01/26/2022 31 128 VAZ 2106

Author: Ivan Baranov

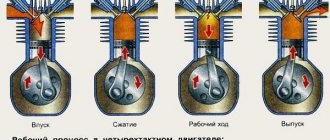

Much depends on the operation of the cylinders, so this unit must always be in working condition. Especially when it comes to old VAZ 2106 cars. In this article you can find out what is the operating order of the VAZ 2106 cylinders and for what reasons they may not work.

[Hide]

Work distribution

It may be necessary if it is necessary to identify a malfunction in the operation of the motor. Such breakdowns consist of unstable engine operation, that is, its tripping. It is necessary to diagnose the unit in cases where the engine power is too low, and the internal combustion engine itself regularly trips.

It should be added that the internal combustion engine throttles not only when driving at speed, but also in neutral gear. In addition to tripping and reduced power, fuel consumption in the vehicle increases. This sign is initial. In practice, interruptions in the operation of the power unit are observed when the carburetor is incorrectly adjusted, the spark plugs are broken, or one of the cylinders fails. In addition, air may leak into one of the cylinders.

But in order to accurately identify the malfunction, you need to know the operation of the cylinders in the vehicle. In a VAZ 2106 car it is as follows: 1-3-4-2. Accordingly, the numbers directly indicate the numbers of the cylinders themselves. The number “1” on the distributor cap is marked on the first cylinder. If you look at its cover from the side of the wires leading to the spark plugs, the cylinder operating mode will be 1-3-4-2.

How to connect wires correctly

When replacing high-voltage conductors, they are first connected to the ignition distributor. The distributor cover is convenient in that it is always installed in one position. There is a special mark on it, thanks to which it will not be difficult to place the part in place. Before connecting the wires, inspect the cover. It must be intact, since if cracks appear, the performance of this unit is not guaranteed.

The mark on the distributor cover is located next to the wire socket of the first cylinder. The firing order of the cylinders is slightly out of order (1-3-4-2) due to the ignition slider. It moves around the circle (distributor) counterclockwise. It is precisely by this principle of movement of the slider that it is easy to remember the order of the wires. They need to be connected to carburetor and injection VAZ-2109 according to the same principle. On the distributor cover, connect the wires according to the principle of movement of the slider, this is the only way you can set the ignition correctly:

- the socket of the first cylinder is located at the mark;

- the third one is connected at the very bottom;

- on the same line with the socket of the first, there is a place for the wire to the 4th cylinder;

- at the top point the second cylinder is connected.

On the engine itself, the cylinder numbering goes from the location of the timing belt to the starter, that is, from left to right. The fourth cylinder is closest to the starter, and the first is closest to the timing belt. When connecting, it is important to look at which socket of the distributor cover the wire comes from, if you confuse their location, the car will not start.

If you have connected the wires correctly, but the car still does not start, then the problem may be in them. Check high-voltage conductors for integrity. If you haven't changed them in a while, it's worth buying a new set. The peculiarity of these wires is that over time microcracks can form on their surface. They lead to a lack of spark when the ignition distribution system is working. Moisture and dust get into these cracks, which damages the wire from the inside, although it appears intact from the outside.

Car enthusiasts recommend purchasing sets of high-voltage wires from foreign manufacturers, as they last much longer than stock or domestic ones. It is advisable to replace the spark plugs along with the wires, especially if cracks or carbon deposits appear on their surface. This is necessary so that after repair you definitely do not have problems with ignition

Causes of failure

Once you have figured out the order of operation of the elements, you can begin diagnosing the motor. As stated above, the failure of one or more components is directly related to the motor tripping, so it is necessary to find out the reasons for its failure.

- Start your VAZ 2106, let it run in neutral gear. Then go to the muffler and listen to how the exhaust pipe works. If there are no interruptions in the functioning of the engine, the exhaust sound will be smooth and soft. If you hear popping noises from time to time, this means that one of the components is not functioning due to a broken spark plug. This may also indicate a lack of spark at the spark plug, excessive oxygen leakage, or an incorrect compression level.

- If the exhaust pipe pops are irregular, that is, they occur from time to time, then this may indicate incorrect operation of the carburetor, failure of the spark plugs, or their wear. This may also indicate a faulty ignition. To fix the problem, you should diagnose the carburetor, ignition system, and replace broken spark plugs.

Non-working car spark plugs

- If popping noises occur regularly in the system, turn off the engine and open the hood. It is advisable to check the condition of the spark plug wires. They must be insulated, and the ends of the wires must not be acidified. If you see that one of the cables is mechanically damaged, then it should be replaced with a new one.

- If the wires are in good condition and no visible signs of damage are found on them, then the distributor cover, as well as the ignition distributor device, should be diagnosed. To do this, you will need to unscrew the bolts securing the cover, and then remove it. Visually inspect it outside and inside. If cracks, carbon deposits are visible on it, the carbon contact is worn out, and damage is visible on the rotor, then the failed elements should be replaced.

