01/26/2022 5,656 Electrical package

Author: Ivan Baranov

The windshield cleaning system includes many elements connected to each other and performing one important function - cleaning the windshield from dirt. If for some reason the system stops working, the driver's visibility of the road will be impaired and, accordingly, this may affect his safety. Find out what functions the windshield wiper arm performs and what elements the system consists of in this article.

[Hide]

Windshield wiper motor repair

There are several factors and reasons that can cause such an important device to fail.

In most cases, this occurs when there is no contact between the commutators and the brushes. If after inspecting the motor and thoroughly cleaning the contacts the problem does not disappear, you will most likely have to disassemble it and replace it. However, before taking such drastic action, there are a few more ways to take decisive action to consider. If the gearbox is stuck and the levers are jammed, most likely a certain fuse in the system, called a bimetallic fuse, has tripped. As a result, the system will not be able to cope with its responsibilities and will cause additional problems for the driver.

True, if you remove the part in time and carry out the appropriate repairs by replacing the fuse, most likely the malfunction will be eliminated in a short time. Provided that everything is done correctly, the windshield wiper will start working normally, as before.

The development of cases where the device is capable of operating only in a specific speed mode cannot be ruled out. This problem is of a completely different nature and lies in a problem with the switch or resistor. Here the brushes do not come to the lower position at all, which makes it necessary to adjust the stopping mechanism.

Situations where strange sounds and noises are heard when starting the windshield wiper are also not uncommon. If such phenomena are in no way related to dry glass, perhaps we are talking about some more serious problem.

As mentioned above, the design characteristics of the wiper motor are extremely simple and understandable. There are small brush levers on the fingers, which most often make an unpleasant sound. Sometimes it happens that the mechanism begins to sour in the bracket bushings due to a violation of the protection. As a result, dirt and water get inside.

If, after a final check of the device, no malfunctions are found, but the noise still makes it difficult to live in peace, the need to replace the motor cannot be ruled out. Now you should disconnect the device from the electrical supply, and then begin dismantling work.

Motor Troubleshooting

There are several different types of failure. The electric motor stopped working, the bimetal fuse is also faulty, while the integrity of the fuse link, which is an indispensable part of the power circuit, is still preserved.

In this case, you should conduct a full analysis of the wiring, the quality of the contact connections and localize possible problems. If there are no wiring problems, you most likely need to evaluate the condition of the wiper switch. Any faulty sharpenings or small parts should be removed and replaced. The risk of engine failure cannot be excluded, which is associated with burning contacts or sticking brushes.

Here you will need to repair the motor, which involves a complete replacement of failed parts and thorough cleaning of contaminants. You also need to look at the condition of the wires going to the motor and pads. At the next stage, you will have to carry out a full diagnosis of the bimetal fuse.

It is thoroughly cleaned of contaminants, and if this is not possible, a new one is replaced.

If the situation has not changed, pay attention to the integrity of the motor armature winding. If there is no chain, it is necessary to replace the anchor or the entire structure

Another situation looks completely different. In this case, the bimetal fuse may work, but the engine does not even start. Before starting any actions, you should make sure that the levers are intact. Very often they fail due to deformation or freezing of the blades to the surface of the windshield.

It is also useful to read: Features of hybrid wiper blades

Repairs are particularly difficult in cases where a short circuit occurs in the anchor circuit. Here you need to decide on one of two solutions: replace the armature or the gearbox.

There are times when the motor stops functioning in intermittent operation. Most often, the problem is explained by some problem with the relay or switch. Both options involve replacing the faulty unit.

If the intermittent windshield wipers still do not stop, it is most likely a faulty limit switch or relay. In the first option, the spring plate is simply not pressed by the cam of the gearbox gear. To solve the problem, you need to bend it slightly.

Car device

Purpose of windshield wipers

Cars are operated in different climatic, road and meteorological conditions, and to ensure traffic safety and comfortable conditions for the driver, it is necessary to ensure perfect visibility of the road situation. The main factors that reduce visibility and visibility to the driver are contamination or moisture (for example, precipitation) of the windshield, rear and side windows, while reduced visibility through the windshield is the most dangerous from the point of view of traffic safety. Contaminated headlight glasses significantly impair visibility at night.

Based on the above, a windshield wiper is designed for mechanical cleaning of the windshield (in many models of passenger cars and the rear window) from precipitation and dirt. Headlight cleaners, recently installed on many passenger cars, are designed to clean the headlight glasses from dirt.

Wiper blades

Glass cleaning is carried out with special rubber-coated brushes, pressed tightly against the glass by the working surface and making oscillatory movements along the surface of the glass.

The number of windshield wiper blades depends on its size and shape; Most cars use two wipers, one on the driver's side and one on the passenger's side, but there are also cars with three windshield wiper blades on the windshield.

