The design of the windshield wiper on the VAZ 2110 is quite reliable and during normal operation the motor and the trapezoid itself can easily move all 300,000 km, which has been proven by the personal experience of many owners. But there are also exceptions to the rules.

It often happens that the splines are bypassed or the trapezoid structure simply breaks down. If you have such problems, the repair procedure will be discussed below.

To replace all the wiper parts, we will need the following tool:

- flat and Phillips screwdriver;

- 10 mm socket head;

- ratchet handle;

To do this job, you first need to do some preparatory steps, namely:

- Remove the windshield trim (jabot).

- Remove the insulation and seal under the hood.

- Disconnect one end of the expansion tank rubber and move it to the side.

Windshield wiper motor - what is it and how does it work?

Modern cars are equipped with two windshield wipers, which for the front window have a double design (there are two rubber bands on the blade for more efficient operation), and for the rear window - a single version. Most windshield wipers operate in three main modes. These modes are intermittent, slow and fast operation.

A windshield wiper includes in its design an electric motor with a gearbox, a system of levers, brushes and a mechanism that automatically returns the car wipers to their original position. The windshield washer operates simultaneously with the cleaner. When this small but important mechanism stops working, you should not hesitate to fix it, because the weather is rarely predictable.

Why does the windshield washer not work?

All washer malfunctions are divided into two groups: electrical and mechanical.

Mechanical:

- Lack of liquid. In winter, you cannot use ordinary water, as it may freeze. If the water still freezes, you need to warm up the car engine and leave it in a warm room.

- The fluid supply hose may fly off or become pinched.

- The nozzles can also stop the washer from working. Poor quality of water and washer fluid leads to the fact that the fittings become clogged with dirt, rust, and washer fluid does not flow. The injectors are cleaned or new ones are purchased.

Electrical:

- Fuse F2(10A) has blown.

- The electric motor does not pump, no fluid flows, which means the terminals are oxidized. You need to clean the terminals and contacts and connect everything.

- Faulty switch. If the motor does not turn when voltage is present, then this is the reason.

- Check the pump motor by connecting it directly to the battery; if it starts spinning, then the fault is in the steering column switch.

Windshield wiper motor repair - how to determine the cause of the breakdown?

There may be several reasons why the windshield wiper does not work; we will consider common situations below. First of all, there may be no contact between the commutator and the brushes. If, after disassembling the electric motor and cleaning the contacts, the fault has not been resolved, then in this case, most likely, repair of the windshield wiper motor is necessary, but there are several other options that are worth checking before drastic measures are taken.

If the levers are jammed or the gearbox is stuck, the bimetallic fuse may trip. Then your system will also not respond to attempts to turn it on. Naturally, by adjusting the position of these components and replacing the fuse, this problem can be solved. After correcting the problem, the windshield wiper should work normally.

Sometimes this mechanism begins to function at only one speed. In this case, the switch or resistor is most likely faulty. The brushes may not be installed in the lower position; to do this, it is necessary to adjust the stopping mechanism. There are often situations when, when you turn on the windshield wiper, extraneous sounds appear in the form of creaking or grinding. If this is not due to the dryness of the glass or the presence of sand under the rubber brushes, then, apparently, something is acting up inside, so it’s time to look deeper.

The structure of the windshield wiper is not complicated. The brush levers are attached to the fingers, which may be the first suspected source of extraneous sounds. As a rule, they sour in the bracket bushings due to protection violations when water and dirt get inside. If the device passed this test successfully and the sound remains, then repair or replacement of the windshield wiper motor is necessary.

In order to remove the motor, you need to de-energize the electrical system, and only then can it be dismantled.

VAZ 2107 wiper malfunctions

Replacing a burnt out motor

During the winter season, at sub-zero temperatures, wipers often stick to the windshield. The wiper motor is under a lot of load, and it burns out if the bimetallic fuse does not work or the fuse burns out.

Location of the glass cleaner and washer fuse in the mounting block

In such cases, it is necessary to replace the motor. To do this, you need to remove all the parts in a certain order:

- Unscrew the fastening nuts;

- bend the lever and remove it from its seat;

- Using a 22mm wrench, unscrew the trapezoid fastenings on both sides;

- remove the plastic inserts;

- remove the hood seal;

- remove power from the windshield wiper motor;

- remove it with the drive from the hole in the body;

- bend the protective cover, unscrew the fastening nuts;

- press on the protrusions of the slots on the reverse side, on which the wiper arms sit, so that they fall inward, move in different directions, the trapezoid with the motor will come out.

Video instructions for replacing the windshield wiper trapezoid

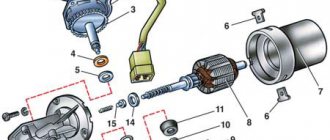

After disconnecting the mechanism parts, you can repair the gear or install a new motor. But the electric motor must be inspected, even if it is in working condition. It is a conventional DC electric motor, the rotation of which, through a worm gearbox, is supplied to a trapezoid.

Walk over the collector with a cloth soaked in solvent. If there is a lot of wear, you need to change the armature or motor. Defects on the gear will require it to be replaced. Assembly occurs in reverse order. Therefore, before installing a replacement electric motor, you need to clean the trapezoid from contamination, lubricate the rubbing elements, motor and gearbox.

Trapezius problems

The trapezoid transmits rotational movements from the electric motor to the wipers and ensures the reciprocating movement of the wipers while cleaning the glass. Interruptions in the operation of wipers occur due to problems with the trapezoid; oxidized bushings and corrosion on the axles lead to jamming and slow operation of the mechanism. You can remove the trapezoid with a flat-head screwdriver. To set the correct position when installing the trapezoid, you must:

- set the motor to the initial position;

- place the crank and short rod parallel to each other;

- After that, attach the motor to the trapezoid.

