Ways to prevent detonation

In most cases, a loud detonation sound can be heard when a cold diesel engine is running at idle or under light load. This is to blame for the long ignition delay, which, as is known, decreases with increasing pressure and temperature. Detonation during idling is not dangerous for the engine and disappears when the load increases.

In engines with direct injection of diesel fuel into the air in the combustion chamber, detonation can be eliminated by reducing the amount of fuel injected during the ignition delay. The main amount is injected immediately after the start of combustion. The disadvantage is the inability to completely eliminate soot emissions, which occurs when the fuel does not have enough time to evaporate and mix with air before ignition. When the temperature and pressure are high and there is not enough air for combustion, a cracking reaction (splitting of molecules) occurs, which leads to the formation of soot. The soot does not burn completely and ends up in the exhaust gases.

Knocking fuel combustion can also be eliminated by separating the combustion chamber. Diesel fuel is injected into an isolated cavity (pre-chamber) in the cylinder head.

Rice. Split combustion chamber of a diesel engine

Due to lack of air, not all fuels can burn there. Due to pre-combustion, the temperature and pressure increase in the pre-chamber. Fuel that is not burned passes through the narrowing at high speed into the main combustion chamber, where it burns out to the end. Due to the extended combustion process, detonation noise is suppressed even when using fuel with a long ignition delay. True, at the same time there is an increased specific fuel consumption.

Along with the mixture formation methods, when fuel is injected into the air, there is a fuel supply method developed in which diesel fuel is injected so that a thin film settles on the surface of the combustion chamber. When using this method, detonation does not occur, since the fuel burns in the volume in which it evaporates from the wall and mixes with air. Engines operating on this principle of mixture formation are called multi-fuel internal combustion engines, as they can use all types of fuel, from lubricating oil and diesel fuel to gasoline.

Fuel manufacturers are also making efforts to eliminate detonation. Diesel fuel after oil refining has a boiling range of 160-90 °C. It contains many saturated hydrocarbons, which are highly flammable. The density of diesel fuel is p - 0.83 g/cm3, and its specific heat of combustion is Нu

42000 kJ/kg. When additives are added to accelerate combustion, the flammability of diesel fuel is further increased. The effect of additives is that the fuel ignites directly when it enters hot air, and as the temperature rises, the ignition delay of diesel fuel decreases. To do this, it is enough to add ignition acceleration additives to diesel fuel in an amount of 0.1-1 percent by volume.

Checking compression in cylinders

You can measure the compression in each cylinder using a device called a compression meter. You can do this yourself, but you need to meet certain conditions and have:

- compression gauge;

- fully charged working battery;

- working starter;

- spark plug key.

Measuring compression in a cylinder

The compression meter has a special adapter that is installed instead of the spark plug. The engine is cranked by the starter. Data from the device is recorded for several seconds until the needle stops growing. This procedure is done with each cylinder. To obtain more accurate data, you need to take measurements on a cold and warm engine.

It is quite normal if the indicators differ from those declared by the manufacturer. This occurs due to wear of the piston group and other parts. A discrepancy of around 10% is considered normal. It is also worth paying attention to the ratio of indicators in different cylinders; they also should not differ much.

Compression in diesel engines is much higher, since the compression ratio is higher. Conditions for measuring compression in a diesel engine:

- turn off the fuel pump;

- have a charged battery and a working starter;

- unscrew one nozzle;

- install the compression gauge in place of the injector.

If the pressure in the cylinders is 10-12% below the established norm, this can lead to the following consequences:

- increased fuel consumption;

- increased oil consumption;

- the appearance of carbon deposits in the combustion chamber, toxicity;

- higher crankcase gas pressure.

The main reason for low pressure is wear of the piston group or poor valve tightness. The liners and piston rings must be replaced, or the interface between the valves and the cylinder head must be repaired.

Low compression in diesel engines results in blue smoke emissions. Insufficient compression and, as a result, temperature does not allow diesel fuel to burn completely. Incorrectly set ignition, incorrect fuel octane number and compression can lead to detonation.

Determination of flammability of diesel fuel

The flammability of diesel fuel is expressed using the cetane number (CZ). It means that the diesel fuel has the same flammability as a certain comparative mixture of cetane and a-methylnaphthalene. The highly flammable reagent in the mixture is cetane. It has a cetane number of 100, while l-methylnaphthalene has a cetane number of 0. Thus, for example, a cetane number of CZ = 55 means that diesel fuel has the same propensity to ignite as a comparative mixture of 55% (volume fractions ) cetane and 45% (volume fractions) a-methylnaphthalene. Flammability increases with increasing cetane number.