The brushes must move smoothly across the glass, without jolts (which is often the “sin” of vacuum and pneumatic drives) with a certain swing angle and pressing force against the glass.

The use of spheroidal glazing of the body and headlight glasses of complex spatial shape on modern cars complicates the operation of the windshield wiper blades, since it is difficult to ensure a tight fit of the blades to the glass surface. Therefore, windshield wiper blades are made flexible and increase the force of the springs pressing them to the glass. The flexibility of the brushes is ensured by increasing the number of rocker arms (joints) of the holder and the use of an optimally shaped brush profile.

Wiper drive types

The main design difference between windshield wipers used on cars is the type of drive of their blades, which can be mechanical (manual), electric, vacuum or pneumatic. Currently, the most widely used electric windshield wiper drive operates stably in all conditions (including when the engine is not running).

Mechanical (manual) windshield wipers, which were equipped with many cars until the middle of the last century, are now practically not used. They are the simplest in design, but are inconvenient to use, and also distract the driver from monitoring the road situation.

Vacuum-driven windshield wipers for their operation use the vacuum formed in the intake tract of the engine power supply system (the same as vacuum brake boosters). Significant disadvantages of such windshield wipers are the impossibility of using them when the engine is not running, as well as the dependence of their operation on the magnitude of the vacuum in the intake tract. However, vacuum-powered windshield wipers are occasionally used on some types of vehicles.

Pneumatic windshield wiper drives are sometimes used on trucks equipped with a pneumatic network. Such windshield wipers were used, for example, on the first models of KamAZ cars, but due to the lack of stability and reliability of the pneumatic valve control system, they were subsequently replaced by electrically driven windshield wipers. The pneumatic type of windshield wiper drive is currently found on some trucks.

Design and operation of electric windshield wipers

The kinematic and design solution of the windshield and rear window wiper mechanisms is quite simple. An electric windshield wiper (Fig. 1) consists of an electric motor, a worm gear (usually made in the same housing as the electric motor), a crank mechanism, a system of levers and brushes.

| Rice. 1. Schematic diagram of a windshield wiper: 1 - levers and brushes; 2 — crank; 3 - electric motor; 4 - gearbox; 5 - operating mode switch | Rice. 2. Rear window wiper motor 47.3730: 1 — gear; 2 - worm; 3 - output shaft; 4 — gear housing; 5, 7 — gear sectors; 6 — earring; 8 — electric motor housing; 9 - permanent magnet; 10 - anchor |

The electric motor 3 of the windshield wiper, through a worm gear 4, rotates the crank 2, which, through a system of drive levers and rods, imparts a rocking motion to the brushes.

On some cars (in particular, on buses with a large windshield area), the windshield wiper blades do not swing, but plane-parallel movements due to a special lever drive design. This allows the brushes to clean a larger surface of the windshield from dirt and moisture, but somewhat complicates the design of the drive.

The gearmotor has a built-in limit switch, which ensures that the brushes are placed in the extreme position when the gearmotor is turned off, and a bimetallic fuse that protects the circuit from overloads.

The limit switch breaks the power supply circuit to the motor when its rod gets into the recess on the output gear. Many windshield wiper gearmotors do not have a crank mechanism, in which the rotation of the motor armature is converted into oscillatory motion using the lever mechanism of the brush.

Different climatic conditions and vehicle speeds necessitate changes in windshield wiper performance. Obviously, in heavy rain or when the car is moving at high speed, even with slight precipitation, the windshield wipers should work more efficiently. Therefore, modern windshield wipers have devices that allow you to adapt the speed of movement of the brushes to the intensity of contamination or wetting of the glass. As a rule, such devices are electronic.

How do windshield wipers work on a car? Let's disassemble the system

Such a simple design as windshield wipers on a car, but who knew that even they could present structural surprises? Let's look at the operation diagram and design of a conventional windshield wiper.

There are many spare parts in a car that we incorrectly consider to be secondary. This is a given, which we consider as such, which means that we often do not notice how fascinating the design of this or that part of the machine can be. These things work well, and why know the structure of these “gray mice”? By the way, this is an extremely fascinating and diverse world. It also includes an element without which it is impossible to imagine safe and comfortable movement during various types of precipitation - car windshield wipers.

We lift the lever and the wipers start moving across the windshield due to the action of the electric motor. Indeed, this is how they work, but the description is extremely basic; in reality, everything is much more varied and fun.

Windshield wiper system

Standard windshield wipers are designed to remove dirt, dust, and excess sediment from its surface. This allows you to increase visibility of the road at any time, including bad weather conditions: heavy rain or snow. For greater efficiency, the device is combined with a windshield washer, which sprays a special washer fluid under high pressure onto the glass surface. Thus, the glass is cleaned from adhering dirt and insects.

Automotive windshield wipers

Some cars have a rear windshield wiper, as well as special devices for cleaning the headlights (washers). This allows you to ensure traffic safety in all weather conditions. The frequency and duration of operation of the windshield wipers is regulated by the driver from the passenger compartment.

