While operating the vehicle, the driver may notice an oil leak between the engine and gearbox. Let us immediately note that a similar malfunction appears on different cars, regardless of what type of engine (diesel, gasoline) and gearbox are installed.

In other words, oil leaks at the junction of the transmission and internal combustion engine on different cars, when the car has a manual transmission, a robotic gearbox with one or two manual transmission clutch discs, an automatic transmission with an automatic transmission torque converter, a continuously variable transmission, etc.

In any case, if oil drips between the engine and gearbox, then this is a sign of serious damage. Faults of this kind require immediate diagnosis and quick elimination.

Next, we will talk about why an oil leak may appear between the power unit and the gearbox, as well as what the driver should do if there are visible leaks of fresh lubricant between the engine and gearbox, oil is actively running, or the lubricant on the parts is covered with dust (the leak is insignificant, there is fogging).

Why does engine oil leak?

When fluid begins to leak, it is best to contact a technical service center. But before that, you can provide first aid to the car and identify a lot of points that will save time for the service station workers and save you money.

So, what is the reason for such breakdowns and how to avoid them? Typically, the most leaky places are:

- Crankshaft oil seals;

- Engine and gearbox sump;

- Oil filter;

- Distributor mounting location;

- Valve lid.

A significant factor in the susceptibility to leakage is the age of the engine. The longer the engine runs, the more significant the damage to its parts, in particular the gasket and seal. Replacing them is the ideal solution.

It is much more difficult to eliminate a leak due to wear on the shaft. The cause of the leaks is the groove made by the shaft in the oil seal. In this case, it will be necessary to change the entire shaft, and to do this, disassemble the engine.

Oil may also leak due to poor crankcase ventilation. The purpose of the ventilation system is to free the crankcase from accumulated gases and relieve pressure. But over time, the system becomes clogged and pressure accumulates in the crankcase. This is what pushes the oil out of the engine. Removing ventilation blockages is a mandatory procedure when repairing a leak.

A common cause of leaks is worn out engine pistons. In this case, even the ventilation system will not help.

The situation with the oil filter is simple - either tighten it tighter or replace it.

Oil also often leaks from the pan. To repair, you need to check the pan for bends, then fix them and seal the pan. In addition, the valve cover may be a source of leaks. It is worth cleaning it, lubricating the gasket with sealant and installing it back. To repair leaks in the place where the distributor is attached, unscrew the distributor and coat the joints with sealant.

In general, this is the entire method of repairing leaks. If the problem lies elsewhere, it can be solved either by replacement, sealing, or simply tightening the fasteners.

The last, but not least important factor in the formation of leaks is the quality of the operating fluid. In some cases, it is no good and leads to breakdowns

Use modern oil from leading manufacturers, they are designed for economical consumption and minimal evaporation.

However, with lubricating fluid, the situation cannot be called deplorable, because in conditions of healthy competition, manufacturers do not slack, and drivers wisely choose the most optimal option.

Simple factors

Circumstances of negligence and incompetence - both of auto mechanics and the owner of the car - can be easily eliminated. Among them:

- loose nut on the drain. He made it through - and off he went;

- The reverse sensor is loosely screwed in. The recommendations are the same;

- The dipstick for measuring the oil level is not inserted tightly (or crookedly, which is worse). Hammered it in tighter, adjusted it - job done;

- oil overflow. Generosity is not always good, and a new driver must learn this. It says “maximum”, which means stop. Excess oil will still have to be drained, and this, again, is a loss of money.

However, if you come across such a simple option, you can start to rejoice. Other reasons cannot be dealt with so easily. Leaking through the lid:

Most often this happens due to gasket wear. And this case, again, is simple and can be corrected without difficulty. You buy a new one, replace it - you don’t even need to go to a service station. It’s a little worse if chips or deep but small scratches are found. In this case, epoxy is used, with the help of which the (relatively) evenness of the surface is restored.

{banner_content}

Connection of automatic transmission with engine

Taking into account the fact that an automatic transmission does not have a classic clutch and differs in design from manual and manual transmissions, the connection of the automatic transmission has its own characteristics.

Currently reading

Internet in cars and more: features of technology...

Coating a car with ceramics: what you need to know

First of all, you need to attach a torque converter to the engine (it will perform the clutch function), and this part must fit exactly into its seat. To check this, after installation it is necessary to separately measure the distance from the rear end of the cylinder block to the plane of the drive plate. It is with this plate that the torque converter is mated. (a)

You also need to measure the corresponding dimension along the gearbox to the plane of the torque converter (b). This plane is connected to the drive plate. Calculations can be carried out using the formula, where size b is equal to size a +2+4 mm.

