What is needed for repairs

First, you need to determine which support on the VAZ 2110 engine should be changed (if you do not want to change all the damper mounts at once). To do this, you need to do an independent inspection of these parts. Sometimes, the power plant seems to be tilted horizontally on one side or tilted along the central axis of the car. This is the first sign to replace the damper mounts.

| Locksmith kit | Rolling jack |

| A couple of short boards | Angle grinder (grinder) |

Two cushions (side) secure the engine to the left and right side members in the engine compartment. And one (rear) fixes the motor to the bottom. Therefore, it is necessary to lift the machine on a lift or install it on a viewing hole. The wear is immediately visible. The rubber has tears and core failure. Depending on the result of visual diagnostics, you should purchase the required number of parts for installation.

You will need a tool. In most cases, a standard locksmith set consisting of open-end and box-end wrenches with heads will be sufficient. In addition, to replace engine mounts on a VAZ 2110 you will need a rolling jack and a pair of short boards. It is advisable to have electricity and a cutting machine with a disc, since you may have to cut off the mounting bolts.

Helpful information! A couple of hours before repairs, it is strongly recommended to apply universal lubricant “Liquid Key” to the threaded connections. Damper supports are changed very rarely, therefore, unscrewing them without prior preparation is quite difficult.

Design features

If you have a “ten” with an 8-valve engine, then the design provides two side and one rear support;

On a 16 valve engine there are two side mounts, one lower and one upper.

It is important to note that 8 valve engines on the 10 have a rear engine mount, while on the 16 valve there is none. But such motors can boast of having additional supports.

Regardless of the design, the replacement procedure is performed using a similar method.

Malfunctions

In fact, it is quite easy to detect failed airbags, since engine vibrations will immediately increase.

If the power unit is working normally, but the body is shaking, vibration is felt on the steering rack, pedals, and dashboard, then there is no doubt that the engine mounts are worn out.

The vibration peak occurs when the engine starts and when it is turned off. If the rubber elements are completely worn out, then a knocking noise will begin to appear. It is caused by contact of engine elements with the supports.

To make sure the cushions are worn, turn on the engine, lift the hood, and visually inspect the supports and cushions. By placing your hand on the engine, you will tactilely feel an increase in vibrations compared to the normal behavior of the car.

There may be several reasons for problems.

| Causes | Peculiarities |

| Deformations | Deformation of elements can occur during the life of the pillows, under mechanical or temperature influences |

| Loss of elasticity | Rubber does not have a large margin of strength, so it ages over time. This effect increases when exposed to temperature changes. |

| Delamination and cracking | The pillow can literally fall apart and creep apart when exposed to chemically aggressive substances. |

Is replacement required?

If you find that the rear airbag or any other airbag has begun to wear out, you should under no circumstances delay repairs.

In addition to the discomfort of the driver and passengers when the car is moving, you risk delaying the breakdown until the moment when destructive processes begin in the operation of the gearbox and power unit.

When starting to repair engine mounts, you should think about whether it is worth changing the cushions separately, or replacing the mounts as a whole.

If the support is not damaged, it is not necessary to replace it. That is, in such situations it is enough to simply replace the pillow. A set of new pillows for a VAZ 2110 today costs about 1.3 thousand rubles. A set of supports will cost you 2.5 thousand rubles.

Doing the work yourself or contacting a service station is your choice. But you should know that you will be charged at least 300 rubles for replacing one pillow.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

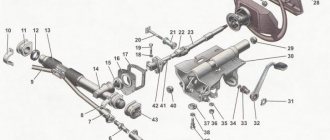

In order to install the additional engine rod, you will need to disassemble it into parts. Then remove the ignition module and install part No. 1. After this, install part No. 2 and secure the structure with bolt No. 3.

If the installation is carried out on an 8kL engine, then you will need to move the ignition module using a special bracket (code 3705.0100.04). On a 16kL engine such a bracket will not be needed, but installing the support is somewhat more difficult due to the smaller space under the hood. It is better to carry out the work on a lift, and at the same time it is recommended to install a standard support from 8kl on the gearbox.