How the device works

Despite the simple functionality of the cleaning system, it is necessary to understand how windshield wipers work. Key details you need to know:

- The electromagnetic relay receives the control command and sets the operating mode of the brushes. Depending on the vehicle, the wipers may operate intermittently at short intervals of 3-5 seconds, continuously move at a set speed, or enter wash mode with the washer on.

- The windshield wiper motor receives power from the on-board electrical system. The exact connection diagram depends on the car model.

- The windshield wiper arms, and along with them the glass cleaning brushes, are driven by an electric motor with a worm gear and a lever drive (trapezoid). The trapezoid transmits and converts rotational motion from the electric motor to brushes, which, pressing tightly against the working surface, remove dirt and moisture from the glass.

How does a trapezoid work?

The windshield wiper trapezoid consists of a system of rods and levers that convert the rotational movement from the gearbox into the reciprocating movement of the leads with brushes. A standard device should perform the following functions:

- movement of the brushes when the windshield wiper motor is running;

- ensuring the required amplitude and speed of cleaning;

- Windshield wiper arms with two or more blades must move synchronously.

Trapezoid wipers

The trapezoid, like the electric motor, is an important component of the system. In case of any malfunctions (the appearance of backlashes) in its operation, the efficiency and quality of glass cleaning deteriorates.

For greater reliability, the trapezoid elements are made of sheet steel, which is resistant to aggressive environments and also has high bending rigidity.

Wiper motor

The windshield wiper motor has a basic design regardless of the car model. The main elements include the electric motor itself and the gearbox (usually a worm gear), which increases the force from the electric motor several times. Modern devices can be equipped with additional elements, including fuses for protection against heavy loads, heating elements for operation at low temperatures, and much more.

Windshield wiper motor for VAZ 2110

The windshield wiper gear motor is the most important element of the system, which ensures its performance. The brushes must fit tightly to the glass and move freely along it, otherwise there will be an increased load on the electric motor.

Selection of brushes

When choosing wipers, you must be guided by the following criteria:

- Length. One of the main indicators - length - is selected in accordance with the car model or taking into account the size of the already installed product.

- Method of fastening products. If the fixing brackets do not match, you simply will not be able to install the products.

- Quality is an equally important criterion. The better quality the products are, the longer they can last.

As practice shows, high-quality products always cost more, and experts advise not to skimp on purchasing products, since they directly affect visibility. We recommend selecting wipers according to the make of the car, as this will allow you to most accurately select the required size.

In addition, it is best to choose products in accordance with the season - they can be both summer and winter. It should be taken into account that winter versions are equipped with special blades that do not freeze or freeze in the cold. Depending on the situation, you can not completely replace the product, but only one blade, of course, if the remaining elements of the leash are in good condition.

Loading …

Windshield wiper design elements

Design features depend on the type of device and the type of fastening elements. The standard windshield wiper circuit consists of the following parts:

- lever drive (trapezoid);

- leashes;

- relay for controlling operating modes;

- electronic control unit (if equipped);

- electric motor with gearbox;

- hinged fastenings;

- brushes

Additionally, control devices are provided. For example, for manual control, a steering column switch for windshield wiper operation modes is used, and for automatic mode, a special electronic control unit and a sensor for analyzing glass contamination (rain sensor) are installed in the vehicle.

Where does which wire go, or just a diagram

Connecting wipers and washer

“Plus” power is supplied from the ignition switch through fuse No. 2 at 10 Amp of the mounting block. The permanent “plus” goes along the black and yellow wires to contacts “4” of the connectors of the gear motor and the steering column switch. It should not disappear even when the switch is in the “off” position. The blue wire supplies “+” 12 V power to the motor when the switch is in the “continuous mode” position. On the blue-white wire, in the “off” position there should be a “minus”, and in the “continuous mode on” position the “minus” is turned off. This is done to slow down the motor when the power to the closer is turned off.

The red wire supplies the relay with “+” 12 V from the switch when the intermittent mode is turned on. At the moment of operation, contacts “2” and “4” close, and “1” and “3” open, the motor starts working and the brushes make one or two movements. Then “+” 12 V is turned off, and contacts “1” and “3” are closed to each other and to “minus”. The motor stops for a few seconds and then the cycle repeats.

The washer pump motor is connected to “+” 12 V constantly with a black and yellow wire through the same fuse No. 2. “Minus” is applied when you press the windshield wiper lever from bottom to top.

Video about how a windshield wiper works

Electric windshield wiper front and rear

With the advent of the era of high technology, the air system was abandoned. It was replaced by compact electric motors, which spun the mechanism quite quickly and are the most reliable and efficient today.