Determining the cetane number is carried out in the same way as determining the octane number of gasoline using a reference engine specifically designed for these measurements. An engine is used to evaluate the detonation resistance of gasoline using the method and a standard engine for assessing the detonation resistance of fuel materials - single-cylinder four-stroke diesel engines with a device for regulating the final compression pressure. While in an engine the final compression pressure is adjusted by restricting the intake air, in a standard engine the adjustment is done by changing the compression ratio.

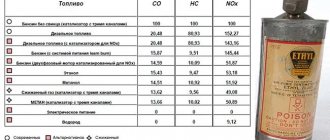

Octane number of gasoline and cetane number of diesel

The gasoline index we are used to at gas stations is its detonation resistance coefficient. The comparison is made in relation to a mixture of gasoline derivative - heptane, with isooctane - one of the most resistant to compression ignition components. Heptane has 0% stability (none), isooctane has 100% stability. For example, the marking “95” indicates that the stability of this gasoline, like isooctane, is 95% “strength”.

To control the combustion of the air-fuel mixture, achieving more “predictable” behavior from it, anti-knock additives that slow down the reaction are added to gasoline and diesel fuel.

Comparison of gasoline composition

The measurement scale up to 100 was quite logical until additives that inhibit compression ignition, more effective than tetraethyl lead, appeared, with the help of which 95 and 98 gasoline (from 92) are now produced.

The quality of the resulting “feed” for the engine depends on how “legal” the compounds are used: its resistance to separation into fractions, to carbon formation, resinity, percentage of sulfur content. Ferrocene, manganese additives, the same tetraethyl lead, now prohibited by law, are not just carcinogenic and harmful to the environment - they are slowly “killing” internal combustion engines equipped with distributed injection and a catalyst. The approved additives - monomethylaniline (MMA), with methyl tert-butyl ether (MTBE) - are also unsafe. The first one increases tar formation (and soot), the second one quickly evaporates in warm weather (if the tank is not sealed), thereby reducing the octane number of gasoline.

Diesel fuel has its own stability equivalent - cetane, which exhibits a large compression ignition delay (100%). Methylnaphthalene (0%) is used as an “antagonist” for it.

The cetane number of modern diesel fuel ranges from 45 to 55. Diesel fuel with a lower number provokes a nonlinear increase in pressure in the combustion chamber, prematurely wearing out the CPG, and with a higher number (58–60) it does not burn completely, causing the internal combustion engine to “smoke.”

What is detonation of an internal combustion engine

Engine detonation is not a pleasant phenomenon. the causes of detonation at the end of the article, but first let’s understand what detonation is and what happens to the engine when it occurs.

Normal combustion of fuel in a cylinder is a chemical reaction that occurs in a mixture of gasoline vapor and air. In order for the process to begin, it is not enough to simply mix fuel with air in the required proportion; this substance must also be given the necessary energy.

In diesel engines, this creates a very high pressure on the combustible mixture and the temperature at the end of the compression stroke promotes ignition of the fuel. In gasoline engines, the mixture must be ignited with a spark, which is created using a car spark plug. The formed flame spreads from the electrodes of the car spark plug to the walls of the entire combustion chamber.

As long as the flame front moves from the spark plug to the distant zones of the combustion chamber, self-ignition may occur before the fire arrives. Undoubtedly, because of this, a weak shock wave arises, which meets the fuel prepared for ignition on its path.

When compressed, the combustible mixture immediately ignites. Simply put, this wave is detonation , the speed of its propagation in the engine cylinder reaches about 1000 m/s. This is several times faster than an ordinary fire front. You may hear a metallic sound when doing this.

This phenomenon manifests itself, as a rule, at medium and high engine speeds. Light and short-term loads do not have serious harmful effects. In addition, the closer the combustion conditions in the engine are to detonation, the higher its efficiency.

In diesel engines, the compression level is much higher, causing the fuel to heat up to five hundred degrees and self-ignite without the help of a spark. In gasoline engines, the compression level is much lower, and accordingly, the temperature in the cylinders is lower. In addition, the ability of gasoline to spontaneously ignite is lower than that of diesel fuel.

