The VAZ 2115 line of cars was equipped with injection engines with electronic control units (ECU). The system collects readings from several controllers, and then adjusts the balanced operation of the engine. The coolant temperature sensor on the VAZ 2115 (DTOZH) is one of the main controllers, thanks to which the crankshaft speed, the proportion of the gasoline/air mixture, as well as the ignition are regulated. Next, we will tell you where the t° sensor is located on the 2115 Samara engine, what symptoms indicate its problems, and how to replace the defective device.

Attention! The VAZ 2115 has two types of water t° sensors. The first 1-pin - sends information to the instrument panel. The second 2-pin is responsible for starting/stopping the radiator fan and exchanging readings with the ECU. In this article we will talk about the second type (hereinafter referred to as DTOZH).

Where to find a temperature sensor in a VAZ-2115

The entire cooling system in cars is divided into several types:

- air;

- liquid;

- combined - combining 2 types at once.

The VAZ-2115 has a built-in liquid cooling system, which involves filling with antifreeze or higher quality antifreeze. In general, the mechanism consists of the following functional elements:

- a radiator that allows the engine to cool;

- radiator fan;

- heater radiator;

- cooling device jacket;

- pump pumping coolant;

- expansion tank;

- connecting pipes;

- antifreeze temperature sensor.

Beginners are wondering where the coolant temperature sensor is located on the VAZ-2115? The unit located between the thermostat and the head of the cylinder combination, directly on top of the cooling system pipe, connects the part to the system using 2 wires.

There is another meter installed nearby, but note that this additional unit is connected on one side to the instrument panel.

A careful study of the design allows you to see a resistor in the sensor, where the resistance is determined depending on the heating of the VAZ-2115 engine.

What symptoms indicate problems with the sensor?

During long-term operation of the car, obvious and indirect signs may be observed indicating problems with the temperature sensor or its electrical circuit. The first ones directly indicate the need to check the functionality of the device:

- The engine heating indicator on the dashboard stopped working;

- the cooling fan stopped turning on, although the engine water jacket had already warmed up to 100 °C;

- antifreeze leakage from under the part body;

- The fan starts at random, including when the engine is cold.

If your car exhibits the listed signs of a malfunction of the coolant temperature sensor, then feel free to proceed to diagnosing it and fixing the problem, which will be discussed below. Indirect symptoms may indicate a breakdown of the meter or other elements of the cooling system or power unit. Here are the most common ones:

- Cold starting of the engine is difficult. The car starts, but immediately stalls, you need to make several repeated attempts. The cause may be a thermocouple, throttle position sensor, insufficient compression or ignition problems.

- Unstable operation at idle. In addition to the temperature meter, it is affected by the serviceability of the spark plugs, mass flow sensor, injectors and many other factors.

- The temperature is within normal limits, but the coolant begins to boil. If the thermostat fails or the level of antifreeze in the jacket decreases, then the readings of the device may differ from the real state of affairs.

Temperature meter sensor malfunctions

Knowing the location of the device, it is easy to get rid of the breakdown yourself. The main reasons for the incorrect operation of the device, according to experts, may be:

- lack of contact;

- rupture and wear of insulation, loss of contact integrity;

- the device is completely out of order;

- The fan is not working well.

Signs that should alert the driver of a VAZ-2115 and prompt them to diagnose the condition of the antifreeze temperature sensor may be:

- fan operation when the machine engine is not warmed up;

- the engine is warmed up, but still refuses to function;

- Fuel costs are gradually and steadily increasing.

How to check the temperature sensor for serviceability

DTOZH signals the heating temperature of the antifreeze on the instrument panel of the VAZ-2115.

The condition of the device can be easily checked by following these instructions:

- Start the car and watch the instrument panel readings. When the arrow is fixed at the maximum value and the engine is cold, disconnect the contacts from the temperature measuring device. If the arrow suddenly drops to the possible minimum, then the unit is really out of order and needs to be replaced.

