausted their service life. The manufacturer usually sets a service life of at least 120,000 km, but this does not mean that all this time you can not look under the hood of your car.

Chassis

Checking the condition of the tires and their pressure++++++++++Checking the condition of the ball joints and silent blocks of the suspension arms++++++++++Checking the condition of the front and rear shock absorbers+++++++ +++Motor line of the Largus model

Over the years, 8 and 16 valve French and domestic engines were installed on the Lada heel. Although today engineers prefer to use only Russian units, there are still many Largus with Renault engines driving on the country's roads. So, during the entire production period, four types of internal combustion engines were used in the model:

Each of these engine types has its own characteristics that affect the belt replacement process. We will dwell on these nuances in detail below, but for now we will only note that it will be a little easier for owners of the 8-valve version to complete the necessary work.

Timing for belt replacement according to regulations and experience

Many people have encountered the problem of a belt breaking on the highway even on “eights” and “nines”, and now they believe that it is better to play it safe and change the belt already at 50 thousand mileage. But as practice shows, this concern is not always justified and many Largus models can easily travel over 100,000 km without replacement.

Much also depends on the specific use of the car - in the ragged city rhythm, wear always occurs faster than on the highway. The manufacturer in the service book recommends replacement no earlier than 120,000 km. However, from the experience of car enthusiasts, we can say that the belt usually exhausts its service life by 100 thousand km. If you don’t want to use the services of a tow truck one day, it’s better to change it in advance.

If you have doubts about whether it is time to change the belt, simply assess its visual condition by opening the hood of the car. If there are cracks on the surface, traces of abrasions, delamination or protruding cord threads are visible, then it is necessary to replace it as soon as possible. Even if there are no external signs of wear, it is still worth periodically checking the degree of tension, since an overtightened or sagging belt can also lead to breakage.

Replacing the belt on the 8-valve version

The 8-valve engine has a simpler design and only one camshaft, so the process of removing the drive belt and its subsequent installation is a little simplified here. In general, the procedure itself is not particularly difficult and even a novice car enthusiast can perform it if he has the necessary tools: a set of keys, hexagons, screwdrivers, as well as a special device for tensioning the belt. Although you will have to tinker a little in the garage.

Removal

To work, you will need a lift or inspection hole. First you need to disconnect the battery and jack up the car a little in the front - you will have to remove the front right wheel. If the car has a K7M engine, then you must also first disconnect the inlet pipe. Next you need to remove the wheel and crankcase protection.

Next, the right engine mount is unscrewed. The engine weighs more than 100 kg and can easily cause injury if dropped. To prevent this from happening, be sure to place a jack under its bottom before starting work. Lower the engine slightly to reach and remove the timing belt covers. Immediately after removing the wheel, it is necessary to remove the crankcase protection, unscrew the fasteners on the pulley and remove it from the crankshaft. In this case, engage fifth gear and press the brake pedal all the way.

To remove the belt from the cylinder, it is necessary to set the latter in the appropriate position. You need to rotate it until the mark shows that it is in the TDC position. On some models of power units there is a special symbol - the Latin letter D. This is necessary to fix the crankshaft in the locking groove. The last step is to loosen the nut on the roller and dismantle the belt itself. You need to remove it from under the roller, and then sequentially from the gear, pump and pulley.

Installation of a new belt on Lada Largus

Once the old belt is removed, a new one is installed in its place. But first you need to carefully examine other timing components; perhaps they are also involved in the rapid wear of the part being replaced. If everything is in order and the service life of the belt has come to an end, according to the regulations, then a new one is installed. The location of the arrows on the new product indicates the direction of rotation of the mechanism. The procedure for installing the belt is as follows:

Next, tension is carried out using a special wrench until the marks are level with each other. At this point, the belt installation process is completed and all that remains is to assemble the motor and check its performance.

Snapshot53252323

Marking of the drive belt for auxiliary units 6РК 995 (six-V-ribbed, length - 995 mm).

Marking of the drive belt for auxiliary units 6РК 995 (six-V-ribbed, length - 995 mm). In order to improve visual control, remove the plastic engine casing. To check the condition of the belt, engage fifth gear in a manual transmission, push the car (or rotate the suspended wheel) and inspect the belt along its entire length. On a car with an automatic transmission, remove the right mudguard of the engine compartment and, by rotating the crankshaft by the bolt of the auxiliary drive pulley, check the condition of the belt.

With any of the gearboxes, the following method is also possible: apply chalk marks to sections of the belt and, turning on the starter for short periods of time, turn the crankshaft at small angles. We inspect the belt along its entire length, checking the areas covered by the marks.

The belt should not have cracks, tears or separation of rubber from the fabric base. A defective belt must be replaced. To do this, from the engine compartment side...

Replacing the belt in the 16-valve version

With a 16-valve engine, replacing the belt will require a little more effort, and most importantly, the presence of additional parts and devices: fixing plates and pins, as well as plugs for the end of the cylinder head and closing camshaft limit switches.

To gain access to the timing belt, you need to go through similar steps as with an 8-valve engine:

Next, in the hood space, the fastening elements of the timing drive are unscrewed and its top cover is removed. The pulley can also be operated by engaging 5th gear and pressing down the brake pedal. Having secured the crankshaft from turning, using a pry bar for this, and unscrewing the fastening element, the camshaft pulley is dismantled, and the bolt holding it with a pair of nuts must be screwed back in. The bottom cover is removed to gain direct access to the timing mechanism.