If the engine is 1.6 l, then a bracket will be required (code 3705.0300.04).

Conclusion

I installed an additional engine mount on a VAZ 2110 and..

Source

Replacing the left engine mount of a VAZ 2110

Place the car on a level and solid surface. Disconnect the negative terminal from the battery. Remove the crankcase protection. We place a jack under the engine, and use a piece of board (as a spacer) to lift the engine. The power plant is suspended in this way and the supports do not experience any load.

Next, we perform the following steps:

- Unscrew the nut of the central stud (15 mm wrench);

- unscrew the two fixing bolts of the protective cover (13mm wrench);

- under the bracket, unscrew the 3 bolts that connect it to the spar (17 mm wrench);

- then, we take out the worn-out pillow;

- We replace the damper part with a new one and assemble the structure in the reverse order.

On a note! Spare parts from imported suspension manufacturers, such as: Lemferder, SWAG, RUVILLE, SKF, can provide high-quality and long-lasting performance. If they are not in the store, they can be delivered to order.

Replacement

For eight-valve engines

- Prepare the car for repair: place it on a flat surface, place stops under the rear wheels, remove the engine protection.

- Unscrew the generator belt tensioner bolt and remove the belt (key 13).

- Place the jack under the engine, place a thick wooden beam or board under its upper part. Raise the engine to remove the load on its mounts.

- Unscrew the nut of the central fastening of the right pillow (15 wrench).

- Unscrew the bolts securing the pillow to the bracket (key 13).

- From the bottom side of the right arch, unscrew the 3 bolts securing the bracket to the spar (17 key).

- Remove the bracket and replace the old cushion with a new one.

- Carry out installation in reverse order.

- Move the jack under the gearbox and lift it up.

- Unscrew the nut of the central fastening of the left pillow (15 wrench).

- Unscrew the two bolts securing the support and remove it (key 13).

- Replace it and reassemble the structure in reverse order.

- Unscrew the two 17 nuts securing the cushion to the body, and then two more nuts securing it to the gearbox (removal and replacement of the rear support is carried out from the bottom of the car).

- Remove the rear support.

- Unscrew the nut securing the pillow to the bracket (19mm wrench). Remove the old pillow and install a new one.

- Install the rear support in reverse order.

Variation and checking the condition of the support bearing

Many owners of VAZ 2114 cars often encounter the problem of extraneous knocking in the struts, the main cause of which is the support bearing. If you suspect a fault in the support bearing, you do not need to immediately rush to replace it; first of all, check its condition.

Before assessing the importance of the support bearing in the overall assembly of the car, it is necessary to understand the structure of the suspension. In the assembly of VAZ models, hydraulic struts are used, the main function of which is to smooth out vibrations in the suspension spring during driving, and also to ensure the quality and safety of its operation.

The support bearing is a component of the front suspension shock absorber strut. Its function is to allow smooth movement of the connection between the shock absorber and the car body. If it malfunctions, problems arise with driving the car, and an unpleasant knocking sound occurs in the suspension, especially when driving on a bad road.

Type of support bearing

- With inner built-in ring or outer built-in ring. For installation there is no need to use clamping flanges; in this case, holes are provided for installation.

- The outer ring is detachable.

- The inner ring is detachable.

- The finishing bearing has strong rigidity.

Type of support bearing

The support bearing has a self-explanatory name; it is something like a support for the front shock absorber strut, located in the area of the connection with the car body. This arrangement provides for axial loads that the bearing can withstand.

To make an accurate diagnosis of a support bearing, it is necessary to carry out a number of simple manipulations:

- Under the hood of the car, you need to place your palm on the bearing. At this moment, the second person is pumping the car, the appearance of knocking indicates the need for an urgent replacement of the support.

- But, still, it is better to carry out the necessary procedures for removing and subsequently disassembling the bearing.

All VAZ models need to change their support bearings after 40,000 km.

A completely deteriorated bearing, in addition to knocking, disrupts wheel alignment; this factor creates a danger when driving and increases wear on the shock absorber struts. Those drivers who categorically do not want to pay attention to the malfunction of their own car increase the chance of complete bearing failure, which will result in a hole in the hood from the strut. And as a result, financial investments increase significantly. Think about whether this is a way to get away from the problem that has arisen.