This type of windshield wiper consists of an electric motor installed under the windshield of the car, a special trapezoid and a pair of windshield wipers. Such a windshield wiper is controlled using a steering column switch installed in the vehicle interior. When lowering it down, the motor is set in motion and spins a special trapezoid, which moves the wipers to one position and then returns to their original position. Once the cleaning is complete, the cycle repeats again. This ensures that the windshield wipers are fully automatic regardless of engine operation.

The electrical circuit of such wipers contains a special electronic wiper relay. This device allows you to take certain pauses between cleaning the glass, when it becomes dirty or covered with moisture not too intensely. This is done so that the windshield wipers do not obstruct the driver’s view and prevent visual fatigue.

With the advent of a large number of station wagon and hatchback cars, there is an urgent need to clean the rear window. For this purpose, a windshield wiper was also installed on the trunk lid. It is powered by exactly the same motor; one trapezoidal mechanism is now designed for one windshield wiper, not two. This innovation allowed the driver to maintain visibility not only in the forward direction, but also in the rear, which improved the comfort of driving the car in various weather conditions.

To save electrical energy from the generator and battery, the rear wiper drive is activated from a separate button. That is, the activation of an additional wiper should only be done if there is an urgent need for it.

Features of the device and wiper circuit

Scheme of the glass cleaning system for Priora The glass cleaning system consists of the following elements:

- Electric motor or wiper drive. This device ensures the normal operation of the system by facilitating the movement of the wipers along the front and rear (for station wagons and hatchbacks) glass. If the windshield wiper gearbox fails, it will cause the wipers to not work. The rear wiper drive is also installed only in hatchback or station wagon vehicles.

- The windshield wiper blade holder, also known as the windshield wiper arm, is also known as the windshield wiper arm - brush holder. The wiper blade itself is fixed to this device and moves along the glass.

- Brush with a rubber or silicone blade. When it wears out, the quality of cleaning the windshield is significantly reduced.

- The fastening of the windshield wiper blades is a structural element of the wipers themselves.

- Expansion tank - liquid is poured into it, which is subsequently transferred to the glass through nozzles through hoses when the wipers are turned on.

- Nozzles - these elements are mounted on the hood, they perform the function of spraying water onto the glass.

- Rubber hoses connecting the expansion tank and injectors - consumables are transferred through them.

- Depending on the car, it may use a windshield wiper control unit or a windshield wiper breaker. The latter is a relay that, in accordance with the actions of the driver, determines the frequency of movement of the brushes at specified time intervals. As for the block, it allows the driver to independently set the required interval.

- The washer motor, which supplies water or washer fluid to the windows.

- Windshield wiper switch. The steering column switch is located inside the car, under the steering wheel. With its help, the driver can set the speed of the wipers, and also, if necessary, supply water to the glass.

- A rod that connects two brushes. Thanks to it, these elements can move synchronously.

Photo gallery “System elements”

1. Six types of fastenings

2. Wiper arm remover

3. Expansion tank

How the windshield wiper works

On VAZ 2108, 2109, 2113, 2114 (hatchback body) cars a windshield wiper and rear window washer are installed. On VAZ 2199, 2115 (sedan) models there is no rear window wiper.

Windshield wipers have several operating modes: intermittent (work with a pause), low (first) speed, high (second) speed, one-time triple cleaning of the glass, operating mode with a windshield washer. The rear wiper operates only in one position and in conjunction with the rear window washer.

Typical windshield wiper malfunctions and methods for eliminating them:

Windshield wiper malfunctions include:

1) Complete inoperability of the system (not a single mode works, the electric motor cannot be heard):

- check the presence of voltage of 12 volts at terminal 6, in the windshield wiper connector, ground 4, and also check all supply circuits (fuses 4 and 5, switch, mounting block, ignition switch, etc.);

- check the operation of the mode switch (presence of 12 V control voltage at terminals 1 and 2 of the windshield wiper connector when switching modes);

- check the functionality of the electric motor itself (dismantling and disassembly is required);

2) Intermittent mode does not work (all others work);

the main reason is a non-working “short circuit” relay, in the diagram, and a mode switch (the easiest way to check is by substitution, for a known good one)

3) The windshield wiper blades do not stop in the down position, but stop anywhere (the blades can extend beyond the windshield):

- the limit switch in the electric motor is broken (or burnt out) (it is not possible to replace it, only the entire motor, but you can try to fix and repair the switch);

- incorrect adjustment of the position of the wipers (align the wipers in place);

- the drive shaft of the brush mechanism began to be dismantled (disassembly and replacement of failed parts);

4) The noise of the electric motor is heard, but the brushes do not move (the brushes may twitch in one place):

- the drive shaft of the windshield wiper mechanism has been damaged (“licked off” the splines) (replace or fix the splined part of the electric motor);

- the nut securing the mechanism rod to the electric motor shaft has become loose (tighten the nut);

5) The wipers do not operate after turning on the windshield washer:

- Most likely, the steering column mode switch has failed (replace with a known good one);

- there may be a malfunction in the operation and serviceability of the mounting block (measure the voltage at terminals 9 and 18);

6) Poor quality of glass cleaning.

