Characteristics of ICE 2105

The ICE of the fourth series 2105 was designed by analogy with the Ford Pinto engine, therefore it received a timing belt drive and attachments, and protection against bending/jamming of the valves in the event of its breakage while driving. The improved technical specifications are as follows:

| Manufacturer | VAZ |

| Engine brand | VAZ-2105 |

| Years of production | 1979 – 1994 |

| Volume | 1.3 l (1294 cm3) |

| Power | 47.2 kW (64 hp) |

| Torque | 94 Nm (3400 rpm) |

| Weight | 104 kg |

| Compression ratio | 8,8 |

| Nutrition | carburetor DAAZ-2105 Ozone |

| Motor type | in-line |

| Number of cylinders | 4 |

| Location of the first cylinder | near the timing belt |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Allowable warpage | manifold gaskets (intake/exhaust) 0.08 mm cylinder head gasket 0.05 mm |

| Valve seat | width 2 – 2.4 mm, angle 45° |

| Camshaft | one upper cylinder head inside, phase width 232°, exhaust valve advance 42°, intake valve lag 40° |

| Camshaft oil seal | diameters – 40 mm, 56 mm, width 7 mm |

| Cylinder block material | cast iron |

| Cylinder diameter | class A – 79 – 79.01 mm class B – 79.01 – 79.02 mm class C – 79.02 – 79.03 mm class D – 79.03 – 79.04 mm class E – 79.04 – 79.05 mm |

| Pistons and rings | piston made of aluminum alloy with tin coating, cast iron rings, compression outside chrome plated (top) and beveled (bottom) |

| Piston diameter | class A – 78.94 – 78.95 mm class C – 78.96 – 78.97 mm class E – 78.98 – 78.99 mm |

| Gaps | piston/cylinder wall – 0.153 – 0.173 mm (standard) or 0.19 mm (maximum) piston rings – 110 mm relative to the cut plane |

| Upper compression ring | 1.535 – 1.555 mm |

| Lower compression ring | 3.957 – 3.977 mm |

| Oil scraper ring | 2.015 – 2.035 mm |

| Gap between piston groove and ring | 0.03 – 0.07 mm |

| Crankshaft | cast iron, casting |

| Number of main bearings | 5 |

| Gearbox neck diameter | 50.795 – 50.775 mm |

| Main journal gap | 0.1 – 0.5 mm |

| Connecting rod bearings | shaft journal diameter – 47.814 mm liner thickness – 1.448 mm liner width – 28.025 – 28.975 mm |

| Crankshaft oil seals | front – diameters 42 mm, 60 mm, width 7 mm rear – diameters 85 mm, 105 mm, width 10 mm |

| Piston stroke | 66 mm |

| Fuel | AI-93 (A-76 allowed) |

| Environmental standards | Euro 1 |

| Fuel consumption | highway – 6 l/100 km, combined cycle 8 l/100 km city – 10 l/100 km |

| Oil consumption | maximum 0.7 l/1000 km |

| Engine oil for 2105 | 5W-30 and 15W-40 |

| Engine oil volume | 3.75 l |

| Replacement frequency | every 55,000 km |

| Operating temperature | 80° |

| Motor life | declared 200,000 km actual 500,000 km |

| Adjustment of valves | nuts and feeler gauge |

| Cooling system | forced, antifreeze-A40 |

| Coolant quantity | 9.75 l |

| water pump | polymer impeller, mounted on a block |

| Ignition | distributor ATE-2 |

| Candles for 2105 | original – A17-DV, |

| Gap between spark plug electrodes | 0.5 – 0.6 mm |

| Timing belt | 122 teeth |

| Cylinder operating order | 1-3-4-2 |

| Air filter | dry with replaceable cardboard cartridge and pre-cleaner, temperature adjustment according to the season |

| Oil filter | recommended Mann W914/2 |

| Flywheel | 129 teeth, 0.62 kg internal hole diameter – 25.67 mm outer diameter – 27.75 mm number of mounting holes – 6 pieces no offsets |

| Flywheel mounting bolts | M10x1.25 mm, length 23.5 mm, |

| Valve stem seals | Manufacturers Horse or Corteco |

| Compression | pressure in the cylinders from 11 – 14 bar, pressure difference in individual cylinders within 1 bar |

| Oil temperature | 80°С |

| Thermostat temperature | 80 – 84°С |

| Valve pressure inside the radiator cap | 0.7 – 1 bar |

| Content of harmful products in the exhaust | CH <200%, CO <0.5% |

| XX speed | 700 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 20 Nm flywheel – 60 + 90° Nm clutch bolt – 20 Nm bearing cap – 65 Nm + 90° (main) and 30 Nm + 90° (rod) cylinder head – 4 stages 40 Nm, 60 Nm + 90° + 90° |