Replacing the right engine mount of a VAZ 2110

Place the jack under the box. We hang the engine and remove the load from the cushion. Completely disconnect the battery and remove it (this will be more convenient).

Next, we move in the following sequence:

- Unscrew the nut of the central stud (15 mm wrench);

- Unscrew two bolts (13 mm wrench);

- We take out the central pin (you will have to loosen the jack a little);

- We take out the support bracket and replace the pillow with a new one;

- We insert the new support into place and raise the engine;

- We tighten the damper assembly with the bolts in the reverse order.

On a note! The support mounting areas on the side members may be in poor condition (rust). In order to extend their “life,” you should cover the damaged area with Movil immediately before installing the bracket.

HOW THE REPLACEMENT IS MADE

It’s immediately worth noting that many modifications of these cars have the same suspension. For example, replacing the support bearing of a VAZ 2115, VAZ 2114 and VAZ 2109 is absolutely identical.

Let's proceed directly to the repair itself. There are several ways to carry out the work:

- removing the entire rack, with steering arms and other parts attached to it. In this case, the wheel tilt settings are saved, and you do not have to perform the wheel alignment again;

- you can disconnect the strut from the steering cam and then dismantle the remaining parts.

FIRST METHOD

- We dismantle the hub cap and unlock the CV joint

- We unscrew the CV joint until it is completely loose, while the brake pedal should be in a clamped state.

- Jack up the car and unscrew the wheel.

- Unscrew and unscrew the tip nut and press out the pin.

- Next, you need to dismantle the ball and free the brake hose from the shock absorber.

- Loosen the strut nut and unscrew the three support fixation nuts. Then the CV joint is removed and the strut is dismantled.

- Next, the spring is tightened, which is required before changing the support bearing on the VAZ 2114.

- After this, we put everything in place until the car is completely assembled.

SECOND METHOD

- We jack up the car and remove the wheel.

- Then loosen the hub mounting clamp and remove the steering tip.

- We dismantle the ball and remove the brake caliper.

- Next, loosen the strut nut and tighten the spring.

- We change the support bearing and put everything back together.

After completing the work, it is advisable to replace the strut mounting nut with a new one.

Functionality check

Before you start replacing the pillows, it is recommended to check whether they have really lost their functionality. It is likely that vibrations can occur for other reasons.

To check you need to do the following operations:

- Place the car on stands;

- Place a jack under the oil pan, placing a block or board at the same time;

- Raise the engine until the mounts relieve the weight of the engine;

- Check the pillows;

- Inspect them for cracks;

- Check if they come off easily from the metal backing;

- Has the original hardness of the material been preserved, or has it become too elastic;

- If no visual defects are found, check the play between the plates and the frame;

- Treat the cushions with protective compounds, return the engine to its place;

- Sometimes, to return the supports with cushions to normal operation, it is enough to tighten the fastening nuts.

If the check shows that the pillows have already served their purpose, then the only correct solution is to replace them. These elements are not subject to restoration.

Replacing the rear engine mount of a VAZ 2110

If, when dismantling/installing the left and right supports, the work was carried out in the engine compartment, then to remove the rear damper you will have to crawl under the car. It’s good if there is an inspection hole in the garage, since the ground clearance of the “ten” is quite low and it’s very difficult to crawl up on your belly.

The replacement process looks like this:

- We install a jack under the box and hang the rear part of the engine;

- Unscrew the two support nuts from the body (17 mm wrench);

- Using 2 19 mm keys, unscrew the support mount from the gearbox;

- We remove the support from the seats and take it out from under the car;

- We take out the bolt and replace the damper with a new element (a vice may be needed);

- We return the knot to its place and tighten it;

- We lower the engine with a jack and install the crankcase protection.

After you have managed to change all the engine mounts on the VAZ 2110, the engine should take a level position. You should start the engine and carefully observe the vibration. It should be minimal. This means that the repair was carried out correctly.

