In modern cars, the normal operation of the internal combustion engine is ensured by its constant cooling (due to the circulation of antifreeze). The liquid cooling system combined with the air cooling system maintains a constant temperature in the engine of about 90°C.

However, during the operation of the vehicle, the car owner may encounter the fact that the antifreeze or antifreeze in the engine begins to boil, leaks occur, etc. In this article we will look at why antifreeze/antifreeze bubbles in the expansion tank, as well as how to fix this problem.

Other reasons

There are two more malfunctions that answer the question: why does antifreeze foam in the expansion tank.

- Unsuitable or poor quality fluid in the system. There is a known real case when an independent but inexperienced girl driver poured ordinary glass washing liquid with a fragrance into the cooling system. Naturally, such a mixture not only slightly tinted the tank and forever imprinted the trace of this ridiculous mistake, but due to the presence of surfactants it foamed. Such errors are not critical and will not lead to a sudden failure of the internal combustion engine. You just have to flush the system and fill it with standard coolant. A rare case today, but antifreeze can also foam in the expansion tank due to poor quality.

- Overheating of the motor with simultaneous malfunction of the steam valve. In this case, some of the coolant is observed splashing out through the valves in the form of a hissing, foaming mass. Under normal conditions, when the valve in the plug is working properly, the coolant will intensively and quickly splash out of the system when it overheats. If the plug does not function as it should, this can lead to rupture or tearing of the pipes from their seats and even destruction of the radiator.

The conclusion here is simple: do not use unsuitable fluids for the cooling system and monitor the engine temperature.

Hi all! Tell me, I have a suspicion that the cylinder head gasket is broken. Bubbles come out in the expansion tank when you accelerate (but not always). Can they come out if something was connected incorrectly when replacing the motor with a contract, and can they come out if the intake manifold gasket is not tight (I left it from the old motor). The exhaust from the pipe is normal, there is no emulsion on the dipstick. Help Guys, I wouldn’t want to open it at random, you understand...

Comments 36

Somehow the gasket also burst - the bubbles were all good - the tempera was jumping, white smoke was pouring out, and this despite the living catalyst - I took off the head - one pot was washed and the piston and chamber and spark plug were cleaned. I milled the head and put it in place with a new gasket. I started it up and warmed it up, but the bubbles were coming out little by little. I was in a jam, the antifreeze was leaving little by little. then I parked the car with its face up at 30 degrees. I drove it until the thermostat opened to a large circle. Gradually, after a couple of days, the bubbles disappeared. The mileage is about 50 thousand, 2 years - the antifreeze does not go away at all.

I still hope there is air in the system, because the temp doesn’t fluctuate, the exhaust is normal, the frieze doesn’t go away.

check the spark plugs, the surface of the piston should be washed somehow, I had 4 cylinders like that, the cylinders were washed too, bubbled and did not go away right away

gases into the expansion tank.

Change the cylinder head - there is a crack somewhere.

Messages: 15,423 From: Far away

+1 crack in the block. I guess it’s not particularly annoying on the highway and the car doesn’t get very hot, but it’s impossible to drive around the city, it spits antifreeze? guessed right?

If the gases didn't go into the tank, I would think about a thermostat.

Post edited by Mikha Zlobny

— Dec 2 2014, 15:33

+1 crack in the block. I guess it’s not particularly annoying on the highway and the car doesn’t get very hot, but it’s impossible to drive around the city, it spits antifreeze? guessed right?

If the gases didn't go into the tank, I would think about a thermostat.

At the service center where the head gasket was changed, the master said that the head was normal. maybe a pump?

Well, take out the spark plugs and inspect the area where the pump is. A crack in the cylinder head is checked in a special bath. If the head was repaired, after the frieze, it is necessary to carry out grinding, was it carried out? With the engine running, open the tank, carefully while it is heated, and give it some gas, you will see it right away. There, the traction of the cylinder head bolts is also important; if they are not tightened evenly, then a surprise awaits. Master, master is different. I don’t understand about the thermostat cover, where is it? Maybe some innovations?