Please note that the indicated gap is leveled after the torque converter is completely pulled to the drive plate, however, such a gap must be present during installation. If there is no clearance, then there is a risk of damage to the drive plate, as well as damage to the oil pump

Parts are quite expensive, so extra care must be taken

Let's move on

At the moment when the box is lifted for installation, you need to pay attention to ensure that the torque converter does not fall out. To prevent it from falling, the box should be lifted at an angle

Then the mounting holes on the torque converter (CT) are aligned with the matching holes, which are made on the drive plate itself.

Further assembly is carried out by tightening all the bolts with the required torque, which fit into the centering sleeves. Then the drives, hoses, etc. are connected. Upon completion, you should check that the GT does not experience any difficulties during rotation (the part rotates freely).

Leaking from the motor

Lubricant leakage from the power unit, as a rule, occurs for several reasons related to malfunction of engine or gearbox components.

Damage to the engine crankshaft oil seal

The problem is typical for cars with high mileage, in which this element has not been replaced for a long time.

The seal has an oil-resistant rubber base, but with prolonged use it becomes less elastic and hardens.

If nothing is done, the oil seal is squeezed out due to damage to the crankshaft rings, and oil leaks out.

An oil seal malfunction can occur when the machine is idle for a long time (30 days or more) without starting the engine. In this case, the lubricant flows into the crankcase, the seals dry out, gradually deform and collapse.

Increase in pressure

The reason may be an increase in pressure in the crankcase (one of the reasons is oil overflow) and the breakthrough of exhaust gases from the combustion chamber through the piston rings.

The situation is aggravated due to the old cylinder-piston group. The leak may be due to a clogged crankcase ventilation system.

An increase in pressure may also occur in the gearbox. As a result, oil seals, sealing elements and gaskets fail, and oil is squeezed out.

With an active leak, the risk of serious engine damage and the need for major repairs increases. The transmission may also need to be restored.

Also read - what to do if you pour oil into the engine.

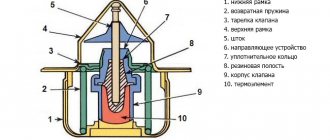

Oil deflector valve malfunction

If there are problems with crankcase ventilation, inspect the oil deflector valve for integrity.

The appearance of a bluish or brown coating indicates problems in the ventilation system.

To confirm the diagnosis, take the following steps:

Unscrew the oil filler cap. Cover it with clean cardboard. Start the engine and let it idle. Gradually increase the speed to 0.9-1.1 thousand rpm. Pay attention to the cardboard. If it is pulled tightly to the neck, this indicates normal operation of the ventilation system

If there is no such effect, you need to clean it.

Troubleshooting Methods

Leaking aluminum radiator: how to fix it yourself

1.Elastic band deformation

Sometimes, when installing the oil filter rubber, he forgets to lubricate it separately, which is why it becomes deformed during installation, and, for example, it can become skewed. If this happens, you should remove the filter barrier and apply lubricants to the rubber band. After this you need to reinstall it in place. If the gasket deformation cannot be corrected, then it is better to replace it.

2.Unscrewed filter

During the next lubrication change, when installing the oil filter, it may not be tightened, which is also why oil sometimes leaks. To fix this and remove the leak, you need to use your hands, without using any other means, so as not to damage it, just screw the filter all the way.

3. The filter will be tightened

This problem occurs if, when changing the lubricant, the filter is once again tightened too much. In such cases, it is advised to remove the filter to assess the condition of the gasket - if the rubber is damaged, it must be replaced with another one. After this, the filter is installed in place, as in the previous case, without applying much effort - twist it by hand until it stops.

4. Damage to the barrier surface

Oil also drives under the filter rubber bands if the mating surface of the barrier itself on the motor has been damaged; the ebb that is directly adjacent to the rubber band must have a flat surface, otherwise it should be replaced.

5. Increased engine oil pressure

Oil pressure can be excessive for a variety of reasons. As a rule, then you have to replace the lubricant with a better one or look for another barrier. In the first case, this may be caused by poor-quality additives, which is why a large amount of gases from the burnout of the lubricating fluid accumulate in the system, and the ventilation does not have time to remove them. In this case, you first need to find the cause of the increase in pressure, and then begin repairs.

