Content

Tuning or functionality?

We create a spoiler ourselves

It takes a lot of skill to make a high-quality spoiler with your own hands. But the main thing is to be patient and take your time in your work. The manufacturing process may be different, but it is always not rushed.

DIY spoiler

Tuning or functionality?

When people talk about tuning a car, a spoiler or a wing is most often thought of. The wing is an additional part of the car, which, thanks to the gap, increases downforce at high speeds, above 80 km/h. This ensures greater vehicle stability and traction on the road surface. Calling it a spoiler is not entirely correct, but most car enthusiasts know it by this name.

A spoiler or, more precisely, a lip spoiler is a part for a different purpose and does not need a gap for this. Its task is to reduce air turbulence and reduce the aerodynamic drag coefficient. It is usually mounted on the trunk lid, especially if there is a sharp transition from a horizontal to a vertical surface.

The wing and spoilers can be installed on the car initially during production or during operation by the car owner himself. Those installed and made independently usually have a decorative function and do not fulfill their intended purpose. If the rear wing is installed incorrectly or incompletely, the car also loses its technical characteristics, and in this case the spoiler has a negative effect on the car.

The wing is a mandatory element of sports cars when driving on race tracks. The cars are equipped with an adjustable rear wing, which is automatically activated when the pilot presses the gas pedal. This detail significantly increases speed on straight sections and helps when overtaking.

Wing - a mandatory element of sports cars

In order for the wing to cope with the task, it is installed not only on the rear of the car, but also on the hood and on the sides, the so-called body kit and sill extension, respectively. Otherwise, at high speed, as a result of the operation of the rear spoiler, the car will rise above the road front. The body kit in the car also serves as an additional cooler for the internal parts of the car, thanks to the redirection of the air stream.

The disadvantages of the wing include:

- reducing vehicle ground clearance;

- poor visibility in the rear window;

- considerable cost if you buy ready-made and high-quality ones.

If you are going to buy a spoiler, pay attention to the material and manufacturer. A quality product will not be cheap. A professional technician should install such a part; it is better not to do it yourself.

The material for making the wing can be:

- fiberglass is the most popular;

- ABS plastic is lightweight, flexible, and becomes brittle over time;

New style spoiler made of ABS plastic

- silicone with organosilicon polymers;

- carbon – excellent characteristics, but high price.

Spoilers can also be custom - these are designer single copies - and factory ones, which are produced in large quantities. The wing can be attached to the car body with double-sided tape or self-tapping screws if the structure has racks. Depending on the design, steel or aluminum is used for the racks.

We create a spoiler ourselves

Many motorists make their own trunk spoiler. This significantly saves money and in some cases looks no worse than expensive tuning parts.

Before you start making a wing yourself, you should purchase materials and tools for the job. You will need:

- foam for the base, thickness 5 mm;

- spray paint to match the car;

- metal sheet, thickness up to 1.5 mm;

- epoxy adhesive;

- carbon fiber.

You will also need brushes, sanding paper and other small items.

Making a spoiler for a car with your own hands

On the Internet there is also a method for self-production based on polyurethane foam. You can spend a lot of effort on it, but the result is amazing. The base is formed from polyurethane foam on a car previously wrapped in film. Then they cut out the desired shape and polish it. Then they also use epoxy resin and fiberglass, but the top layer is putty mixed with fiberglass and only then regular putty. The further process is similar to the others: priming, sanding, painting, polishing. But as a result, the visor you made yourself for the rear window is indistinguishable from the factory one and looks like an original part of the car.

When making it, you should remember that it doesn’t matter how to make a spoiler for a VAZ or a foreign car, the main thing is that the result is worthy of attention and brings aesthetic pleasure to the owner.

On motorcycles they also install a part related to the spoiler - a fairing. Performs a protective function: the motorcyclist from the headwind and the dashboard in the event of an accident. Thanks to various, sometimes completely unique designs, the bike stands out from the crowd.