- The windshield wiper blades have lost their elasticity (replace the blades with new ones);

- contact with oily materials on the glass (oil from the exhaust pipe of a car in front, waxing at a car wash, contamination after polishing, etc.)

Troubleshooting and repair of the rear windshield wiper follows similar principles (the diagram is attached below), with the exception of the absence of operating modes in the rear windshield wiper, and accordingly the absence of some parts (relay, limit switch in the electric motor, and so on).

Electrical part of the windshield wiper:

The windshield wiper circuit has several types of design. With any design, windshield wipers must ensure cleaning of the windshield regardless of the amount of precipitation. Automotive windshield wiper drives usually have two speeds. It should ensure that the brushes are placed in the extreme position when turning off, which does not interfere with the driver’s view.

On modern cars, the windshield wiper drive has an intermittent operation mode. It is provided by a thermal or electronic relay included in the power supply circuit of the wiper drive. This mode can be either with a constant period of time or adjustable. During intermittent operation, one or two cycles of brushes pass across the windshield with breaks of 3 - 5 seconds. In addition, on some cars, for example VAZ classic, the intermittent mode serves as a low-speed wiper drive.

On some imported cars, intermittent operation uses a smooth speed control, which is ensured by changing the voltage to the electric motor by an electronic unit.

Windshield wipers: design and principle of operation

A dirty car windshield significantly impairs visibility on the road, which negatively affects the quality and safety of driving. Therefore, Motorpage experts remind you of the need to keep your windshield clean.

Windshield wipers are installed in cars specifically for this purpose. On some cars they are present not only on the windshield, but also on the rear window.

Windshield wiper device

- Wipers are oblong elements that move along the glass. At rest they are located at the bottom of the windshield. Both wipers are connected by a rod, due to which they move synchronously. The main cleaning function is performed by brushes with a rubber or silicone blade or tape, located on the wipers using a special leash (brush holder). They are a consumable item, since over time the tape wears out and the quality of the cleaning procedure deteriorates. If this happens, the consumable (brush or tape) must be replaced.

- Windshield wiper drive with gearbox Provides movement of the wipers. There are different types: mechanical, pneumatic, etc. Electric drives are installed in modern passenger cars. If this unit fails, then when the windshield wiper is turned on, the wipers do not move.

- Trapezium - the element is located between the drive and the wipers. It consists of rods and levers, the task of which is to convert the rotational motion created by the electric drive into reciprocating motion and transmit it to the leashes.

- The tank is a plastic container (volume from 2.5 to 5 liters) located under the hood or fender of the car. Water is poured into the tank, which is subsequently supplied to the glass when the corresponding wiper function is activated.

- The nozzles are located on the hood and connected to the tank via rubber hoses, through which liquid is sprayed onto the glass.

- The washer motor is a pump in the reservoir that supplies water. At the moment when the car owner turns on the spraying mode, the device creates pressure in the system, which squeezes the liquid through the nozzles onto the glass.

- The switch is located under the steering wheel to control the windshield wiper system. Using it, the driver adjusts the movement of the wipers (single sweep, or at a specified interval, or constant movement at low/high speed), and also activates the fluid supply, if necessary.

- Control unit - the device is not installed in all cars; its main function is to automatically start and turn off the windshield wiper. A rain sensor helps determine when to activate the cleaning system, which analyzes current weather conditions and the cleanliness of the glass.

- Interrupter - the device allows you to adjust the interval between wiper strokes when selecting the intermittent operating mode. This function is useful in light rain to prevent the wipers from rubbing the dry glass.

About heated wiper blades

The option of heating the windshield, which is extremely useful in Russia, is not always available and is not offered on all models. But there is an alternative and budget solution - windshield wiper blades with an electric heating function. They are heated from the inside due to a flexible heating element installed in the body, powered by the vehicle's on-board network. Heating occurs from the inside evenly throughout the entire body, the heating temperature is about 70 ° C. The frameless wiper blade is designed in such a way that when the rubber wiper blade wears out, it can be easily replaced without removing the frame with a flexible heating element. There are several options for connecting to the on-board network. The simplest is to install a button, but as an option you can use a “radio key fob” to remotely control the heating, or you can install an automatic thermal relay that will independently turn on the heating when the engine is running and the temperature is below zero degrees.

Methods for attaching brushes

Before 1999, most car manufacturers used a type of mounting for OEM windshield wiper blades called a "hook" or "hook". This is a universal device in the shape of the letter “U”, which allows you to snap the brush into place and not worry about the reliability of its installation. The following types of mounts are currently gaining popularity:

- Side pin - appeared in 2005 on BWM, Volvo and other cars. Allows brushes to be fixed using a special 22 or 17 mm side pin.