6. Cold engine

When oil leaks due to a cold engine, the problem is most likely in the internal structure of the car. This reason has already been discussed above. Since older cars most often do not have a valve to regulate the lubricant pressure, a change in pressure may result in an oil leak. In this case, most likely the car does not have an automatic valve installed on the outside, and if it does, it may be worth checking to see if it is working properly. In order to avoid further leaks, it is worth warming up the engine and inspecting the valves and oil filter.

7. Filter contamination

All you need to do in this case is simply replace the filter. It is also worth calculating the force so as not to lead to deformation of the rubber gasket - you should not use a wrench for this. It is enough to screw the filter tightly by hand.

8. Damage to the pressure reduction valve

Because of this, oil usually leaks when the lubricant and filter element are in satisfactory condition, but the leak continues. To eliminate a leak, first remove the valve without removing the pump, using a rag and keys. Remove the timing belt cover, unscrew the valve plug, removing the spring. The valve is removed and inspected for damage and scoring. Sometimes it is necessary to replace the spring if a bend is detected or the nominal height (44.72 mm) differs from the actual one.

The main reason why your oil has been squeezed out through the oil filter is mainly due to starting a cold engine. The oil is thick and does not have time to pass through the filter device. This mainly applies to older cars with oil pumps without a bypass valve. Naturally, this does not happen on new cars, well, only if it itself is poorly screwed on.

Once, after another seasonal oil change in the fall, naturally with the replacement of the oil filter, I started the car in the morning, everything seemed to be in order, but then I noticed that the oil pressure began to drop. I opened the hood and checked the level, there was no oil. I got out of the car and only then saw that all the oil was under the car. It turned out that it was squeezed out through the oil filter.

Somehow the oil filter gasket was squeezed out, and then the oil side itself was twisted. There was no frost, so there was no risk of the butter being too frozen. I still don’t understand the reason, I bought a new one and installed it. Imagine the surprise when a few days later he was squeezed out again.

I removed the filter again and placed it next to the old one and only then noticed the difference between them. The new one had only 4 oil inlets, while the old one had 8 (photo above).

Maybe there was also some difference in the design of these filters, I don’t know.

This time, when buying a new one, I paid attention to this and, even though the seller did not admonish me that there was no difference, I still chose the one I needed. I replaced the filter and this problem that squeezed oil through the oil filter was no longer there

On a note

Please note! The internal cavity of the gearbox of any car is necessarily connected to the atmosphere through an ordinary small-diameter tube, called a breather. Due to clogging of the ventilation channel, the air expanded as a result of heating the oil is not removed and begins to create additional pressure on the oil, leading to its leakage through the seals, and in more advanced cases, to squeezing out the sealing elements from their seats.

Cars with automatic transmissions usually have an additional external oil cooling circuit with an aluminum radiator. Due to prolonged exposure to salt, the radiator fittings begin to rot at the point of their connection with the oil supply pipes. The malfunction can be easily eliminated either by replacing the part or by welding new fittings using argon arc welding.

If oil is leaking from a brand new gearbox, the cause is likely due to a damaged crankcase or rear cover of the unit. Cracks can form as a result of non-compliance with the technology for obtaining castings of the corresponding parts of the assembly unit. If such a manufacturing defect occurs, you should immediately contact the dealership.

A crack in the “box” housing can also form due to irreversible changes in the gear shift mechanism itself. After the teeth of one of the rings are chipped, the rear cover or gearbox housing is often damaged. In this case, almost all the oil often leaks out of the internal cavity.

Let's sum it up

As you can see, drops of transmission oil under the car or obvious oiling of any areas with transmission fluid is a reason for a detailed inspection of the car. If there is no obvious suspicion that the gearbox housing has recently been damaged, then diagnostics are necessary.

Read more: Why brakes squeak when braking, main reasons

First of all, you need to check the oil level in the gearbox to ensure it is not overfilled. At the same time, the performance and condition of the gearbox breather should be assessed in order to prevent transmission oil from being squeezed out due to an increase in pressure in the internal cavities of the box.

Finally, we note that when purchasing a new car or after repairing a gearbox with the replacement of individual elements, one should not exclude the possibility that a defective gearbox housing (with cracks) may be installed. Also, the oil seals, cuffs and seals themselves have defects and are often of poor quality.

Gears are difficult to engage or speeds on a manual transmission do not engage: the main causes of the malfunction and possible problems.

How to choose oil for a manual transmission. Changing the oil in a manual transmission, frequency and features of changing transmission oils in a manual transmission.