Wiper relay not working

If the wipers fail to operate in intermittent mode, it can be argued that the relay has failed. First you need to check the power supply to the relay block. To do this, you need to remove the relay, turn on the wipers in intermittent mode, and check the voltage at the terminals. If no current flows, you need to repair the open circuit or replace the switch. The design of the relay is such that it cannot be repaired. So, if it does not work under voltage, you need to replace the part with a new one.

Replacing a windshield wiper motor - how to remove the device?

Sometimes the rear wiper motor, just like the front one, simply fails. It is unlikely that this will be a frequent breakdown, but if it catches you, there is nothing you can do, you will have to figure it out. In order to repair the device, it must be removed, and this is a rather labor-intensive process. As an example, classic VAZ models are usually given, which most fully demonstrate the entire technical process. So, removing the motor takes place in several stages:

- The nuts that secure the brush arms are unscrewed, after which they can be removed from the cone splines of the drive. If this is difficult to do, a penetrating lubricant can be applied to the splines.

- The drives of the brush levers are dismantled by unscrewing the fastening nuts, and then the plastic bushings and rubber gaskets are removed.

- The block of wires in the harness is disconnected and removed by lifting the edge of the seal through the slot in the partition of the engine compartment.

- The next step is to directly remove the wiper. Then the washer and spring clamp are unscrewed from it, and the rod is disconnected.

- After unscrewing the three mounting bolts, you can remove the motor.

Checking the functionality of the mechanisms

How to give new life to worn out windshield wipers.

how to change rubber bands on frameless wipers: video instructions and advice from professionals replacing rubber bands in frame wipers At the repair stage or during a preventative check of windshield wipers, you can identify problems in the device in several ways. The quality of the mechanism is primarily determined by the function of the brush and its position in the brush holder. The cleaning elements must move freely and easily at the specified speed. The electric motor itself is checked by a tester. In particular, such diagnostics makes it possible to detect irregularities in contacts and connections. When disassembled, the device allows you to evaluate the condition of the gearbox gear - in particular, the mentioned teeth and threads on the rollers are checked. The remaining components can be checked with the naked eye, even with a superficial inspection.

How to remove the windshield wiper gear motor?

To remove the gear motor, we only need to unscrew 4 fasteners! But there are two nuances:

- not convenient location;

- you need to remember the position of the crank.

The crank is a curved rod from the motor to the trapezoid rods. If you do not install the crank correctly, there is a high probability of damaging the teeth on the new motor.

So:

- Open the hood, disconnect the wiring block from the fuse block to the gear motor.

- We remember (indicate with a marker) the position of the crank.

- We unscrew the fastening of the piston to the motor with a key set to “13” and remove it.

- Using a “10” wrench, unscrew the three bolts securing the gear motor to the trapezoid.

- We take out the gear motor.

If the gear motor cannot be pulled out, unscrew the fastenings of the fuse block and move it away.

Where does which wire go, or just a diagram

Connecting wipers and washer

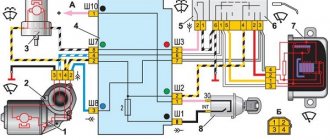

“Plus” power is supplied from the ignition switch through fuse No. 2 at 10 Amp of the mounting block. The permanent “plus” goes along the black and yellow wires to contacts “4” of the connectors of the gear motor and the steering column switch. It should not disappear even when the switch is in the “off” position. The blue wire supplies “+” 12 V power to the motor when the switch is in the “continuous mode” position. On the blue-white wire, in the “off” position there should be a “minus”, and in the “continuous mode on” position the “minus” is turned off. This is done to slow down the motor when the power to the closer is turned off.

The red wire supplies the relay with “+” 12 V from the switch when the intermittent mode is turned on. At the moment of operation, contacts “2” and “4” close, and “1” and “3” open, the motor starts working and the brushes make one or two movements. Then “+” 12 V is turned off, and contacts “1” and “3” are closed to each other and to “minus”. The motor stops for a few seconds and then the cycle repeats.

The washer pump motor is connected to “+” 12 V constantly with a black and yellow wire through the same fuse No. 2. “Minus” is applied when you press the windshield wiper lever from bottom to top.

Video about how a windshield wiper works

Review

Many dozens of car owners agree that the windshield wiper motor of the VAZ 2110 is quite frail - both in old and new modifications. Moreover, its operation depends on many parameters: the condition of the wiper rubber bands, wind, the amount of water pouring onto the glass, the voltage supplied to the wiper motor. Usually there are more complaints about the front window wiper, but the rear window on models 2111 and 2112 also has exactly the same gear motor.

Methods for attaching brushes

Before 1999, most car manufacturers used a type of mounting for OEM windshield wiper blades called a "hook" or "hook". This is a universal device in the shape of the letter “U”, which allows you to snap the brush into place and not worry about the reliability of its installation. The following types of mounts are currently gaining popularity:

- Side pin - appeared in 2005 on BWM, Volvo and other cars. Allows brushes to be fixed using a special 22 or 17 mm side pin.

- Button or “Push Button” is an adapter for standard 16 mm wide wiper blades. It is enough to snap the device into place for fastening, and to remove it you need to press a special button.

- Pin lock - fixation of brushes using a special built-in lock. Used in Audi cars.

“Push Button” mounting scheme

Despite the relative simplicity of windshield wipers, it is difficult to imagine a modern car without them. Drivers can control the operation of the wipers directly from the cabin, remove dirt and improve visibility of the road situation. And electronic systems automatically monitor the cleanliness of the glass, increasing the comfort and safety of driving without human intervention.

Source