Post edited by sporky

— Dec 2 2014, 18:54

We did the same thing at the tag, we changed the head twice, changed the pump, changed everything when there was nothing left to change), we changed the block and it helped, there was a crack in the block, in one of the cylinders there was a barely noticeable strip, more like a scratch. The main thing is when it’s cold and on the highway everything is fine, as soon as you get into a traffic jam everything boils and the tank swells from pressure. What do you think about the pump? The blades have fallen off)

Thermostat malfunction

Under normal operating conditions, the thermostat must open fully to ensure an uninterrupted flow of coolant. They must also close to allow the antifreeze to heat up quickly during cold engine starting conditions. If the thermostat mechanism gets stuck in the open or closed position, then this will lead to overcooling or overheating, respectively. A faulty thermostat may open and close spontaneously, foaming the fluid and causing bubbles in the radiator and expansion tank. Rapid opening and closing of the thermostat valve will cause noise inside the radiator because the liquid will flow in uneven bursts.

Antifreeze and its properties: what you need to know

Antifreeze is a name given to coolants that have a low freezing point. They consist of varying proportions of water and a concentrate (for example, ethylene glycol or propylene glycol, the latter being more expensive but less toxic). Antifreeze is a Soviet trademark, but in fact it is a separate type of antifreeze.

Let's move on. Initially, the engines were cooled with water, but it had to be abandoned due to a number of properties: low boiling point (100°C), volume expansion in cold weather when freezing, as a result of which the block and engine head crack and this leads to expensive repairs or replacement of elements.

Antifreeze, compared to water, has a higher boiling point and a lower freezing point. When using antifreeze, the extreme boiling point ranges from 108 to 125 °C. The reason for this run-up is the different composition, which also affects the quality of coolants. The lower their price, the lower the boiling point becomes. Especially low-quality antifreezes boil already at 85°C. It is quite obvious that it is not advisable to save when purchasing, since the proper operation and service life of the engine depend on the quality of the coolant.

It is important to remember that even temperature-resistant antifreezes boil for one reason or another. Let's look at the main reasons for antifreeze (antifreeze) boiling.

Foam in the radiator due to burnt gaskets

Burnt or failed head gaskets are one of the most common obvious causes of coolant bubbles. If the gasket burns out between the cylinder and the water jacket, then compression gases will enter the latter, and air will leak through the head into the cooling system. Due to a damaged head gasket, abundant formation of bubbles occurs in the radiator and expansion tank. As a result, this leads to rapid overheating.

What not to do when the engine is boiling

There are a number of strict rules that limit the driver’s actions during a situation when antifreeze boils in the radiator, expansion tank or other element of the cooling system. These rules are designed to protect human health from causing serious injury, and to minimize material losses that may arise in the described situation.

- Do not load the engine (do not accelerate, but instead you need to reduce the speed to idle as much as possible, usually around 1000 rpm).

- Do not stop abruptly and turn off the engine, thinking that the engine will stop boiling; on the contrary, everything will only get worse.

- Do not touch hot parts in the engine compartment!

- While steam is coming from under the cap of the expansion tank or other unit and while the antifreeze is bubbling in the system, you should absolutely not open the cap of the expansion tank! This can only be done after the time specified above has passed.

- Do not pour cold water on the engine! You need to wait for the engine to cool down on its own.

- After the engine has cooled down and new antifreeze has been added, you should not drive after the temperature reaches more than +90 degrees.

Compliance with these simple rules will ensure the safety of the driver, and also minimize the degree of breakdown and, consequently, possible material costs.

Coolant boiling

Over time, radiators rust and oxidize, especially if they are not flushed and the proper ratio of antifreeze to water is not maintained. Particles of rust, slime and dirt will clog the radiator core tubes and interfere with the thermostat and water pump impeller. Excessive heat and rust will cause the coolant to boil and create small bubbles that can be seen in the radiator neck or expansion tank.

Air pockets in the cooling system are usually the result of a poorly flushed or incompletely filled radiator. Plugs lead to a decrease in fluid volume, which often affects the operating temperature. As a result, air bubbles are visible through the radiator inlet neck or in the expansion tank.

>

What are crankcase gases

During operation of the internal combustion engine, high pressure is formed inside the cylinder. During combustion of the air-fuel mixture, exhaust gases partially break through the piston rings and penetrate into the crankcase cavity. When gasoline burns incompletely and during the compression stroke, fuel, oil, and water vapors also enter the crankcase.