- Button or “Push Button” is an adapter for standard 16 mm wide wiper blades. It is enough to snap the device into place for fastening, and to remove it you need to press a special button.

- Pin lock - fixation of brushes using a special built-in lock. Used in Audi cars.

“Push Button” mounting scheme

This is not a complete list of types of fastenings. Each manufacturer can use their own designs for fixing brushes.

Despite the relative simplicity of windshield wipers, it is difficult to imagine a modern car without them. Drivers can control the operation of the wipers directly from the cabin, remove dirt and improve visibility of the road situation. And electronic systems automatically monitor the cleanliness of the glass, increasing the comfort and safety of driving without human intervention.

Why are car wipers needed and how do they work?

Car wipers are designed to clean the windshield from water, dirt, snow, etc. falling on it while driving. The principle of operation of the windshield cleaning system, which includes wipers, is quite simple - the electric drive motor, through a system of rods and levers, acts on the drive rollers, with leads attached to them, and the windshield wiper blades themselves are attached to them. The system of rods and levers does not ensure circular movement of the drive rollers; they only rotate around their axis by 90-110 degrees and then return back. Almost all cars have two wipers on the windshield. The same system of rods and levers is made so that both drive rollers rotate synchronously; as a result, the brush leads themselves move synchronously, which prevents them from touching. Providing better downforce - the leashes are spring-loaded.

Video: Testing wiper blades

Often another wiper is installed on a car - on the rear window. Its function is the same as that of windshield wipers. But the design itself is somewhat simpler. The rear wiper is also driven by an electric motor. It is usually located next to the drive roller of the leash, but drives it not through levers, but through a small gear reducer.

In principle, the drive mechanism is reliable and breaks down infrequently. Much more important in this system is the condition of the wipers themselves. After all, they provide visibility to the driver in driving conditions during rain and snow. When driving on a busy highway, especially in the autumn-spring period, water with mud impurities often rises into the air from under the wheels of overtaking cars, which settles on the windshield. Much the same thing happens when driving on a snowy road. If the windshield is not cleaned, it will be impossible to move on very quickly due to poor visibility through the glass.

But in addition to the performance of this system, you also need to monitor the wipers themselves. Severely worn cleaning elements will not ensure proper cleaning of the glass. As a result, visibility will be insufficient, and the driver will have to strain his eyesight more, which will lead to rapid fatigue.

The design and principle of operation of automobile windshield wipers

All modern cars are equipped with windshield wipers or wipers, which are designed to clear the windshield of dirt, dust or precipitation. With their help, the driver can significantly improve visibility without leaving the cabin. Automotive windshield wipers are an integral part of the vehicle design, and their malfunction prohibits the operation of the vehicle.

- Windshield wiper system

- Windshield wiper design elements

- How the device works

- How does a trapezoid work?

- Wiper motor

- Purifier management

- Types of brushes

- Methods for attaching brushes

Function and principle of operation of wipers

The key task of the windshield wiper mechanism is to clean the windshield from water during rain, as well as dirt that falls on its surface during movement. These wipers operate using special mechanisms.

Using the scheme of rods and hinges, the non-circular movement of special cones is ensured; they only provide translational-rotational action, after which they return. Almost every car has two wipers. The design of the rods and hinges is designed in such a way that the drive cones work synchronously, which facilitates the simultaneous movement of the wiper arms. This helps prevent them from touching.

Often a wiper is also installed on the rear window of the car. Its function is similar, but the circuit is a little simpler. An electric motor helps drive the rear window wiper, since these mechanisms work almost the same on all cars. Most often it is located close to the drive cone of the lever, but begins its movement with the help of a small gear reducer.

The car windshield wiper system consists of the following elements:

- 1.

The windshield wiper motor (electric motor) is located in the engine compartment. It initiates the movement of the brushes at different operating speeds.

At 48 seconds of the video, a completely disassembled windshield cleaning system is shown.

- 2.

The electric motor is no different in its internal structure from other types of these motors: brushes, windings, magnets, output rod, everything is standard. But the torque transmission system itself is quite original; it includes a spiral gear that transmits rotation to the movement of the remaining parts of the circuit (the internal structure can be seen from 1.57 to 3.41 minutes of the video) of the windshield wipers, and a large gear that is driven first. - 3.

But how is the drive motor capable of moving in different directions, since it only rotates in one direction? This becomes possible with the help of a special articulated connecting rod mechanism, which converts the rotational movement of the motor into translational movements of the brushes (4 minute video) - 4.

Windshield wiper blades. The main thing for them is to fit well to the glass area. This becomes possible due to the spring, indicated at the 5th minute of the video, and the many joints directly on the brush itself, which, being closer to the immediate brush, decrease in size and more precisely press the brush blade to the curved surface of the glass. - 5.