Diesel engine detonation

Unlike injectors, in diesel engines the fuel is not ignited; it spontaneously ignites when injected into the cylinder with hot compressed air. If the volume of fuel exceeds the set value, a shock wave develops in the combustion chamber. Engine detonation at idle speed is accompanied by a loud sound; it is believed that this effect does not pose a danger and gradually disappears with increasing load.

The reasons for diesel engine detonation at idle speed are a delay in fuel combustion. This time period shortens as the temperature in the system increases.

How to reduce the likelihood of detonation:

- Reduce the amount of fuel injected.

- Divide the combustion chambers (preliminary compartment, working compartment).

- Inject fuel using the MAN method.

- Add special additives to diesel fuel, which accelerate combustion.

Diesel engine detonation after turning off the ignition occurs for the following reasons:

- clogged injector holes;

- fuel injection pump failure;

- carbon deposits.

Causes of engine detonation

The cause of detonation in modern engines, including VAZ, is most often the low quality of fuel and the amount of impurities in it. Before going to the service center, try changing the gas station. If detonation does not disappear, then it is necessary to check the operation of the fuel system using computer diagnostics. It is also necessary to contact a service center if the detonation is severe.

In addition to poor fuel quality, detonation can be caused by:

- low octane number of fuel used

- dirty fuel filter

- poorly functioning injectors

- Problems with the fuel pump

- faulty oxygen sensor

- Using the wrong spark plugs

- engine cooling system malfunction

- malfunction of the engine control unit

That is, there are many reasons, but most of them can only be determined with the help of special diagnostic equipment.

Diesel detonation((

Features of the design and operation of diesel engines installed on KIA SORENTO BL (2002..2009)

Re: Diesel detonation((

Accent-58 » 03 Feb 2010, 12:41

I'm going through the same thing. There was one working nozzle. I replaced all the injectors one by one. There is no difference. Could the noise be coming from some kind of valve or due to different compression? The most interesting thing is that after 2500 rpm, detonation disappears. The hydraulic compensators were also changed.

ಠ_ಠ

ಠ_ಠ

Accent-58 Messages: 7070 Registered: April 30, 2008, 07:48 From: Penza Thanked: 228 times. Thanked: 577 times. Name: Alexander Car: Another car Year of manufacture: 2012 Add. information: were SORENTO BL 2.5TD SORENTO BL 3.3 SORENTO XM 2.4 Now LCP 150

- Website

- ICQ

Re: Diesel detonation((

Gosh » Apr 13, 2010, 07:50 pm

The sore is typical. The symptoms appeared the same when there was a load of chattering. I searched through all the topics, people are grieving, but I still don’t see anyone curing it. Is it really such a terrible malfunction that no one has cured it?

Gosh Messages: 297 Registered: 09 Feb 2009, 22:38 From: Lipetsk Thanked: 0 times. Thanked: 0 times. Name: Georgy Car: Another car Year of manufacture: 2008

Re: Diesel detonation((

Accent-58 » April 13, 2010, 08:57 pm

I think the compression in some pot has gone bad, I’ll check it in the summer.

ಠ_ಠ

ಠ_ಠ

Accent-58 Messages: 7070 Registered: April 30, 2008, 07:48 From: Penza Thanked: 228 times. Thanked: 577 times. Name: Alexander Car: Another car Year of manufacture: 2012 Add. information: were SORENTO BL 2.5TD SORENTO BL 3.3 SORENTO XM 2.4 Now LCP 150

- Website

- ICQ

Re: Diesel detonation((

Fisher » Apr 13, 2010 9:24 pm

I had this sound before the engine was overhauled. I don't notice it now. I didn’t change the hydraulics, but they were lying around in oil for several weeks, getting soaked

But the piston rings have been replaced, but I don’t think it was them that were ringing.

Time spent fishing does not count towards your life!

Fisher Messages: 3705 Registered: Aug 12, 2008, 09:10 From: St. Petersburg Thanked: 0 times. Thanked: 4 times. Name: Sergey Car: Other car Year of manufacture: 2013 Add. information: There was a black Korean, limited.

Re: Diesel detonation((

Accent-58 » April 13, 2010, 9:33 pm

that’s what I’m saying. It might be stuck in one cylinder. Moreover, it gets worse with the low temperature of the air sucked into the engine. Even if you warm up the engine with Webasto, it still rings if the air is cold.