A complete description of the internal combustion engine parameters is contained in the official manual of the manufacturer. It states that opposite the valves in the engine pistons there are slots that ensure the safety of the internal combustion engine in the event of a timing belt break - the piston will not be able to “meet” the valve physically. The user simply replaces the rubber product; no major repairs are required.

Groove in the piston to protect the valve

Design nuances

To obtain the above engine characteristics, the manufacturer carried out experiments:

- piston stroke reduced to 66 mm;

- the cylinder diameter, on the contrary, is increased to 79 mm.

The result was a revving, powerful engine with an aluminum valve cover that absorbed the sounds of the drive. Another feature of the internal combustion engine is the fastening of the timing belt pulley - users do not need to unscrew the bolt on the crankshaft, unlike previous VAZ engine models.

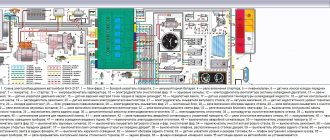

Design 2105

In the operating instructions, the manufacturer recommends which oil to pour into the engine - 5W30 - 15W40.

Lada 2105 VFTS

First of all, a disclaimer: yes, this is a Zhiguli again. If you have not yet imbued with the culture of the domestic rear-wheel drive automobile industry, sooner or later we will convince you. And today we’ll even talk a little about a place where they love “classics” and know how to build no less than ours. It will be interesting!

Sergei, the owner of this project, first encountered Zhiguli 10 years ago, when at the age of 18 he received his license and his dad gave him a VAZ 2106. Then the OnlyDropped and RLC movements had already gained momentum, so Sergei, having stumbled upon photographs of an incredibly stylish “ classics”, I quickly understood what was what. The first coils of springs were cut down at the club’s birthday, in honor of which the newly minted stanzer was even given a branded wheel spacer.

What cars were equipped with ICE 2105?

This modernization could not satisfy users of the domestic automobile industry. The main drawback was the regular breakage of the timing belt, AvtoAZ management reduced production volumes, then removed the 2105 engine from production, so only three modifications of the Zhiguli were equipped with the engine:

- 2105 sedan;

- 2104 station wagon;

- 21072 sedan.

Four with engine 2105

Currently, tuning for the engine of this series is not difficult, but among the operating fleet of Zhiguli “fives” with the “native” engine there are very few left.

Service for searching the characteristics of the original battery

The service for selecting batteries for VAZ cars is located on this page. Follow the link and on the page you will see a form for entering the model and modification of the car. Below you can read instructions for using the service. The selection process is outlined there step by step. These steps can be seen visually in the picture below.

Now let’s look at how selection works using the example of a specific modification of the VAZ-2105. Return to content

An example of selecting a battery for a VAZ-2105 using the service

All modifications of the VAZ-2105, regardless of the engine, were equipped with batteries with the same characteristics. Therefore, as an example, it will be enough to consider one option. Let’s take, for example, the VAZ-2105 “five” with the VAZ-2106 engine (distributed injection, 1.6 l, 80 hp) and 5-speed. Manual transmission. The car was produced from 1985 to 2011.

Currently, the service for selecting batteries for VAZ (Lada) cars is operating in test mode. Information about car models, modifications and data on batteries for them is supplemented. Please note that there may be errors, incomplete information and typographical errors. We recommend checking the data obtained in the selection with information from other sources. If you find errors, please report them to the site administration in this forum thread. We will double-check the information and correct errors. Also leave your feedback on the selection process. Thank you! Return to content

Pros and cons

Subject to compliance with maintenance and operation regimes, major repairs were not required for the machines for decades. In capable hands, the 2105 engine produced in 1989 is still in use today, and the timing belt life is enough for 40,000 km. If there are no problems with consumables, then the demand for spare parts is not fully satisfied. For example, the cylinder head is always available, and the intake manifolds are welded on site.

Intake manifold

What is the difference between 5 and 7?

The interior of the VAZ 2107 is equipped with more convenient instruments and has a more presentable appearance than the VAZ 2105. The plastic radiator grille of the “five” is more practical than the chrome grille of the “seven”.