How to replace gearbox seals

At the same time, as practice shows, if the gearbox has not experienced shocks, and the wear of the unit itself is not too great, then most often the culprit is the gearbox seals. Below we will look at how to replace them.

Often the seals (cuffs) in the gearbox are placed on the input shaft, there are also axle shaft seals, and there is also a gear selector rod seal. To replace drive shaft seals, you will need:

- drain the oil from the gearbox;

- Unscrew the wheel bearing nut and the ball joint bolts;

- Next you need to move the steering knuckle towards the side;

- dismantle the axle shaft and remove the old oil seal (removed with a flat-head screwdriver);

Then you can begin installing new axle seals

In this case, you should pay attention to certain nuances. First of all, the left and right cuff differ in the direction of the oil grooves

The arrow on the right oil seal is clockwise, while the arrow on the left is in the opposite direction.

Before installation, the working surface of the oil seals must be separately lubricated with oil, and the installation itself must be performed by carefully and lightly hitting the spacer (mandrel) with a hammer.

If oil leaks as a result of wear of the cuff of the gear selector rod on machines with a manual transmission, then the oil seal is replaced as follows:

- at the initial stage, you need to unscrew the screw securing the gear shift drive hinge, then disconnect the element from the rod;

- then the protective cover of the hinge is removed, the oil seal is removed with a screwdriver;

- then you will need to install a new cuff, striking through the spacer, while the oil seal must first be lubricated with oil.

We also note that often experienced owners of cars with front-wheel drive, if this is possible, recommend additionally installing one or two more similar oil seals on top of the gear selector rod oil seal, between which a layer of sealant is placed.

To change the drive shaft oil seal, the gearbox itself must be removed. Often in this case, owners simultaneously change the car’s clutch. At the same time, the shaft is checked for play, the condition of its seating surfaces, bearings, etc. is assessed.

To gain access to the oil seal, you need to remove the release bearing bushing. The oil seal is removed with a special hook, and installation is performed by tapping it with a hammer through a mandrel.

Front

It is much easier to change than the rear one. The element is located at the end of the crankshaft (on cars with a transverse engine - near the right pillar). To replace, we need to remove the timing belt cover and place the piston of the first cylinder at TDC. We loosen the tensioners and remove the timing belt from the outside, as well as the generator, having first removed the pulley.

Drain the engine oil. Remove the crankshaft pulley. Unscrew the oil pump. An oil seal will be pressed inside it. You can remove it using a minus screwdriver. The new one is pressed in using a large head (27 and above) or on a special machine. Further assembly is in reverse order.

Additional symptoms

Oil leakage through the rear oil seal often leads to low oil levels in the crankcase. Also, on cars with “mechanics” and “robots”, motor lubricant can get into the clutch.

This in turn leads to poor traction, slipping and jolting while running.

When the above signs appear and the pressure indicator lights up to “ordered”, it is necessary to check the lubricant level in the engine.

Oil is leaking from the gearbox

The second situation is when the oil comes out of the gearbox and not from the engine. We immediately notice that problems with “mechanics” rarely arise. This is due to the position of the input shaft bearing - it is installed above the oil level.

For such gearboxes, other problems are also relevant - the appearance of a leak in the area of the gearbox cup or breather.

Loss of oil from the “box” is usually relevant for automatic transmissions. In such devices, lubrication is carried out not by “splashing”, but under high pressure.

In most cases, the cause of the problem is a failed torque converter.

In many situations, it fails along with the oil pump, which requires serious repairs or installation of a new automatic transmission.

Sometimes oil loss occurs simultaneously with the appearance of foam, the reasons may be the following:

- use of a product that does not meet the requirements/approvals.

- level decrease/excess;

If inspection shows an increase in the lubricant level in the gearbox or internal combustion engine, excess lubricant must be removed.

Read how to pump out excess oil from the engine.

To avoid foaming, it is prohibited to mix different oils for automatic transmissions and engines. If such a need arises, it is recommended to rinse the unit and then refill it.

Read on to find out if motor oils can be mixed.

If a malfunction is detected, automatic transmission repair does not always give the expected effect, which is important even at high costs. Therefore, it is necessary to diagnose the unit and only then decide on further actions - repair or replacement.

The main ones include:

- Loose installation of the oil dipstick.

- Weak drain plug pull.

- Poor sensor connection.

- Damage to the O-rings at the installation site.

If oil is leaking through the ECM (electronic engine management) sensors, the cause may be a damaged, crushed, or deformed gasket.

