I am glad to welcome you, my dear readers! If you are the happy owner of a Volkswagen car manufactured after 2000, then with a high degree of probability, when you open the hood and look at the engine cover, you will see the FSI nameplate. So, on the agenda of this article, revealing the secret of the symbols - decoding fsi.

As well as a description of the diagram of the unit hidden under this abbreviation and its main components.

What does this abbreviation mean?

Some will throw up their hands, some have heard of such a system, and others may be well versed in this issue.

Be that as it may, we hope that today’s article will be useful to absolutely everyone. And if you don’t yet have a car or buying a four-wheeled friend is in your plans, then finding out what these mysterious three letters mean will be doubly interesting.

What is an FSI injection system?

This is a development that was presented to motorists by Volkswagen. In fact, this is a gasoline supply system that works on a similar principle to that of a similar Japanese modification that has existed for quite some time (called gdi). But, as representatives of the concern assure, the vehicle operates on a different principle.

The engine, which has an FSI label on the cover, is equipped with fuel injectors installed near the spark plugs - in the cylinder head itself. Gasoline is supplied directly into the cavity of the working cylinder, which is why it is called “direct”.

The main difference between the emerging analogue is that every engineer of the company worked to eliminate the shortcomings of the Japanese system. Thanks to this, a very similar, but slightly modified vehicle appeared in the automotive world, in which fuel is mixed with air directly in the cylinder chamber.

Poor starting in severe frost

A considerable part of cars with a 2.0 FSI engine with the BVY index suffer from poor starting in severe frosts, although many cars start completely normally even in a 30-degree engine.

It is believed that when the temperature drops below -17°, the ECU prepares a too rich air-fuel mixture, which floods the spark plugs.

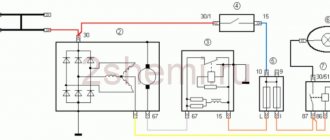

The most effective solution to the cold start problem is to trick the coolant temperature sensor, thanks to which the ECU “sees” a sufficiently warm engine and does not flood the spark plugs.

The snag is a resistor or variable resistor with a resistance of about 50 kOhm, soldered in parallel to the coolant temperature sensor, the sensitive element of which is the resistor. Thus, the overall resistance is reduced, the ECU “sees” that the antifreeze temperature is at least +5°, and does not overthink the composition of the fuel mixture.

The temperature sensor is tricked with a switch so that it is activated only before a cold start. And the required resistance of the variable resistor can be set by turning on the climate control service mode: on its right display you can display readings from the coolant temperature sensor (for this you need to select channel 19.2). In this mode, you can rotate the resistor, “increasing” the temperature of the antifreeze

Operating principle of FSI engines

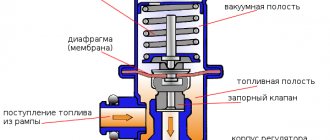

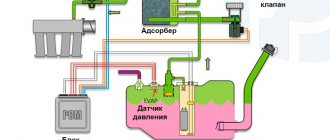

The manufacturer divided the entire system into 2 circuits. Basically, gasoline is supplied under low pressure. It reaches the high pressure fuel pump and accumulates in the rail. The injection pump is followed by a circuit in which high pressure is created.

The first circuit contains a low-pressure pump (most often located in the gas tank), a sensor that records the pressure in the circuit, and a fuel filter.

All the main elements are located after the injection pump. This mechanism maintains a constant pressure, which ensures stable fuel injection. The electronic control unit receives data from the low pressure sensor and activates the main fuel pump depending on the fuel consumption of the fuel rail.