- The spark plugs should be unscrewed. To do this, remove the cable ends and unscrew the spark plugs using a wrench. Inspect them: ideally, the gap between the electrodes should not exceed 0.7 mm. Pay attention to the color and condition of the candle: if the element is black from soot and wet, then it needs to be disposed of.

- Now take a working spark plug and fix it on the engine body. Do not install a spark plug on the engine fluid filler neck, on the dipstick for checking the oil level, on the fuel pump, carburetor, or fuel hoses. It is desirable that the threaded part of the component is in contact with the ground. You should connect the spark plug wire from the first cylinder to the working spark plug that was installed on the internal combustion engine. After this, start the engine of your 2106 and listen to the exhaust. If you notice that the “irregularities” have not intensified, then replace the spark plug in the first cylinder with a working one. If the “irregularities” have increased, then repeat the procedure with all components.

Distributor cover VAZ 2106

Adjustment of valves

If knocking, unstable operation, or increased vibration occur, you should pay attention to the valves.

If the valve timing of the gas distribution mechanism is disrupted, they do not operate accurately, that is, the full volume of gas does not enter the working area of the cylinders, complete combustion of the fuel-air mixture in the working chamber does not occur, and the cylinders are not purged. This is all accompanied by the appearance of a shock load on the camshaft cams on the drive lever and the shaft rod. Fuel and engine oil consumption also increases. What happens if you drive with unadjusted valves? Answer: rapid wear of engine parts, increasing cost and repair time.

Rubber oil deflectors, also known as oil deflectors, also burn out due to a burnt valve cap, which leads to increased engine oil consumption. If the wear of engine parts is large, then it may be better and easier to do an engine swap with your own hands or at a service station.

Even if your engine does not have a belt drive, but a chain drive, then if you do not change the chain before its service life expires, the valves will bend on the piston, as, for example, in the sr20det engine manufactured by Nissan.

Technical characteristics of the motor 2106

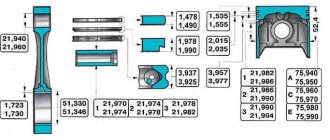

After a failure with the timing belt in the internal combustion engine 2105, the manufacturer AvtoVAZ returned to the chain drive. The standard for the 2106 engine was version 2103; the cylinder diameter was increased to the original 79 mm, as in modification 21011.

Therefore, the technical characteristics of the internal combustion engine are important:

| Manufacturer | VAZ |

| Engine brand | VAZ-2106 |

| Years of production | 1976 – 2006 |

| Volume | 1569 cm 3 (1.5 l) |

| Power | 64-75 hp |

| Torque | 87.3 Nm (3400 rpm) |

| Weight | 121 kg |

| Compression ratio | 8,5 |

| Nutrition | carburetor Solex 1107010-01, then 1107010, since 1980 Ozone 1107010-20 |

| Motor type | in-line |

| Number of cylinders | 4 |

| Location of the first cylinder | near the timing chain |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Allowable warpage | manifold gaskets (intake/exhaust) 0.08 mm |

cylinder head gasket 0.05 mm

Valve seat width 2 mm, angle 45° Camshaft single upper inside the cylinder head, phase width 232°, exhaust valve advance 42°, intake valve lag 40° Camshaft oil seal diameters - 40 mm, 56 mm, width 7 mm Cylinder block material cast iron Cylinder diameter class A - 79 - 79, 01 mmOnline calculator

Determining the volume of a cylinder using an online calculator is a method that is popular among motorists. For the calculation, you can also use a regular mathematical calculator, which allows you to determine the volume of the cylinder using the available parameters.

The volume of a cylinder can be calculated using:

- base radius and height, with the height equal to the piston stroke;

- base area and height.

But there are also more complex calculators with an expanded range of functions. They allow you to calculate not only engine volume, but also the compression ratio. For calculations, the values of the following parameters are required:

- connecting rod length;

- piston stroke;

- piston under-return;

- cylinder diameter;

- piston chamber volume;

- thickness and diameter of the gasket;

- chamber volume in the cylinder head;

- number of cylinders.

Before calculating the volume of a cylinder or the entire engine, or calculating the compression level, you should clarify and record all of the above parameters. Beginners may have difficulty with this, so they will have to be persistent.

In what models was the VAZ used?

Improved engine characteristics made it possible to equip VAZ cars of the following models with it:

Due to the following difficulties in manufacturing some parts, management considered the 2106 motor to be economically unprofitable and it was discontinued.

Engine operating temperature

We have learned the resource, now we move on to another important indicator. The optimal operating temperature is 90-95°C. After 97°C, engine number 126 with 16 valves will “slow down” a little, but according to the rules, temperatures up to 100°C are considered normal. If the Lada unit is operated with this indicator, then you need to be sure that the radiator fan is running at this time. When you see an indicator below +90°C on the dashboard, you need to assume that this is underheating. Of course, in cold weather the power plant needs more time for the temperature to reach normal levels.