- If the arrow is still at the maximum, consider the contact; perhaps it is shorted to ground on the VAZ-2115.

- If the engine heats up well, but the needle continues to jump or is opposite the zero value, start checking the wear of the fuses.

- If the fuses are not worn out, then it remains to close the contact to ground of the VAZ-2115. Monitor the position of the arrow; if it shoots up, it means the VAZ-2115 DTOZH is not functioning correctly.

How else to check the DTOZH:

- You will need a multimeter, it should be set to ohmmeter mode. Also equip yourself with a thermometer that can measure temperatures greater than 100 degrees. Prepare a container that will not melt under the influence of hot coolant.

- Fix the multimeter probes to the body base and the terminal of the measuring device.

- Place the attached sensor directly into a container with antifreeze and heat it well.

- Look at the thermometer and ohmmeter readings. At a temperature of 30 degrees, the resistance should be equal to 1350-1880 Ohms. If the temperature rises to 50 degrees, the resistance decreases to 585-820 degrees. A temperature of 70 degrees corresponds to a resistance from 280 to 390 Ohms inclusive. If the antifreeze is heated to 90 degrees, the normal resistance value is in the range of 155-196 Ohms. At 110 degrees the resistance is the lowest - from 87 to 109 Ohms.

How to change the temperature sensor on a VAZ-2115

The instructions for replacing the VAZ-2115 DTOZH are clear even to a beginner:

- Dismantle the old model, first draining the antifreeze from the car.

- Using the key number 21, place the new unit in the right place.

- Apply heat sealant while tightening the threads.

- Fill in new antifreeze; before using this special product, it is advisable to clean the entire cooling system.

Why the new unit may not work:

- You may have bought a defective device, which is why experts recommend checking the serviceability of the product with a multimeter.

- If there was an antifreeze leak, there is a possibility of the generator getting dirty.

- Screw the sensor tighter.

Step-by-step video instructions for replacing the coolant temperature sensor can be viewed below:

Temperature sensor for VAZ 2115

The VAZ 2115 line of cars was equipped with injection engines with electronic control units (ECU). The system collects readings from several controllers, and then adjusts the balanced operation of the engine. The coolant temperature sensor on the VAZ 2115 (DTOZH) is one of the main controllers, thanks to which the crankshaft speed, the proportion of the gasoline/air mixture, as well as the ignition are regulated. Next, we will tell you where the t° sensor is located on the 2115 Samara engine, what symptoms indicate its problems, and how to replace the defective device.

Attention ! The VAZ 2115 has two types of water t° sensors. The first 1-pin - sends information to the instrument panel. The second 2-pin is responsible for starting/stopping the radiator fan and exchanging readings with the ECU. In this article we will talk about the second type (hereinafter referred to as DTOZH).

How to replace the coolant sensor

Coolant temperature sensor VAZ 2109 – VAZ 2115

When driving a car, it is very important for the driver to obtain reliable information from control sensors. But much more important is their uninterrupted operation.

If you notice that the readings of any sensor do not correspond to the actual process, you need to check its condition and, if necessary, replace it.

We propose to consider this problem using an example such as replacing a coolant sensor on a VAZ 2114. First of all, you need to learn to distinguish the coolant temperature sensor from the pointer sensor.

The sensor is an indicator located on the control panel and visually shows the driver the necessary data on the coolant temperature. Temperature detection sensor - installed on the inlet cooling pipe of the cylinder block. See photo below:

VAZ 2114 fluid sensor replacement

The need to monitor the engine cooling system

Every experienced motorist knows perfectly well that overheating a car engine has very dire consequences for the car.

It is the coolant temperature sensor that allows you to monitor the temperature of the engine and, if necessary, take timely measures to correct it.

A reduced temperature does not allow the engine to develop the required power and significantly affects fuel consumption, and an increased temperature can lead to engine seizure. The operation of the coolant temperature sensor is directly connected to the electronic control unit.