All these gases are collectively called crankcase gases. When they accumulate, the pressure in the crankcase increases, and the side effect is accelerated engine wear. There is also dilution and deterioration in the quality of the engine oil.

Why does the cylinder head gasket break?

In most cases, the reason why problems arise with the cylinder head gasket is simple overheating . Because of it, the block cover may “lead”, and the plane along which the gasket adheres to two contacting surfaces will be disrupted. As a result, depressurization of the internal cavity occurs with all the ensuing consequences. It is mainly aluminum heads that change their geometry. Cast iron is not subject to such malfunctions; they are more likely to crack than to bend, and only in the most extreme cases.

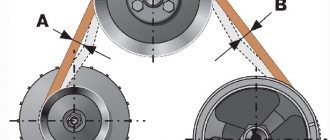

Scheme for pulling cylinder head bolts on VAZ “classics”

Also, due to overheating, the gasket can heat up to temperatures at which it changes its geometry. Naturally, in this case depressurization will also occur. This is especially true for iron-asbestos gaskets.

Another reason is a violation of the bolt tightening torque . Both very large and small torque values have a detrimental effect. In the first case, the gasket may collapse, especially if it is made of low-quality materials. And in the second, exhaust gases pass out without obstructing them. In this case, gases together with atmospheric air will have a detrimental effect on the gasket material, gradually destroying it. Ideally, the bolts should be tightened using a dynamometer that shows the torque value; in addition, the sequence of their tightening should be observed. Help information about this can be found in the manual.

Crankcase gas measuring device

You can measure pressure with a monometer; normal readings should not exceed 60 millimeters of mercury. First, make sure there is no blockage in the breather tube. Also check the engine oil level. The model of the measuring device is selected based on the power and type of engine. It is important to ensure that the device fits the diameter of the calibrated hole.

On vehicles with a closed ventilation system, the breather tube must be disconnected. A plug is placed on the channel inside the intake manifold. A pressure gauge is attached to the tip of the tube. A pressure sensor is connected to the device itself.

The engine must be operated at the load and speed at which the rated power is achieved. You need to wait until the pressure gauge readings level out.

Pressure gauge

After the device has stabilized, the results are recorded. You can then remove the device, pull out the plug and reconnect the tube.

It is important to consider that gas consumption may differ on two engines with the same displacement. This situation is possible when the models under consideration are differentiated by performance indicators per unit of time and torque.

| Crankcase gas consumption in cars with diesel engines | |

| Engine power | from 280 to 450 liters |

| Volumetric flow rate of crankcase gases at idle speed | 4-120 l/min |

| Volume flow in rated power mode | 140-130 l/min |

| Mass flow at idle | 0.7-5 g/h |

| Mass flow at rated power mode | 5-10 g/h |

Homemade device for measuring crankcase gases

Using available materials, you can measure the pressure of crankcase gases, expressed in liters per minute. It is more convenient to perform the operation with an assistant. You will need the following materials:

First you need to turn off and plug the purge hoses. Next, you will need to draw some water into the basin. Fill the canister to the top with water and close the lid. Now you need to turn it over, put it in a basin and carefully open the lid.

The engine starts. One end of the hose is connected to the oil filler neck, the other is bent upward and lowered into the canister. When gases begin to escape, it is important to immediately note the time using a stopwatch. If the engine is running normally, the readings should not exceed 20 l/min.

Gases in the expansion tank

Fellow diesel drivers, don't pass by! Renault Kengo engine F8Q 632 1.9 D I've been tinkering with the car myself for a month now because... no one wants, or rather does not know how to turn a diesel engine, and there is no desire to drag it for 70 km. I installed another motor (I didn’t check the block for plane), I installed the head from the repair, left the cylinder head bolts with the old ones (I have 20 of them), the cylinder head gasket was on the motor, but they didn’t drive it, they just threw it on the motor, put the head on and tightened the bolts( they didn’t tighten it) The trouble is this: -gases go into the expansion tank -the thermostat squeezes out (I bought a new one assembled, I installed the same body of the old one) the thermostat is attached with 3 bolts by 7 to the head there are 2 by 7d. and 1 8d. Don’t scold too much, point your finger where to look, what to pay more attention to, what to replace besides the cylinder head gasket and bolts.

Comments 54

The cylinder head and block planes also need to be ground along the plane, just not by hand but on a machine

should the economy be economical?