The sensor itself, requiring replacement, can also be a problem. If the problem is just the rubber band, just replace it.

What should you keep in mind?

Undesirable consequences can be caused by mixing fluids of different manufacturers and viscosity characteristics: if the oil leaks while driving, and there is nothing to top it up with, the car cannot be operated further. Call a tow truck and take the car to the nearest service station. Adding oil of a different composition - transmission or engine - is not allowed due to the fact that a destructive chemical reaction may begin inside the installation, which in turn will lead to even greater consequences. Of course, if a loss of fluid occurs on the highway, the driver can fill the system with oil at hand, but only to get to the specialists. In the future, the oil “compote” will have to be drained, and the installation into which it was poured will have to be thoroughly rinsed.

Other causes of gearbox oil leaks

In addition to oil seals, there are other common gearbox malfunctions that cause transmission fluid leaks. For example, if oil flows from the joint of the box body, the unit must be removed and disassembled. The surfaces at the joints should be cleaned of old sealant and then degreased. During reassembly, sealant is applied to threaded connections and other elements.

Also, as mentioned above, the diameter of the shafts often decreases in the place where the shaft contacts the oil seal. As a result, oil leaks from the gearbox appear in this place. To fix this problem, it is necessary to install a new cuff, and the new oil seal is not pressed in completely.

This makes it possible to ensure that the unworn part of the shaft begins to contact the working edges of the oil seal, that is, the necessary seal is created

However, it is important to take into account when pressing the oil seal in such an incomplete manner that the oil seal should not be skewed. In order to avoid distortion, experts recommend using spacers, the thickness of which is about a millimeter

We also add that the internal cavity of the box must communicate with the atmosphere. For such a message, an element better known as a breather is used. So, if the breather is clogged, as a result of heating the oil, the air inside the gearbox does not come out and begins to create excess pressure. This often causes the oil to “press” through the oil seals and oil seals. It is also possible that the cuffs are simply squeezed out of their installation locations.

As for automatic transmissions, cars with such a gearbox usually have an additional circuit for cooling the automatic transmission oil. The automatic transmission oil passes through the additional radiator and then returns to the box. Often road reagents destroy the automatic transmission radiator fittings at the junction with the oil supply pipes. In such a situation, you can either change the radiator and/or pipes, or weld new fittings to the old radiator.

In cases where oil leaks from the gearbox on a new car, that is, the gearbox has practically no mileage, there is a high probability of defects and damage to the crankcase or rear gearbox cover. Cracks may be a manufacturing defect that occurred during the casting of parts.

Another crack in the gearbox housing may be the result of a serious breakdown of the gearbox itself. For example, if a tooth on one of the rings breaks off, the rear cover/gearbox housing is also damaged. As a rule, in such a situation, the oil leak is very strong, the lubricant quickly flows out of the cavities of the box. In this case, the unit must be defective, after which either the gearbox housing and damaged elements are replaced, or a contract unit is installed.

Oil leaks caused by problems with the gearbox

Lubricant leakage occurs not only from under engine parts, but also from the gearbox. In cars equipped with manual transmissions, transmission fluid rarely leaks out. In such gearboxes, the lubricant level is lower than the input shaft bearing.

It is much more common for transmission fluid to leak from automatic transmissions. In such units, the lubricant is supplied to the rubbing parts by force. An oil pump is used for this. As a result, the internal pressure in the lubrication system of the automatic transmission increases.

The main culprit in the problem of oil leakage from the automatic transmission is the torque converter. In many situations, it goes out of service at the same time as the pump. Forced replacement of the listed parts entails significant financial costs. Moreover, repairs sometimes turn out to be ineffective. Then it is easier to purchase a new automatic transmission than to repair the old one.

Where can engine oil leak from?

If during the next daily inspection it turns out that the oil level is significantly below the maximum mark, you should seriously look into troubleshooting

First of all, it is important to determine where the leak is located.

First of all, it is advisable to pay attention to the accessible engine components. One of them is the valve cover.

From under the valve cover

A leak in the valve mechanism may result in oil leakage from the engine lubrication system. Often, this problem is signaled by a characteristic burning smell from under the engine exhaust manifold.

In this case, it cannot be said with a high degree of probability that replacing the gasket will solve the problem. The occurrence of the presented malfunction may be associated with excessive pressure in the engine lubrication system.

This situation can be caused, for example, by a malfunction of the so-called pressure reducing valve.

Crankshaft oil seal

If a leak in the valve cover gasket can be corrected with little effort, as they say, the situation with the crankshaft oil seal is much more complicated. Replacing it due to the design features of the engine will require a lot of time and labor.