Interesting materials:

Which country is famous for its cheese production? Which country created Skype? Which country created Viber? Which country was responsible for the discovery of Japan? Which country is the fashion capital? Which country was formerly a colony of France? Which wine country? Which country led the Triple Alliance on the eve of World War I? Which country ranks first in the world in terms of armaments? Which country ranks first in the world in terms of coal reserves?

Maintenance regulations

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 40,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/20000 |

| Fuel filter | 4 years/20000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | — |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 2 years |

Knowing what kind of oil is used in the engine and the type of liquid with which the cooling system is filled, you can carry out maintenance of the “five” internal combustion engine yourself.

Problems with the engine in question

An important point is that the VAZ 2105 is equipped with an engine that is structurally not significantly different from the engine on the 21011. The only significant difference is that the drive is belt driven to reduce the hum coming from the engine compartment. Other positive qualities include the following:

1.As the history of the vehicle’s operation has shown, the engine does not bend the valve.

2. A disadvantage of the design is that it is necessary to periodically adjust the valves due to changes in the clearance.

3. A common situation is difficulty starting due to the high thickness of the oil in the box.

4. There are frequent cases when the engine seals. As practice shows, the reason is untimely oil change or insufficient quantity.

5. After several years of operation, the engine begins to smoke.

6. A knocking sound may indicate that it is time to adjust the valves.

Important! Models 21011 and 2105 are equipped with almost identical engines, they are tuned in the same way.

Let's take a closer look at how the design is refined.

Causes of malfunctions and their elimination

In principle, the 2105 engine has all the typical malfunctions of carburetor in-line internal combustion engines:

- clogging of the fuel system, fuel pump, carburetor, throttle, jets and filter;

- exhaustion of the life of the air filter and microswitch;

- failure of the ignition system and stuck valves and piston rings;

- breakdown of gaskets and seals, misadjustment of cam gaps;

- production of cylinders/pistons, bearing shells;

- loosening the flywheel bolts and attachment drive belts.

But the engine diagram allows you to avoid major repairs if the timing belt breaks by 100%.

Why didn't the triumph take place?

The only drawback of the new engine was the short life of the timing belt. It was recommended to change it after 60 thousand km. In fact, the belts “died” even before this period. No catastrophe occurred, except for the fact that the car stopped where the break occurred. Experienced drivers carried a spare copy in the trunk, since replacing the VAZ 2105 timing belt was not too difficult.

Another reason why the engines were considered problematic was the shortage of spare parts characteristic of that time. VAZ 2105 pistons were interchangeable with 21011 parts that did not have counterbores. Sometimes unscrupulous mechanics, either deliberately or due to the lack of regular ones, installed the wrong components.

Naturally, when the belt broke, the valve plates and piston heads entered into a hard “clinch”, and the driver was forced to do a major overhaul of the engine.

A common drawback of all “classic” engines was the need to periodically adjust the valves, and in the first thousand kilometers, also tighten the cylinder head bolts. In addition, the attachments (water pump, starter, generator, distributor) had a short service life. The latter, however, has been absent in recent years due to the use of injection.

One of Murphy's laws states: if there is a part in a device that can be put in reverse, there will always be a person who will do it. This part turned out to be a remote plastic spacer for the fuel pump drive. Signs of its incorrect installation: the engine stalls during acceleration, in the heat, when driving with a lateral roll.

The mounting holes on the spacer flange are located asymmetrically, and the difference is almost invisible to the eye. This “jamb” was present on all “classic” engines, and perhaps migrated back to the FIAT 124. It happened that the spacer was installed upside down at the factory. At the same time, the engine was running, but the stroke of the fuel pump pusher decreased, which led to a decrease in its performance.

After a certain mileage, the level of gasoline in the float chamber barely covered the fuel supply nozzle, and the engine began to stall. Since the cause is quite unexpected, it can sometimes be difficult to determine.

Engine tuning

By analogy with the manufacturer’s previous internal combustion engines, the 2105 engine can increase power in several ways:

- boring the cylinders to fit the size of the larger piston;

- increasing the stroke length of the connecting rod;

- installation of a sports camshaft;

- installation of 4 or 2 carburetors;

- boring of cylinder head channels.

Tuning 2105

Thus, the ICE 2105 produced by AvtoVAZ was not produced for long. The engine consumed little oil; boosting it on its own was extremely difficult for Soviet-era motorists.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them