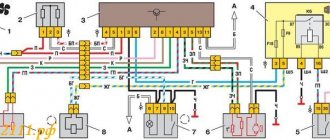

Through this block, signals are transmitted from the sensor to other engine components. The timely switching on and off of these jointly working units depends on how accurately this sensor works. In this case, we mean the operation of a fan that cools the engine radiator.

Attention: Some car owners force the above-mentioned fan to turn on. In this case, technical changes are made in the electrical circuit of the car. It is strongly recommended that such issues be resolved in the presence of a specialist - an auto electrician and accompanied by the necessary documentation.

Checking the correct operation of the sensor

It is quite possible to check the accuracy of the sensor readings using an ohmmeter and a small container of coolant. As a visual aid, we suggest watching the video:

In this case, everyone is interested in one question: “How to correct the operation of the sensor?”:

- You can install an on-board computer and set the necessary temperature parameters for the sensor in the program.

- You can include additional resistance in the electrical circuit of the sensor and thereby facilitate the transmission of a signal to turn on the fan at a lower temperature.

It is strongly recommended: All technical problems of this kind must be solved only with the help of a specialist.

Many car enthusiasts are inclined to discuss any engineering solutions, despite the quality of spare parts and the complexity of the vehicle’s operating conditions.

It is for them that we offer an alternative solution to this problem - replacement. Moreover, the price of the issue is not a large expense, and the sensor itself cannot be repaired.

This work can be done with your own hands, without resorting to the services of a service station.

Before replacement, it is strongly recommended to check the condition of the fuses and, if necessary, replace them (see How to replace fuses). They may well affect the operation of the sensor.

Caution: Perform all work on a cold engine, after it has completely cooled down.

Replacement is carried out in the following order:

- Disconnect the negative terminal of the battery.

- Then, the coolant must be drained into a pre-prepared container.

- Disconnect the electrical wiring from the sensor.

- Using the R19 key, unscrew the sensor and remove it together with the sealing ring.

- Next, using a rag, clean the sensor seat.

- We install a new sensor.

- We connect the electrical wiring to the sensor.

- Fill with coolant.

- Connect the negative terminal to the battery.

Therefore, the replacement of this device will be considered completed. This instruction is quite suitable for replacing the coolant temperature sensor on a VAZ 2109 and a VAZ 2115. When installing a new sensor, it is not recommended to use any sealants. This may affect the operation of the sensor itself. The same design solutions are provided for the engine of the VAZ 2112 car.

The only difference is that the thermostat has an increased resistance of the throttle opening. After completing all the work, it is recommended to start the engine, add coolant to the required level and finally check the operation of the sensor.

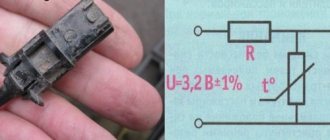

Principle of operation

The two-contact temperature sensor on the VAZ 2110–2115 family is a resistor mechanism with a negative temperature coefficient. That is, in the cold its resistance is high, and when heated, on the contrary, it is low. During operation, the DTOZ transmits impulses to the ECU. The device has 2 contacts: one for communication with the control unit, the second for starting/stopping the radiator fan.

Table 1. Units of measurement of water temperature and data on DTOZH VAZ 2115

| Degrees t°C | Resistance (Ohm) |

| 100 | 177 |

| 40 | 1459 |

| 0 | 9420 |

| −20 | 28680 |

| −40 | 100700 |

Information for self-checking with the meter

Simply put, the VAZ 2115 temperature sensor (8-valve injector) performs one of the functions of a damper (choke), which was traditionally located on carburetor cars. Having received readings from the DTOZH, the ECU system ensures that the cold engine is injected with a rich fuel mixture, and the hot engine is injected with a lean mixture.

Design

The VAZ-2115 temperature sensor is a thermistor with a negative temperature coefficient. This means that its resistance decreases as the engine warms up. This is very convenient because you can connect an ammeter, calibrated accordingly, in series and get a simple temperature indicator without additional transformations.