And here are ways on how to make a motorcycle fairing yourself. According to the manufacturing principle, they do not differ from those given above. The only difference is in the shape of the fairing and its layout.

Why is this necessary?

A spoiler installed on the rear of a car is also called a wing.

With proper installation and certain calculations, the body kit part improves the aerodynamic properties of the car.

It also helps to slightly reduce fuel consumption; power is added by reducing air resistance.

What is a car spoiler

A spoiler is one or more special elements designed to change the aerodynamics of a car body by redirecting air flows. The main purposes of installing this part are:

- reduction of aerodynamic drag;

- increased downforce;

- combating vehicle body pollution.

It is worth mentioning that many install a spoiler as a decorative (tuning) element. Its mounting can be done in front, behind, on the roof or on the side of the car. With an individual approach, you can make a custom-made spoiler, which will allow even a production car to stand out in traffic.

An original spoiler from a tuning studio will make your car stand out on city streets.

Pros and cons of installation

The spoiler gives the car the following qualities:

- attractive appearance;

- improved dynamics;

- increased adhesion to the canvas;

- reducing fuel consumption;

- increasing braking efficiency.

It should be clarified that the positive qualities of the element in question appear at speeds above 100 km/h.

Installing a spoiler on a car gives it a number of advantages, but they appear at speeds above 100 km/h

The disadvantages include:

- high cost of structural elements;

- increased fuel consumption due to incorrectly selected form or installation;

- fragile material of manufacture (plastic).

The most popular types of spoilers

All spoilers can be divided into two types:

- decorative - small linings on the rear contour of the trunk, they have little effect on the dynamics, but give the car a more elegant silhouette;

- functional - high spoilers in a sporty style, which really change the pressure of the air flow at high speed and the downforce of the car.

The spoiler does not have to be made entirely by yourself. If you like the store-bought parts, but do not fit the width of the trunk, you can buy a ready-made one, saw it and extend it with an insert (or cut it) to the desired size.

To make a spoiler for a car yourself, you don’t need special tools or expensive materials, but when tuning a car with your own hands, it’s important to know when to stop. If you go too far with the size of the element, the car will look ridiculous, and driving such a car will be unsafe due to impaired aerodynamics.

Source

Car tuning options

Today you can choose a spoiler for almost any car, regardless of body type: from a sedan to a minibus. To make the choice easier, you need to understand in more detail the criteria by which this tuning element is classified:

- at the installation site;

- by installation method;

- by material;

- according to form.

You can secure the spoiler using double-sided tape, but only if the part is small in size

The main location for installing the spoiler is the rear of the roof or trunk lid. This depends on the body type, as well as the size of the spoiler and its shape. You can attach a tuning element:

- using double-sided tape. This option is appropriate for small spoiler sizes;

- bolted fastening. Many motorists do not like this method because of the need to make holes in the body part;

- fastening with staples. This option is suitable for those cars that have a certain shape of the rear cover and a gap between the body.

What material is suitable for tuning

As for the material for making the spoiler, the most common are:

- ARB plastic;

- ordinary plastic;

- fiberglass;

- polyurethane;

- aluminum.

To give preference to a design made from one material or another, it is first necessary to consider each of them in more detail, taking into account its chemical and technical characteristics.

Which form to choose

Spoilers can be quite varied in shape. To conclude whether this option is suitable or not, you need to see the part in front of you. There are cases when the shape of an element complements a part of the body, but generally spoilers are represented by the most non-standard designs. With their help, you can give your car not only exclusivity, but also aggressiveness.

Spoilers can also be classified by design:

- custom - represented, as a rule, by a single copy;

Custom spoilers are produced in single copies, which allows you to make the car unique

A spoiler bought at a car store will decorate the car, but will significantly lighten the pocket of its owner

Rules for selecting a suitable spoiler

Today, many spoilers are produced for a specific car make and model, but there are also universal options that are suitable for almost any car. The only difference is where they will be attached. The car itself should also be taken into account: if we are talking about the executive class, then the spoiler will obviously be an unnecessary element in the design.