Switch. The devices are simple and almost trouble-free. There are two contacts on the moving part on the switch side, and on the stationary part there are other multiple contacts, which, when closed, increase the speed of glass cleaning. This is controlled by a microcircuit in which the program for interruption and intensity of brush strokes is written. - 6.

Washer reservoir. At 6.10 minutes the liquid level meter was demonstrated, and at 6.30 minutes the motor was removed

Every driver strives to keep the windshield of his car as clean as possible, since the degree of visibility of the road depends on this. This is especially important in bad weather, in rain or snowstorms at night, when a dangerous situation arises on the road. In order to keep the viewing glass clean, the car is equipped with devices that remove dirt, moisture, and raindrops. The windshield wiper drive is one of these devices. There are two types of such devices - mechanical and pneumatic. You can read about how this mechanism works in this material.

Windshield wiper drive and principle of its operation

Often, the impulse is transmitted to the brushes through the use of some mechanical elements that are connected in parallel or in series. Windshield wipers of a pneumatic operating principle are less common. Such a device is located in a circuit with a certain volume of air from the brake system. A device with a pneumatic operating principle is located slightly higher than the level of the windshield, and begins to work when the valve opens.

The cleaning mechanism works on a very simple principle. The brushes have blades that move back and forth to clean the surface. You can also adjust the speed at which the brushes move as the weather changes. There are some car models that have “hidden” windshield wipers, that is, they are moved down by a special mechanism as soon as the device is turned off.

Once hidden, the windshield wipers will be invisible. This device is more typical for large machines.

Systems with two synchronous levers rotating in a semicircle are widely used. But in Mercedes models there is only one windshield wiper, but it moves along a W-shaped path.

Windshield wiper motor and other components of the device

The wipers on the front and rear window are not very different, but there is still a difference between them. The difference is that you can change the speed at which the front blades rotate, but the rear wipers only have one operating mode. Based on this, front windshield wipers are formed by a gearbox, an electric motor, blades that clean the surface, a lever system and a control that allows the blades to automatically return to the starting point after the driver switches the lever to the “off” position.

This system can also wash the front glass. This washer consists of a deposit that makes the wiper motor work, lines, nozzles and a special tank into which you need to fill distilled water or a special liquid that needs to be diluted with water. The washer turns on at the same moment when the brushes start working.

The design of the rear wiper drive is the same as the front one. There is such a thing as a rear window washer. It also has all the vital components. The rear washer and cleaner are activated directly from inside the car by moving the lever.

Selection of windshield wiper blades - by car make or not?

When choosing blades for a windshield wiper, you need to be guided by information about the following parameters:

quality, brush length and fastener design.

The quality of brushes varies from manufacturer to manufacturer; the situation is similar for products from different price categories. But it’s still better not to skimp on brushes, because the transparency and cleanliness of the windshield will depend on them, and as a result, the visibility of the road. When choosing windshield wiper blades, you should also focus on the make of the car. If the length of the brushes is too long, the brushes will exert too little pressure on the glass, which will make the glass difficult to clean.

It is very advisable to use brushes depending on the time of year, that is, in the summer you need to install summer brushes, and in the winter - winter ones. Winter brushes have special rubber shields that will protect the rocker joints from ice. Sometimes the brushes do not need to be changed, since in some models you can simply insert a rubber strip that will serve as shields. But this becomes possible only if the adapters and hinges are in satisfactory condition. The rubber layer must be selected in such a way that the new device has the same grooves as the old tape.

We hope that it has become clear to you, as a driver, that you need to monitor not only the condition of the engine, engine, etc., but also such a part as the windshield wiper drive. It may seem that such a detail is a trifle, but this is a deep misconception. You need to be sure that all elements of the car are in good working order.

Subscribe to our feeds at

What is the purpose of a windshield wiper, how does it work and how does it work?

The windshield wiper is used to clean the windshield to improve visibility. Most cars have an electric windshield wiper (Fig. 111). It consists of an electric motor 12, a worm gear 10, drive levers 14, brush holders 2 with springs 3 and brushes 4 mounted on axles 1. The brushes are mixed along the windshield 5. The drive axis is connected by levers 14 to the axis 6 of the worm gear 8. Worm 9, located in constant mesh with the worm gear, it is made as one piece with the armature shaft 11 of the electric motor 12. A shaped contact disk 13 of limit switches 7 is fixed on the shaft of the worm gear 6. Switch 15 has three positions: off; low speed, at which brushes 3 make 27 double strokes per minute, and high speed - 45 double strokes per minute. The change in speed is achieved by including additional resistance in the excitation winding circuit. When the switch is set to the first or second position, current flows into the field windings of the electric motor and the armature begins to rotate. Torque is transmitted to the worm 9 of the gearbox 10 and from it to the worm gear 8. The worm gear makes it possible to reduce to the required limits the rotational speed of the worm gear shaft, on which a crank is mounted, connected to the lever drive system of the brushes 4. The crank converts the rotational movement of the worm gear into a rocking movement of the brushes . After turning off the switch, the electric motor does not turn off immediately and the brushes continue to move along the glass until they reach their extreme positions. At this moment, limit switch 7, located on the gearbox housing and operating in parallel to the main switch 15, will open the electrical circuit using a shaped disk 13 with a contact. The motor will turn off and the blades will stop at the bottom edge of the glass.