This is exactly the scheme that is used in the fifteenth model. In addition, the fluid temperature sensor in the VAZ-2115 is connected to an electronic control unit (ECU). Thus, the computer receives information about the thermal conditions of the engine and makes adjustments to the composition of the working mixture. But that's not all. In the “tag”, as in any car with an injection engine, there is no separate sensor for turning on the fan. It is launched by a signal from the ECU in accordance with the data received from the DTOZH.

Causes and symptoms of malfunction

In most cases, if the temperature sensor stops working on a VAZ 2115, then most often the problems occur for natural reasons (for example, rupture of internal contacts). A faulty device sends incorrect engine temperature information to the control unit. And the computer reads the starting temperature of the engine as 0 °C, after which it orders another sensor, the mass air flow sensor, to add air, that is, to enrich the mixture. Sometimes problems arise because:

- the seal of the housing is broken;

- broken electrical wiring;

- The connector fell off the block.

As a result, the yellow “Check Engine” icon lights up on the panel. Thus, the ECU warns the driver about problems in the system. What symptoms on a working VAZ 2115 indicate that the temperature sensor “died a heroic death”:

- difficult starting, especially in frosty weather;

- floating speed until fully warmed up t 90 °C;

- strong detonation appears;

- power is lost;

- the engine stalls.

In addition to the listed defects, gasoline consumption increases noticeably, and dark smoke comes out of the exhaust pipe.

Electronic engine control unit

The engine control unit is a kind of head control center for the entire car. This device processes all the readings provided by the vehicle’s sensors, regulates the engine control process, determines the required fuel and air ratios, generates a spark supply to the desired cylinder, and much more. The ECU is located inside the car, under the dashboard.

Where is the temperature sensor located?

The front-wheel drive family from Togliatti has a transverse engine installation. The VAZ 2115 temperature sensor is located between the cylinder block and the thermostat. It is located on the coolant flange located on the right side of the engine. The sensor is easy to see if you look down, between the head and the air filter housing. (A little lower, directly into the block, a 1-pin water t° indicator sensor is screwed in. 1 green wire goes to it).

Where is DT located?

This will probably be a revelation for many, but there are two temperature sensors in the VAZ-2115. One of them is installed on the thermostat and works in full cooperation with the on-board computer. The other is designed to operate a dial gauge indicating temperature. It is located at the end of the cylinder head and is screwed into it horizontally. The sensors are similar in principle of operation, but differ in design. The one installed in the thermostat has two contacts for connection. The second connector of the instrument cluster sensor is the vehicle ground.

Replacement

To install a new cooling sensor on the LADA 2115 Samara, you need to select a flat area. You will need a tool: open-end and spanner wrenches (19 mm, 13 mm, 10 mm, 8 mm), as well as a large medical syringe 100–250 ml, and a 15–20 cm dropper tube to it. It is recommended to buy the original sensor itself, here its number is 21120–3851010–05. It is easy to replace the DTOZH yourself. The step-by-step process looks like this:

- Allow the engine to cool to at least 40 °C.

- Use a syringe to pump out antifreeze/antifreeze from the expansion tank (so as not to drain the coolant).

- Unscrew the negative terminal of the battery (10–13 mm wrench).

- Disconnect the plug from the air flow sensor.

- Unscrew the air filter housing (8 mm wrench).

- Carefully removes the “pan” and moves it to the right.

- Disconnect the plug from the DTOZH.

- Unscrew the sensor (19 mm spanner).

- Cleaning the landing area.

- We screw in the new DTOZH.

Let's collect everything in reverse chronology. It is not recommended to use sealant, as the copper ring is perfectly crimped, ensuring a tight seal.

Summary

The coolant temperature sensor is an important element for the balanced operation of the VAZ 2115 engine. If it malfunctions, the car loses its driving characteristics: it starts poorly, stalls, loses power, consumes more fuel, and sometimes the engine does not work at all. You can replace the DTOZH yourself using a minimal set of tools.