It is important to evaluate how the chosen accessory will look. To do this, just take the part, apply it to the car and see from the outside how well it matches its appearance. Many tuning studios have a special program with which you can choose the best option, after which they determine the location of the element’s installation. If the spoiler is designed for a specific car, then this question does not arise.

It is better to purchase a spoiler without a paint layer, which will allow you to find a color that matches the car. An important point is the selection of a suitable fastening method.

In order not to make a mistake with your choice, it is better to contact only reputable tuning companies. Only in such studios can truly high-quality products be installed.

How to make a spoiler for a car with your own hands

When and why do you have to ask yourself the question of making a spoiler yourself? Today, a large selection of the element in question is offered and, it would seem, doing something with your own hands in this regard is not required. But then the cost of a high-quality spoiler turns out to be quite high, and this indicator is not a guarantee that the desired effect will be achieved.

Therefore, some car owners design spoilers themselves, obtaining the desired design and the desired effect from installing such an element. A homemade accessory can be made using various materials, which the owner chooses based on his imagination and free time.

Tools and materials

To start making a spoiler, you will need to prepare the following list of materials and tools:

- foam sheet;

- fiberglass about two meters;

- fastening and welding;

- spray paint (2 pcs.);

- primer (3 cans);

- epoxy glue 2 kg;

- tassels;

- spatulas;

- mesh for reinforcement;

- sandpaper.

Depending on the specific design of the product, the main material is:

- gypsum;

- Styrofoam;

- polyurethane foam;

- metal carcass.

Stages of making a homemade spoiler

The entire process of creating a structure can be divided into several stages:

- mold making;

- material reinforcement;

- putty;

- painting;

- installation.

One of the stages of creating a spoiler is strengthening, i.e. imparting rigidity to the structure

It is best to use cardboard as a pattern. You can also use plywood, but this will lead to additional costs.

Regardless of the material chosen, after realizing the desired shape, be sure to try on the pattern on the machine. You need to make sure that the size is correct and the attachment points correspond to the intended locations. You should make sure that the future product is symmetrical, for which the pattern is bent in half.

The frame can be made of different materials, but its main role is to hold the given shape at the beginning of the manufacture of the part. The spoiler will be given rigidity by fiberglass, as well as a layer of putty and paint. When choosing a filler, you need to take into account the planned shape of the future product.

Video: making tuning elements with your own hands

Types of tuning elements

It would seem that a spoiler is a highly specific element for a car. However, there are several types of spoilers, each of which stands out depending on the style, location on the car body or material.

Variations in style

There are only two types of spoiler styles in the world:

- factory - these are products that are produced by the largest manufacturers of elements for car tuning, as well as homemade spoilers that are externally identical to factory products. As a rule, such elements have a classic appearance and are suitable for installation on most car models;

- individual - this type of spoilers includes both factory spoilers produced in limited quantities and homemade products. However, there is a significant difference in shape, color and proven aerodynamic properties. Individual style does not always guarantee giving the car additional acceleration.

Differences in location on the car body

There are four types of spoilers based on their location, with the most common being the rear spoiler. It is mounted on the trunk lid.

Making a spoiler from foam plastic and fiberglass

One of the important stages in creating a spoiler is proper design. This element cannot be done “by eye”. The ideal option at the design stage would be to involve an engineer or an experienced person who is involved in this type of tuning.

After determining the dimensions and design, you can begin to create a metal frame.

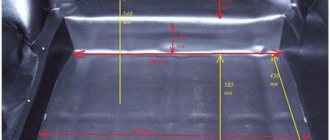

- Quite often, when making a rear spoiler, a sheet of galvanized iron 1.5 mm thick is used, the edges of which are bent upward. M6 nuts should also be welded to the base for subsequent installation of the product.