ಠ_ಠ

ಠ_ಠ

Accent-58 Messages: 7070 Registered: April 30, 2008, 07:48 From: Penza Thanked: 228 times. Thanked: 577 times. Name: Alexander Car: Another car Year of manufacture: 2012 Add. information: were SORENTO BL 2.5TD SORENTO BL 3.3 SORENTO XM 2.4 Now LCP 150

- Website

- ICQ

Re: Diesel detonation((

Gosh » April 13, 2010, 10:00 pm

Fisher wrote: before engine repair

I didn’t change the injectors. Or did I repair anything at all?

Gosh Messages: 297 Registered: 09 Feb 2009, 22:38 From: Lipetsk Thanked: 0 times. Thanked: 0 times. Name: Georgy Car: Another car Year of manufacture: 2008

Re: Diesel detonation((

Alexander » April 13, 2010, 11:03 pm

This sound has nothing to do with detonation, IMHO. Listen to the previous generation Audi 2.5TDI or Multivan 2.5 TDI. My neighbors are leaving their garages, it seems to me that the tractors have arrived for cleaning. There is no such chirping sound on the Mercedes CDI - that’s why it’s a Mercedes. I heard this sound on a Sorento in the UK, and the quality of the fuel has nothing to do with it, well, how long will the engine last with detonation combustion of the fuel, and I’ve been listening to this sound for the second hundred times. I enjoy it, which is what I wish for everyone.

In vino veritas, in aqua sanitas.

Alexander Messages: 2069 Registered: Dec 16, 2007, 2:25 pm From: Moscow VAO Thanked: 35 times. Thanked: 310 times. Name: Alexander Car: Sorento XM, 2.2TD (197 l/s), 4WD, AT Year of manufacture: 2009 Add. information: And again a diesel, and again a Korean dealer.

Re: Diesel detonation((

Jeck00 » April 19, 2010, 20:47

I got a similar sound after maintenance at Automir on Varshavka (disgusting office...) More details, vibration, detonation (scraping), bass growl when accelerating, loss of acceleration dynamics. In cold weather the problem becomes worse. I’ve been trying to resolve this issue for almost a year now, but so far everything is in vain... It starts at the drop of a hat. Diagnostics show nothing...

Jeck00 Messages: 24 Registered: June 21, 2009, 10:45 pm From: Noginsk Thanked: 0 times. Thanked: 0 times. Name: Vyacheslav Car: Sorento BL, 2.5TD (170 l/s), TOD, AT Year of manufacture: 2008

Re: Diesel detonation((

Andrey59 » April 19, 2010, 20:59

Alexandr wrote: and fuel quality has nothing to do with it

Since there are more than a ton of fuel reserves and different “brands” in different containers, I can say with confidence that the sound depends on the fuel, I didn’t expect it myself, but it changes right during the refueling process, I try not to use “ringing” diesel fuel, since even the additive increasing the cetane number does not help, but Lukoil 2T oil does not help much.

Andrey59

Re: Diesel detonation((

Alexander » April 20, 2010, 09:58

Andrey59 wrote: different “brands” in different containers

For the last two years there has been one “brand” - Lukoil Euro-4 (Tsentrnefteprodukt) and the sound is the same, in winter the engine chirps until it warms up, in summer the chirping almost disappears. I don't use additives.

In vino veritas, in aqua sanitas.

Alexander Messages: 2069 Registered: Dec 16, 2007, 2:25 pm From: Moscow VAO Thanked: 35 times. Thanked: 310 times. Name: Alexander Car: Sorento XM, 2.2TD (197 l/s), 4WD, AT Year of manufacture: 2009 Add. information: And again a diesel, and again a Korean dealer.

Re: Diesel detonation((

Lyokha Yurich » June 15, 2010, 00:32

knocking/clattering noise during acceleration/load As a rule, remove the injectors (the pre-injection mode is broken), check them on a bench, and repair them. Good luck

Repair of injectors and fuel injection pumps, exchange of injectors. Engine repair.

Lyokha Yurich Messages: 2456 Registered: Aug 10, 2009, 10:44 pm From: Moscow Thanked: 267 times. Thanked: 397 times. Car: Sorento BL, 2.5TD (170 l/s), TOD, AT Year of manufacture: 2007 Add. information: Koni-HT, IronMan +3.5 + spacers, Binar-5 with GSM launch, self-written Chiptuning, mud slippers for the summer, cooler where required

Re: Diesel detonation((

Khabibulin » 31 Aug 2010, 21:08

After changing the turbine and intercooler, when starting on a cold engine, detonation occurs for 2-3 minutes, blue smoke. Then it works without any comments. I’m already tired of these servicemen. Colleagues, tell me how to treat it.