TOZh sensors, from left to right: 1 Sensor for the fan, 2 sensor for the pointer, 3 a cleverly crafted old sensor of mine.

The conclusion is this: there are two temperature sensors - one for the “brains”, the fan, the on-board computer. (It screws in vertically, is easy to change, costs a little more. - the second one is on the arrow (single-pin, screwed horizontally under the pipe), behaves strangely when screwed in.

Now I will look for and ask for a sensor like my old one (in the photo with an orange neck). He gave me temperature readings exactly the same as on BC.

Features of the DTOZH operation on the fifteenth VAZ model

The coolant temperature sensor (CTS) relates to the cooling system of the machine. Its purpose is to control the coolant temperature. While the engine is cold, the ECU sets an enriched fuel assembly; after the engine warms up, it becomes normal.

The device is a resistor called a thermistor placed in a metal case.

Device diagram

The resistance of the thermistor increases as the temperature decreases, and at the same time the voltage supplied to it will increase.

Idle speed control

A sensor that keeps the engine idling. It is a DC motor with a worm gear; there is a metal wedge on the shaft, which, if necessary, opens or closes the air channels of the throttle assembly. Installed on the throttle valve, secured with two screws to the body. Quite often it fails due to contamination of the shaft or aging of the sealing ring.

Signs of malfunction:

- Uneven idle speed;

- Long start of the internal combustion engine;

- Spontaneous engine stop;

Possible sensor malfunctions

If the DTOZH breaks down, the ECU considers that the engine temperature is zero, so it enriches the combustible mixture. A broken device must be replaced as quickly as possible. Most often, a meter malfunction is a calibration violation. In this case, the resistance does not change correctly, and since the control unit is based on meter readings, it does not work correctly.

You can identify a DTOZ malfunction by turning on the fan. It should turn on if permissible values are exceeded. True, there is also a fan switch sensor, which can also fail.

Thus, the fan may not turn on if:

- contacts have oxidized;

- wiring is damaged;

- sensors are faulty.

Incorrect operation of the DTOZ leads to increased fuel consumption, detonation, and high idle speeds. The most dangerous thing is if the engine temperature sensor is broken. In this case, the fan does not start, there is no cooling of the engine, it overheats, and as a result, the cylinder head may misfire.

Mass air flow sensor

Mass air flow sensor is one of the most expensive sensors in a car. It is responsible for counting the air passing through it. These readings are necessary for proper mixing of air and fuel. The flow meter can fail if the air filter is not replaced for a long time, as well as with strong ventilation of crankcase gases due to the high content of oil combustion products in the internal combustion engine. It is located on the air filter housing and is attached to it with two bolts.

Signs of malfunction:

- Uneven idle speed;

- Increased fuel consumption;

- Long start of the internal combustion engine;

Methods for checking the regulator for operability

Before checking the meter, you should first check the serviceability of the fuses, the integrity of the wiring and measure the incoming voltage, which should be 5V. If there are no wiring faults and the voltage is normal, then the meter is checked for resistance. To check it, you need to remove it (the author of the video is Car Design and Repair).

To check, you will need an electric kettle, a thermometer to measure the outside temperature, and a multimeter set to resistance measurement mode.

It is advisable to take an electronic thermometer not to measure the outside air temperature.

There are two ways to check:

- In the first case, the coolant temperature sensor with a thermometer is placed in an electric kettle. In this case, the device must be connected to the tester. The electric kettle should be plugged in and monitor the readings. As the temperature increases, the resistance should increase. When it becomes +15 degrees, the resistance should be 4450 Ohms, +40 - 1459 Ohms. At 100 degrees, the resistance reaches a minimum of 177 Ohms. If the values are different, this indicates a malfunction.

- If there is no thermometer, then the meter is checked after the water boils. When immersed in freshly boiled water, the multimeter should display a resistance of slightly more than 177 ohms. Otherwise the device is broken.

Checking with a multimeter