Galvanized iron is often used as a frame for the spoiler, to which nuts are welded to secure the future product.

To increase the volume of the workpiece, foam plastic is used, which is pasted over the metal frame.

To give the product rigidity, several layers of fiberglass are applied, and drying is performed before applying the next one.

The surface of the spoiler is primed to improve adhesion, puttied, primed again, cleaned and covered with several layers of paint and varnish.

After applying the paint layer and drying, the spoiler is installed on the car

Video: tuning the rear window of the Audi A8

What can a body kit be made from?

- Fiberglass;

- ABS plastic;

- Polyurethanes (foamed or rubberized);

- Carbon.

Aerodynamic body kit made of fiberglass

- Low price.

- The quality of the finished fiberglass product is not much lower than ABS plastic or polyurethane, provided that the manufacturing technology has been followed.

- Fiberglass is a lightweight material.

- Simple repair.

- When physically impacted, it is able to return to its original form.

- Not a simple technology for manufacturing fiberglass parts. Failure to comply with it makes the finished part of poor quality (breaks, crumbles in the cold, etc.).

- Toxicity.

- Requires adjustment of parts during installation.

Aerodynamic body kit made of ABS plastic (ABS plastic)

- Low price.

- Good performance in terms of impact resistance and flexibility.

- With minor deformations, it is able to restore its original shape.

- Good adhesion (ability to hold paint).

- With minor non-compliance with manufacturing technology, the product becomes brittle at low temperatures.

- Requires adjustment of parts during installation.

Aerodynamic body kit made of polyurethane

- Has very high quality.

- High impact resistance, and the presence of rubber makes the material very flexible.

- Able to return to its original shape even after severe deformation.

- It cannot be broken, it can only be chopped or cut.

- High precision of molding of finished products. The finished product does not require adjustment during installation.

- High adhesion.

- High price.

Aerodynamic carbon fiber body kit

- Very high quality.

- Carbon is 40% lighter than steel and 20% lighter than aluminum.

- Maximum strength with minimum weight.

- Original appearance.

- High price.

- Carbon doesn't stretch.

- Carbon is afraid of targeted strikes. In order for a carbon product to be of high quality, you must follow the technology described in the “carbon tuning” category.

Toyota Mark II 44 Logbook 1GZ-FE V12 5L

xn--2111-43da1a8c.xn--p1ai

Step-by-step production of a plaster spoiler

Using a material such as gypsum, you can make not only a matrix, but also a copy of your favorite spoiler.

- To pour the gypsum, we make a polystyrene foam box. Then we place the part matrix or the finished spoiler into it, after wrapping it in cling film to avoid damage.

To make a spoiler from gypsum, a polystyrene box is prepared, into which the matrix for the new spoiler is then placed.

After filling the matrix with gypsum, you must wait until it hardens.

After the plaster has hardened, all that remains is to open the halves of the matrix and take out the future spoiler frame

To give the matrix strength, you should follow the same recommendations that are given for making a spoiler from foam plastic.

How to make a foam spoiler at home

The procedure is simple, but requires care to avoid damage to the bodywork.

- We cover the upper part of the trunk lid with polyethylene, you can also use masking tape.

Before applying foam, protect the surface of the trunk lid with plastic film or masking tape.

Polyurethane foam is applied to the prepared surface, which should preferably be moistened for better hardening.

When the foam hardens, use a knife to form the future spoiler

To impart rigidity to the structure, fiberglass is used, which covers the product in several layers.

The matrix can also be made from plasticine. The process is similar to the described sequence of actions for making a foam spoiler. Regardless of the chosen method, care must be taken to ensure sufficient rigidity of the structure. In addition, fastening such a tuning element should prevent its loss, ensuring reliable fixation.

Not only foam plastic, but also plasticine can be used as a material for making the matrix.