- Operating temperature – 90-95°C.

- Normal temperature (engine runs worse) is 97-110°C.

- Reduced temperature – 90°C and below.

Disadvantages and advantages

The 2106 engine has significant disadvantages:

- excess heat is transferred to the well of the piston bottom and fins by steel control plates inside the bosses;

- dynamic loads are reduced due to the displacement of the finger from the axis of symmetry to the right;

- When assembled into an engine, the pistons are mounted with markings in one direction, which increases labor costs and the human factor.

The internal combustion engine uses a cylinder head from model 2103, a starter 35.3708 and a G221 generator for an engine with a current of 42A. Oil consumption does not exceed 700 g/1000 km. The instruction manual states that it is recommended to add 200 ml less lubricant than the volume of the system as a whole. The markings for which oil to pour are given in the upper table.

Numbering of cylinders in different types of internal combustion engines

As for the standards for numbering combustion chambers, there are none. The way they are numbered in the internal combustion engine is influenced by the following factors:

- Type of drive;

- ICE type, block layout;

- Transverse or longitudinal arrangement of the unit under the hood;

- Side of rotation.

On standard front-wheel drive cars with a transversely mounted engine, the numbering begins on the timing side. So, near the timing belt there is the first cylinder and then all the others. The latter is located near the checkpoint.

Examples

In multi-cylinder V-twin engines, the first cylinder is located in the bank on the driver's side.

In American-made engines, the combustion chambers and their numbering may differ and defy logic.

So, for in-line fours and sixes, the first cylinder may be near the radiator, while on all other models the numbering begins towards the interior. If the numbering is reversed, then the cylinder closest to the passenger compartment is considered first.

Note: How to remove a hernia on a car wheel and why it is dangerous

The French are very original and use two methods of numbering the combustion chambers of internal combustion engines.

- On inline fours, the numbering starts from the flywheel.

- If it is a V-shaped six, then the row closest to the radiator is the first three cylinders, and the row closer to the passenger compartment is the last three.

Maintenance Procedure

The classic design of the internal combustion engine allows you to get by with simple steps when servicing the engine:

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Engine oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

As the actual life of the internal combustion engine increases, consumables may be replaced more frequently than specified, or operations for cleaning the carburetor, engine, jets, and other attachments may be added.

Frequent malfunctions

In addition to the fact that when the timing chain breaks, the piston bends the valve, the classic engine circuit has characteristic malfunctions:

| Defect | Cause | Elimination |

| Knock | 1) the main bearings knock dully, the frequency coincides with the crankshaft speed |

2) the sound of connecting rod bearings is sharper, present at XX

3) the sound of the pistons is dull, observed at low speeds

4) the valves knock less intensely, the shaft rotation is half as frequent

1) adjusting the ignition, checking the oil level, replacing bearings, tightening the flywheel bolts2) replacing bearings, checking lubricant pressure

3) replacement of rings, pistons, cylinder boring

4) replacing springs, adjusting gaps

Low oil pressure on a warm engine1) wear of oil pump gears2) increased clearances of liners and bearings

1) unit repair2) replacement of bearing shells or housings

Increased lubricant consumption1) leakage of seals2) clogging of the ventilation system

3) wear of cylinders/rings

1) replacement of consumables2) cleaning channels

3) installation of repair kit

Increased gasoline consumption1) the throttle opening angle is off2) high resistance to movement

3) ignition timing is off

4) breakdown of the vacuum distributor

1) damper adjustment3) ignition adjustment

4) replacing the regulator

Reduced throttle response and power1) pump failure2) ignition fault

3) the fuel filter is clogged

4) the damper is not fully open

1) pump repair2) ignition check

3) filter replacement

4) damper adjustment

Engine overhaul includes boring cylinders, replacing shafts, piston and crank groups in any combination.

How much does engine No. 126 cost?

As it turns out, buying a new 16-valve unit for a Lada Priora is an expensive proposition. Today you can purchase a 16 valve 1.6 liter EURO-3 and EURO-4 engine. The first option costs approximately 102 thousand rubles, and the second – 103 thousand. Motorists are also interested in how much it costs to purchase a used Lada unit. Used ones can be purchased even for 20 thousand rubles. But you can find out what condition this unit is in only after a complete disassembly or a trip to a car service center. The average price for a used one is 50-60 thousand rubles.

Source

Injection modification

The first in the line of internal combustion engines of the AvtoVAZ manufacturer, the 2106 engine received tuning in the form of distributed injection. At the same time, the owners received a headache:

- intense heating, since the mixture is lean, the manufacturer’s cooling system cannot cope with temperature loads;

- increased fuel consumption up to 13 l/100 km in winter.

A positive feature is the low budget for major repairs within 10,000 rubles.