What could have caused the breach of its tightness?

Let us arrange the most probable causes of this malfunction in a certain sequence, starting with the most frequent:

- the operational resource has been developed;

- failure in the crankcase ventilation system;

- defective components;

- unscrupulous repairs.

Oil leak between engine and gearbox

Do not forget that the clutch flywheel housing also contains an oil seal, which sometimes makes itself felt, although extremely rarely. To verify the presence of such a malfunction, you will have to look under the bottom of the car.

In this case, it is best to drive the car into an inspection hole or so-called overpass. The presence of a leak will be indicated by an oily surface of the clutch housing and gearbox housing. To replace the oil seal, you will need to dismantle the gearbox.

Let us focus our attention on the reasons for this unfavorable phenomenon. Among them are:

- mismatch of lubricant viscosity;

- failures in the crankcase ventilation system;

- loss of elasticity of rubber goods;

- poor quality components.

Oil filter gasket

The oil filter seal can also be the culprit for an oil leak. So, during the next scheduled filter replacement, it could simply be tightened, and this is unacceptable. With such repairs, unfortunate oil leaks may appear over time.

It is also worth mentioning the fact that after each filter replacement, all associated rubber goods must be replaced. If this is not done, there is a high probability that oil formations will soon appear at the filter connection site.

In a particular case, oil from the engine lubrication system may be squeezed out due to malfunctions in the operation of the VKG system.

Engine crankcase problems

A frequent cause of engine oil leaks can be violations of the crankcase ventilation system. For the most part, owners of fairly used cars face a similar problem.

The fact is that as the CPG wears out, exhaust gases begin to accumulate in the engine crankcase. With a working crankcase ventilation system, excess pressure would be vented into the engine intake manifold. But it also happens that after prolonged use, and in the absence of proper care, the elements of the system become clogged.

This state of affairs leads to the fact that the gases have nowhere to go, and they begin to look for the most vulnerable places, which are played by various sealing elements.

Piston rings wear out

How to eliminate oil leaks from under the valve covers

First of all, the elements on which the strongest contact pressure is exerted wear out, regularly changing their location and being little treated with lubricating fluid. Oil scraper rings, mounted much lower than the compression rings, exactly correspond to this description. The design features of these components imply increased contact pressures in the area of operation of the scrapers. This contributes to their accelerated wear. If there is such a defect, it will not take long since the last check when the dipstick, after being immersed in the oil crater, will begin to record the flow rate.

Looking for reasons

Oil leakage from a car engine or gearbox may begin immediately after it is replaced. The presence of smudges may indicate that the fresh fluid does not meet the requirements stated by the car manufacturer. For example, instead of the usual thick mineral water, you decided to use liquid synthetics. If the car refuses to accept it, you will know about it immediately. This problem can be easily resolved - just fill the engine or transmission with oil with the required viscosity.

If the lubricants used have the required parameters, and smudges are still visible on the engine or gearbox, then the situation may be serious. Failure of one, even the smallest component, can disrupt the tightness of systems and cause oil starvation

This is why it is so important to fix the leak in a timely manner.

Primary diagnosis begins with studying the consistency, smell and color of the leaked liquid. Gearbox fuels and lubricants have a dark, sometimes reddish tint and a very pungent odor. The liquid is thick and does not absorb contaminants. Those. a drop of transmission oil will be covered with a layer of dust, but will not absorb it.

As for motor lubricant, it will behave differently towards contaminants: it completely absorbs them. Fuel and lubricants for internal combustion engines have a more liquid base, a reddish-amber tint and a faint odor.

If visual inspection of smudges is difficult due to the design features of the car, then the problem can be solved using an oil dipstick. Measure the fluid level in the engine compartment; deviation of this indicator from the norm will indicate a problem.

Some modern cars have a dipstick to check the oil level in the box. But it will only identify the problem if the lubricant is rapidly leaking out of the gearbox. In these cases, dark stains of technical fluid can be recognized under the front of the car. Minor leaks at the lubricant level will not be immediately noticeable; the dipstick will not be able to “notice” them.

Grease leaks from the engine

If an inspection of the car and a study of the condition of the leaking fluid gave reason to believe that the problem lies in the engine compartment, then it is necessary to identify the weakest points of the system through which the oil could escape.