What do you mean there was a gasket on the engine? Did they install something? If they squeezed it and removed it, it’s in the trash!

There is nothing to guess here. Head for crimping and checking the mating, check the block for mating too. From overheating, these heads vomit under the prechamber. Maybe the new guides were torn. Lots of options. The Reinz gaskets and bolts on three of these engines have already run for 50 tons, no questions asked. It's better to use new bolts if you're thinking about driving. The tightening comes with plastic deformation (stretch) and may burst when used again. But in general the engine is durable and successful

There is a high probability that the bolts are to blame, if it is possible to unscrew two bolts and fold the thread onto the thread, there should be no gap between them, if the thread is stretched then this is the problem.

Good day, dear ones! Question. 1. Do gas bubbles appear in the expansion tank immediately after starting the engine or not? 2. Has the color of the coolant changed or remains the same?

Explanations for questions: For question 1. — If gas appears in the expansion tank immediately, the fault may be on the gasket, on the surface of the block and cylinder head. — If gas appears as it warms up, we have a microcrack (microcracks) in the metal of the block (which is unlikely), the cylinder head (very common), the turbine (if present, it is not uncommon).

To question 2. If the color of the coolant changes (as a rule, it acquires a brownish tint with small oily stains), this is because exhaust gases enter the coolant, we are guilty of: - everything connected with the exhaust side of the cylinder head, as a rule these are microcracks in the area of the exhaust valve and manifold (very often located in the valve seat area); — Turbine from the exhaust gas inlet side (microcracks in the turbine housing).

If the color has not changed, then it is most likely blowing from the turbine (if there is one), i.e. microcracks on the discharge side. Unfortunately, not all microcracks can be detected by crimping under normal conditions. Some of them open only when the metal is very hot. Be sure to pay attention to the coolant level; in any case, if there are microcracks, it should decrease, at least a little, but it should

When opening the cylinder head, the gasket must be changed! The bolts do not need to be changed (depends on the amount of elongation (there is such a concept in the theory of internal combustion engines) and on how many times they have already been opened and how they have been tightened (if history is silent about this, it is better to change).

It is necessary to estimate the planes of the block and cylinder head on the plate, if they are made of luminium, cast iron is rarely used; it is more likely to crack. It is possible to sin if they sanded crookedly, but it is unlikely, since such things are usually not done on the knee... well, unless the machine has a crooked plate ! Something like this... But you should always start with something simple - watch! Start the engine and watch the coolant reservoir and a lot will become clear! Good luck to you! Hello Crimea!

In what cases is the presence of oil in the breather not related to the crankcase?

Before diagnosis, it is recommended to make sure that the unpleasant symptoms are actually associated with gases. Oil ingress is also possible in other cases, for example, if more fluid is poured than required according to the standards. It is possible that the breather is not installed correctly and moving it will correct the problem.

Oil in breather

Sometimes oil penetrates from the internal elements of the power unit, including injectors. Driving style, as well as the condition of the roadway, also influences. Oil particles may remain when the motor actively moves in the transverse direction.

Which gasket material is better?

Gaskets made of different materials

When replacing a gasket, many car owners have a reasonable question: which gasket is better - metal or paronite? Each of these materials has its own advantages and disadvantages. At the same time, you need to understand that if the manufacturer recommends using gaskets made of a certain material, then you must adhere to these requirements.

As a rule, a metal gasket is stronger than its paronite counterpart. Therefore, it is advisable to install it on powerful turbocharged or forced engines. If you do not plan to tune the engine of your car, but simply operate it in a gentle mode, then the choice of material does not matter much to you. Accordingly, a paronite gasket is quite suitable. Moreover, this material is more flexible and is able to adhere more tightly to work surfaces.

Also, when choosing, it is necessary to take into account that the material from which the gasket is made does not have a primary impact on its service life. A much more important indicator is how the gasket was installed. The fact is that there are very thin walls between the individual groups of holes. Therefore, if the gasket is not installed exactly in the seat, then there is a high probability of burnout even in the strongest material.

The most obvious sign that the gasket was installed incorrectly is its rapid failure. Also, if you installed it incorrectly, the car may simply not start. In diesel engines, the knocking of the pistons may also be heard. This happens because the piston touches the edge of the gasket.