Fig. 111. Wiper.

*** Test your knowledge and answer the

The windshield cleaning system includes many elements connected to each other and performing one important function - cleaning the windshield from dirt. If for some reason the system stops working, the driver's visibility of the road will be impaired and, accordingly, this may affect his safety. Find out what functions the windshield wiper arm performs and what elements the system consists of in this article.

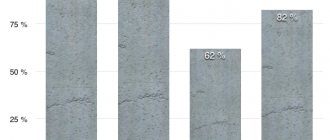

Quality control and tests: a mandatory component of the production of Masuma wipers at our factory

The plant has its own testing laboratory, where products are tested for compliance with a wide range of indicators.

The quality of parts and their compliance with the declared characteristics are checked in our own laboratory. Tests are carried out here to:

- determine the resistance of Masuma wiper blades to abrasion, temperature changes and other factors;

- make sure that there is a good fit to the surface and that there is no possibility of damage to the glass during operation;

- evaluate the quality of paintwork frames and their resistance to external factors;

- check how effectively the glass surface is cleaned with brushes.

Based on the results of tests in the laboratory, if necessary, decisions are made to make changes to the production technology of specific brush models. These processes take place continuously at the enterprise, ensuring product quality.

Go to the Masuma wiper catalog

Advice from car enthusiasts and professionals

1. How to change the rear wiper motor

The mounting of the rear window of a car is usually different from the front. Therefore, the windshield wiper drive system is also designed differently there. Accordingly, the answer to the question of how to change the rear wiper motor also has a number of nuances:

- First of all, the windshield wiper is fixed in a vertical position to provide access to the fastening screws.

- The next stage is to disconnect all external communications from the mechanism and disassemble the structure itself. First of all, dismantle the lever, then the protective cap of the rotary shaft and unscrew the bracket fasteners.

- It is impossible to remove the rear wiper motor without freeing the trunk from the upholstery. It is held on by pistons that need to be removed in those places where the wiring connection block to the gearmotor is located.

Be sure to disconnect two pads. One is used for connecting cables, the second for cables.

- After disconnecting the electrical part, unscrew the screws holding the motor.

- Then you can remove the engine by turning it left and right.

We recommend

“The wipers squeak: causes and solutions to the problem” More details2. How to check the performance of the wiper motor

During repairs or inspections for preventive purposes, there are several ways to see malfunctions in the operation of the glass cleaning system:

Brushes must be secured in their holders in a normal position, swing at a speed appropriate to the task, and not encounter any obstacles along the way. To diagnose the electric motor, use a tester. Its capabilities are sufficient to detect broken contacts and identify poor-quality connections. Disassembly of the mechanism is necessary for visual inspection of the condition of the gearbox gears

Pay special attention to the condition of the gears and threads on the rollers. Other mechanical components can be assessed during inspection even without disassembly.

Right choice

It is better to select according to the time of year in which you most often drive; the car will not be worse off. Nowadays, counterfeiting various car parts is just a mega profitable business, this has not escaped our topic, even wiper blades are counterfeited. Here, the selection before purchasing must be done very carefully. Ideally, you need to familiarize yourself with the most common companies on the Internet and see how to distinguish each one from a fake, by what markers. If we judge, in general, then any normal and high-quality auto chemicals must have high-quality printing, with a label carefully and in the right place, all details and the date of issue must be clearly printed on the wrapper. Start choosing for yourself by checking these points.

If you are too lazy to think through all this for you, then you can simply come to a good expensive store, where they will recommend you the best that can be available today.

Car wipers. We select for the car

If you decide to replace the brushes, then the wipers should be selected for the car. This can be done by comparing with old wipers, previously removed from the car, which have already been working for some time.

The choice must be made in accordance with the following rules:

- Type of fastening. Some single-brand automotive brushes may use different mounting methods on the arm. Therefore, it is advisable to compare the type of attachment with the previous brush. If you choose wipers with unsuitable mounting, you can buy a special adapter.

- Length. It is important to consider that the maximum deviation in the length of car wipers should not be 1.5-2.0 centimeters.

- Wiper blade type. Here you choose at your own discretion. You can order a cheap frame model or spend more and buy hybrid or frameless wipers.

- Manufacturing company. When buying cheap Chinese windshield wiper blades, you can't count on their long service life. There are many companies that specialize in producing high quality windshield wiper blades. In particular, Bosch, SWF, Denso and Valeo.