Manufacturers and prices

Now you know how to change engine mounts, and you need to talk about the cost of the products. The most popular producers in Russia are Balakovo and Tolyatti. Which manufacturer of the part to choose is up to you to decide. They differ little in quality; the choice depends only on individual preferences. Their prices are approximately the same:

- Engine side mount (popularly called “guitar” for its resemblance) - cost 480-600 rubles, depending on the seller.

- Rear airbag attached to the gearbox (without bracket) – 350 rubles.

- For 16-valve engines, supports cost about 450-500 rubles.

A complete set will cost you approximately 1500-1800 rubles.

But this will significantly improve driving comfort, and the level of extraneous noise will decrease, since the new rubber installed in the supports is much more elastic. Usually there is little choice in stores. Therefore, before removing the engine, make sure that all the cushions are in good condition. If not, replace it. Source

Characteristics

Additional engine support for 8 cells. VAZ 2110 engine is attached to the engine bracket. Designed to limit the movement of the power unit, especially when braking the engine, when hitting road irregularities, you can install an additional (fourth) support for the power unit, as well as when the car suddenly starts moving. An additional support for the VAZ 2110 connects the clutch housing to the cross member of the front suspension. The part ensures uninterrupted operation of the system. The support is made of high-strength material, the distinctive feature of which is reliability and wear resistance. Additionally, a plate for transferring the ignition module is purchased.

The manufacturer reserves the right to change the characteristics of the product, its appearance and completeness without prior notice to the seller.

| Packed length | 0.25 m |

| Packed width | 0.11 m |

| Packed height | 0.11 m |

| Package weight | 1.6 kg |

| Automobile model | VAZ 2110, VAZ 2111, VAZ 2112, VAZ 2170 Priora, VAZ 2171 Priora, VAZ 2172 Priora |

Supports for shock absorber struts for VAZ cars, front-wheel drive

Upper strut supports and RTI repair kits...

Hello dear readers of the RtiIvaz.ru blog. Let's take a look today at RTI kits (rubber technical products) for a front-wheel drive VAZ car. First, let's look at the repair kit for the "ten", which includes: the front strut support 2110, as well as the front bumper, which is more elongated compared to the rear bumper.

The video clearly shows that branded spare parts have easy to read, clear inscriptions indicating the part designation. Nearby are the bumpers on fret 2108, which, when compared with the “tenth” ones, are somewhat smaller in height, both front and rear bumpers.

The repair kit for the VAZ-2110 also includes rubber bushings (popularly called donuts) for the rear shock absorbers, two pieces for each shock absorber. There are also rubber-metal bushings for the rear shock absorber in the repair kit (RTI).

Bushings are a loaded unit and therefore must be replaced quite often. To protect the mirror shock absorber rods, they are equipped with anthers, which are also present in the VAZ-2110 repair kit. Let's look separately at the front strut supports of front-wheel drive Lada cars...

Design number -2110-2902820 upper support, front strut for VAZ-2110, 2111, 2112

If you look at the supports of the front struts of the VAZ-2110, then inside you can clearly see a rubber cushion (cupcake), which, as it wears out, loses its elasticity and resilience and therefore quite often also needs to be replaced. Here, a lot still depends on driving style, so the timing of replacing the front strut supports is different for all car owners.

Design number -2108-2902820 upper support, front strut for VAZ-2108, 2109, 21099, 2113, 2114, 2115

Front strut supports for Lada 2108...

The front strut support for the VAZ-2108, as well as VAZ-09, 014, 015. In the strut support, a double-row bearing is pressed into the body of the rubber cushion itself.

Upper supports with bearings, front struts of a VAZ-2170 car, design number -2170-2902820

Front strut supports for Lada 2170 Priora...

For Priora, the plant produces front strut supports separately with bearings. The shock mount is noticeably different from both the 2110 fret mount and the 2108 fret mount. This is mainly due to the petal-shaped configuration of its top cushion. The front supports come with support bearings made in the form of rings. Bearings are installed at the bottom of the supports.

Upper supports with bearings, front struts of a VAZ-1118 car, design number -1118-2902820

Front supports on fret "Kalina" - 1118 and 1119...