Khabibulin Messages: 636 Registered: 04 Feb 2010, 15:32 From: Orel Thanked: 162 times. Thanked: 21 times. Name: Pavel Car: Sorento XM F/L, 2.2TD (197 l/s), 4WD, AT Year of manufacture: 2015 Add. information: there was a dark gray EX on springs from Vlad with Horses XT without a USR.

Re: Diesel detonation((

KLIG.

» 11 Nov 2010, 18:17 A problem appeared: when accelerating (when you load the engine), you can hear something like detonation or a clattering sound, I don’t even know what it sounds like, what could it be?

Before this, I repaired 3 injectors because they were draining into the return line....

If your hands are golden, then it doesn’t matter where they grow from......

KLIG. Messages: 932 Registered: July 28, 2010, 16:56 From: Irkutsk region. Taishet Thanked: 0 times. Thanked: 6 times. Name: Sergey Car: Sorento BL, 2.5TD (14X l/s), Part-Time, MT Year of manufacture: 2002 Add. information: Repair of the industrial shaft, injectors, front driveshaft. Replaced the low pressure fuel pump, the bearing in the front axle and installed the bushing in the DiFa housing (left side). Barnaul springs.

Re: Diesel detonation((

BlkDem » November 11, 2010, 6:28 pm

Is the 4th knocking?

BlkDem Moderator Messages: 23780 Registered: Sep 16, 2009, 12:01 From: Kiselevsk/Krasnoobsk Thanked: 1438 times. Thanked: 1148 times. Name: Maxim Car: Sorento BL, 2.5TD (170 l/s), TOD, AT Year of manufacture: 2007 Add. information: There was a SORENTO 2.5TD 2002 SuperTOD II, Binar, CB

- Website

- ICQ

Return to Diesel Engines (BL)

Go to:

Who's at the conference now?

This forum is currently viewed by: no registered users and guests: 3

What to do if the engine knocks?

Detonation, as a rule, occurs under certain engine operating conditions, characterized by high engine speeds and increased load.

This could be a sudden start from a standstill, driving uphill, driving with a full load, etc.

To combat detonation, modern engines use a special sensor, which is called a knock sensor . It monitors engine operating parameters, and in the event of detonation, changes the engine operating mode by changing the composition of the fuel mixture and ignition timing parameters.

However, if while driving you notice that the engine is knocking, then the first thing you need to do is change your driving style. Pressing the gas pedal as smoothly as possible, try to move off as smoothly as possible, reduce the speed, and climb hills in a lower gear (compared to the normal mode).

At the first opportunity, fill the tank with guaranteed good gasoline, purchased at an official gas station of the same Lukoil or BP. If the detonation does not stop, then go to a service center for diagnostics.

The process in which uncontrolled spontaneous combustion of the air-fuel mixture occurs in the cylinders is called engine detonation. This defect is an explosion; it produces destructive effects on components and parts of power units of any kind. In a physical sense, detonation is a destructive blast wave created by excess pressure and ultra-high temperature of the fuel.

How to prevent detonation

Knock sensor

In injection engines, a knock sensor is installed. This small device detects vibrations, detects detonation and adjusts the ignition if necessary. The device sends a signal to the control unit, which then transmits it to the system. Fuel supply and ignition timing are adjusted. The knock sensor is usually located between the second and third cylinders.

It must be remembered that the most effective way to combat detonation is to use high-quality fuel recommended by the automaker.

Description of detonation and its consequences

When accelerating a car, the driver presses on the accelerator pedal, and the fuel mixture enters the cylinders and experiences very high pressure and temperature. The pressure increases as the piston moves upward and the fuel from the glow plug ignites. The flame, spreading throughout the combustion chamber, generates additional pressure.

Under the influence of ultra-high temperature and increased pressure, the remaining combustible mixture spontaneously ignites, creating one after another blast waves with a rapid increase in amplitude.

The effect of an uncontrolled chain reaction occurs, during which the flame presses on the sleeve at enormous speed, the engine speed increases to infinity - the engine goes wild, spinning up spontaneously . This situation is difficult to control.

The consequences of engine detonation are expressed by the following breakdowns:

- Breakage of piston edges.

- Damage to the cylinder walls.

- Cylinder head gasket rupture.

- Broken throttle sensor.