Reasons for failure:

- Overflow of liquid. No matter how trivial it may sound, oil can leak due to its overflow into the oil compartment. If you filled in lubricant “by eye” and did not check its level, a leak may form around the entire perimeter of the engine. The excess amount of material circulating under high pressure in the internal combustion engine will simply be squeezed out of the working space and flow down the outer sides of the internal combustion engine. The problem can be easily fixed: unscrew the oil plug at the bottom of the engine and allow excess fluid to drain out of the crankcase.

- Wear, incorrect installation or destruction of sealing elements. If the car has been sitting for a long time, the seals and gaskets may have failed due to insufficient moisture. After starting the car, they cannot function normally (their ability to be elastic is lost), and therefore lubricant leaks out. The solution in this case is to replace the problematic parts with new ones; You can read on the Internet how to correctly install sealing parts to eliminate oil leaks in the engine.

- Insufficient crankcase ventilation. Excessive accumulation of exhaust gases in the car crankcase can create additional pressure and squeeze consumables out. This situation occurs when the ventilation system ducts are clogged. An oil deflector valve will help diagnose this problem. Check its condition. Did you see a bluish or dark brown coating? This means that the reason for the leaks lies precisely here. If the presence of deposits still raises doubts about insufficient crankcase ventilation, cover the open oil filler neck with a small sheet of white cardboard and start the car engine (it is recommended to keep it at 900-1100 rpm). A tight fit of the cardboard to the oil fill hole indicates normal operation of the ventilation system. Otherwise, it is necessary to clean or replace the engine pipes.

- Valve cover deformation. In rare cases, when car manufacturers use low-quality metal, a violation of the valve cover geometry may occur, which will be accompanied by large oil losses. Unfortunately, installing a new gasket will not solve the problem. The only possible option is to replace this very cover.

Peculiarities

Oil stains as a result of fluid leakage

Lubricants poured into the engine compartment and transmission of a car, first of all, must provide structural parts with a reliable degree of protection against premature wear. But due to the fact that the operating conditions of these systems differ significantly, it is impossible to use a liquid with the same viscosity and chemical composition in both cases.

Both lubricants - transmission and motor - are classified according to the international SAE system and can have mineral, semi-synthetic and synthetic bases. This is probably where their similarities end.

The vehicle's engine system operates under conditions of high temperature and operational overloads. That is why it requires a liquid that is resistant to climatic changes and prevents the formation of oxidative reactions inside the working area. In addition, it should wash out carbon particles formed during the operation of the car from the engine compartment, making it easier for the parts to “freely move.” Motor fluid circulates inside the system under high pressure, so its viscosity should not be excessively high.

As for gearbox oil, excessive fluidity cannot occur here. It is supplied to parts by spraying, is not subjected to critical overloads and does not require a large amount of additives.

Such differences in the use of lubricants determine their useful life in a vehicle: for motor fluid it varies between 5-10 thousand kilometers, for transmission fluid - 60-80.

Types of faults in manual transmissions of cars

The internal structure of the mechanical gear shift mechanism has its own characteristics, and its malfunctions can be divided into both breakdowns of the box itself and malfunctions of the transmission mechanism.

In order to be able to restore the car’s operation if any type of malfunction occurs, you should detect them in time and know the basic techniques for eliminating them.

This is especially important if the breakdown occurred on the highway, on the road - then it will be important to resume the operation of the car until a visit to a repair specialist

Let us list the main manifestations of malfunctions.

How to detect a malfunction?

The most common manifestations of malfunctions in the operation of manual transmissions include the following:

- The occurrence of extraneous noise when the handle is positioned in neutral;

- Noises when turned on, as well as when starting work;

- Difficulty when changing gears;

- The gear is switched off without affecting the shift lever;

- There is oil leakage from the transmission.

Why the engine is in oil: possible reasons

It becomes clear that for normal operation of the internal combustion engine, it is necessary to eliminate the causes of oil leaks in the engine as quickly as possible. At the same time, experts identify several such reasons.

Let us note right away that it is not always possible to quickly detect the location of the leak. Many parts and elements of attachments make it difficult to access for inspection, and the space in the engine compartment on many cars is very limited.

So, the main causes of oil leaks are as follows:

- increase in engine oil level (overflow);

- using the wrong type of lubricant;

- problems with crankcase ventilation;

- oil leak from under the valve cover;

- oil leak in the distributor area;

- oil flows from under the oil filter;

- the oil pan is broken or cracked;

- The front/rear crankshaft oil seal is leaking;

Quite often, car owners who change the engine oil themselves accidentally (sometimes deliberately) exceed the lubrication level. The result is increased pressure in the lubrication system; excess oil is simply squeezed out through gaskets and seals (especially on older engines). In this case, you need to pump out excess oil from the engine.