Then a resonator is taken out to supply air. At the end of the head (it is located on the flywheel side) two plugs are knocked out. You can do this with a regular screwdriver. Now you need to set the 1st and 4th cylinders to the TDC position. The crankshaft is rotated until the grooves on the camshaft ends are horizontal. They need to be fixed in this position using a pre-prepared plate. The crankshaft may spin. To eliminate the problem, a pin is installed on a special plug on the block. The pin will serve as a kind of lock, preventing the shaft from turning, the main thing is that it goes into the hole all the way.

Alternative method

There is also an alternative replacement method that does not require a plate or pins, but does require the assistance of another person. He will have to insert thin metal spokes into the spark plug holes of the 1st and 4th cylinders, while holding them strictly vertically.

Next, the crankshaft rotates until the Renault logos are in the correct position, namely on the top on the left pulley and on the right on the bottom. By looking at the spokes, it will be possible to determine the moment when the pistons reached TDC and further scrolling leads to their lowering. Once the parts are in the correct position, it is advisable to mark this with a felt-tip pen or paint on the camshaft and flywheel housing.

Belt removal

You need to loosen the nut on the roller and carefully dismantle it and remove the drive element itself from it. Next, it is disconnected from the pump, crankshaft and camshaft. It is first advisable to loosen the tension a little by turning the structure in the opposite direction to the marks indicated on the belt.

Belt attachment in a 16-valve Largus unit

Installing the belt is also easy. Everything is done in the same order as in the case of an 8-valve engine. In this case, you need to put the drive belt on the roller in advance and only then return the mechanism to its place, sequentially putting the element on the crankshaft, pump and camshaft. When installing, again you need to pay attention to the arrows - they should be directed in the direction of rotation.

If the work is carried out without the use of additional fixing devices, then an assistant will be needed when installing the belt. When putting the drive element on the camshaft pulleys, they need to be aligned according to the previously left marks. To perform the procedure, turn the camshafts with keys until they are aligned with the marked marks. It is necessary to hold the mechanism in a given position while the belt is tensioned on it. It is impossible to complete this sequence of actions alone, so you need a partner.

Features of service provision

Before talking about the services we offer and their relevance, you should pay attention to the design features of the engines installed on this station wagon, its pseudo-off-road version and van. There are four in total

Initially, the model, which is essentially a modernized version of the Dacia/Renault Logan MCV of the first generation, was equipped with engines installed on Renault Largus cars. It received K4M and K7M gasoline engines, both in-line “fours”, the first has 16 valves, the second has 8 valves. A further development of the model was the installation of motors of our own production, adapted for French gearboxes. The K7M engine was replaced by the VAZ 11189 (a slightly modified version of the VAZ 11186); this power unit is not found anywhere else on other Togliatti-assembled models. The K4M was replaced in 2022 by the VAZ 21129 (a modernized version of the VAZ 21127 brought into compliance with Euro5 environmental standards), this engine is also installed on the Lada Vesta and Lada X-Ray

There are four of them in total. Initially, the model, which is essentially a modernized version of the Dacia/Renault Logan MCV of the first generation, was equipped with engines installed on Renault Largus cars. It received K4M and K7M gasoline engines, both in-line “fours”, the first has 16 valves, the second has 8 valves. A further development of the model was the installation of motors of our own production, adapted for French gearboxes. The K7M engine was replaced by the VAZ 11189 (a slightly modified version of the VAZ 11186); this power unit is not found anywhere else on other Togliatti-assembled models. The K4M was replaced in 2022 by the VAZ 21129 (a modernized version of the VAZ 21127 brought into compliance with Euro5 environmental standards), this engine is also installed on the Lada Vesta and Lada X-Ray.

On the timing belt of all Lada Largus engines there is a belt, or rather a timing belt of the Lada Largus, there are toothed pulleys for the crankshaft, camshaft (if there are 16 valves, then there are two pulleys, according to the number of camshafts, that is, one pulley for the intake camshaft, the second for the exhaust), water pump . A Largus timing tension roller is also used (if there are 16 valves, then the tension roller tensions the belt, and a second Largus timing support roller is also used).

Our specialists carry out both replacement of the timing belt for 16 Largus valves and replacement of the timing belt for Largus 8 valves.

In addition to the timing belt, the Lada Largus uses a belt that drives auxiliary units. This is the so-called Lada Largus generator belt or the second name is the Largus drive belt. We replace the Largus drive belt. The specifics depend directly on the design of the drive that ensures the operation of the auxiliary units, or more precisely, the configuration of the car. A number of configurations are “empty”. This is the simplest diagram, there are two pulleys, one for the generator, the other for the crankshaft, between them is the Lada Largus generator belt. In this case, we offer such type of work as replacing the Lada Largus belt.

The second scheme is a little more complicated. A number of trim levels include the installation of power steering (power steering). Then a power steering pump pulley and a belt tensioning roller (it’s called a tensioner) are additionally installed. This Largus drive belt differs from the generator belt, it is longer. In other words, a diagram with three pulleys and one roller.

Our craftsmen are replacing the Largus drive belt.

The richest trim levels come with not only power steering, but also air conditioning. In this case, an additional drive pulley for the air conditioning compressor and a bypass pulley for the belt, that is, four pulleys, two rollers and a Lada Largus air conditioning belt.

We replace the Largus air conditioner belt, and also offer to purchase the Lada Largus spare parts necessary to provide this type of service.