With stable engine operation, uniform combustion of the fuel mixture occurs with the subsequent transfer of energy to the pistons.

What is detonation of power equipment

Before fuel combustion begins in the engine, the fuel must be mixed with air in the correct ratio. Next, the resulting composition must be given energy. In gasoline engines, energy is supplied through a spark generated by a spark plug. It happens that the fuel composition in the cylinders of power equipment ignites spontaneously. This uncontrolled combustion is called “detonation.”

If the engine is working properly, when it is running, the flame circulation speed is about 20 m per second. If detonation occurs, the propagation speed multiplies several tens of times: it can reach up to 2 thousand m per second. As a result, the motorist hears an unusual noise, reminiscent of tapping fingers. This is because detonation is a miniature explosion that emits waves that hit the surface of the cylinders.

Engine detonation often occurs when the ignition is turned off. In this situation, even a switched off engine continues to function. Often in this mode the engine runs for several seconds, sometimes such work can last up to 20 seconds.

Causes of detonation when the engine is turned on cold

Detonation when starting the engine occurs when lean air-fuel mixtures enter one or more cylinders. The reason for the depletion of the mixture is the clogging of special sprayers - nozzles.

When blockages appear, the calculated value of the volume of fuel supplied is violated. To determine the cause of the blockage, it is necessary to check the coarse filter, as well as the filters of each injector.

A cold engine, after warming up, often restores its operation, and engine detonation stops.

Recommendations from experienced motorists

In the manufacture of automobile engines, all parts have certain parameters designed for operation in nominal temperature conditions. When an engine detonates, the vehicle is subjected to shock loads that exceed permissible values. Uneven distribution of fuel and oxygen masses leads to unexpected strong explosions.

To identify and prevent cases of detonation, it is recommended to listen to the uniformity of the sounds of the running engine. If unusual tapping or noise is detected, you must stop and turn off the engine. Next, you need to determine the source of the unknown sounds and try to eliminate it.

To avoid devastating consequences, detonation must be constantly monitored. The main thing to remember is that during normal operation there should not be even slight changes in the sound of the motor.

Source

Adjusting engine operation using electronic control

An electronic control unit (ECU), installed in cars with an injection engine, regulates the parameters of the fuel mixture. Using the ECU, the ignition timing is corrected with a forced reduction in the volume of the injected fuel mixture.

The causes of detonation partially disappear, but as a result of such regulation, the power of the power unit is significantly reduced. If the injectors are clogged at a high level, the ECU cannot always perform compensating functions.

Common Rail Repair

Diagnostics and repair

Bosch, Lucas, Zexel, Denso, Delphi, Motorpal

If there is an excess or shortage of fuel

provides repair services for Common Rail diesel injectors and other fuel equipment for diesel engines.

About the Common Rail system

The common rail fuel injection system is used on diesel engines of passenger trucks. The main elements are a high-pressure fuel pump and injectors. The fuel pump (fuel injection pump) supplies diesel fuel to the pressure line. Fuel is supplied to the line under high pressure. At the outlet of the line, system injectors are installed, which at the right moment inject fuel directly into the cylinder.

Effect of fuel quality and spark plugs

Engine knock can also be caused by an imbalance in the delicate balance between two factors:

- quality of spark plugs;

- fuel compression force.

The use of incorrectly selected spark plugs can cause detonation in the engine. The purpose of these devices is to control the internal environment of the engine; the timeliness and quality of fuel combustion depends on the accuracy of the spark plugs.

If the fuel combustion regime is violated, the temperature in the combustion chamber increases and the elements of the power unit overheat, leading to detonation. To eliminate the defect that has appeared, it is necessary to replace the existing spark plugs with another recommended type.

Insufficient compression of the fuel in the cylinders leads to incomplete combustion of the mixture and sticking of the remaining components to the cylinder walls in the form of carbon deposits. Depending on the quality of gasoline and the level of fuel purification, carbon deposits form, which significantly reduces the volume of the cylinder and causes detonation.

To destroy harmful deposits, special additives are used or the fuel brand is replaced with another.

Phenomena preventing detonation

But there are also positive aspects that can prevent detonation. Any of them, as a rule, accelerates the combustion processes of unspent fuel or slows down oxidation. These include:

- increasing engine speed. Because of this, the duration of oxidative reactions may decrease, which will reduce the degree of possible ignition;

- rotation in the fuel flow chamber. The spark spreads faster, which prevents harmful phenomena;

- shortening the distance that the fire front must overcome. This can be achieved by lowering the volume of the cylinders or installing a second spark plug.