Also, oil may leak if the engine is filled with too “liquid” or counterfeit lubricant (SAE viscosity is not suitable, oil properties do not correspond to the declared ones). In such a situation, the lubricant must be drained, after which the engine is washed and a proven, high-quality product that meets the tolerances and recommendations is filled.

It may also be necessary to make additional adjustments for individual operating conditions (constant operation of the engine under heavy loads at high speeds, extreme heat in the region, etc.).

The engine crankcase actually acts as an oil reservoir on many vehicles (except for dry sump systems). As the piston rings and CPG wear out of the combustion chamber, some of the exhaust gases escape into the boat. This leads to an increase in pressure.

This excess pressure must be compensated by the crankcase ventilation system. If the system does not work or does not work correctly, the exhaust gases “squeeze” the oil out of the crankcase. Often the driver may find that the entire engine is covered in oil, and the oil dipstick has been squeezed out.

Valve covers most often leak due to failure of the valve cover gasket, as well as as a result of deformation or damage to the cover itself.

Depending on the problem, it is necessary to replace the cover with a new one or limit yourself to only replacing the valve cover gasket. The lid can also be sealed with a special sealant.

On domestic cars, one of the most common places for oil leaks is the distributor. If oil leaks from under the distributor, in some cases the problem can be solved quite simply.

To do this, remove the cover from the distributor, then remove the device itself. Next, you need to apply sealant at the joint, after which assembly is performed in the reverse order.

On many cars, oil leaks from under the oil filter. The reason may be improper tightening of the filter without a special wrench (the filter is under-tightened or twisted).

Cracks and damage to the oil pan occur quite often, especially considering the operation of the car on domestic roads without the installation of additional engine protection.

As a rule, such a breakdown leads to intense leaks. In this case, it is necessary to replace the sump with a new one or repair the engine sump (weld the sump).

Repair operations are carried out only after dismantling the pallet. It is quite obvious that installing crankcase protection, although it does not completely eliminate it, significantly reduces the risks of such malfunctions.

Quite often, drivers encounter such a nuisance when the crankshaft oil seal leaks. The power unit has two crankshaft oil seals (front oil seal PSKV and rear oil seal ZSKV).

Such a breakdown is serious and requires specialist intervention. It is not recommended to drive the car until it is repaired. For example, if the front oil seal leaks, oil can get onto the timing belt with all the ensuing consequences (belt slippage, breakage and bent valves). Leaks in the rear seal area can cause lubricant to leak onto the clutch elements. To replace the SSC, the gearbox must be removed.

Tips and tricks

The appearance of malfunctions or noises clearly indicates both breakdowns and problems with the lubricant (insufficient or high level, loss of properties, non-compliance of the lubricant with tolerances and requirements, etc.).

For example, if the box hums in neutral, then the bearing on the drive shaft may fail or the transmission oil level may be low. If the problems are related to the synchronizer clutch or blocking element, then noise in the box appears when driving in a certain gear (usually in high gear, 3rd speed, 4th, etc.).

A hum from the box may also appear when the gearbox is loosened. Insufficient clutch pedal pressure or problems with this unit (especially on cars with a single-disc “robot” manual transmission) cause crunching, jerking, jolting, and difficult shifting. In this case, the parts experience increased loads, after which defects arise, and oil appears at the junction of the box and the engine.

If the situation is emergency, that is, a lubricant leak appears on the road and there is no way to send the car for repairs, then many drivers try to stop the leak with the help of special additives. As a rule, softening sealants of the “stop-leak” type contain components that allow the elasticity of the sealing elements to be restored.

Read more: Water gets into engine oil: causes and consequences

In other words, it is possible to restore the tightness between the shafts and seals for some time. This allows you to get to the vehicle repair site on your own. So, we strongly do not recommend using such solutions both in the engine and in the gearbox.

First of all, the additive does not remove wear on parts, that is, the damage itself not only persists, but also progresses. Also, this method is not suitable for strong leaks. Moreover, the additive has a serious impact on the lubricant and on the parts themselves inside the assembly. Otherwise, adding an additive worsens the basic properties of the engine or transmission oil and clogs the engine and gearbox lubrication system.

A frequent result is that after disassembling the unit into which such additives were previously poured, it is discovered that it is completely unrepairable or there is significant wear not only on the initially problematic ones, but also on other structural elements.