The Kalina's front strut supports, like those on the Priora, are equipped with support bearings. The support itself is somewhat similar to the Priora support, but has a more elongated upper neck.

Rear boot for fret 2108, 2110, 2170 and their modifications

Rear suspension boot, repair kit design number: VAZ 2108-2915681…

Repair kit for rubber products for Lada 2170 Priora:

The “Priora” repair kit includes two rear bumpers from fret 2110, four rubber upper “donut” bushings (two per rod - top and bottom), two rubber-metal bushings for the lower shock absorber eye, as well as two boots (corrugations) from fret 2108 The bushings for the lower shock absorber mounting have an aluminum bushing inside, through which the fastening bolt passes.

Rear shock absorber bushings numbered -1 “upper” and numbered -2 “lower” frets 2108, 2110, 1118, 2170 and their modifications

Rear shock absorber bushings catalog numbers:

Bushings for fastening the upper end of the rear shock absorber, design number: VAZ 2110-2915450 (4 pieces under number 1, see photo). Bushing for mounting the lower rear suspension shock absorber, design number of the repair kit: VAZ 2108-2914054-10 (2 pieces under number 2, see photo).

In general, if there is a need to replace a shock absorber, then it is often necessary to change the entire repair kit for safe and reliable further operation of the car.

The rubber of all parts loses elasticity over time, and therefore it is better to purchase a new repair kit (RTI) for fret 2170 Priora for new shock absorbers, which will help extend the life of the car. Particular attention should be paid to the integrity of the boot, since the “life” of the entire shock absorber largely depends on this.

Useful tips

Please note that when engine vibrations occur, you should not always immediately change all the supports “in a circle”. It happens that even on a relatively “fresh” car, only one element fails, while others are quite suitable for further use. This occurs as a result of technical fluids getting into contact with the rubber part of the cushion, etc.

However, as for basic recommendations, if the car has a mileage of about 80-100 thousand km. and more, and all engine mounts have the same service life and have begun to fail, it is better to immediately replace all such mounts.

The reason is obvious - if the rubber begins to deteriorate from old age, after replacing one clearly faulty element, after a while the next cushion will also no longer cope with its task.

It is also important to select only original products or high-quality analogues for replacement, as well as purchase parts from trusted sellers. The fact is that there are a large number of spare parts on the market for VAZ cars, but not all of them are of high quality. Moreover, you often come across cheap fakes of an original of unknown origin.

Basic faults

When a support bearing fails, a knock resembling dull blows appears in the front part of the car in the area of the pillars. Most often, such symptoms are observed when driving over uneven surfaces.

A knock indicates that the bearing has ceased to cope with its duties due to a violation of its integrity. This is caused by the destruction of its structure due to:

- exceeding the recommended resource;

- excessive dynamic loads;

- dirt and moisture getting inside the bearing.

However, knocking in the area of the racks may have other causes. To check the bearings and make sure that they are the ones knocking, lift the hood of the car, remove the cover of the supposed “glass”, and place your palm on the upper shock absorber support.

Rock the car up and down. If at the same time you hear the same knock and feel the corresponding vibration with your hand, immediately replace the bearing.

Features of replacing engine mounts with a 16-valve engine

The main difference in the mounting of the 16-valve engine is the absence of a rear lower support. The engine is attached with a rear support from above to the number plate of the body. Another additional damper bracket is located at the bottom front. It connects the motor and the lower beam of the radiator (TV) frame. These parts are called “guitar”. After hanging the engine with a jack, they change simply.

Sources

- https://FokSevmash.ru/dvigatel/podushka-dvigatelya-vaz-2110.html

- https://www.tuningsvs.ru/zapchasti/sportivnyje-zapchasti-vaz/podvjeska-rastjazhki-opory-stojki/usiljenija-podvjeski/usileniya-podveski-lada-priora/dopolnitelnaya_opora_dvigatelya_svs_dlya/

- https://medwegonok.ru/dopolnitelnaya-podushka-dvigatelya-vaz-2110-8-klapanov-svoimi-rukami/

[collapse]