Not so long ago, drivers tried to combat the phenomenon with the help of a “dropper”. This was the name of the device through which water was supplied to the cylinders. The invention was primitive, but it had its effect. However, the structure was weak, and the water had its own negative signs.

Eliminating engine detonation

The occurrence of detonation in an injection engine is influenced by the following parameters:

- Ignition timing.

- Leaning of the fuel mixture.

Many car owners are interested in how to eliminate engine detonation with their own hands. In order to get rid of explosive combustion of flammable mixtures, craftsmen often use the following techniques:

- Operating the engine in higher gears. When operating at high speed, fuel combustion time is reduced against the background of maximum pressure. Accelerating the car reduces the likelihood of detonation.

- Replacing spark plugs.

- Increase in air humidity. More humid air significantly reduces the temperature in the combustion chamber.

- Using an intercooler air cooler to reduce the temperature of the air before it is forced into the cylinders.

- Replacing gasoline with fuel having a higher octane number.

- Moving the distributor to change the ignition timing towards a decrease for stable operation of the carburetor engine at idle speed.

- Engine braking to advance ignition timing.

The method of adjusting the position of the distributor is used for a short time to get to the nearest gas station and change the fuel to higher octane gasoline. After this, the distributor must be installed in its previous position to ensure the optimal advance angle.

There are cases when car owners deliberately adjust the ignition timing upward, leaning the fuel mixture. As a result, the dynamic characteristics of the car increase and the torque increases. When carrying out this operation, the likelihood of engine detonation increases significantly.

Eliminating or reducing engine knock is a difficult task. To identify the real cause of explosions inside the engine, it is necessary to carefully study the operating principle of the power unit and understand what contributes to their occurrence.

Causes of diesel engine detonation

During normal operation of the internal combustion engine, the mixture ignites when the piston is at the top point of TDC, with an advance of the ignition angle by 2 - 3 °. Afterburning of the mixture continues after TDC when the piston moves in the opposite direction. The estimated speed of movement of the flame is 30 m/sec. During an explosion, this parameter increases sharply, reaching a value of 2 thousand meters in one second.

Engine detonation occurs when:

- constant movement of the machine;

- increasing loads;

- when working in various gears;

- including at idle speed.

It is caused by violations of parameters during fuel combustion. A smooth process is instantly replaced by a strong explosion, which leads to negative consequences:

- destruction of pistons, cylinders;

- parts of the crank mechanism;

- a sharp increase in temperature;

- reduction in power characteristics;

- increase in fuel consumption.

The most common causes of engine detonation:

- Violation of regulations.

- Poor mixing of fuel with oxygen.

- Insufficient cooling system efficiency.

- Violation of operational requirements.

- Use of low octane gasoline.

- Engine design defects.

Signs of engine detonation

As a result of the shock loads that occur during explosions, characteristic sounds appear in the form of a loud knock, the composition and color of the exhaust gases change, and engine parts receive serious defects. In addition to bright noise effects, there are external signs of detonation:

- short-term release of black smoke from the exhaust pipe;

- reduction of exhaust gas temperature;

- short-term loss of engine power;

- loss of engine control due to its instability;

- critical overheating of engine elements.

The elements that make up the power unit are manufactured to operate at certain temperatures and pressures. Shock loads arising during detonation exceed all permissible values.

The detonation effect is the most dangerous for a vehicle. It can occur when there is uneven distribution of air and fuel inside the cylinders, leading to sudden, uncontrolled explosions.

To detect this defect in a timely manner, it is necessary to regularly monitor the appearance of extraneous sounds and knocking sounds coming from the vehicle’s power unit. It is the sources of these ringing signals that need to be identified and the cause of their occurrence immediately removed.

Detonation is a potential hazard for the engine, so it must be kept under control at all times. It should not be present during normal engine operation. Even slight noise in the engine must be constantly examined and the causes that caused it must be eliminated.

Consequences of detonation

As mentioned above, the consequences of detonation in a car engine are very serious, and under no circumstances should repair work be delayed, because the longer you drive with this phenomenon, the more damage the engine and its individual elements are susceptible to. So, the consequences of detonation include:

- Cylinder head gasket combustion . The material from which it is made (even the most modern ones) is not designed to work under conditions of elevated temperature and elevated pressure that arise during the detonation process. Therefore, it will fail very quickly. A broken cylinder head gasket will lead to other problems.

- Accelerated wear of elements of the cylinder-piston group . This applies to all its elements. And if the engine is no longer new or has not undergone a major overhaul for a long time, then this can end very badly, up to its complete failure.

- Cylinder head breakdown . This case is one of the most difficult and dangerous, but if you drive for a long time with detonation, then its implementation is quite possible.

Burnt cylinder head gasket

Damage and destruction of the piston

- Burnout of piston/pistons . In particular, its bottom, lower part. However, it is often impossible to repair it and will only need to be completely replaced.

- Destruction of jumpers between rings . Under the influence of high temperatures and pressure, they can be one of the first to break down among other engine parts.

Cylinder head breakdown

Piston burning

- Connecting rod bend . Here, similarly, in conditions of an explosion, its body can change its shape.

- Burning valve plates . This process happens very quickly and has unpleasant consequences.

Consequences of detonation

Piston burnout

As can be seen from the list, the consequences of the detonation process are the most serious, therefore the engine should not be allowed to operate under its conditions; accordingly, repairs must be performed as quickly as possible.

Detonation sound during acceleration

#1 zuzen

- Regular visitors

- Posts: 7

- City: Simferopol

- Car: Opel Combo 1.3 cdti

- @Mention

Good day to all.

I have an Opel combo, 2008, 1.3 SDT, and the following phenomenon is observed: a knock appears, very similar to detonation (sharp and loud), if you move with the gear engaged at idle speed, and then sharply press on the gas. No more than 3-4 knocks. Otherwise, there are no complaints about the engine, it starts well, does not consume oil, and consumption is normal.

If anyone has encountered a similar phenomenon, please write back.

- Top

- Answer

- Quote

#2 grazimel

- Car: astra h

- @Mention

- Top

- Answer

- Quote

#3 DIESELPOINT

- City: Ukraine.Kievskaya.Pereyaslav-Khm.

- Interests: Repair of diesel fuel systems COMMON RAIL

- @Mention

There are problems with some kind of injector. If the system is Bosch, then the fuel system is repairable, if it is Denso, then alas.

Post edited by DIESELPOINT: April 28, 2012 - 09:09

- Top

- Answer

- Quote

#4 zuzen

- City: Simferopol

- Car: Opel Combo 1.3 cdti

- @Mention

Yes, I’ve talked to the diesel engineers on the phone so far - they say that the injector can knock under load. After the holidays I will go to them for repairs. But the question is: “Why is it that if the system is Bosch, then the fuel system is repairable, but if it is Denso, then alas. ". What is meant?

- Top

- Answer

- Quote

#5 DIESELPOINT

- City: Ukraine.Kievskaya.Pereyaslav-Khm.

- Interests: Repair of diesel fuel systems COMMON RAIL

- @Mention

Denso, for its common rail systems, does not supply spare parts for sale, that is, replacing the unit with a new one, but according to Bosch, you can find and repair almost everything - with the exception of spare parts for piezo injectors, they are still difficult to find.

Post edited by DIESELPOINT: 03 May 2012 - 08:05

- Top

- Answer

- Quote

The clatter of the 2.2 diesel engine!

- Log in to reply to this topic

#4721 Sergo

- Forum members

- 701 messages

- MY Antara:: Not Antara

- Gender: male

- City:: Mo, Ramenskoye

- Top

#4722 Evgeniy26

- MY Antara:: C145 2.2D AT6 Cosmo

- Gender: male

- City:: Moscow Region Podolsk

The funny thing is that they replaced both of them for me. The very first operation.

There is another thought.

Right now I’ll drive around in the warm weather for a couple of days and see.

I can tell you the main message - why the knocking appears only after active driving and why it does not exist in the city.

- Top

#4723 tepaniko

- MY Antara:: C145 2.2D AT6 Cosmo

- Gender: male

- City:: St. Petersburg

- Top

#4724 Evgeniy26

- MY Antara:: C145 2.2D AT6 Cosmo

- Gender: male

- City:: Moscow Region Podolsk

Not if you're stuck in traffic jams.

At least that's the case in my city.

- Top

#4725 Sergo

- MY Antara:: Not Antara

- Gender: male

- City:: Mo, Ramenskoye

- Top

#4726 Evgeniy26

- MY Antara:: C145 2.2D AT6 Cosmo

- Gender: male

- City:: Moscow Region Podolsk